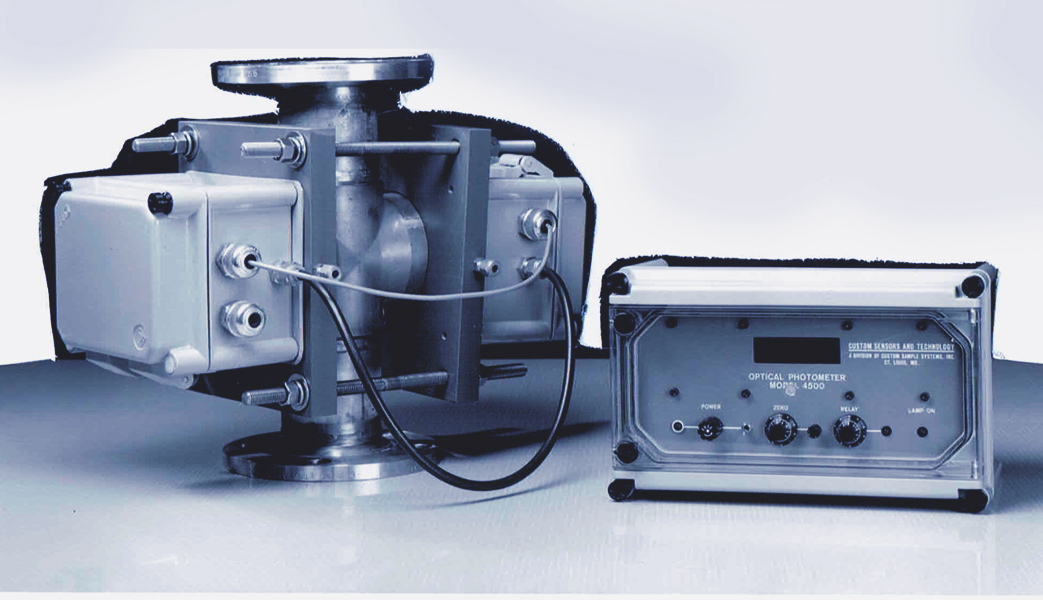

Custom Sensors and Technology: Shaping the Future

Custom sensors and technology are revolutionizing industries by providing tailored solutions for specific needs. This trend is driven by the increasing demand for personalized experiences, advancements in sensor technology, and […]

Custom sensors and technology are revolutionizing industries by providing tailored solutions for specific needs. This trend is driven by the increasing demand for personalized experiences, advancements in sensor technology, and the growing adoption of the Internet of Things (IoT) and Industry 4.0.

From healthcare to manufacturing and environmental monitoring, custom sensors are enabling unprecedented levels of precision, efficiency, and data-driven insights. This article explores the evolution of custom sensors, their diverse applications, the technologies behind their development, and the exciting future they hold.

The Rise of Customization in Sensors

The world of sensors is undergoing a significant shift, moving away from standardized, one-size-fits-all solutions towards highly customized options. This trend is driven by a growing demand for tailored solutions across various industries, fueled by advancements in sensor technology and the widespread adoption of the Internet of Things (IoT) and Industry 4.0.

Factors Driving the Customization Trend

The increasing demand for tailored solutions is a key driver behind the rise of custom sensors. Businesses are seeking sensors that are specifically designed to meet their unique needs and challenges. This includes factors such as:

- Specific environmental conditions: Sensors need to operate reliably in extreme temperatures, high humidity, or corrosive environments.

- Precise measurement requirements: Industries demand sensors that can measure specific parameters with high accuracy and sensitivity.

- Integration with existing systems: Customized sensors need to seamlessly integrate with existing equipment and software infrastructure.

Advancements in sensor technology are another significant factor driving customization. New materials, fabrication techniques, and miniaturization capabilities are enabling the development of sensors with enhanced performance, smaller form factors, and greater functionality.

- Nanotechnology: Enables the creation of highly sensitive and miniature sensors with increased accuracy.

- Advanced materials: Allows for the development of sensors that can withstand harsh environments and offer extended operating life.

- Wireless communication: Facilitates the integration of sensors into wireless networks, enabling remote monitoring and data collection.

The widespread adoption of IoT and Industry 4.0 is further accelerating the trend towards custom sensors. These technologies rely on interconnected devices and data exchange, creating a demand for sensors that can provide real-time insights and support intelligent decision-making.

