Haas Laser Technologies: Precision Cutting & Innovation

Haas Laser Technologies has revolutionized the manufacturing landscape with its advanced laser cutting solutions. The company, renowned for its commitment to innovation and customer satisfaction, offers a comprehensive range of […]

Haas Laser Technologies has revolutionized the manufacturing landscape with its advanced laser cutting solutions. The company, renowned for its commitment to innovation and customer satisfaction, offers a comprehensive range of laser machines designed to meet the diverse needs of various industries. From precision cutting to intricate designs, Haas laser technology has become a cornerstone for businesses seeking to enhance efficiency, quality, and productivity.

Haas Automation, Inc., the parent company, has a rich history of providing high-quality CNC machine tools. Founded in 1983, the company quickly established itself as a leader in the industry, known for its robust machines, reliable performance, and exceptional customer support. Haas laser technologies are a testament to the company’s dedication to pushing the boundaries of innovation, offering cutting-edge solutions that empower businesses to achieve their manufacturing goals.

Haas Automation, Inc.

Haas Automation, Inc. is a prominent American manufacturer of CNC machine tools. The company is known for its high-quality, reliable, and affordable CNC machines, which are used in a wide range of industries worldwide.

History and Founding

Haas Automation was founded in 1983 by Gene Haas, a former race car mechanic. Haas started the company in his garage, building his first CNC machine from scratch. The company’s early success was driven by the affordability and ease of use of its machines. Haas quickly gained a reputation for producing reliable and high-performance CNC machines, and the company’s growth was fueled by its focus on innovation and customer satisfaction.

Core Values and Mission Statement

Haas Automation’s core values are centered around innovation, quality, customer service, and employee empowerment. The company’s mission statement reflects these values: “To provide our customers with the best possible CNC machine tools, service, and support, while continually striving to improve our products and services.”

Global Presence and Market Share, Haas laser technologies

Haas Automation has a strong global presence, with manufacturing facilities in the United States, Europe, and Asia. The company’s machines are sold in over 100 countries worldwide. Haas Automation is a major player in the CNC machine tool industry, holding a significant market share in several key segments. The company’s success can be attributed to its focus on innovation, quality, and customer service.

