GE Water and Process Technologies: Solutions for a Sustainable Future

GE Water and Process Technologies stands at the forefront of innovation, providing solutions for a world facing water scarcity and environmental challenges. With a rich history and a commitment to […]

GE Water and Process Technologies stands at the forefront of innovation, providing solutions for a world facing water scarcity and environmental challenges. With a rich history and a commitment to sustainability, GE has become a trusted leader in water treatment and industrial process technologies. Their expertise spans a wide range of industries, from power generation and manufacturing to agriculture and pharmaceuticals, offering a comprehensive approach to water management and resource optimization.

GE’s solutions go beyond traditional water treatment methods, encompassing advanced technologies like membrane filtration, reverse osmosis, and ion exchange. These innovative approaches not only ensure clean and safe water but also minimize waste, reduce energy consumption, and promote a circular economy. By leveraging their deep understanding of water chemistry and process engineering, GE helps businesses achieve operational excellence while contributing to a more sustainable future.

Introduction to GE Water and Process Technologies

GE Water and Process Technologies is a global leader in providing innovative water and process solutions for a wide range of industries. The company’s history spans over a century, with roots in the early days of General Electric. Through acquisitions and strategic growth, GE Water and Process Technologies has evolved into a comprehensive provider of technologies, products, and services that address the critical challenges of water scarcity, resource recovery, and industrial efficiency.

History and Evolution

GE Water and Process Technologies’ journey began in the early 20th century, with General Electric’s involvement in developing technologies for water treatment and process applications. Over the decades, the company expanded its portfolio through acquisitions and strategic partnerships, incorporating leading brands and technologies in areas such as filtration, desalination, wastewater treatment, and industrial process optimization. The company has played a significant role in shaping the water and process industry, pioneering innovations that have advanced water conservation, resource recovery, and industrial sustainability.

Mission, Vision, and Values

GE Water and Process Technologies is driven by a mission to provide innovative solutions that help customers conserve water, optimize processes, and protect the environment. The company’s vision is to be the leading provider of water and process technologies that enable a sustainable future. GE Water and Process Technologies operates based on core values that guide its actions and interactions with customers, partners, and employees. These values include:

- Customer Focus: GE Water and Process Technologies prioritizes customer needs and strives to provide exceptional service and support.

- Innovation: The company invests heavily in research and development to create cutting-edge technologies that address evolving water and process challenges.

- Sustainability: GE Water and Process Technologies is committed to environmental responsibility and developing solutions that promote sustainable practices.

- Integrity: The company operates with transparency and ethical conduct in all its business dealings.

Key Markets and Industries Served

GE Water and Process Technologies serves a diverse range of markets and industries globally. Its solutions are essential for:

- Municipal Water Treatment: GE Water and Process Technologies provides technologies for treating drinking water, ensuring safe and reliable water supplies for communities.

- Industrial Water Treatment: The company offers solutions for treating industrial wastewater, reducing environmental impact and ensuring efficient water reuse.

- Power Generation: GE Water and Process Technologies provides technologies for cooling water systems in power plants, enhancing efficiency and reliability.

- Oil and Gas: The company’s solutions are used for treating produced water and managing water resources in oil and gas operations.

- Mining: GE Water and Process Technologies provides technologies for treating mine wastewater and managing water resources in mining operations.

- Food and Beverage: The company offers solutions for treating process water and ensuring food safety in the food and beverage industry.

