Metal Sawing Technology Inc: Precision Cutting Solutions

Metal Sawing Technology Inc. is a leading provider of cutting-edge metal sawing solutions, renowned for its expertise and commitment to delivering high-quality results. The company’s journey began with a vision […]

Metal Sawing Technology Inc. is a leading provider of cutting-edge metal sawing solutions, renowned for its expertise and commitment to delivering high-quality results. The company’s journey began with a vision to revolutionize the metal sawing industry, and through unwavering dedication and innovation, Metal Sawing Technology Inc. has established itself as a trusted partner for businesses across diverse sectors.

Their comprehensive range of services encompasses a wide spectrum of metal sawing technologies, tailored to meet the unique requirements of each project. From precision cutting to intricate designs, Metal Sawing Technology Inc. utilizes state-of-the-art equipment and highly skilled professionals to ensure unparalleled accuracy and efficiency.

Company Overview

Metal Sawing Technology Inc. (MST) is a leading provider of high-quality metal sawing solutions. Founded in [Year of Founding] by [Founder’s Name], MST has a rich history of innovation and customer satisfaction. Driven by a commitment to excellence, MST has become a trusted partner for businesses across various industries.

Mission, Vision, and Core Values

MST’s mission is to deliver cutting-edge metal sawing technology that empowers businesses to achieve their manufacturing goals. The company’s vision is to be the industry’s leading provider of innovative and reliable sawing solutions. MST’s core values guide its operations and relationships with customers, partners, and employees. These values include:

- Customer Focus: MST prioritizes customer satisfaction and strives to exceed expectations.

- Innovation: MST is committed to developing and delivering cutting-edge technologies.

- Quality: MST maintains the highest standards of quality in its products and services.

- Integrity: MST operates with honesty and transparency in all its dealings.

- Teamwork: MST fosters a collaborative and supportive work environment.

Key Products and Services

MST offers a comprehensive range of metal sawing products and services, designed to meet the diverse needs of its customers.

- Metal Sawing Machines: MST manufactures a wide variety of metal sawing machines, including band saws, circular saws, and cold saws. These machines are designed for precision cutting, high-speed operation, and durability.

- Saw Blades: MST offers a comprehensive selection of saw blades, including HSS, carbide, and diamond blades. These blades are engineered for specific applications and materials, ensuring optimal cutting performance.

- Sawing Services: MST provides custom sawing services, including cutting to size, deburring, and surface finishing. These services are tailored to meet the specific requirements of each project.

- Maintenance and Repair: MST offers comprehensive maintenance and repair services for its metal sawing machines and equipment. This ensures that customers can maximize the lifespan and performance of their investments.

- Technical Support: MST provides expert technical support to its customers, helping them to optimize their sawing processes and troubleshoot any issues.

Target Market and Customer Base

MST serves a diverse range of customers across various industries, including:

- Manufacturing: MST’s metal sawing solutions are widely used in manufacturing industries, such as automotive, aerospace, and construction.

- Metal Fabrication: MST’s products and services are essential for metal fabrication shops, providing the precision and efficiency needed for intricate cutting tasks.

- Distribution: MST’s metal sawing solutions are also used by distributors who provide metal products to various industries.

- Research and Development: MST’s advanced sawing technologies are utilized in research and development labs for material testing and prototyping.

Metal Sawing Technology

Metal Sawing Technology Inc. utilizes a variety of metal sawing technologies to cater to diverse customer needs and project requirements. Each technology offers unique advantages and disadvantages, making it crucial to select the most suitable option based on the specific application.

Types of Metal Sawing Technologies

Metal Sawing Technology Inc. specializes in various metal sawing technologies, each with its own set of advantages and disadvantages. These technologies are:

- Band Sawing: Band sawing utilizes a continuous, toothed band blade to cut through metal. This method is highly versatile, capable of handling various materials and shapes, and is often employed for intricate cuts.

- Circular Sawing: Circular sawing utilizes a rotating circular blade with teeth to cut through metal. This method is known for its speed and efficiency, making it ideal for high-volume production.