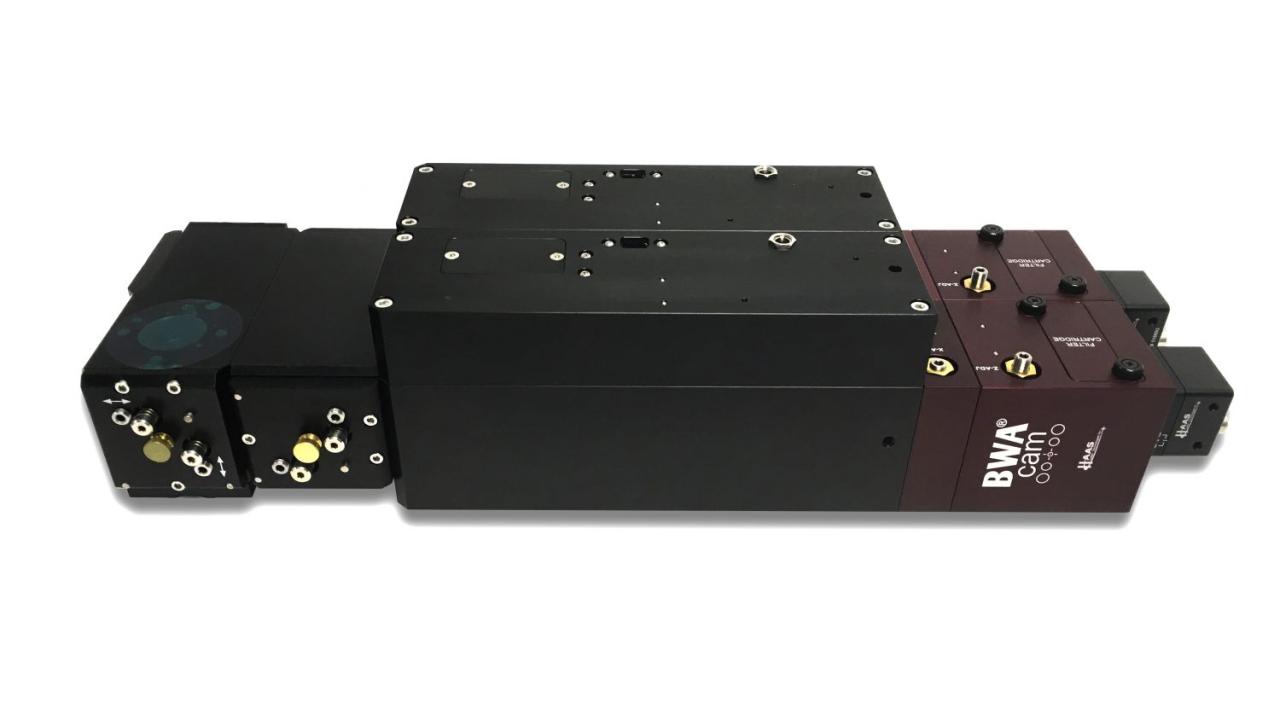

Haas Laser Technologies

Haas Automation, Inc. is a renowned manufacturer of CNC machine tools, including laser cutting machines. Haas laser technologies are known for their precision, efficiency, and affordability. They offer a range of laser cutting machines that cater to various industries and applications.

Laser Technologies Employed by Haas Automation

Haas utilizes different laser technologies to provide diverse cutting capabilities and meet specific industry requirements. The choice of laser technology depends on the material being cut, the desired cut quality, and the production volume.

Types of Lasers

- Fiber Lasers: These lasers are known for their high power density and efficiency, making them ideal for cutting thin to thick materials, including metals, plastics, and composites. Fiber lasers are characterized by their high beam quality, resulting in precise cuts with minimal heat-affected zones. They are also known for their long lifespan and low maintenance requirements.

- CO2 Lasers: These lasers are versatile and well-suited for cutting a wide range of materials, including non-metals like wood, acrylic, and fabrics. They are known for their ability to cut complex shapes and patterns with high precision. CO2 lasers are typically less expensive than fiber lasers but may have lower power density and efficiency.

Applications of Haas Laser Technologies

Haas laser technologies are used in a wide range of applications, including:

- Metal Fabrication: Haas laser cutting machines are used for cutting various metals, such as steel, aluminum, stainless steel, and titanium. They are used in manufacturing industries like automotive, aerospace, construction, and medical devices.

- Sheet Metal Processing: Haas laser cutters are used for cutting sheet metal into precise shapes and sizes. This is essential for producing parts for various industries, including automotive, electronics, and appliances.

- Prototyping and Design: Haas laser cutting machines are valuable tools for prototyping and design. They allow designers to quickly create prototypes and test different designs before moving to production.

- Sign Making and Engraving: Haas laser cutters are used for creating signs, logos, and engravings on various materials, including wood, acrylic, and metal.

- Custom Manufacturing: Haas laser cutting machines are used for custom manufacturing applications, allowing businesses to create unique products and components according to specific requirements.

Advantages of Haas Laser Technologies

- Precision Cutting: Haas laser cutting machines are known for their high precision, enabling the production of parts with tight tolerances.

- High Speed Cutting: Haas lasers offer fast cutting speeds, increasing production efficiency and reducing manufacturing time.

- Versatile Cutting Capabilities: Haas lasers can cut a wide range of materials, from thin to thick, including metals, plastics, and composites.

- Reduced Material Waste: Haas laser cutting machines minimize material waste, leading to cost savings and sustainability.

- Easy Operation and Maintenance: Haas laser cutting machines are designed for user-friendliness and ease of maintenance, making them accessible to operators with varying levels of experience.

Comparison with Competitors

Haas laser cutting machines are known for their competitive pricing and comprehensive features. They offer a balance of performance, reliability, and affordability, making them attractive options for businesses of all sizes. While some competitors may offer higher power lasers or more advanced features, Haas laser technologies provide a strong value proposition, particularly for small and medium-sized enterprises.

Haas Laser Machine Applications: Haas Laser Technologies

Haas laser machines are renowned for their versatility and precision, making them suitable for a wide range of applications across diverse industries. From intricate metalwork to large-scale production, these machines offer a robust solution for businesses seeking to enhance efficiency and productivity.

Applications in Various Industries

The industries where Haas laser machines are utilized are vast and diverse, showcasing the technology’s adaptability.

- Automotive: Haas laser machines are instrumental in automotive manufacturing, enabling precise cutting and shaping of metal components for vehicles. They are used for creating body panels, chassis parts, and exhaust systems, among other applications.

- Aerospace: In the aerospace industry, Haas laser machines play a crucial role in producing lightweight and durable components for aircraft and spacecraft. They are employed for cutting and engraving intricate designs on parts like engine components, fuselage sections, and landing gear.

- Medical Devices: The precision and accuracy of Haas laser machines make them ideal for manufacturing medical devices. They are used to cut, engrave, and mark components for surgical instruments, implants, and prosthetics.

- Electronics: Haas laser machines are essential in the electronics industry, where they are used for cutting and etching circuits, creating intricate patterns on printed circuit boards, and producing precise components for electronic devices.

- Construction: Haas laser machines are used in construction for cutting and shaping steel beams, plates, and other structural components. Their precision and efficiency contribute to the construction of buildings, bridges, and other infrastructure projects.