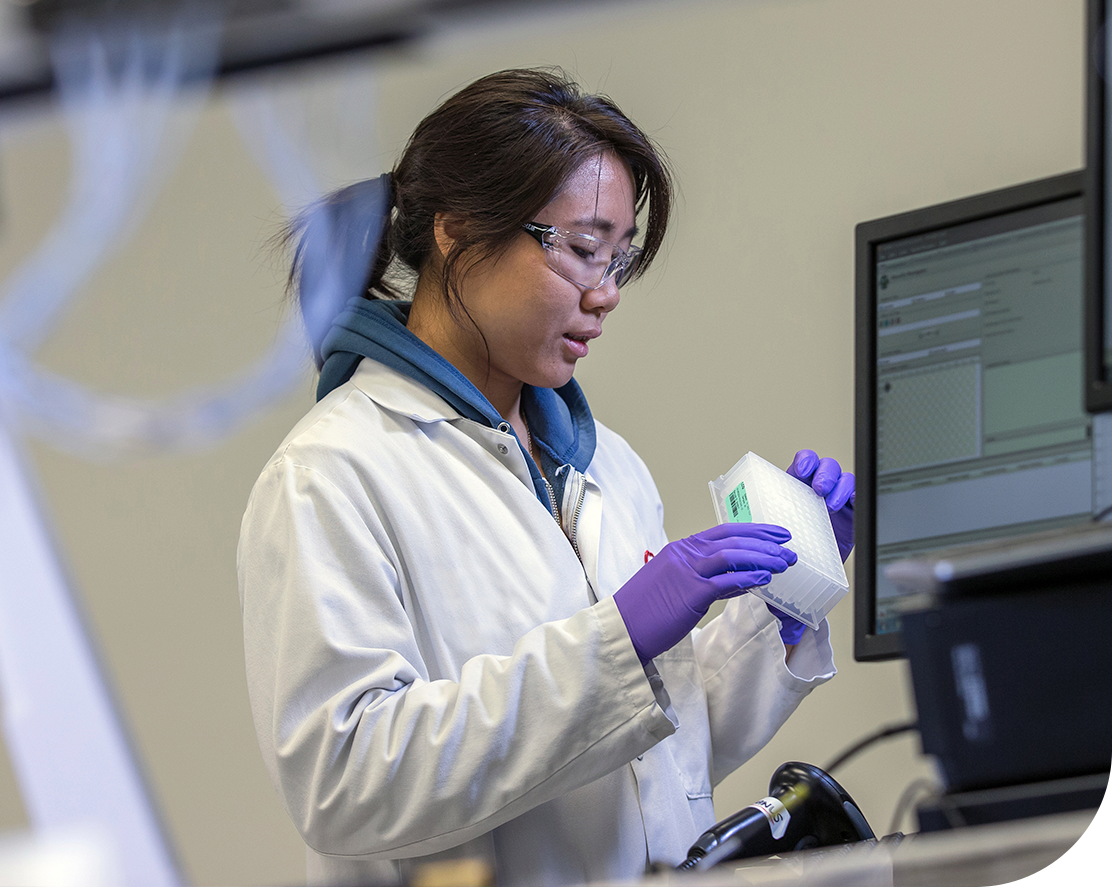

- Pharmaceuticals: GE Water and Process Technologies provides technologies for treating high-purity water used in pharmaceutical manufacturing.

Water Treatment Technologies

GE Water & Process Technologies offers a wide range of water treatment solutions to meet the diverse needs of various industries. These technologies play a crucial role in ensuring the quality and availability of water for drinking, industrial processes, and environmental protection.

Membrane Filtration

Membrane filtration is a versatile water treatment technology that uses semi-permeable membranes to separate contaminants from water. These membranes act as barriers, allowing water molecules to pass through while retaining larger particles, bacteria, viruses, and dissolved solids. GE offers a variety of membrane filtration technologies, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

Benefits of Membrane Filtration

Membrane filtration offers several benefits, including:

- High efficiency in removing a wide range of contaminants.

- Low energy consumption compared to other treatment methods.

- Compact and modular design, allowing for flexible system configurations.

- Reduced chemical usage, minimizing environmental impact.

Applications of Membrane Filtration

Membrane filtration finds applications in various industries, including:

- Municipal water treatment: Removing turbidity, bacteria, and viruses from drinking water.

- Industrial water treatment: Pretreatment for boiler feedwater, process water purification, and wastewater reuse.

- Food and beverage processing: Removing microorganisms and impurities from water used in food and beverage production.

- Pharmaceutical manufacturing: Producing high-purity water for pharmaceutical processes.

- Electronics manufacturing: Providing ultra-pure water for semiconductor and electronics production.

Reverse Osmosis

Reverse osmosis (RO) is a highly effective membrane filtration technology that uses pressure to force water molecules through a semi-permeable membrane, leaving behind dissolved salts, minerals, and other contaminants. RO is widely used for producing high-quality potable water, desalination, and industrial process water.

Benefits of Reverse Osmosis

RO offers several advantages, including:

- Excellent removal of dissolved salts, minerals, and organic compounds.

