Applied Industrial Technologies Near Me: A Guide to Innovation

Applied industrial technologies near me are revolutionizing the way we work and live. From advanced robotics and automation to the integration of artificial intelligence, these innovations are transforming industries like […]

Applied industrial technologies near me are revolutionizing the way we work and live. From advanced robotics and automation to the integration of artificial intelligence, these innovations are transforming industries like manufacturing, energy, and transportation. This guide explores the benefits and challenges of adopting these technologies, providing insights into their potential impact on your business and community.

Whether you’re a small business owner looking to increase efficiency or a large corporation seeking to gain a competitive edge, understanding applied industrial technologies is essential. This guide will help you navigate the landscape of these technologies, identify opportunities, and overcome potential challenges.

Locating Applied Industrial Technologies Near You

Finding the right applied industrial technologies for your needs can be a challenging task, especially when you’re looking for local options. However, with a strategic approach, you can easily identify and connect with businesses, organizations, or institutions offering the specific technologies you require.

Identifying Local Providers

This section Artikels the key steps to identify local providers of applied industrial technologies. The approach involves utilizing various resources and strategies to effectively locate suitable options in your area.

- Online Directories and Search Engines: Start by searching online directories and search engines like Google, Yelp, and Yellow Pages. Use specific s related to your industry and desired technology, such as “robotics manufacturers in [your city],” “3D printing services near me,” or “laser cutting companies in [your state].”

- Industry Associations and Trade Organizations: Many industry associations and trade organizations maintain lists of their members, which often include businesses specializing in applied industrial technologies. Contact these organizations for information about local members or attend their events to network with potential providers.

- Local Chambers of Commerce: Chambers of commerce often have databases of local businesses, including those in the manufacturing and technology sectors. Reach out to your local chamber for a list of potential providers of applied industrial technologies.

