Oil Industry Technology: Transforming the Energy Landscape

Oil industry technology has been the driving force behind the energy revolution, shaping the way we extract, process, and utilize this vital resource. From the early days of hand-dug wells […]

Oil industry technology has been the driving force behind the energy revolution, shaping the way we extract, process, and utilize this vital resource. From the early days of hand-dug wells to the sophisticated automation and digitalization of today, the oil industry has witnessed a remarkable evolution.

This journey has been marked by groundbreaking innovations that have transformed every aspect of oil operations, from exploration and production to refining and distribution. The impact of these advancements is undeniable, driving efficiency, safety, and environmental sustainability in the sector.

Upstream Technology

Upstream technology encompasses the processes involved in finding, extracting, and preparing crude oil and natural gas for transportation and refining. It involves a wide range of technologies and innovations that are constantly evolving to meet the demands of the industry.

Seismic Imaging

Seismic imaging is a crucial technology used in oil exploration to create detailed images of the Earth’s subsurface. It involves sending sound waves into the ground and analyzing the reflected waves to identify potential oil and gas reservoirs. Advanced seismic imaging techniques, such as 3D and 4D seismic, provide highly accurate and detailed images of the subsurface, enabling oil companies to make informed decisions about drilling locations.

Advanced Drilling Techniques

Advanced drilling techniques play a significant role in maximizing oil and gas production. These techniques include horizontal drilling, directional drilling, and multilateral drilling, which allow oil companies to access reservoirs that were previously inaccessible. These techniques also help to increase the efficiency of oil and gas extraction by reducing the number of wells required and maximizing the amount of oil and gas extracted from each well.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are transforming the oil and gas industry by providing powerful tools for optimizing well placement, production, and reservoir management. AI and ML algorithms can analyze vast amounts of data from various sources, such as seismic data, well logs, and production data, to identify patterns and trends that would be difficult for humans to detect. This data-driven approach enables oil companies to make more informed decisions about well placement, optimize production, and minimize costs.

Robotics and Automation

Robotics and automation are increasingly being used in offshore oil and gas extraction to improve safety, efficiency, and productivity. Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) are used for tasks such as inspection, maintenance, and repair of subsea infrastructure. These technologies enable oil companies to operate in harsh and hazardous environments without putting human lives at risk. Automation is also being used in various aspects of offshore operations, such as drilling, production, and processing, to reduce the need for human intervention and improve efficiency.

Upstream Technologies

| Technology | Benefits | Limitations |

|---|---|---|

| Seismic Imaging | Provides detailed images of the subsurface, enabling accurate identification of potential oil and gas reservoirs. | Can be expensive and time-consuming. |

| Advanced Drilling Techniques | Allow access to previously inaccessible reservoirs, increase efficiency, and maximize production. | Can be complex and require specialized expertise. |

| Artificial Intelligence and Machine Learning | Optimize well placement, production, and reservoir management by analyzing vast amounts of data. | Requires significant data processing capabilities and expertise. |

| Robotics and Automation | Improve safety, efficiency, and productivity in offshore operations. | May require significant investment in technology and infrastructure. |

