American Spray Technology: Innovation and Impact

American spray technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. From […]

American spray technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. From its humble beginnings to its sophisticated present, the evolution of spray technology in the United States has been a journey of innovation and progress, shaping industries and impacting our daily lives.

This exploration delves into the diverse applications of spray technology across various sectors, from agriculture and manufacturing to healthcare and beyond. We’ll examine the intricate mechanisms behind these technologies, their environmental considerations, and the regulatory landscape that governs their use. Furthermore, we’ll venture into the future, exploring the potential advancements and trends that will shape the landscape of American spray technology in the years to come.

History of American Spray Technology

The development of spray technology in the United States has a long and fascinating history, intertwined with the growth of various industries and the evolution of scientific understanding. From the early days of rudimentary hand-operated sprayers to the sophisticated automated systems of today, American ingenuity has consistently driven advancements in this field.

Early Innovations and Developments

The origins of spray technology can be traced back to the 19th century, with the development of hand-operated sprayers for agricultural applications. These early devices were primarily used for insecticide and pesticide application. The invention of the first practical compressed-air sprayer in 1876 by Thomas J. Handley marked a significant milestone. This invention enabled more efficient and widespread application of liquid solutions, laying the groundwork for future advancements.

The Rise of the Automobile Industry and Spray Technology

The early 20th century witnessed a rapid expansion of the automobile industry, which had a profound impact on the development of spray technology. The need for efficient paint application processes led to the development of specialized spray guns and equipment. The development of the airless spray gun in the 1920s revolutionized paint application, enabling faster and more even coatings.

Post-World War II Innovations

The post-World War II era saw a surge in technological innovation across various industries, including spray technology. The development of new materials, such as synthetic polymers, and the emergence of new applications, such as aerospace and electronics, spurred advancements in spray technology. The introduction of electrostatic spray technology in the 1950s allowed for more efficient and controlled application of coatings, reducing overspray and waste.

Prominent Figures and Companies

Several individuals and companies played a pivotal role in shaping the history of American spray technology.

- Thomas J. Handley, inventor of the first practical compressed-air sprayer.

- DeVilbiss Company, a leading manufacturer of spray equipment, established in 1888.

- Binks Manufacturing Company, another prominent manufacturer of spray equipment, established in 1908.

- Graco Inc., a global leader in fluid handling equipment, including spray technology.

Types of Spray Technology in America

Spray technology plays a crucial role in various industries across the United States, contributing to efficiency, precision, and innovation in diverse applications. This section delves into the different types of spray technologies commonly used in America, categorizing them based on their applications and elaborating on their underlying principles and mechanisms.

Agricultural Spray Technology

Agricultural spray technology encompasses methods and equipment designed for applying pesticides, herbicides, fertilizers, and other agricultural chemicals to crops and fields.

- Airblast Sprayers: These sprayers utilize high-velocity air to create a fine mist that covers the target area evenly. Airblast sprayers are commonly used for orchards, vineyards, and row crops, allowing for efficient application and minimizing drift.

- Boom Sprayers: Boom sprayers feature a long horizontal bar equipped with multiple nozzles that distribute liquid chemicals across a wide area. These sprayers are widely used for large-scale applications in row crops, pastures, and grasslands.

- Drone Sprayers: Unmanned aerial vehicles (UAVs) equipped with spray systems offer precision application and coverage in challenging terrains. Drone sprayers are becoming increasingly popular for targeted pesticide application, minimizing chemical usage and environmental impact.

Industrial Spray Technology

Industrial spray technology encompasses a wide range of applications, including painting, coating, cleaning, and surface treatment in manufacturing, construction, and other industrial sectors.