- Abrasive Sawing: Abrasive sawing utilizes a rotating abrasive wheel to cut through metal. This method is particularly effective for cutting hard and abrasive materials, including those with complex geometries.

- Waterjet Cutting: Waterjet cutting utilizes a high-pressure jet of water, often mixed with an abrasive, to cut through metal. This method is highly precise and can cut intricate shapes and delicate materials without causing heat damage.

- Laser Cutting: Laser cutting utilizes a focused laser beam to cut through metal. This method is extremely precise and can cut intricate shapes and delicate materials at high speeds.

Advantages and Disadvantages of Each Technology

The choice of metal sawing technology depends on various factors, including the material being cut, the desired cut quality, and the production volume.

- Band Sawing:

- Advantages: Versatile, capable of handling various materials and shapes, can produce intricate cuts, relatively low cost.

- Disadvantages: Slower cutting speed compared to other methods, can produce burrs, limited to smaller workpieces.

- Circular Sawing:

- Advantages: Fast cutting speed, high production volume, efficient for repetitive cuts, relatively low cost.

- Disadvantages: Limited to straight cuts, can produce burrs, not suitable for delicate materials or intricate shapes.

- Abrasive Sawing:

- Advantages: Can cut hard and abrasive materials, effective for complex geometries, minimal heat generation.

- Disadvantages: Relatively slow cutting speed, can produce burrs, requires specialized equipment and expertise.

- Waterjet Cutting:

- Advantages: Highly precise cuts, can cut intricate shapes and delicate materials, minimal heat damage, can cut various materials.

- Disadvantages: Relatively slow cutting speed, can be expensive, requires specialized equipment and expertise.

- Laser Cutting:

- Advantages: Extremely precise cuts, high cutting speed, minimal heat damage, can cut intricate shapes and delicate materials, can cut various materials.

- Disadvantages: Expensive, requires specialized equipment and expertise, not suitable for all materials.

Factors Influencing the Choice of Sawing Technology

The choice of sawing technology is influenced by various factors, including:

- Material type: Different sawing technologies are best suited for different materials. For example, abrasive sawing is ideal for hard and abrasive materials, while waterjet cutting is suitable for delicate materials.

- Desired cut quality: The desired cut quality, including precision, surface finish, and burr formation, influences the choice of technology. For example, laser cutting offers the highest precision, while band sawing may produce burrs.

- Production volume: The required production volume influences the choice of technology. High-volume production may necessitate faster technologies like circular sawing, while low-volume production may favor slower but more versatile technologies like band sawing.

- Cost: The cost of the technology, including equipment, operation, and maintenance, is a crucial factor. Less expensive technologies like band sawing and circular sawing are suitable for low-volume production, while more expensive technologies like waterjet cutting and laser cutting are suitable for high-precision and high-volume production.

Equipment and Machinery

Metal Sawing Technology Inc. utilizes a diverse range of cutting-edge sawing equipment and machinery to deliver precise and efficient metal cutting solutions. These tools are carefully selected based on their capabilities, specifications, and ability to meet the specific requirements of various sawing projects.

Sawing Equipment and Machinery

The following are the key types of sawing equipment and machinery used by Metal Sawing Technology Inc., along with their capabilities, specifications, and applications:

- Band Saws: These saws utilize a continuous band of toothed steel to cut through metal. They are versatile and can handle a wide range of materials and shapes, including thick sections and intricate designs.

- Capabilities: Cutting various materials, including steel, aluminum, brass, and titanium.

- Specifications: Available in different sizes and blade widths to accommodate various material thicknesses.

- Applications: Used for cutting intricate shapes, bevels, and complex profiles.

- Circular Saws: These saws feature a rotating circular blade with teeth. They are commonly used for cutting straight lines and are ideal for high-volume production.

- Capabilities: Cutting steel, aluminum, and other metals with high accuracy and speed.

- Specifications: Available in different blade diameters and tooth configurations to suit various material thicknesses and cutting speeds.

- Applications: Used for cutting straight lines, squares, and rectangles, particularly in high-volume production settings.