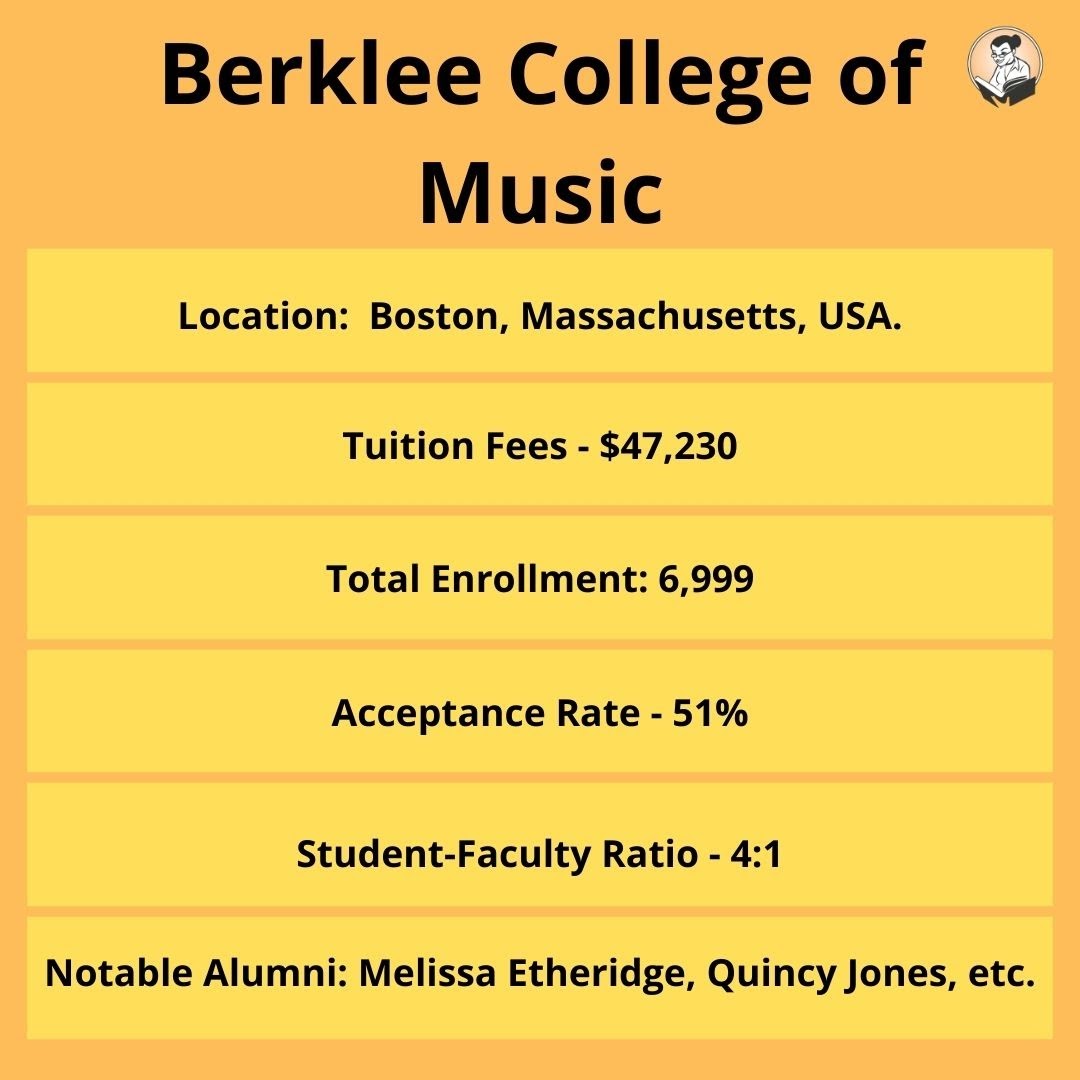

- University and College Engineering Departments: Universities and colleges often have engineering departments with research labs and facilities that may offer access to or expertise in applied industrial technologies. Contact these departments to inquire about potential partnerships or collaborations.

- Government Agencies: Some government agencies, such as the Small Business Administration (SBA) or local economic development organizations, may have programs or resources to help businesses find and implement applied industrial technologies. Check with your local government agencies for relevant information.

Table of Local Providers

This table provides examples of local providers of applied industrial technologies in various industries. The information is for illustrative purposes and may not be exhaustive.

| Industry | Technology | Location | Contact Information |

|---|---|---|---|

| Manufacturing | Robotics and Automation | [City, State] | [Website/Phone Number] |

| Construction | 3D Printing and Building Information Modeling (BIM) | [City, State] | [Website/Phone Number] |

| Healthcare | Medical Imaging and Diagnostic Technologies | [City, State] | [Website/Phone Number] |

| Energy | Renewable Energy Technologies and Smart Grid Solutions | [City, State] | [Website/Phone Number] |

Considering Industry-Specific Needs, Applied industrial technologies near me

When searching for applied industrial technologies, it’s crucial to consider your specific industry and project requirements. Factors to consider include:

- Industry Regulations and Standards: Different industries have specific regulations and standards that need to be met when implementing applied industrial technologies. Ensure the technology you choose complies with all relevant regulations and standards.

- Production Volume and Scale: The technology’s capacity should align with your production volume and scale. For example, a small-scale manufacturing operation might not need a highly automated system.

- Budget and Return on Investment (ROI): Consider your budget and the potential return on investment (ROI) of the technology. Some technologies may have higher upfront costs but offer significant long-term benefits.

- Integration with Existing Systems: Ensure the technology can seamlessly integrate with your existing systems and processes. Compatibility issues can lead to delays and inefficiencies.

- Skillset and Training: Consider the skillset of your workforce and the training required to operate and maintain the technology. Some technologies may require specialized skills or training.

Examples of Applied Industrial Technologies

Applied industrial technologies are revolutionizing industries across the globe, driving innovation, efficiency, and sustainability. These technologies are transforming the way we design, manufacture, and operate industrial processes, leading to significant improvements in productivity, quality, and environmental impact.

Automation and Robotics

Automation and robotics are playing a crucial role in enhancing industrial efficiency and productivity. They are deployed in various tasks, from assembly line operations to complex logistics processes.

- Manufacturing: Robots are increasingly used in manufacturing for tasks such as welding, painting, and assembly. They can perform these tasks with high precision and speed, reducing human error and improving product quality. For example, in automotive manufacturing, robots are used for tasks like welding car bodies and installing components, enabling faster production cycles and increased output.