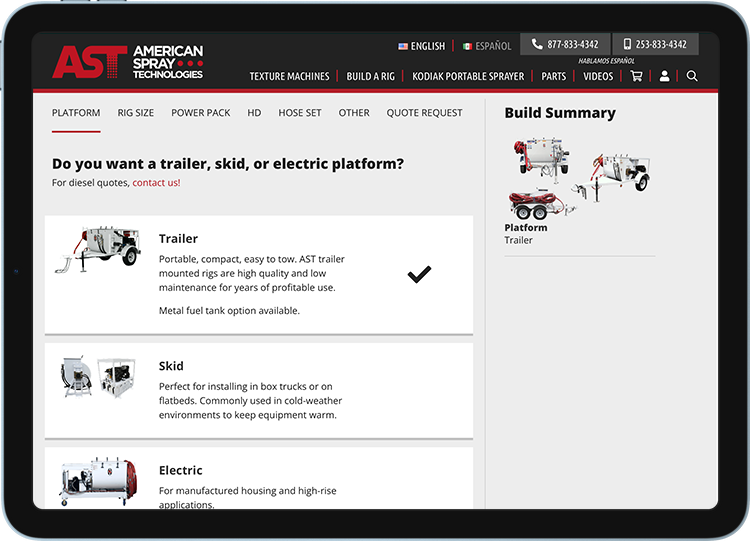

- Airless Sprayers: Airless sprayers use high pressure to force paint or coating through a small nozzle, creating a fine spray pattern. These sprayers are suitable for applying thick materials and achieving a smooth finish.

- HVLP (High Volume Low Pressure) Sprayers: HVLP sprayers utilize a high volume of air at low pressure to atomize paint or coating, resulting in a fine, even spray pattern with minimal overspray. These sprayers are ideal for applying delicate coatings and minimizing material waste.

- Electrostatic Sprayers: Electrostatic sprayers use an electrical charge to attract paint or coating particles to the target surface, resulting in efficient coverage and reduced overspray. These sprayers are particularly effective for coating irregular or complex shapes.

Automotive Spray Technology

Automotive spray technology focuses on applying paint, coatings, and other materials to vehicles, ensuring durability, aesthetics, and protection.

- Spray Guns: Spray guns are handheld devices that utilize compressed air to atomize paint or coating, allowing for precise control over the spray pattern and coverage.

- Robotic Sprayers: Automated robotic sprayers are increasingly used in automotive manufacturing, offering high precision, consistency, and efficiency in applying paint and coatings.

- Powder Coating: Powder coating involves applying a dry powder coating to a surface, which is then cured under heat to create a durable and protective finish. Powder coating is commonly used for automotive parts and accessories.

Applications of American Spray Technology

Spray technology has revolutionized various industries, offering precise and efficient methods for applying liquids and powders. This technology plays a vital role in agriculture, manufacturing, healthcare, and numerous other sectors, impacting productivity, efficiency, and innovation.

Agriculture

Spray technology is indispensable in modern agriculture, enabling farmers to apply pesticides, herbicides, and fertilizers with precision and minimal waste.

- Precision Spraying: Sprayers equipped with GPS and other advanced technologies allow farmers to target specific areas, reducing chemical usage and environmental impact. This precise application minimizes drift and runoff, protecting nearby waterways and ecosystems.

- Increased Productivity: Spray technology significantly increases productivity by allowing farmers to cover large areas quickly and efficiently. This reduces labor costs and improves crop yields.

- Improved Crop Health: Precise application of pesticides and fertilizers through spray technology helps control pests and diseases, ensuring healthy crops and maximizing yields.

Manufacturing

Spray technology plays a crucial role in manufacturing, enabling efficient and precise application of coatings, adhesives, and other materials.

- Surface Coating: Spray technology is widely used for applying protective coatings to various surfaces, including metal, plastic, and wood. This process enhances durability, corrosion resistance, and aesthetic appeal.

- Adhesive Application: Spray technology allows for precise and even application of adhesives in various manufacturing processes, such as bonding components and creating durable assemblies.

- Automated Spraying: Robots and automated systems equipped with spray technology enable high-volume and consistent application of coatings and adhesives, improving efficiency and reducing labor costs.

Healthcare

Spray technology finds significant applications in healthcare, enabling efficient and controlled delivery of medications and other solutions.

- Drug Delivery: Spray technology is used for delivering medications to the respiratory system, such as inhalers for asthma and other respiratory conditions. This method offers fast and direct delivery of drugs, improving patient outcomes.