Midstream Technology

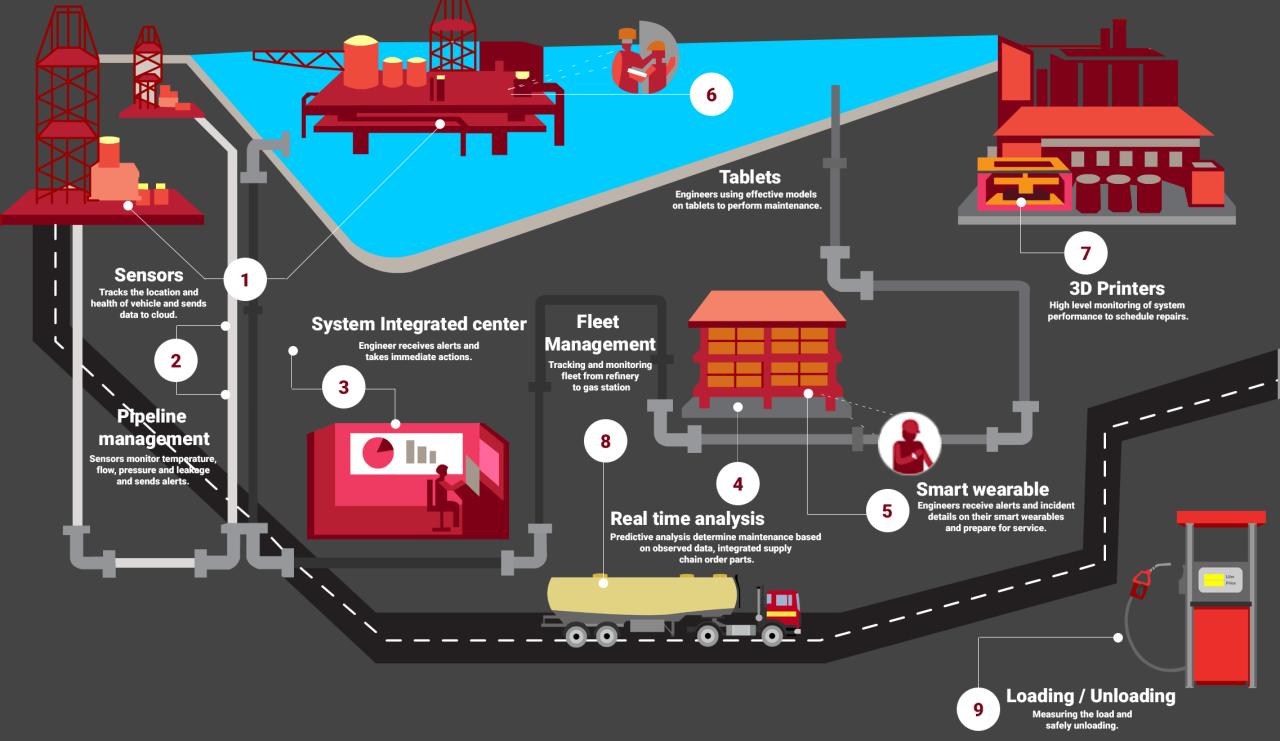

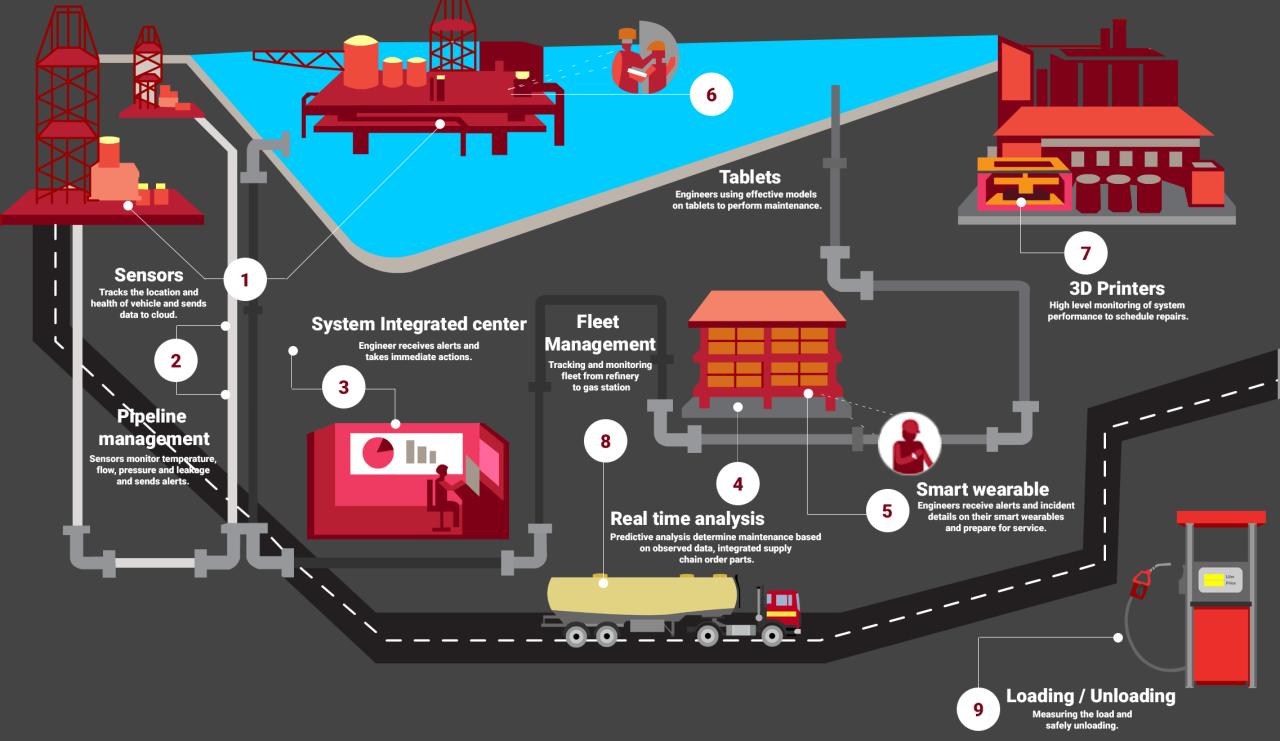

The midstream sector of the oil and gas industry plays a crucial role in transporting and storing hydrocarbons from production sites to refineries and end-users. This involves a complex network of pipelines, storage tanks, and other infrastructure, which are essential for ensuring a continuous and efficient supply of energy resources.

Pipeline and Storage Tank Roles

Pipelines and storage tanks are fundamental components of midstream operations, facilitating the safe and efficient movement and storage of oil and natural gas. Pipelines act as the primary transportation arteries, transporting vast quantities of hydrocarbons over long distances. Storage tanks provide a buffer for supply and demand fluctuations, ensuring a consistent flow of resources even during periods of high demand or production disruptions.

Pipeline Monitoring Systems and Leak Detection Technologies

Pipeline monitoring systems and leak detection technologies are critical for maintaining the integrity and safety of pipelines. These systems use a combination of sensors, data analytics, and remote monitoring to detect potential leaks, corrosion, or other issues that could lead to environmental damage or safety hazards.

- Pressure Monitoring: Sensors along the pipeline continuously measure pressure changes, which can indicate a leak or blockage.

- Flow Measurement: Flow meters track the volume of oil or gas passing through the pipeline, helping to identify any discrepancies that could point to a leak.

- Acoustic Leak Detection: Acoustic sensors listen for unusual noises that could indicate a leak, such as the hissing sound of escaping gas.

- Inline Inspection Tools: Specialized tools are periodically sent through the pipeline to assess its internal condition, identifying corrosion, cracks, or other potential issues.

Advancements in Pipeline Construction Materials

Advancements in pipeline construction materials have significantly enhanced the safety, efficiency, and longevity of pipelines.

- High-Strength Steels: The use of high-strength steels has allowed for the construction of pipelines with greater capacity and resistance to corrosion and mechanical stresses.

- Coated Pipes: Applying protective coatings to the exterior of pipelines helps prevent corrosion and extends their lifespan, reducing the need for frequent maintenance and replacements.

- Composite Materials: Composite materials, such as fiberglass-reinforced plastic (FRP), offer lighter weight, corrosion resistance, and greater flexibility compared to traditional steel pipelines.

Technologies Used in Midstream Operations

Midstream operations rely on a diverse range of technologies to ensure the efficient and safe transportation and storage of oil and natural gas.