- Logistics: Robotics is transforming logistics by automating tasks such as warehouse picking and packing, order fulfillment, and material handling. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) navigate warehouses and factories efficiently, moving goods and materials without human intervention. For example, Amazon’s use of robots in its fulfillment centers allows for faster and more accurate order processing, leading to improved customer satisfaction.

- Other Industries: Automation and robotics are also being adopted in industries like agriculture, healthcare, and construction. In agriculture, robots are used for tasks such as planting, harvesting, and weeding, improving efficiency and reducing labor costs. In healthcare, robots assist surgeons in performing complex procedures with greater precision and minimal invasiveness.

Advanced Materials

The development of advanced materials is driving significant advancements in product design, performance, and sustainability. These materials offer unique properties that enhance durability, strength, and functionality.

- Product Design: Advanced materials enable the creation of lighter, stronger, and more durable products. For example, carbon fiber composites are used in aerospace and automotive industries to build lighter and more fuel-efficient vehicles.

- Performance: Advanced materials can enhance product performance by improving properties like heat resistance, electrical conductivity, and corrosion resistance. For example, ceramics are used in high-temperature applications like turbine blades due to their excellent heat resistance.

- Sustainability: Advanced materials can contribute to sustainability by reducing waste, improving energy efficiency, and enabling the use of recycled materials. For example, bio-based polymers are derived from renewable sources and offer a sustainable alternative to traditional plastics.

Data Analytics and Artificial Intelligence

Data analytics and artificial intelligence (AI) are revolutionizing industrial decision-making and process optimization. By analyzing vast amounts of data, these technologies can identify patterns, predict outcomes, and optimize operations for increased efficiency and productivity.

- Process Optimization: AI-powered systems can analyze data from sensors and other sources to identify bottlenecks, predict equipment failures, and optimize production processes. For example, predictive maintenance systems use AI to analyze sensor data and predict equipment failures, allowing for proactive maintenance and minimizing downtime.

- Decision-Making: Data analytics and AI can provide insights into customer behavior, market trends, and supply chain dynamics, enabling better informed business decisions. For example, AI-powered systems can analyze customer data to personalize marketing campaigns and improve customer satisfaction.

3D Printing and Additive Manufacturing

3D printing, also known as additive manufacturing, is transforming industrial production by enabling the creation of complex and customized products. It involves building objects layer by layer from a digital design.

- Prototyping: 3D printing allows for rapid prototyping, enabling engineers to quickly create and test different designs before committing to mass production. This accelerates the product development process and reduces costs.

- Customization: 3D printing enables the production of highly customized products, meeting specific customer requirements. This opens up new possibilities for product design and personalization.

- Production: 3D printing is also used for direct production of parts and products, particularly for small batches or complex geometries. This eliminates the need for traditional tooling and allows for on-demand production.

Renewable Energy Technologies

Renewable energy technologies, such as solar and wind power, are playing an increasingly important role in promoting sustainable industrial practices. These technologies reduce reliance on fossil fuels and minimize environmental impact.

- Reduced Carbon Footprint: Renewable energy sources generate electricity without producing greenhouse gases, reducing the carbon footprint of industrial operations.

- Energy Security: Renewable energy sources can provide a more secure and reliable energy supply, reducing dependence on volatile global energy markets.

- Cost Savings: In some cases, renewable energy technologies can offer cost savings over traditional energy sources, particularly in the long term.

Future Trends in Applied Industrial Technologies

The world of applied industrial technologies is constantly evolving, driven by advancements in digitalization, automation, and artificial intelligence. Emerging technologies are reshaping how industries operate, creating new opportunities for efficiency, innovation, and sustainability.

The Impact of Emerging Technologies

These emerging technologies are poised to revolutionize industrial practices, impacting everything from manufacturing processes to supply chain management.

- The Internet of Things (IoT): The IoT is a network of interconnected devices, sensors, and software that collect and exchange data in real-time. In industrial settings, IoT sensors can monitor equipment performance, track inventory levels, and optimize production processes. This data can be used to improve efficiency, reduce downtime, and enhance product quality.

- Blockchain: Blockchain technology provides a secure and transparent way to record and track transactions. In industries like supply chain management, blockchain can help to ensure the authenticity of products, track their origin, and improve transparency throughout the supply chain. It can also be used to automate payments and reduce fraud.