- Smart factories: Customized sensors play a crucial role in optimizing production processes, improving efficiency, and reducing downtime.

- Precision agriculture: Sensors tailored for specific crops and environmental conditions help farmers optimize resource utilization and improve yields.

- Smart cities: Customized sensors are deployed for traffic management, environmental monitoring, and infrastructure optimization.

Industries Embracing Custom Sensors

Custom sensors are making a significant impact across a wide range of industries. Here are some examples:

- Healthcare: Customized sensors are used in wearable devices for health monitoring, implantable devices for disease diagnosis and treatment, and diagnostic equipment for accurate and efficient patient care.

- Automotive: Sensors are integral to advanced driver-assistance systems (ADAS), autonomous vehicles, and connected car technologies. They provide real-time data on vehicle speed, braking, steering, and surrounding environment, enabling enhanced safety and efficiency.

- Aerospace: Customized sensors are used in aircraft for flight control, engine monitoring, and structural health monitoring. They ensure safety, optimize performance, and reduce maintenance costs.

Types of Custom Sensors and Their Applications

The increasing demand for customized solutions in various industries has led to the development of a wide range of custom sensors tailored to specific requirements. These sensors are designed to measure a variety of parameters, providing valuable data for monitoring, control, and decision-making processes. This section explores the different types of custom sensors, their sensing principles, measurement parameters, and diverse applications across various domains.

Classification of Custom Sensors

Custom sensors can be categorized based on their sensing principles, measurement parameters, and application domains. This classification provides a comprehensive overview of the diverse range of custom sensors available and their potential applications.

Sensing Principles

Custom sensors employ various sensing principles to detect and measure specific parameters. These principles are based on the physical phenomena that underlie the sensor’s operation.

- Optical Sensors: These sensors utilize light as the sensing medium. They work by measuring changes in light intensity, wavelength, or polarization due to the interaction of light with the target parameter. For example, optical fiber sensors can measure strain, temperature, and pressure by detecting changes in the light transmitted through the fiber.

- Acoustic Sensors: Acoustic sensors rely on sound waves to detect and measure parameters. They work by generating and receiving sound waves and analyzing their properties, such as frequency, amplitude, and phase. Acoustic sensors are commonly used in applications like ultrasound imaging, leak detection, and acoustic emission monitoring.

- Magnetic Sensors: Magnetic sensors measure magnetic fields or changes in magnetic fields. They utilize the interaction of magnetic fields with materials to detect and measure parameters. Magnetic sensors are used in various applications, including navigation, proximity detection, and magnetic field mapping.

- Chemical Sensors: Chemical sensors detect and measure the concentration of specific chemical species. They work by interacting with the target analyte and generating a measurable signal proportional to its concentration. Chemical sensors are widely used in environmental monitoring, food safety, and medical diagnostics.

- Thermal Sensors: Thermal sensors measure temperature changes. They rely on the principle of thermal expansion or changes in electrical resistance due to temperature variations. Thermal sensors are commonly used in industrial process control, HVAC systems, and medical devices.

Measurement Parameters

Custom sensors are designed to measure a wide range of parameters, providing insights into various physical and chemical processes. These parameters include:

- Temperature: Custom temperature sensors are used in various applications, including industrial process control, environmental monitoring, and medical diagnostics. They are designed to measure temperature accurately over a wide range, from cryogenic temperatures to high-temperature environments.

- Pressure: Custom pressure sensors measure the force exerted by a fluid or gas per unit area. They are used in various applications, including industrial automation, aerospace, and medical devices.

- Flow: Custom flow sensors measure the volume of fluid passing through a specific point in a given time. They are used in various applications, including water and gas metering, industrial process control, and medical devices.

- Force and Torque: Custom force and torque sensors measure the forces and torques acting on an object. They are used in various applications, including robotics, manufacturing, and aerospace.

- Displacement and Position: Custom displacement and position sensors measure the linear or angular displacement of an object. They are used in various applications, including robotics, machine vision, and motion control.

Application Domains

Custom sensors are used in a wide range of application domains, enabling advancements in various industries. These domains include:

- Healthcare: Custom sensors are used in various medical applications, including patient monitoring, diagnostics, and drug delivery. For example, wearable sensors can monitor vital signs like heart rate, blood pressure, and body temperature, providing real-time data for personalized healthcare.