- Cold Saws: These saws use a rotating blade that operates at high speeds to cut metal without generating heat. This prevents the metal from becoming distorted or losing its temper.

- Capabilities: Cutting a wide range of metals, including stainless steel, tool steel, and high-strength alloys.

- Specifications: Available in various sizes and blade configurations, with features like automatic feed systems for precise cutting.

- Applications: Used for cutting high-strength materials, where precision and minimal heat generation are crucial.

- Plasma Saws: These saws utilize a high-temperature plasma arc to melt and cut through metal. They offer high cutting speeds and can handle a wide range of materials.

- Capabilities: Cutting steel, aluminum, and other metals with high speed and precision.

- Specifications: Available with different plasma cutting power sources and torch configurations for various material thicknesses.

- Applications: Used for cutting intricate shapes, bevels, and complex profiles in a wide range of materials.

- Waterjet Saws: These saws use a high-pressure stream of water mixed with abrasive particles to cut through metal. They are particularly suitable for cutting complex shapes and delicate materials.

- Capabilities: Cutting a wide range of materials, including stainless steel, titanium, and composites, with minimal heat generation.

- Specifications: Available with various waterjet cutting systems, including different nozzle sizes and abrasive types for different materials.

- Applications: Used for cutting intricate shapes, delicate materials, and complex profiles, particularly in industries like aerospace and medical device manufacturing.

Maintenance and Safety Procedures

Regular maintenance and adherence to strict safety procedures are crucial for ensuring the longevity and safe operation of sawing equipment.

- Regular Inspections: Daily inspections are conducted to identify any potential problems, such as loose bolts, worn blades, or malfunctioning components.

- Blade Maintenance: Blades are regularly inspected and sharpened to maintain cutting efficiency and prevent damage to the material.

- Lubrication: Moving parts are lubricated regularly to prevent friction and wear.

- Safety Training: All operators receive comprehensive safety training on the proper operation, maintenance, and safety procedures for each piece of equipment.

- Personal Protective Equipment: Operators are required to wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, to minimize the risk of injury.

- Emergency Procedures: Emergency procedures are established and regularly practiced to ensure prompt and safe responses in case of accidents or malfunctions.

Examples of Sawing Projects

Metal Sawing Technology Inc. utilizes its diverse range of sawing equipment to handle a wide range of projects, including:

- Structural Steel Fabrication: Cutting steel beams, columns, and other structural components for buildings, bridges, and other infrastructure projects.

- Aerospace Manufacturing: Cutting precision parts for aircraft, satellites, and other aerospace components.

- Medical Device Manufacturing: Cutting delicate and intricate parts for medical devices, such as implants and surgical instruments.

- Automotive Manufacturing: Cutting components for cars, trucks, and other vehicles.

- Industrial Equipment Manufacturing: Cutting parts for machinery, equipment, and other industrial products.

Industry Applications

Metal Sawing Technology Inc. provides specialized cutting solutions across a wide range of industries, where precision, efficiency, and material handling are critical. The company’s expertise in metal sawing technology enables it to cater to the unique challenges and requirements of diverse sectors.

Aerospace

The aerospace industry demands the highest standards of precision and quality in manufacturing components. Metal Sawing Technology Inc. provides specialized sawing solutions for aerospace applications, including:

- Cutting high-strength alloys and composites for aircraft and spacecraft components.

- Precision sawing of intricate shapes and complex geometries for critical parts.

- Providing customized sawing services for aerospace manufacturers, ensuring compliance with stringent industry standards.

The company’s expertise in handling sensitive materials and adhering to strict tolerances makes it a trusted partner for aerospace manufacturers.

Automotive

The automotive industry relies on efficient and precise metal cutting for manufacturing components. Metal Sawing Technology Inc. offers a range of services for automotive manufacturers, including:

- Cutting steel, aluminum, and other materials for engine parts, chassis components, and body panels.

- Providing high-volume sawing solutions for automotive production lines, ensuring consistent quality and efficiency.

- Delivering customized sawing services to meet the specific requirements of different automotive models.

Metal Sawing Technology Inc.’s ability to handle large volumes of materials and maintain tight tolerances contributes to the efficiency and quality of automotive manufacturing.