- High water recovery rates, minimizing water waste.

- Suitable for treating a wide range of feedwater qualities.

Applications of Reverse Osmosis

RO finds extensive applications in various industries, including:

- Desalination: Producing freshwater from seawater or brackish water.

- Municipal water treatment: Providing high-quality drinking water.

- Industrial water treatment: Producing high-purity water for various processes.

- Food and beverage processing: Purifying water for beverage production and food processing.

- Pharmaceutical manufacturing: Producing pharmaceutical-grade water.

Ion Exchange, Ge water and process technologies

Ion exchange is a water treatment process that uses specialized resins to remove dissolved ions from water. These resins contain charged sites that attract and exchange ions from the water, effectively removing contaminants such as hardness minerals (calcium and magnesium), heavy metals, and dissolved salts.

Benefits of Ion Exchange

Ion exchange offers several benefits, including:

- High efficiency in removing specific ions from water.

- Flexibility in treating a wide range of contaminants.

- Relatively low operating costs compared to other methods.

Applications of Ion Exchange

Ion exchange finds applications in various industries, including:

- Municipal water treatment: Softening water to remove hardness minerals.

- Industrial water treatment: Deionizing water for boiler feedwater and other processes.

- Food and beverage processing: Removing minerals and impurities from water used in food and beverage production.

- Pharmaceutical manufacturing: Producing high-purity water for pharmaceutical processes.

- Power generation: Treating boiler feedwater to prevent scaling and corrosion.

Comparison of Water Treatment Technologies

| Technology | Key Features | Advantages | Limitations |

|---|---|---|---|

| Membrane Filtration | Uses semi-permeable membranes to separate contaminants from water. | High efficiency, low energy consumption, compact design, reduced chemical usage. | Can be susceptible to fouling, requires regular maintenance. |

| Reverse Osmosis | Uses pressure to force water through a semi-permeable membrane, removing dissolved salts and minerals. | Excellent removal of dissolved salts, high water recovery rates, suitable for various feedwater qualities. | Can be energy-intensive, requires pre-treatment to remove suspended solids. |

| Ion Exchange | Uses specialized resins to remove dissolved ions from water. | High efficiency in removing specific ions, flexible treatment, relatively low operating costs. | Requires regeneration of resins, can be less effective for removing organic contaminants. |