- Augmented Reality (AR): AR overlays digital information onto the real world, enhancing user perception and interaction. In industrial settings, AR can be used for training, maintenance, and assembly. For example, AR can provide step-by-step instructions for complex tasks, making it easier for workers to learn new skills and perform tasks accurately.

Potential Applications in Various Industries

These technologies are finding diverse applications across various industries:

- Manufacturing: The IoT is transforming manufacturing by enabling real-time monitoring of production processes, predictive maintenance, and data-driven decision-making. Blockchain can enhance supply chain transparency and traceability, ensuring product authenticity and reducing counterfeit goods. AR can be used for training, assembly, and maintenance, improving worker efficiency and safety.

- Healthcare: IoT devices are used to monitor patient health, collect data, and provide remote care. Blockchain can be used to securely store and share patient medical records, enhancing data privacy and security. AR can assist surgeons during complex procedures, providing real-time information and guidance.

- Energy: The IoT can optimize energy consumption in buildings and industrial facilities, reducing waste and costs. Blockchain can facilitate peer-to-peer energy trading, enabling energy sharing among consumers and businesses. AR can assist technicians in inspecting and maintaining energy infrastructure, improving efficiency and safety.

The Evolving Role of Applied Industrial Technologies

These technologies are shaping the future of work and society, leading to:

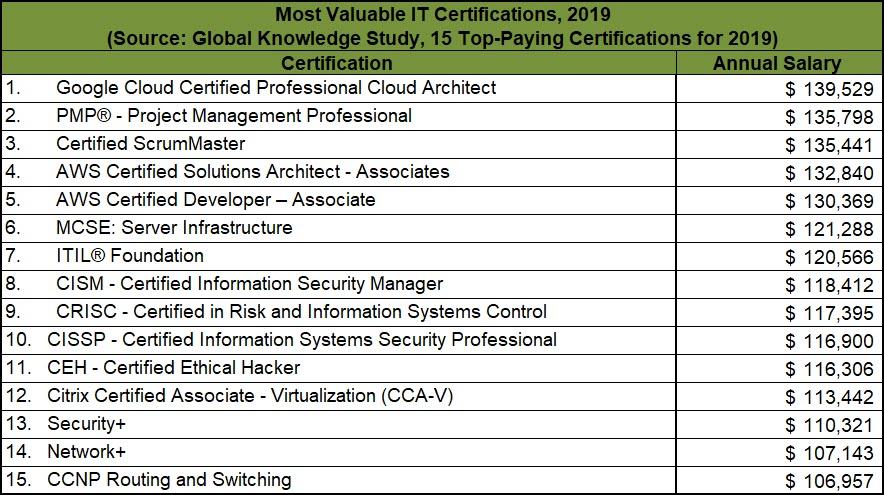

- Increased Automation: The adoption of these technologies is leading to increased automation in various industries, leading to job displacement in some roles. However, it also creates new opportunities for workers with specialized skills in technology and data analysis.

- Upskilling and Reskilling: As automation becomes more prevalent, there is a growing need for workers to upskill and reskill to adapt to the changing demands of the workplace. Educational institutions and training programs are adapting to provide workers with the skills they need to succeed in the digital economy.

- Sustainable Practices: Applied industrial technologies can contribute to sustainable practices by enabling resource optimization, reducing waste, and improving energy efficiency. For example, IoT sensors can monitor energy consumption and identify areas for improvement, while blockchain can promote sustainable supply chains by tracking the origin and environmental impact of products.

Conclusive Thoughts: Applied Industrial Technologies Near Me

The adoption of applied industrial technologies presents a unique opportunity to drive innovation, boost productivity, and create a more sustainable future. By embracing these technologies, businesses and communities can unlock their full potential and navigate the challenges of the 21st century. This guide has provided a starting point for understanding the world of applied industrial technologies, and we encourage you to continue exploring these exciting developments.

Applied industrial technologies are transforming industries across the globe, and Los Angeles is no exception. The city is a hub for innovation, with a growing demand for skilled professionals in the information technology sector. If you’re interested in pursuing a career in IT, check out the many exciting opportunities available on information technology jobs in los angeles.

With its thriving tech scene, Los Angeles offers a wealth of opportunities to apply your skills and contribute to the advancement of applied industrial technologies.