- SCADA (Supervisory Control and Data Acquisition) Systems: SCADA systems provide centralized monitoring and control of pipeline and storage facilities, enabling operators to remotely manage and optimize operations.

- GIS (Geographic Information Systems): GIS software helps visualize and manage pipeline networks, providing detailed information on pipeline routes, locations, and assets.

- Remote Pipeline Inspection: Drones and other unmanned aerial vehicles (UAVs) are increasingly used to inspect pipelines, offering a cost-effective and efficient way to monitor remote and hazardous areas.

- Automated Valve Control: Automated valve control systems enhance pipeline safety by allowing for rapid isolation of sections in the event of a leak or other emergency.

- Smart Pigging: Smart pigging technology involves sending specialized inspection tools through pipelines to collect data on internal conditions, including corrosion, wall thickness, and other factors.

- Data Analytics: Advanced data analytics techniques are used to analyze pipeline performance data, identify potential issues, and optimize operations.

Downstream Technology

Downstream technology encompasses the processes and technologies used in the final stages of the oil and gas industry, specifically focusing on refining crude oil into usable products like gasoline, diesel, and kerosene. This involves a complex series of physical and chemical transformations, with advancements in technology continuously improving efficiency and sustainability.

Oil Refining Technologies

The refining process involves several key technologies that separate and transform crude oil into various products.

- Distillation: This is a fundamental process that separates crude oil into different fractions based on their boiling points. The process involves heating crude oil in a large furnace, causing it to vaporize. The vapors then rise through a distillation tower, where they condense at different levels based on their boiling points. This results in various fractions, including naphtha, kerosene, diesel, and asphalt.

- Cracking: This process breaks down large hydrocarbon molecules into smaller, more valuable molecules. Cracking can be done using heat (thermal cracking) or catalysts (catalytic cracking). This technology allows refiners to produce more gasoline and other lighter products from heavier fractions of crude oil.

- Blending: The final step involves blending different refined products to meet specific quality and performance requirements. This involves mixing different fractions and additives to create gasoline, diesel, and other fuels with desired properties like octane rating and viscosity.

Automation and Process Control in Refineries, Oil industry technology

Automation and process control play a crucial role in modern refineries, enhancing safety, efficiency, and environmental performance.

- Automated Process Control Systems: These systems use sensors, actuators, and advanced software to monitor and control various processes in the refinery, including temperature, pressure, flow rates, and product quality. They ensure optimal operation and minimize human error.

- Real-Time Data Analysis: Sophisticated data analytics tools are used to analyze real-time data from sensors and control systems, allowing operators to identify potential issues and optimize processes for efficiency and safety.

- Predictive Maintenance: By analyzing historical data and real-time sensor readings, predictive maintenance algorithms can anticipate equipment failures and schedule maintenance proactively, reducing downtime and improving reliability.

Comparison of Traditional and Modern Technologies

The table below highlights the key differences between traditional and modern technologies used in downstream operations.

| Feature | Traditional Technology | Modern Technology |

|---|---|---|

| Process Control | Manual control with limited automation | Advanced automation and process control systems |

| Data Analysis | Limited data collection and analysis | Real-time data analysis and predictive analytics |

| Efficiency | Lower energy efficiency and higher emissions | Improved energy efficiency and reduced emissions |

| Safety | Higher risk of accidents and incidents | Enhanced safety features and automated safety systems |

| Environmental Performance | Higher environmental impact | Reduced environmental footprint and improved sustainability |

Technology for Improved Efficiency and Environmental Performance

Technological advancements are continuously improving the efficiency and environmental performance of refineries.

- Energy Efficiency: Technologies like advanced heat recovery systems and process optimization software are being implemented to reduce energy consumption and greenhouse gas emissions. For instance, the use of cogeneration plants, which generate both electricity and steam, has significantly reduced energy consumption in refineries.