Construction

The construction industry requires efficient and reliable metal cutting for various applications. Metal Sawing Technology Inc. provides specialized sawing solutions for construction projects, including:

- Cutting steel beams, rebar, and other structural components for buildings and infrastructure projects.

- Providing on-site sawing services for large-scale construction projects, ensuring efficient and timely material handling.

- Offering customized sawing solutions to meet the specific requirements of different construction projects.

The company’s expertise in handling heavy materials and working in demanding environments makes it a valuable partner for construction projects.

Energy

The energy industry relies on specialized metal cutting for the manufacture of components for power generation, transmission, and distribution. Metal Sawing Technology Inc. provides sawing solutions for the energy sector, including:

- Cutting steel, stainless steel, and other materials for turbines, generators, and other power generation equipment.

- Providing specialized sawing services for the manufacture of components for wind turbines, solar panels, and other renewable energy technologies.

- Delivering customized sawing solutions to meet the specific requirements of different energy projects.

The company’s ability to handle large and complex materials, coupled with its commitment to precision and quality, makes it a reliable partner for the energy industry.

Medical

The medical industry demands the highest standards of precision and cleanliness in manufacturing components. Metal Sawing Technology Inc. provides specialized sawing solutions for medical device manufacturers, including:

- Cutting titanium, stainless steel, and other biocompatible materials for implants, surgical instruments, and other medical devices.

- Providing cleanroom sawing services for medical device manufacturers, ensuring compliance with stringent hygiene standards.

- Delivering customized sawing solutions to meet the specific requirements of different medical devices.

Metal Sawing Technology Inc.’s expertise in handling sensitive materials and maintaining sterile environments makes it a trusted partner for medical device manufacturers.

Quality Control and Standards

At Metal Sawing Technology Inc., quality is not merely a goal; it is an unwavering commitment that permeates every aspect of our operations. Our rigorous quality control measures and adherence to industry standards ensure that we consistently deliver products and services that meet the highest expectations.

Quality Control Measures

Quality control is an integral part of our manufacturing process, ensuring that each product meets our stringent standards. We implement a comprehensive approach that encompasses:

- Incoming Material Inspection: Every raw material is thoroughly inspected upon arrival to verify its compliance with our specifications and quality standards. This includes checking for defects, dimensions, and chemical composition.

- In-Process Inspection: Throughout the manufacturing process, we conduct regular inspections at critical stages to monitor the quality of the work. This ensures that any potential issues are identified and addressed promptly, preventing defects from progressing further.

- Final Inspection: Before products are shipped, they undergo a final inspection to confirm their conformance to specifications, including dimensional accuracy, surface finish, and overall quality. This ensures that only products meeting our standards reach our customers.

- Statistical Process Control (SPC): We utilize SPC techniques to monitor and control the consistency of our manufacturing processes. This involves collecting data, analyzing trends, and making adjustments to maintain optimal performance and minimize variability.

- Non-Conformance Management: We have a robust system for managing non-conforming products. This involves identifying the root cause of the issue, implementing corrective actions, and preventing similar occurrences in the future.

Industry Standards and Certifications

Metal Sawing Technology Inc. adheres to the highest industry standards and certifications, demonstrating our commitment to quality and customer satisfaction. Our company is:

- ISO 9001 Certified: This internationally recognized standard signifies our commitment to a quality management system that ensures consistent product quality, customer satisfaction, and continuous improvement.

- ASME Certified: Our manufacturing processes comply with ASME standards, which are widely recognized for their rigor and emphasis on safety and reliability in the design, fabrication, and inspection of pressure vessels and other critical equipment.

- API Certified: For projects in the oil and gas industry, we adhere to API standards, which are essential for ensuring the quality, safety, and performance of equipment used in this demanding sector.

Commitment to High-Quality Products and Services

Our dedication to quality extends beyond our products to encompass all aspects of our business. We strive to provide:

- Responsive and Reliable Service: We are committed to providing prompt and reliable service to our customers. Our team is available to answer questions, address concerns, and provide support throughout the entire project lifecycle.