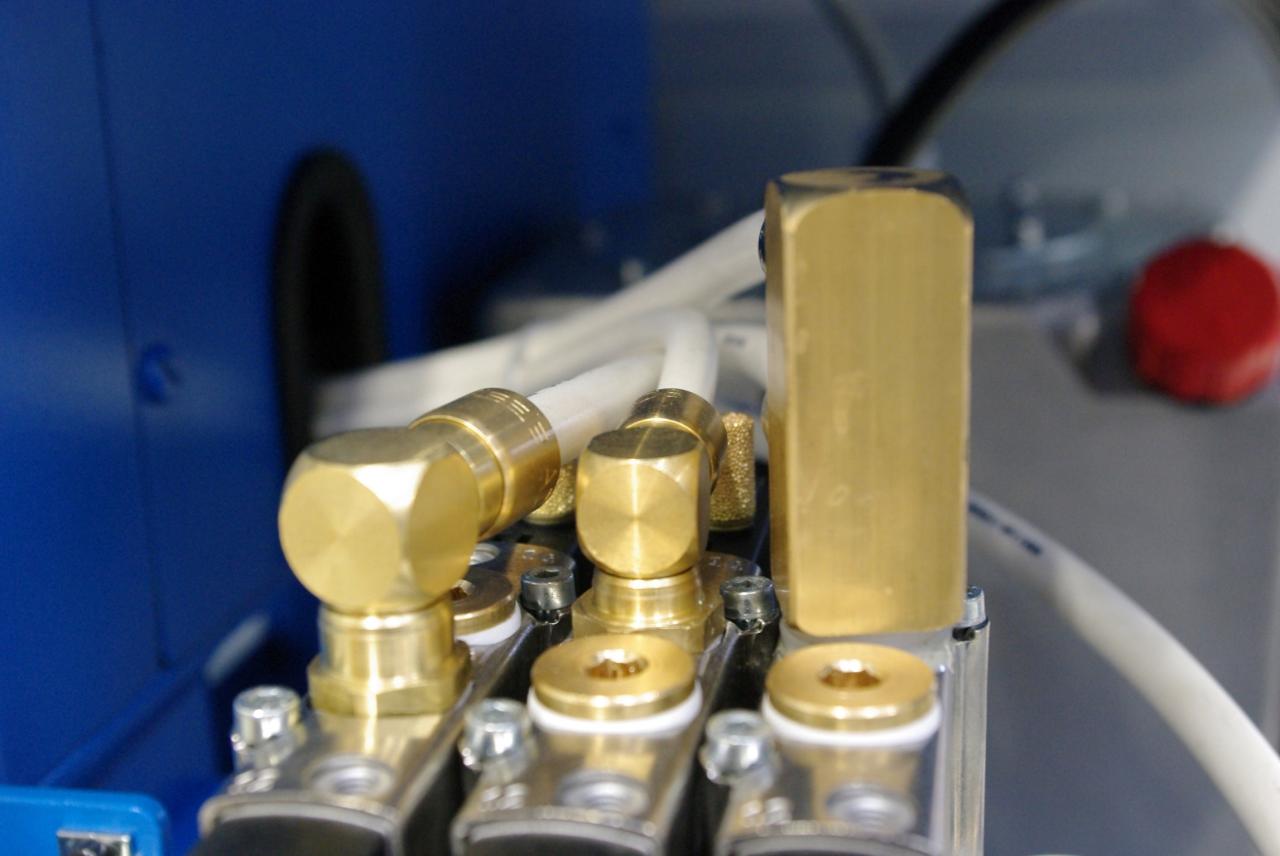

Process Technologies

GE Water & Process Technologies offers a range of process technologies that address various industrial challenges related to water treatment, purification, and separation. These technologies are designed to optimize processes, improve efficiency, and ensure compliance with environmental regulations.

Filtration

Filtration is a crucial process in water treatment, removing suspended solids, bacteria, and other contaminants. GE provides a wide array of filtration technologies, each tailored to specific applications and contaminant removal requirements.

- Sand filtration: This traditional method uses a bed of sand to trap suspended particles. It is commonly used for preliminary treatment of municipal and industrial water.

- Membrane filtration: GE offers various membrane filtration technologies, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. These membranes have different pore sizes, allowing for selective removal of contaminants based on their size and properties.

- Activated carbon filtration: Activated carbon is highly porous material that effectively removes organic contaminants, chlorine, and taste and odor compounds from water.

Separation

Separation technologies are essential for separating different components of a mixture, such as solids from liquids, or different liquid phases. GE provides a range of separation technologies, including:

- Centrifugation: This process uses centrifugal force to separate solids from liquids or different liquid phases based on their density. GE offers a variety of centrifuges for various industrial applications, including wastewater treatment and oil and gas production.

- Decantation: This simple yet effective method involves allowing solids to settle at the bottom of a container, followed by carefully removing the liquid from the top. It is often used in preliminary treatment stages to remove large solids.

- Flocculation and sedimentation: These processes use chemicals to bind small particles together, forming larger flocs that settle out of the water. This is a common step in water treatment to remove suspended solids.

Purification

Purification technologies aim to remove specific contaminants from water, often targeting dissolved impurities, heavy metals, or organic compounds. GE offers various purification technologies, including:

- Ion exchange: This process uses specialized resins to exchange specific ions in the water with other ions, effectively removing contaminants such as hardness ions (calcium and magnesium) or heavy metals.

- Distillation: This method involves heating water to its boiling point and collecting the steam, which is then condensed back into pure water. It is highly effective in removing dissolved salts and other contaminants.

- Oxidation: This process uses oxidizing agents, such as chlorine or ozone, to break down organic contaminants and disinfect water. GE provides various oxidation technologies, including chlorination systems and ozone generators.

Sustainability and Environmental Impact

GE Water and Process Technologies recognizes the critical role it plays in safeguarding the environment and promoting sustainable practices. The company’s commitment to sustainability is deeply ingrained in its operations, product development, and customer solutions.

Reducing Water Consumption

GE Water and Process Technologies develops innovative solutions that help industries and communities reduce their water footprint. By optimizing water usage, improving efficiency, and minimizing waste, the company contributes to water conservation efforts.