- Emissions Reduction: Modern refineries are adopting technologies like catalytic converters, sulfur removal processes, and flare gas recovery systems to minimize emissions of harmful pollutants like sulfur dioxide, nitrogen oxides, and volatile organic compounds.

- Waste Management: Wastewater treatment technologies and advanced recycling processes are being implemented to reduce the environmental impact of refinery operations.

Emerging Technologies in the Oil Industry

The oil industry is constantly evolving, and new technologies are emerging to improve efficiency, reduce costs, and minimize environmental impact. These innovations are shaping the future of the industry, driving a transition towards a more sustainable and technologically advanced landscape.

Blockchain Technology in the Oil Supply Chain

Blockchain technology has the potential to revolutionize the oil supply chain by providing greater transparency, security, and efficiency. It offers a decentralized and immutable ledger that records all transactions, making it difficult to tamper with data.

The use of blockchain can help:

- Track the origin and movement of oil: Blockchain can trace the journey of oil from the wellhead to the refinery and ultimately to the consumer, enhancing supply chain transparency and accountability.

- Reduce fraud and counterfeiting: The immutability of blockchain data can help prevent fraudulent activities and ensure the authenticity of oil products.

- Improve payment processing: Smart contracts on blockchain can automate payments and streamline transactions, reducing administrative burdens and delays.

Renewable Energy Sources in the Oil Industry

The oil industry is increasingly incorporating renewable energy sources into its operations to reduce reliance on fossil fuels and contribute to a cleaner energy future.

Renewable energy sources can be used for:

- Powering oil and gas facilities: Solar, wind, and geothermal energy can be utilized to generate electricity for oil and gas production sites, reducing greenhouse gas emissions.

- Developing new energy sources: Oil companies are investing in renewable energy technologies, such as biofuels and hydrogen, to diversify their energy portfolio.

- Reducing operational costs: Renewable energy sources can help lower energy costs for oil companies, making their operations more sustainable and cost-effective.

Carbon Capture and Storage Technologies

Carbon capture and storage (CCS) technologies play a crucial role in mitigating climate change by capturing and storing carbon dioxide emissions from industrial processes, including oil and gas production.

CCS technologies work by:

- Capturing CO2: Various technologies, such as amine scrubbing and membrane separation, are used to capture CO2 from flue gases or directly from the atmosphere.

- Transporting CO2: Captured CO2 is transported via pipelines or ships to storage locations.

- Storing CO2: CO2 is stored in geological formations, such as depleted oil and gas reservoirs or saline aquifers, where it is permanently isolated from the atmosphere.

3D Printing and Additive Manufacturing

3D printing and additive manufacturing are emerging technologies that are transforming the oil industry by enabling the creation of complex parts and tools on-demand.

The benefits of 3D printing in the oil industry include:

- Reduced lead times: 3D printing allows for the rapid production of parts, reducing downtime and accelerating project timelines.

- Improved design flexibility: 3D printing enables the creation of intricate and customized parts that would be difficult or impossible to manufacture using traditional methods.

- Cost savings: 3D printing can reduce the cost of manufacturing, particularly for low-volume or specialized parts.

Challenges and Opportunities: Oil Industry Technology

The oil industry is facing a period of significant change, driven by the rapid pace of technological innovation and the increasing need for sustainable practices. While new technologies offer exciting opportunities for improving efficiency, reducing environmental impact, and driving growth, they also present a range of challenges that must be addressed.

Challenges of Implementing New Technologies

Implementing new technologies in the oil industry presents several challenges.

- High Initial Investment Costs: The development and deployment of advanced technologies, such as artificial intelligence (AI), robotics, and digital twins, often require significant upfront capital investment. This can be a barrier for smaller companies and may require strategic partnerships or access to venture capital.

- Integration and Compatibility Issues: Integrating new technologies into existing infrastructure and systems can be complex and time-consuming. Ensuring compatibility between different technologies and legacy systems is crucial to avoid disruptions and ensure smooth operation.