- Manufacturing: Custom sensors are used in various manufacturing processes, including quality control, process optimization, and predictive maintenance. For example, sensors can monitor machine vibration, temperature, and pressure, providing early warning of potential failures and reducing downtime.

- Environmental Monitoring: Custom sensors are used in environmental monitoring applications, including air quality monitoring, water quality monitoring, and soil analysis. For example, sensors can monitor air pollutants, water contaminants, and soil properties, providing valuable data for environmental protection and resource management.

- Automotive: Custom sensors are used in various automotive applications, including engine control, safety systems, and driver assistance systems. For example, sensors can monitor engine parameters, tire pressure, and vehicle speed, enhancing vehicle performance, safety, and efficiency.

- Aerospace: Custom sensors are used in various aerospace applications, including aircraft control, navigation, and satellite communication. For example, sensors can monitor aircraft altitude, speed, and orientation, providing critical data for safe and efficient flight operations.

Technologies Behind Custom Sensor Development

The development of custom sensors relies on a diverse array of technologies that enable the design, fabrication, and integration of these specialized devices. These technologies play a crucial role in shaping the capabilities and applications of custom sensors, driving innovation across various fields.

Microelectromechanical Systems (MEMS), Custom sensors and technology

MEMS technology involves the miniaturization of mechanical and electrical components onto a single chip, creating micro-scale sensors that are compact, lightweight, and cost-effective.

- MEMS-based sensors leverage microfabrication techniques to create intricate structures, such as cantilevers, diaphragms, and resonators, which respond to physical stimuli like pressure, acceleration, and temperature.

- The miniaturization offered by MEMS technology allows for the integration of multiple sensors on a single chip, creating multi-functional sensor systems with enhanced capabilities.

- MEMS sensors are widely used in smartphones, automotive systems, and industrial applications due to their high sensitivity, fast response times, and low power consumption.

Nanotechnology

Nanotechnology focuses on manipulating matter at the nanoscale, enabling the creation of sensors with enhanced properties and functionalities.

- Nanomaterials, such as graphene and carbon nanotubes, possess unique electrical, mechanical, and optical properties that can be harnessed to create highly sensitive and responsive sensors.

- Nanotechnology allows for the development of sensors with smaller dimensions, increased surface area, and improved sensitivity, leading to advancements in fields like bio-sensing, environmental monitoring, and medical diagnostics.

- Nanomaterials can be integrated into various sensor platforms, including MEMS devices, to enhance their performance and create sensors with unique capabilities.

3D Printing

3D printing, also known as additive manufacturing, offers a versatile approach to sensor fabrication, enabling the creation of complex and customized sensor designs.

- 3D printing allows for the direct fabrication of sensor components with intricate geometries and complex structures, enabling the creation of sensors with unique shapes and functionalities.

- The ability to print multiple materials in a single fabrication process allows for the integration of different sensing elements and electronic circuitry, creating multi-functional and highly customized sensors.

- 3D printing offers flexibility in sensor design and prototyping, allowing for rapid experimentation and development of custom sensors for specific applications.

Advanced Materials

The use of advanced materials plays a critical role in enhancing the performance and functionalities of custom sensors.

- Materials with unique properties, such as high sensitivity, selectivity, and stability, are crucial for developing sensors that can detect specific analytes or respond to specific stimuli.

- Advanced materials, including polymers, ceramics, and composites, are used in sensor fabrication to achieve desired properties, such as biocompatibility, temperature resistance, and chemical stability.

- The development of new materials with tailored properties is an ongoing area of research, continuously expanding the possibilities for custom sensor development.

Design Considerations for Custom Sensors

Custom sensor design is a multi-faceted process requiring careful consideration of various factors to ensure the sensor meets its intended application and performs optimally. These design considerations encompass performance requirements, environmental factors, integration with existing systems, and cost-effectiveness.

Performance Requirements

Performance requirements define the sensor’s operational characteristics and how it interacts with the environment. These requirements are crucial for ensuring the sensor accurately and reliably measures the desired parameter.

- Sensitivity: This refers to the sensor’s ability to detect small changes in the measured parameter. A highly sensitive sensor can detect subtle variations, which is essential for applications requiring precise measurements.