- Competitive Pricing: We offer competitive pricing without compromising on quality. Our efficient operations and focus on value allow us to provide high-quality products at competitive prices.

- On-Time Delivery: We understand the importance of timely delivery. We have robust systems in place to ensure that our products are delivered on time, minimizing disruptions to our customers’ projects.

Quality Control Practices and Customer Satisfaction

Our commitment to quality control has a direct impact on customer satisfaction. Examples include:

- Reduced Returns and Complaints: Our rigorous quality control measures have significantly reduced the number of product returns and customer complaints, resulting in increased customer satisfaction and loyalty.

- Improved Product Performance: The consistent quality of our products ensures optimal performance and reliability, minimizing downtime and operational issues for our customers.

- Enhanced Customer Relationships: Our dedication to quality has fostered strong relationships with our customers, who appreciate our commitment to delivering high-quality products and services.

Customer Service and Support

At Metal Sawing Technology Inc., we believe that exceptional customer service is the cornerstone of our success. We are dedicated to providing our customers with the highest level of support, ensuring their satisfaction and fostering long-term partnerships.

Our customer service approach is rooted in a commitment to understanding our clients’ needs, providing timely and efficient solutions, and building lasting relationships. We strive to be a trusted advisor and partner, offering comprehensive support throughout the entire customer journey.

Metal Sawing Technology Inc. is a leading provider of innovative metal sawing solutions. Their commitment to quality and efficiency has earned them a reputation for excellence in the industry. They are constantly exploring new technologies to improve their offerings, and have recently partnered with amgo technology co.

limited to develop a cutting-edge saw blade that delivers superior performance and longevity. Metal Sawing Technology Inc. continues to set the standard for metal sawing technology, ensuring that their customers have access to the most advanced and reliable solutions available.

Technical Assistance and Training

Metal Sawing Technology Inc. offers a comprehensive suite of technical assistance and training programs designed to empower our customers with the knowledge and skills needed to maximize the performance and longevity of their metal sawing equipment.

- Phone and Email Support: Our team of highly skilled technicians is available 24/7 to provide prompt and knowledgeable support via phone and email. We address a wide range of technical inquiries, troubleshooting issues, and offering guidance on equipment operation and maintenance.

- On-Site Support: For complex technical challenges or specialized training requirements, our experienced engineers can be dispatched to customer sites to provide hands-on support and personalized guidance. This on-site service ensures a swift resolution to technical issues and facilitates seamless integration of new equipment.

- Remote Diagnostics: Leveraging cutting-edge technology, we offer remote diagnostics capabilities, enabling our technicians to remotely access and analyze equipment data. This proactive approach allows for early detection of potential issues, minimizing downtime and optimizing equipment performance.

- Training Programs: We offer a variety of training programs tailored to meet the specific needs of our customers. These programs cover a range of topics, including equipment operation, maintenance procedures, safety protocols, and advanced applications. Our training programs are conducted by certified instructors with extensive experience in the metal sawing industry, ensuring participants receive the highest quality instruction.

Building Long-Term Customer Relationships

At Metal Sawing Technology Inc., we prioritize building strong and lasting relationships with our customers. Our commitment to exceptional customer service extends beyond technical support, encompassing proactive communication, personalized solutions, and a genuine desire to understand and meet our clients’ evolving needs.

- Proactive Communication: We believe in open and transparent communication, keeping our customers informed about new product releases, industry advancements, and any relevant updates that may impact their operations. This proactive approach fosters trust and ensures customers are well-equipped to make informed decisions.

- Personalized Solutions: We understand that every customer has unique requirements. Our team works closely with clients to develop customized solutions that address their specific needs and challenges. This personalized approach ensures that our customers receive the most effective and efficient metal sawing solutions for their specific applications.

- Customer Feedback: We actively solicit and value customer feedback, recognizing its crucial role in our continuous improvement journey. We use feedback to refine our products, services, and support offerings, ensuring we consistently exceed customer expectations.