Examples of Specific Applications

Beyond the general applications, Haas laser machines are employed in various specific tasks within these industries.

- Cutting complex shapes in sheet metal: Haas laser machines are capable of cutting intricate designs and complex shapes in sheet metal with high precision and speed, reducing waste and maximizing material utilization.

- Engraving intricate patterns on metal surfaces: The technology allows for detailed engravings on metal surfaces, creating unique designs and logos for various purposes, such as product branding and decorative elements.

- Drilling precise holes in metal components: Haas laser machines can drill precise holes in metal components with high accuracy and repeatability, essential for applications requiring precise tolerances.

- Marking and labeling metal parts: Haas laser machines can be used to mark and label metal parts with permanent and legible markings, enhancing traceability and identification.

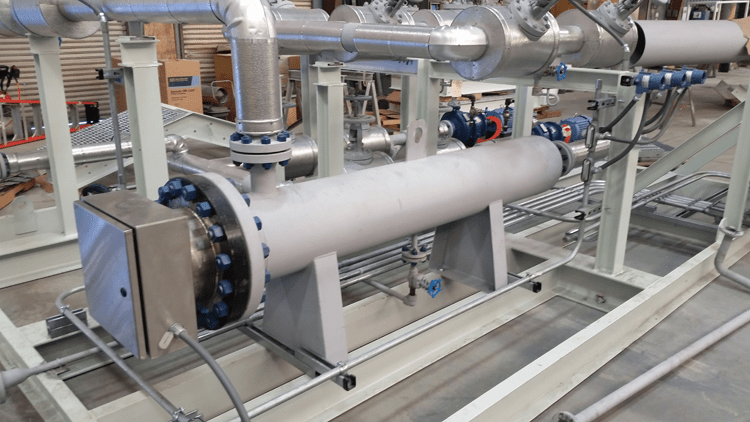

- Cutting and shaping metal tubes and pipes: The technology is suitable for cutting and shaping metal tubes and pipes with high precision, facilitating efficient production of components for various industries.

Key Features and Benefits of Haas Laser Machines

The versatility and precision of Haas laser machines are attributed to their key features and benefits.

| Application | Features | Benefits | Industry |

|---|---|---|---|

| Cutting sheet metal | High-power laser source, precision optics, CNC control | Precise cuts, high speed, reduced waste, improved efficiency | Automotive, aerospace, electronics |

| Engraving metal surfaces | Fine-beam laser, precise control, high-resolution optics | Intricate designs, durable markings, enhanced aesthetics | Medical devices, electronics, jewelry |

| Drilling holes in metal components | Focused laser beam, precise positioning, high-speed drilling | Accurate holes, minimized burrs, improved component performance | Automotive, aerospace, construction |

| Marking and labeling metal parts | Permanent markings, high-contrast laser engraving, clear visibility | Improved traceability, product identification, reduced errors | Medical devices, electronics, manufacturing |

| Cutting and shaping metal tubes and pipes | High-power laser, precise cutting path, automated operation | Efficient production, precise shapes, reduced material waste | Construction, automotive, aerospace |

Haas Laser Machine Features and Innovations

Haas laser machines are renowned for their advanced features, robust construction, and user-friendly interfaces. These machines are designed to meet the demands of a wide range of industries, including manufacturing, fabrication, and automotive.

Advanced Features and Functionalities

Haas laser machines are equipped with a variety of advanced features and functionalities that enhance performance, precision, and ease of use.

- High-Precision Cutting: Haas laser machines utilize high-quality laser sources and advanced motion control systems to achieve exceptional cutting accuracy and repeatability. These machines can cut intricate designs and complex geometries with minimal deviation from the programmed path.

- Automated Features: Many Haas laser machines are equipped with automated features, such as automatic bed indexing, material handling systems, and laser head height adjustment. These features streamline the cutting process, reduce manual intervention, and improve efficiency.

- User-Friendly Interface: Haas laser machines feature intuitive user interfaces that are easy to learn and operate. The control panels are designed to be user-friendly, with clear displays and simple navigation menus.

- Advanced Software: Haas laser machines are supported by powerful software packages that provide advanced cutting capabilities, including nesting optimization, path generation, and real-time monitoring.

Latest Innovations and Technological Advancements

Haas Laser Technologies continuously invests in research and development to introduce cutting-edge innovations and technological advancements in its laser machines.

- Fiber Laser Technology: Haas laser machines utilize advanced fiber laser technology, which offers numerous advantages over traditional CO2 lasers. Fiber lasers are known for their high efficiency, excellent beam quality, and longer lifespan.