- Accuracy: Accuracy measures how closely the sensor’s output matches the actual value of the measured parameter. A high accuracy sensor provides reliable and trustworthy measurements.

- Response Time: This parameter defines the time it takes for the sensor to respond to changes in the measured parameter. A fast response time is crucial for applications requiring real-time monitoring or control.

- Range: The range specifies the minimum and maximum values the sensor can measure. Choosing an appropriate range ensures the sensor can handle the expected variations in the measured parameter.

- Resolution: Resolution refers to the smallest change in the measured parameter the sensor can detect. A higher resolution sensor provides more detailed measurements, enabling finer distinctions between different values.

Environmental Factors

Custom sensors are often deployed in challenging environments with varying conditions that can affect their performance.

- Temperature: Temperature fluctuations can affect the sensor’s sensitivity, accuracy, and stability. Temperature compensation techniques are often employed to minimize these effects.

- Humidity: Humidity can impact the sensor’s performance, especially for sensors based on hygroscopic materials. Moisture-resistant coatings or designs are used to mitigate these effects.

- Electromagnetic Interference (EMI): EMI can interfere with the sensor’s signal, leading to inaccurate measurements. Shielding and filtering techniques are employed to reduce EMI susceptibility.

- Pressure: Sensors used in high-pressure environments require robust designs to withstand the external forces.

- Vibration: Vibrations can affect the sensor’s accuracy and stability. Shock absorbers or vibration-dampening materials are used to minimize these effects.

Integration with Existing Systems

Custom sensors are often integrated into existing systems, requiring careful consideration of compatibility and communication protocols.

- Interface Compatibility: The sensor’s output should be compatible with the input requirements of the system it is integrated with. This might involve using specific connectors, signal levels, or communication protocols.

- Power Requirements: The sensor’s power consumption should be compatible with the system’s power supply. Power management techniques can be used to optimize energy efficiency.

- Communication Protocols: The sensor should communicate with the system using a compatible protocol. Common protocols include SPI, I2C, UART, and CAN.

Cost and Manufacturability

Cost and manufacturability are crucial considerations for custom sensor development, balancing performance requirements with economic feasibility.

- Material Cost: The cost of materials used in sensor fabrication can significantly impact the overall cost. Choosing cost-effective materials without compromising performance is essential.

- Manufacturing Process: The complexity of the manufacturing process can affect the production cost. Simplifying the manufacturing process can reduce costs without sacrificing quality.

- Volume: The production volume influences the cost per unit. Higher volumes typically result in lower unit costs due to economies of scale.

Design Trade-offs and Optimization Strategies

Custom sensor design often involves trade-offs between different performance parameters, environmental factors, and cost considerations. Optimization strategies are employed to achieve the best balance for the specific application.

For example, increasing sensitivity may come at the expense of response time or accuracy. Similarly, improving environmental robustness might increase cost or complexity.

Optimization strategies involve using advanced materials, innovative designs, and simulation tools to achieve the desired performance while minimizing costs.

Integration of Custom Sensors with Technology

The integration of custom sensors with other technologies is crucial for unlocking their full potential and creating innovative applications. This integration allows for seamless data collection, processing, and analysis, enabling real-time monitoring, decision-making, and control.

Wireless Communication Protocols

Wireless communication protocols are essential for transmitting data collected by custom sensors to remote locations for processing and analysis. These protocols enable wireless connectivity and data exchange between sensors and other devices, such as smartphones, computers, or cloud platforms.

- Bluetooth: Bluetooth is a short-range wireless communication protocol commonly used for connecting sensors to smartphones, tablets, and other nearby devices. It offers low power consumption and ease of use, making it suitable for applications requiring real-time data transfer over short distances.

- Wi-Fi: Wi-Fi is a more robust and longer-range wireless communication protocol that provides higher bandwidth for data transmission. It is suitable for connecting sensors to local networks and accessing the internet for data analysis and storage.

- LoRa: LoRa is a long-range, low-power wireless communication protocol designed for applications requiring long-distance data transmission with low power consumption. It is ideal for IoT applications involving sensors deployed in remote locations.

Data Acquisition and Processing Systems

Data acquisition and processing systems play a crucial role in collecting, storing, and processing data from custom sensors. These systems are responsible for converting raw sensor data into meaningful information that can be used for decision-making and analysis.