Examples of Successful Customer Service Interactions

Metal Sawing Technology Inc. has a proven track record of providing exceptional customer service, resulting in numerous positive interactions and long-term partnerships. Here are a few examples of successful customer service interactions:

- Rapid Response to Technical Issue: A customer experienced a critical equipment malfunction that threatened to disrupt their production schedule. Our technical support team responded promptly, providing remote diagnostics and identifying the root cause of the issue. Within hours, a solution was implemented, minimizing downtime and ensuring the customer’s production remained uninterrupted.

- Customized Training Solution: A customer was implementing a new metal sawing process and required specialized training for their operators. We tailored a customized training program that addressed their specific needs, equipping their team with the skills and knowledge necessary to operate the new equipment safely and efficiently. The result was a significant improvement in productivity and a reduction in errors.

- Proactive Product Update: We identified a potential performance enhancement for a specific model of our metal sawing equipment. We proactively reached out to all customers using that model, informing them about the update and providing instructions on how to implement it. This proactive approach ensured customers benefited from the latest advancements, optimizing their equipment’s performance and extending its lifespan.

Future Trends and Innovations

The metal sawing industry is constantly evolving, driven by technological advancements and changing market demands. Metal Sawing Technology Inc. is committed to staying ahead of the curve by embracing emerging trends and investing in innovative solutions.