- Wound Care: Spray technology is used for applying antiseptic solutions and wound dressings, promoting healing and reducing infection risk.

- Pain Management: Spray technology is used for applying topical pain relief medications, providing targeted and effective pain management.

Innovations and Trends in American Spray Technology

American spray technology is constantly evolving, driven by advancements in materials science, robotics, and automation. These innovations are transforming the way we approach spraying applications, leading to greater efficiency, precision, and sustainability.

Advancements in Materials Science

The development of new materials is playing a crucial role in shaping spray technology. For instance, the introduction of nanomaterials has led to the creation of spray coatings with enhanced properties like increased durability, corrosion resistance, and water repellency. These advancements have opened up new possibilities in various sectors, including aerospace, automotive, and construction.

Robotics and Automation in Spray Technology

Robotics and automation are revolutionizing the spray industry by enabling faster, more accurate, and consistent spraying processes. Robots equipped with advanced sensors and software can precisely control the spray pattern, ensuring uniform coverage and minimizing waste. This automation is particularly beneficial in industries like automotive painting, where high-quality finishes are essential.

Impact of Innovations on the Future of American Spray Technology

The innovations in materials science, robotics, and automation are poised to have a significant impact on the future of American spray technology.

- Increased efficiency and productivity: Automated spray systems will lead to faster production cycles, reducing labor costs and increasing output.

- Improved quality and precision: Advancements in materials and robotics will enable the creation of spray coatings with enhanced properties and greater precision, leading to higher-quality products.

- Enhanced sustainability: Spray technology is becoming more environmentally friendly, with innovations like water-based coatings and automated systems that minimize overspray and waste.

Environmental and Safety Considerations

Spray technology, while instrumental in various industries, necessitates careful consideration of its environmental and safety implications. The widespread use of spray applications raises concerns about potential harm to the environment and human health.

Environmental Impact of Spray Technology, American spray technology

Spray technology’s environmental impact is multifaceted, encompassing air quality, water pollution, and ecosystem health. The use of volatile organic compounds (VOCs) in spray paints, pesticides, and other applications can contribute to smog formation and respiratory problems. Improper disposal of spray materials and cleaning solvents can lead to soil and water contamination, harming aquatic life and impacting human health.

- Air Quality: Spraying processes often release volatile organic compounds (VOCs) into the atmosphere. VOCs contribute to smog formation, which can lead to respiratory problems and other health issues.

- Water Pollution: Improper disposal of spray materials and cleaning solvents can contaminate water sources. Runoff from sprayed areas can carry pesticides, herbicides, and other chemicals into rivers, lakes, and groundwater, harming aquatic life and potentially affecting drinking water supplies.

- Ecosystem Health: Pesticides and herbicides applied through spraying can have unintended consequences for ecosystems. They can harm beneficial insects, disrupt food webs, and contribute to the decline of biodiversity.

Safety Considerations in Spray Technology

Spray technology poses various safety risks to workers and the public. Exposure to hazardous materials, including solvents, pigments, and pesticides, can lead to skin irritation, respiratory problems, and long-term health effects. Proper training, protective equipment, and ventilation are crucial to mitigating these risks.

- Worker Safety: Workers handling spray materials are exposed to potential hazards, including skin irritation, respiratory problems, and long-term health effects. Proper training, protective equipment (such as respirators, gloves, and eye protection), and adequate ventilation are essential to minimize these risks.

- Public Safety: Spraying operations can also pose risks to the public, particularly if hazardous materials are released into the environment. Proper planning, containment measures, and warning signs are necessary to ensure public safety during spraying activities.

Sustainable Practices and Responsible Use of Spray Technology

Minimizing the environmental and safety impacts of spray technology requires adopting sustainable practices and promoting responsible use. This includes using environmentally friendly materials, reducing waste, and implementing proper safety protocols.

- Choosing Environmentally Friendly Materials: Opting for low-VOC paints, water-based coatings, and biodegradable pesticides can significantly reduce the environmental impact of spray applications.

- Reducing Waste: Implementing efficient spray techniques and minimizing overspray can reduce material waste. Proper disposal of spray materials and cleaning solvents is also crucial to prevent contamination.