- Adaptive Cutting Control: Haas laser machines incorporate adaptive cutting control systems that adjust the laser power and cutting speed in real-time based on material thickness and cutting conditions. This ensures consistent cut quality and reduces material waste.

- Remote Monitoring and Diagnostics: Some Haas laser machines offer remote monitoring and diagnostics capabilities, allowing users to monitor machine performance, track production data, and diagnose issues remotely.

Comparison with Competing Brands

Haas laser machines are known for their high quality, reliability, and value for money. When compared to competing brands, Haas laser machines often stand out in terms of:

- Robust Construction: Haas laser machines are built with durable components and robust construction, designed to withstand demanding industrial environments.

- User-Friendliness: Haas laser machines are renowned for their user-friendly interfaces and ease of operation.

- Cost-Effectiveness: Haas laser machines offer a competitive price-to-performance ratio, making them an attractive option for businesses of all sizes.

- Comprehensive Support: Haas Laser Technologies provides comprehensive support and service to its customers, including training, technical assistance, and spare parts availability.

Haas Laser Machine Maintenance and Support

Haas laser machines are designed for high-performance and reliability, but like any sophisticated equipment, they require regular maintenance to ensure optimal performance and longevity. This section delves into the crucial aspects of maintaining Haas laser machines, including recommended procedures, the support services provided by Haas Automation, Inc., and the resources available to ensure seamless operation.

Maintenance Procedures and Recommendations

Maintaining a Haas laser machine involves a combination of preventative measures and regular inspections to identify potential issues before they escalate. Haas Automation, Inc. provides comprehensive documentation and resources to guide users through the maintenance process.

- Regular Cleaning: Dust, debris, and metal shavings can accumulate within the machine, hindering performance and potentially causing damage. Regular cleaning of the machine, including the optics, cutting head, and work area, is essential.

- Lubrication: Moving parts, such as the linear rails, bearings, and guides, require lubrication to minimize friction and wear. Haas provides specific lubrication recommendations and intervals for different components.

- Optical Alignment: The laser optics play a crucial role in beam focusing and cutting accuracy. Regular alignment checks and adjustments ensure optimal performance and prevent cutting inconsistencies.

- Filter Replacement: Air filters protect the machine’s internal components from contaminants. Replace filters according to the manufacturer’s recommendations to maintain optimal air quality and prevent clogging.

- Regular Inspections: Visual inspections of the machine’s components, including the laser source, cutting head, and control system, can help identify potential issues early.

Support Services

Haas Automation, Inc. is renowned for its comprehensive support services, ensuring customers have the resources they need to maintain their laser machines effectively.

- Technical Support: Haas offers 24/7 phone and online support, providing expert guidance on troubleshooting issues, diagnosing problems, and resolving technical challenges.

- On-site Service: For complex repairs or maintenance tasks that require on-site expertise, Haas has a network of certified technicians available for prompt service calls.

- Remote Diagnostics: Utilizing advanced remote diagnostics capabilities, Haas technicians can connect to the machine remotely to identify and resolve issues quickly, minimizing downtime.

- Training Programs: Haas provides extensive training programs for operators and maintenance personnel, covering machine operation, programming, troubleshooting, and preventative maintenance techniques.

Spare Parts and Resources

Haas Automation, Inc. ensures the availability of genuine spare parts and comprehensive resources to support customers’ maintenance needs.

- Spare Parts Availability: Haas maintains a vast inventory of spare parts, ensuring prompt delivery and minimal downtime for repairs. Customers can order parts directly through the Haas website or authorized distributors.

- Technical Documentation: Haas provides comprehensive technical documentation, including user manuals, maintenance guides, and troubleshooting guides, available online and in printed format.

- Training Resources: Haas offers a variety of training resources, including online courses, videos, and webinars, to enhance users’ knowledge and skills in operating and maintaining Haas laser machines.

Last Word

Haas Laser Technologies has emerged as a leading force in the world of precision cutting, offering a range of laser machines that cater to diverse applications. From the automotive and aerospace industries to the medical and electronics sectors, Haas laser technology has proven its versatility and reliability. With its unwavering commitment to innovation, Haas continues to develop advanced features and functionalities, ensuring its laser machines remain at the forefront of the industry. The company’s dedication to customer support, coupled with its comprehensive training resources and readily available spare parts, makes Haas laser technologies a preferred choice for businesses seeking to achieve manufacturing excellence.

Haas laser technologies are known for their precision and reliability in various applications. While Haas focuses on cutting-edge laser technology, antares technologies specializes in automation solutions that can be seamlessly integrated with Haas machines, enhancing their capabilities and efficiency.

The combination of Haas’s laser expertise and Antares’s automation solutions can lead to significant improvements in productivity and overall performance for businesses looking to optimize their manufacturing processes.