- Skills Gap: The adoption of new technologies requires a workforce with specialized skills and expertise. The oil industry faces a skills gap in areas such as data science, AI, and cybersecurity. Training and upskilling programs are essential to bridge this gap and prepare employees for the future of work.

- Regulatory and Safety Considerations: Implementing new technologies in the oil industry must comply with strict regulatory frameworks and safety standards. Ensuring that new technologies meet these requirements can be a complex and time-consuming process.

Opportunities for Environmental Sustainability

Technological advancements offer significant opportunities for the oil industry to address environmental concerns and contribute to a more sustainable future.

- Reduced Emissions and Improved Efficiency: AI-powered optimization tools can help reduce emissions by improving operational efficiency and minimizing waste. For example, AI can optimize drilling operations, predict equipment failures, and optimize production processes, leading to reduced energy consumption and greenhouse gas emissions.

- Enhanced Carbon Capture and Storage: Emerging technologies for carbon capture and storage (CCS) can help mitigate the impact of greenhouse gas emissions from oil and gas operations. These technologies capture CO2 emissions from power plants and industrial facilities and store them underground, preventing them from entering the atmosphere.

- Development of Renewable Energy Sources: The oil industry is exploring opportunities to diversify its energy portfolio by investing in renewable energy sources such as solar, wind, and geothermal. These investments can contribute to a cleaner energy mix and reduce dependence on fossil fuels.

Impact on Workforce and Skills Development

Technological innovation is transforming the oil industry workforce, creating new roles and requiring new skills.

- Shift Towards Digital and Data-Driven Roles: The increasing adoption of digital technologies is leading to a shift towards data-driven roles such as data scientists, software engineers, and cybersecurity specialists.

- Automation and Robotics: The use of automation and robotics is transforming many traditional oil and gas operations, leading to a decrease in demand for manual labor and an increase in demand for skilled technicians and engineers.

- Importance of Continuous Learning: The rapid pace of technological change requires employees to engage in continuous learning and upskilling to stay competitive. Training programs and online courses can help bridge the skills gap and prepare employees for the future of work in the oil industry.

Future of Oil Industry Technology

The future of oil industry technology is promising, with advancements in AI, robotics, and data analytics expected to drive innovation and sustainability.

- Artificial Intelligence and Machine Learning: AI and machine learning are expected to play a key role in optimizing operations, reducing costs, and improving safety. AI-powered systems can analyze vast amounts of data to identify patterns, predict equipment failures, and optimize production processes.

- Robotics and Automation: Robotics and automation are expected to continue transforming oil and gas operations, improving efficiency and safety while reducing the need for manual labor. For example, autonomous vehicles and drones can be used for inspection, maintenance, and exploration tasks.

- Digital Twins and Simulation: Digital twins, virtual representations of physical assets, can be used to simulate and optimize operations, reducing the need for physical testing and minimizing downtime.

- Sustainable Technologies: The oil industry is investing in research and development of sustainable technologies such as carbon capture and storage, renewable energy sources, and biofuels. These technologies have the potential to reduce the environmental impact of oil and gas operations and contribute to a cleaner energy future.

Outcome Summary

As the oil industry continues to evolve, technology remains at the forefront, paving the way for a more sustainable and efficient future. From renewable energy integration to carbon capture and storage solutions, the industry is embracing new frontiers, ensuring a responsible and resilient energy future. The ongoing pursuit of technological advancements will play a crucial role in addressing the challenges and harnessing the opportunities that lie ahead, ultimately shaping the future of the energy landscape.

The oil industry is constantly evolving, seeking innovative technologies to improve efficiency and sustainability. One company at the forefront of this technological advancement is mcr technologies , specializing in solutions that optimize production processes and reduce environmental impact. Their expertise in automation, data analytics, and advanced monitoring systems is proving invaluable in the quest for a more sustainable and efficient oil industry.