- Promoting Safety: Providing comprehensive training on safe handling procedures, ensuring proper ventilation, and requiring the use of personal protective equipment are essential for worker and public safety.

Regulatory Landscape of Spray Technology in the US

The use of spray technology in the United States is subject to a complex regulatory framework designed to protect human health, the environment, and consumer safety. This framework involves a multifaceted approach, encompassing various federal agencies, state and local regulations, and industry standards.

This regulatory landscape is essential for ensuring the responsible development, production, and application of spray technologies across various sectors, including agriculture, manufacturing, construction, and consumer products. The impact of these regulations is significant, influencing the design of spray equipment, the types of chemicals used, and the practices employed in spray applications.

Federal Regulations

Several federal agencies play a crucial role in regulating spray technology in the United States. These agencies work together to establish comprehensive standards and guidelines for the safe and environmentally sound use of spray technologies.

- Environmental Protection Agency (EPA): The EPA is responsible for regulating pesticides and other chemicals used in spray applications. The agency sets standards for the registration, labeling, and use of these substances, ensuring they meet safety and environmental protection requirements.

- Food and Drug Administration (FDA): The FDA oversees the safety of food and drugs, including those that may be affected by spray technologies. The agency sets standards for the residues of pesticides and other chemicals on food products, ensuring they meet safety thresholds for human consumption.

- Occupational Safety and Health Administration (OSHA): OSHA focuses on worker safety and health in various industries, including those involving spray technologies. The agency sets standards for workplace safety, including the use of personal protective equipment (PPE) and safe handling practices for spray materials.

- Department of Transportation (DOT): The DOT regulates the transportation of hazardous materials, including those used in spray applications. The agency sets standards for the packaging, labeling, and transportation of these materials, ensuring safe handling and transport.

State and Local Regulations

In addition to federal regulations, states and local governments often have their own laws and regulations regarding spray technology. These regulations can vary significantly from one jurisdiction to another, reflecting local environmental concerns, agricultural practices, and population density.

- Air Quality Regulations: Many states and local governments have regulations to control air pollution, including emissions from spray applications. These regulations may limit the use of certain spray technologies, require specific application techniques, or set limits on the amount of chemicals that can be released into the air.

- Water Quality Regulations: State and local regulations are also in place to protect water quality from contamination by spray chemicals. These regulations may restrict the use of certain pesticides near water bodies, require buffer zones around sensitive areas, or mandate the use of specific application techniques to minimize runoff.

- Pesticide Use Regulations: Some states have specific regulations governing the use of pesticides, including licensing requirements for applicators, restrictions on the use of certain pesticides, and requirements for pesticide drift management.

Industry Standards

Beyond government regulations, industry standards play a significant role in shaping the development and application of spray technologies. These standards are often developed by professional organizations and industry groups, and they provide guidance on best practices, safety protocols, and quality control.

- American Society of Agricultural and Biological Engineers (ASABE): ASABE develops standards for agricultural equipment, including sprayers, addressing factors such as design, performance, and safety.

- National Pesticide Applicator Certification Program (NPAC): NPAC offers certification programs for pesticide applicators, ensuring they have the necessary knowledge and skills to safely and effectively apply pesticides.

- American National Standards Institute (ANSI): ANSI develops voluntary standards for a wide range of products and services, including spray technologies. These standards can address factors such as safety, performance, and compatibility.

Last Word

The journey of American spray technology is a testament to human ingenuity and its profound impact on society. From revolutionizing agricultural practices to enhancing manufacturing processes and contributing to advancements in healthcare, spray technology has proven to be a versatile and indispensable tool. As we look toward the future, the continued development and innovation in this field hold immense promise for addressing global challenges and improving our lives in countless ways.

American spray technology has come a long way, with advancements in precision and efficiency. This is evident in areas like automotive painting and agricultural applications. It’s interesting to note how similar technology is used in other sectors, like the applause technology charge on credit card system, which relies on precise application of digital technology.

The similarities highlight how innovative solutions can be applied across diverse industries, driving efficiency and progress.