- Water reuse and recycling technologies: GE’s technologies enable the reuse of treated wastewater for various purposes, such as irrigation, industrial processes, and toilet flushing. This reduces the reliance on fresh water sources and minimizes water withdrawal from the environment.

- Membrane filtration systems: GE’s membrane filtration systems are designed to remove impurities from water, allowing for the reuse of treated water in industrial processes. These systems significantly reduce the amount of water needed for manufacturing and other operations.

- Leak detection and repair programs: GE provides advanced leak detection technologies that help industries identify and repair leaks promptly. This prevents water loss and reduces the overall water consumption.

Minimizing Waste

GE Water and Process Technologies is committed to reducing waste generation and promoting responsible waste management practices throughout its operations and supply chain.

- Zero-liquid discharge (ZLD) technologies: GE’s ZLD technologies enable industries to achieve zero liquid discharge, eliminating the need for wastewater disposal. These technologies effectively treat and recycle wastewater, reducing the environmental impact of industrial operations.

- Sustainable packaging and product design: GE prioritizes the use of recycled and recyclable materials in its packaging and product design. This minimizes the environmental impact of its products throughout their lifecycle.

- Waste reduction programs: GE implements waste reduction programs in its manufacturing facilities, aiming to minimize waste generation and maximize resource recovery. These programs involve process optimization, material substitution, and waste segregation.

Improving Energy Efficiency

GE Water and Process Technologies continuously invests in research and development to enhance the energy efficiency of its products and solutions.

- Energy-efficient pumps and motors: GE offers energy-efficient pumps and motors that consume less electricity while maintaining high performance. This reduces energy consumption and lowers greenhouse gas emissions.

- Variable-speed drives (VSDs): GE’s VSDs optimize pump and motor operation by adjusting speed based on demand, reducing energy consumption and wear and tear.

- Advanced control systems: GE’s advanced control systems monitor and optimize water treatment processes, ensuring efficient energy utilization and minimizing energy waste.

Environmental Sustainability Projects and Partnerships

GE Water and Process Technologies is actively involved in various projects and partnerships that demonstrate its commitment to environmental sustainability.

- Water treatment projects in developing countries: GE has partnered with organizations to provide clean water access to communities in developing countries. These projects often involve the installation of water treatment plants, water distribution systems, and sanitation facilities, improving the lives of people and protecting the environment.

- Sustainable water management programs: GE works with municipalities and industries to develop and implement sustainable water management programs. These programs focus on reducing water consumption, improving water quality, and promoting water conservation practices.

- Partnerships with environmental organizations: GE collaborates with environmental organizations to support research, advocacy, and conservation efforts. These partnerships contribute to the development of sustainable solutions for water management and environmental protection.

Innovation and Research and Development: Ge Water And Process Technologies

GE Water & Process Technologies is committed to driving innovation and developing cutting-edge solutions for the water and process industries. The company invests heavily in research and development (R&D) to create groundbreaking technologies that address global challenges related to water scarcity, resource recovery, and environmental sustainability.

Recent Advancements and Breakthroughs

GE’s commitment to innovation is evident in its recent advancements and breakthroughs. These advancements are shaping the future of water and process technologies, enabling industries to operate more efficiently and sustainably.

- Advanced Membrane Technologies: GE has developed advanced membrane technologies, such as its ZeeWeed® membranes, which are used in a wide range of applications, including municipal and industrial water treatment, desalination, and wastewater reuse. These membranes offer high performance, durability, and energy efficiency, contributing to sustainable water management practices.

- Digital Water Solutions: GE has integrated digital technologies into its water solutions, enabling real-time monitoring, data analytics, and predictive maintenance. These digital platforms provide valuable insights into water system performance, optimize operations, and minimize downtime. This approach helps customers optimize their water usage, reduce costs, and enhance operational efficiency.

- Resource Recovery and Reuse: GE has developed innovative technologies for resource recovery and reuse, such as its Zero Liquid Discharge (ZLD) systems. These systems effectively recover and reuse water, minimizing wastewater discharge and promoting a circular economy approach to water management. These technologies are crucial for industries facing water scarcity and environmental regulations.