- Microcontrollers: Microcontrollers are small, embedded computers that can be used to acquire and process data from sensors. They are often used in conjunction with wireless communication protocols to transmit data to other devices.

- Data Loggers: Data loggers are specialized devices that collect and store data from sensors over extended periods. They can be programmed to record data at specific intervals or triggered by events, providing a comprehensive record of sensor readings.

- Signal Processing Software: Signal processing software is used to analyze and interpret sensor data, identifying patterns, trends, and anomalies. It can be used to extract meaningful insights from raw data, enabling data-driven decision-making.

Cloud Computing and Analytics Platforms

Cloud computing and analytics platforms offer scalable and cost-effective solutions for storing, processing, and analyzing large volumes of sensor data. These platforms provide a wide range of tools and services for data management, visualization, and analysis, enabling insights that can be used to optimize operations, improve efficiency, and make informed decisions.

- Data Storage and Management: Cloud platforms provide secure and scalable storage solutions for sensor data, ensuring its availability and integrity. They offer data backup and recovery capabilities, minimizing the risk of data loss.

- Data Analytics and Visualization: Cloud platforms offer advanced analytics tools and visualization capabilities for extracting insights from sensor data. These tools enable users to identify trends, patterns, and anomalies, providing valuable information for decision-making.

- Machine Learning and Artificial Intelligence: Cloud platforms provide access to machine learning and artificial intelligence algorithms that can be used to analyze sensor data and identify complex patterns, enabling predictive modeling and automation.

Benefits and Challenges of Integration

Integrating custom sensors with different technologies offers numerous benefits, but it also presents certain challenges.

| Technology | Benefits | Challenges |

|---|---|---|

| Wireless Communication Protocols | – Enables remote data access and monitoring. – Facilitates real-time data transmission. – Reduces wiring and installation costs. |

– Security concerns related to data transmission. – Interference and signal limitations. – Battery life considerations for wireless devices. |

| Data Acquisition and Processing Systems | – Provides accurate and reliable data collection. – Enables data processing and analysis in real-time. – Offers flexibility in data handling and storage. |

– Complexity of system integration and configuration. – Compatibility issues between different devices and software. – Cost considerations for hardware and software. |

| Cloud Computing and Analytics Platforms | – Enables scalable data storage and processing. – Provides advanced analytics tools and services. – Offers cost-effective solutions for data management. |

– Dependence on internet connectivity for data access. – Data privacy and security concerns in the cloud. – Complexity of managing and configuring cloud services. |

Future Trends in Custom Sensors and Technology

The field of custom sensors is constantly evolving, driven by advancements in technology and the growing demand for specialized solutions across various industries. Several emerging trends are poised to revolutionize the way we design, manufacture, and utilize custom sensors, leading to a new era of innovation and applications.

Artificial Intelligence and Machine Learning

The integration of AI and ML algorithms into custom sensors is transforming their capabilities. AI and ML can analyze vast amounts of sensor data, identify patterns, and make predictions in real time. This enables sensors to perform tasks that were previously impossible, such as:

- Predictive Maintenance: Sensors equipped with AI can monitor the health of equipment and predict potential failures, enabling proactive maintenance and reducing downtime.

- Smart Agriculture: AI-powered sensors can analyze soil conditions, weather patterns, and crop health, providing farmers with real-time insights to optimize irrigation, fertilization, and pest control.

- Autonomous Vehicles: AI-driven sensors play a crucial role in self-driving cars, providing data on surroundings, traffic conditions, and pedestrian movements.

These advancements are driving the development of intelligent sensors that can learn and adapt to changing environments, improving accuracy, efficiency, and decision-making capabilities.

Conclusion: Custom Sensors And Technology

As custom sensors and technology continue to evolve, they will undoubtedly play an increasingly vital role in shaping our future. From enhancing our understanding of the world around us to improving the quality of our lives, custom sensors hold immense potential to drive innovation across industries and create a more connected and intelligent world.

Custom sensors and technology are rapidly evolving, enabling advancements in various fields. One notable example is the integration of advanced sensors in body cameras, like the halo technologies body camera , which provides high-quality video recording and evidence capture. This integration of custom sensors and technology enhances the capabilities of law enforcement and security personnel, contributing to improved safety and accountability.