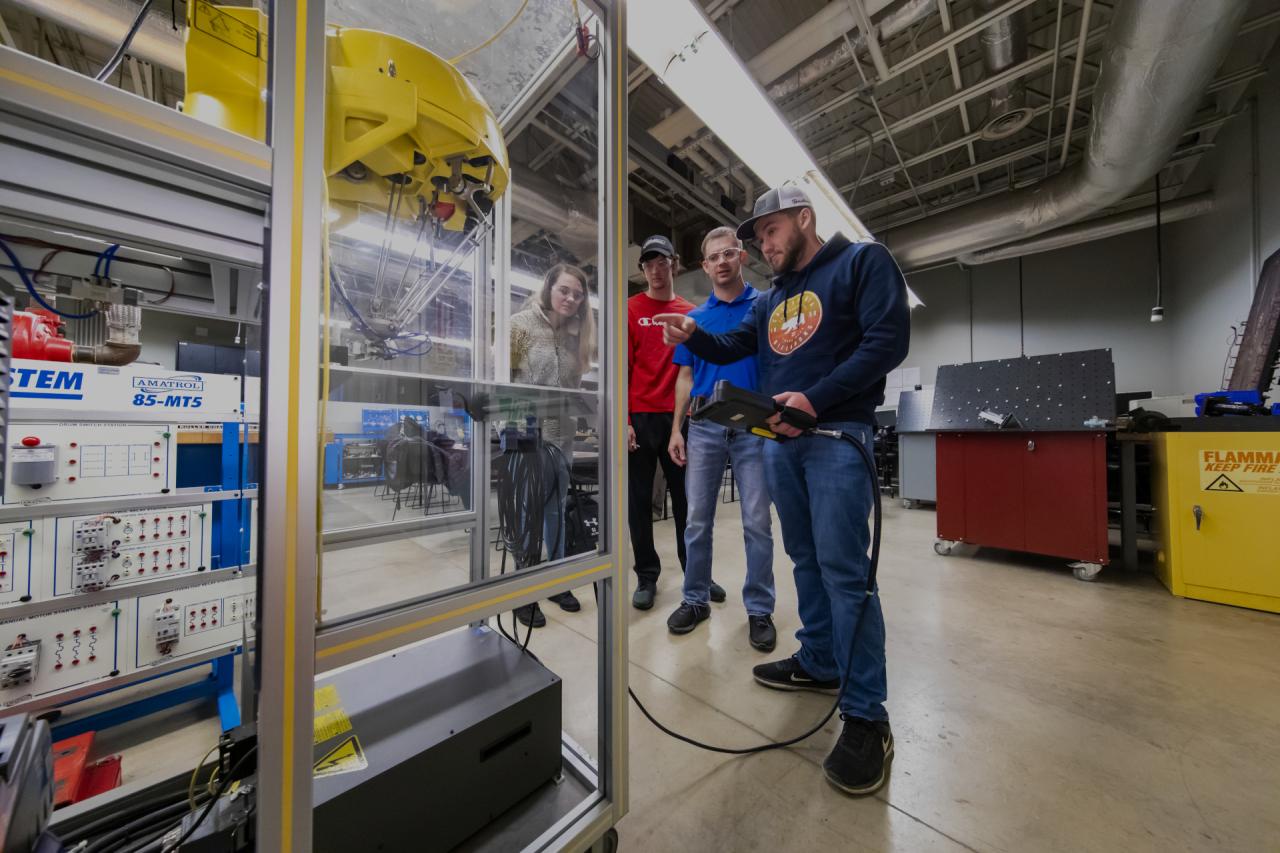

Automation and Robotics

Automation is rapidly transforming the metal sawing industry, improving efficiency, accuracy, and productivity. Metal Sawing Technology Inc. is actively integrating robotics and automation into its operations. The company is investing in advanced robotic systems that can perform complex sawing tasks with greater precision and speed, reducing the need for manual intervention.

- Increased Productivity: Robots can work continuously without breaks, significantly boosting production output.

- Improved Accuracy: Automated systems offer high precision and repeatability, resulting in consistent cut quality.

- Enhanced Safety: By automating hazardous tasks, robots contribute to a safer working environment.

Digitalization and Data Analytics

The integration of digital technologies is revolutionizing metal sawing processes, enabling better decision-making and optimization. Metal Sawing Technology Inc. is leveraging data analytics to gain valuable insights into its operations.

- Real-time Monitoring: Data analytics provides real-time insights into machine performance, allowing for proactive maintenance and optimization.

- Predictive Maintenance: By analyzing data patterns, predictive maintenance can anticipate potential issues and schedule maintenance before breakdowns occur.

- Process Optimization: Data analysis helps identify bottlenecks and areas for improvement, leading to enhanced efficiency and cost savings.

Sustainable Sawing Technologies

Sustainability is becoming increasingly crucial in the metal sawing industry. Metal Sawing Technology Inc. is committed to developing and implementing environmentally friendly sawing technologies.

- Energy Efficiency: The company is exploring energy-saving technologies, such as variable speed drives and high-efficiency motors, to reduce energy consumption.

- Waste Reduction: Metal Sawing Technology Inc. is investing in technologies that minimize waste generation, such as optimized cutting processes and recycling initiatives.

- Eco-friendly Coolants: The company is using biodegradable coolants to reduce environmental impact.

Advanced Materials and Cutting Technologies

The emergence of new materials, such as advanced alloys and composites, is posing new challenges for metal sawing. Metal Sawing Technology Inc. is adapting to these challenges by investing in advanced cutting technologies.

- High-Performance Cutting Tools: The company is using high-performance cutting tools specifically designed for cutting challenging materials.

- Laser Cutting: Metal Sawing Technology Inc. is exploring laser cutting technology for its precision and ability to cut intricate shapes in various materials.

- Waterjet Cutting: Waterjet cutting offers a non-thermal cutting method suitable for delicate materials and complex geometries.

Collaborative Robotics (Cobots), Metal sawing technology inc

Cobots are becoming increasingly popular in manufacturing, offering a safer and more collaborative approach to automation. Metal Sawing Technology Inc. is exploring the use of cobots for tasks such as material handling and assisting human operators.

- Increased Flexibility: Cobots can be easily reprogrammed for different tasks, making them highly versatile.

- Improved Ergonomics: Cobots can handle repetitive or physically demanding tasks, reducing strain on human workers.

- Enhanced Collaboration: Cobots can work alongside human operators, improving efficiency and productivity.

Final Review: Metal Sawing Technology Inc

Metal Sawing Technology Inc.’s dedication to excellence is evident in every aspect of their operations, from their meticulous quality control measures to their unwavering commitment to customer satisfaction. By staying at the forefront of industry trends and embracing innovative technologies, Metal Sawing Technology Inc. continues to redefine the standards of metal sawing, empowering businesses to achieve their goals with confidence.