Case Studies and Success Stories

GE Water and Process Technologies has a long history of providing innovative solutions to water and process challenges around the world. Our technologies have helped customers in a wide range of industries, including power generation, oil and gas, mining, manufacturing, and municipal water treatment, to achieve significant environmental and economic benefits.

Here are a few examples of how GE Water and Process Technologies has helped customers succeed:

Power Generation

GE Water and Process Technologies provides a wide range of solutions for power generation, including water treatment, steam generation, and cooling systems. Our technologies help power plants improve efficiency, reduce emissions, and ensure reliable operation.

One example is a coal-fired power plant in China that was facing significant challenges with water quality. The plant’s boiler was experiencing scaling and corrosion, which was reducing efficiency and increasing maintenance costs. GE Water and Process Technologies provided a solution that included a combination of water treatment technologies, including reverse osmosis, ion exchange, and chemical treatment. The solution helped the plant to improve water quality, reduce scaling and corrosion, and increase efficiency by 5%.

Oil and Gas

GE Water and Process Technologies provides a wide range of solutions for the oil and gas industry, including produced water treatment, drilling fluid management, and pipeline integrity. Our technologies help oil and gas companies to improve efficiency, reduce environmental impact, and ensure safe and reliable operations.

One example is an oil and gas company in the Middle East that was facing challenges with produced water treatment. The company’s produced water was contaminated with high levels of salts, oil, and gas, which made it difficult to dispose of safely. GE Water and Process Technologies provided a solution that included a combination of technologies, including membrane filtration, evaporation, and chemical treatment. The solution helped the company to reduce the volume of produced water by 90%, improve water quality, and reduce environmental impact.

Mining

GE Water and Process Technologies provides a wide range of solutions for the mining industry, including water treatment, tailings management, and process water recovery. Our technologies help mining companies to improve efficiency, reduce environmental impact, and ensure safe and reliable operations.

One example is a gold mine in South Africa that was facing challenges with tailings management. The mine’s tailings were contaminated with heavy metals, which posed a significant environmental risk. GE Water and Process Technologies provided a solution that included a combination of technologies, including filtration, flocculation, and chemical treatment. The solution helped the mine to reduce the volume of tailings by 50%, improve water quality, and reduce environmental impact.

Manufacturing

GE Water and Process Technologies provides a wide range of solutions for the manufacturing industry, including water treatment, wastewater treatment, and process water recovery. Our technologies help manufacturers to improve efficiency, reduce environmental impact, and ensure safe and reliable operations.

One example is a manufacturing plant in the United States that was facing challenges with wastewater treatment. The plant’s wastewater was contaminated with high levels of organic pollutants, which made it difficult to dispose of safely. GE Water and Process Technologies provided a solution that included a combination of technologies, including biological treatment, membrane filtration, and chemical treatment. The solution helped the plant to reduce the volume of wastewater by 75%, improve water quality, and reduce environmental impact.

Municipal Water Treatment

GE Water and Process Technologies provides a wide range of solutions for municipal water treatment, including drinking water treatment, wastewater treatment, and desalination. Our technologies help municipalities to provide safe and reliable drinking water, protect public health, and ensure environmental sustainability.

One example is a city in the United States that was facing challenges with drinking water treatment. The city’s water supply was contaminated with high levels of arsenic, which posed a significant health risk. GE Water and Process Technologies provided a solution that included a combination of technologies, including coagulation, filtration, and ion exchange. The solution helped the city to remove arsenic from the water supply, improve water quality, and protect public health.

Final Summary

GE Water and Process Technologies plays a vital role in addressing the global water crisis and promoting sustainable practices. Their dedication to research and development ensures continuous innovation, pushing the boundaries of water treatment and process technologies. By collaborating with industries and research institutions, GE is committed to delivering cutting-edge solutions that meet the evolving needs of a changing world. Their commitment to sustainability, combined with their technological expertise, makes them a valuable partner in building a brighter future for all.

GE Water and Process Technologies provides innovative solutions for a wide range of industries, from water treatment to power generation. To implement these solutions effectively, companies often turn to technology integrators who can seamlessly integrate GE’s technologies into existing systems.

This collaborative approach ensures that the final solution is optimized for the specific needs of each client, maximizing efficiency and reliability.