Ferrite Microwave Technologies: Shaping the Future of Communications

Ferrite microwave technologies have revolutionized the world of communication, enabling us to transmit information at unprecedented speeds and distances. These materials, possessing unique magnetic properties, play a pivotal role in […]

Ferrite microwave technologies have revolutionized the world of communication, enabling us to transmit information at unprecedented speeds and distances. These materials, possessing unique magnetic properties, play a pivotal role in shaping the future of wireless networks, radar systems, and medical imaging.

Ferrite materials are ceramic compounds with a unique ability to interact with electromagnetic waves, particularly in the microwave frequency range. Their versatility stems from their tunable magnetic properties, allowing for the manipulation of microwave signals. This control over microwaves has led to the development of a wide range of devices, including filters, circulators, isolators, and phase shifters, all of which are essential components in modern communication systems.

Introduction to Ferrite Microwave Technologies

Ferrite microwave technologies play a crucial role in modern communication systems and electronic devices. These technologies utilize the unique magnetic and electrical properties of ferrites, a class of ceramic materials, to manipulate electromagnetic waves in the microwave frequency range.

Ferrites are magnetic oxides with a complex crystal structure. Their magnetic properties arise from the interaction of electron spins within their crystal lattice. This interaction gives rise to a phenomenon known as ferrimagnetism, which is characterized by a net magnetic moment due to the alignment of electron spins.

Historical Overview

The development of ferrite microwave technologies can be traced back to the early 20th century. In 1945, J.L. Snoek at Philips Research Laboratories in the Netherlands discovered the first commercially viable ferrite material, known as “ferrite.” This discovery paved the way for the development of a wide range of microwave devices, including:

- Microwave isolators

- Circulators

- Phase shifters

- YIG filters

These early devices found applications in radar systems, communication networks, and other military and industrial applications.

Advantages of Ferrites in Microwave Applications

Ferrites offer several advantages over other materials for microwave applications:

- High magnetic permeability: Ferrites have a high magnetic permeability, which allows them to effectively confine and guide electromagnetic waves. This property is crucial for the design of microwave components such as waveguides and resonators.

- Low dielectric loss: Ferrites exhibit low dielectric losses at microwave frequencies, ensuring minimal signal attenuation. This property is essential for achieving high efficiency in microwave circuits.

- High saturation magnetization: The high saturation magnetization of ferrites enables them to generate strong magnetic fields, which are essential for various microwave applications, including magnetic resonance imaging (MRI).

- Wide frequency range: Ferrites can operate over a wide frequency range, from a few gigahertz (GHz) to tens of GHz, making them suitable for a variety of microwave applications.

- Cost-effectiveness: Ferrites are relatively inexpensive to manufacture compared to other materials, such as metals or semiconductors. This makes them an attractive choice for various microwave applications.

Applications of Ferrite Microwave Technologies

Ferrite microwave technologies have revolutionized various fields, including telecommunications, radar systems, and medical imaging. Their unique properties, such as high permeability, low losses, and tunability, make them ideal for a wide range of applications.

Applications of Ferrite Microwave Technologies

| Application | Description | Key Features | Benefits |

|---|---|---|---|

| Microwave Filters | Ferrite materials are used in microwave filters to selectively pass or block specific frequency bands. | High permeability, low losses, and tunability. | Improved signal quality, reduced interference, and enhanced bandwidth. |

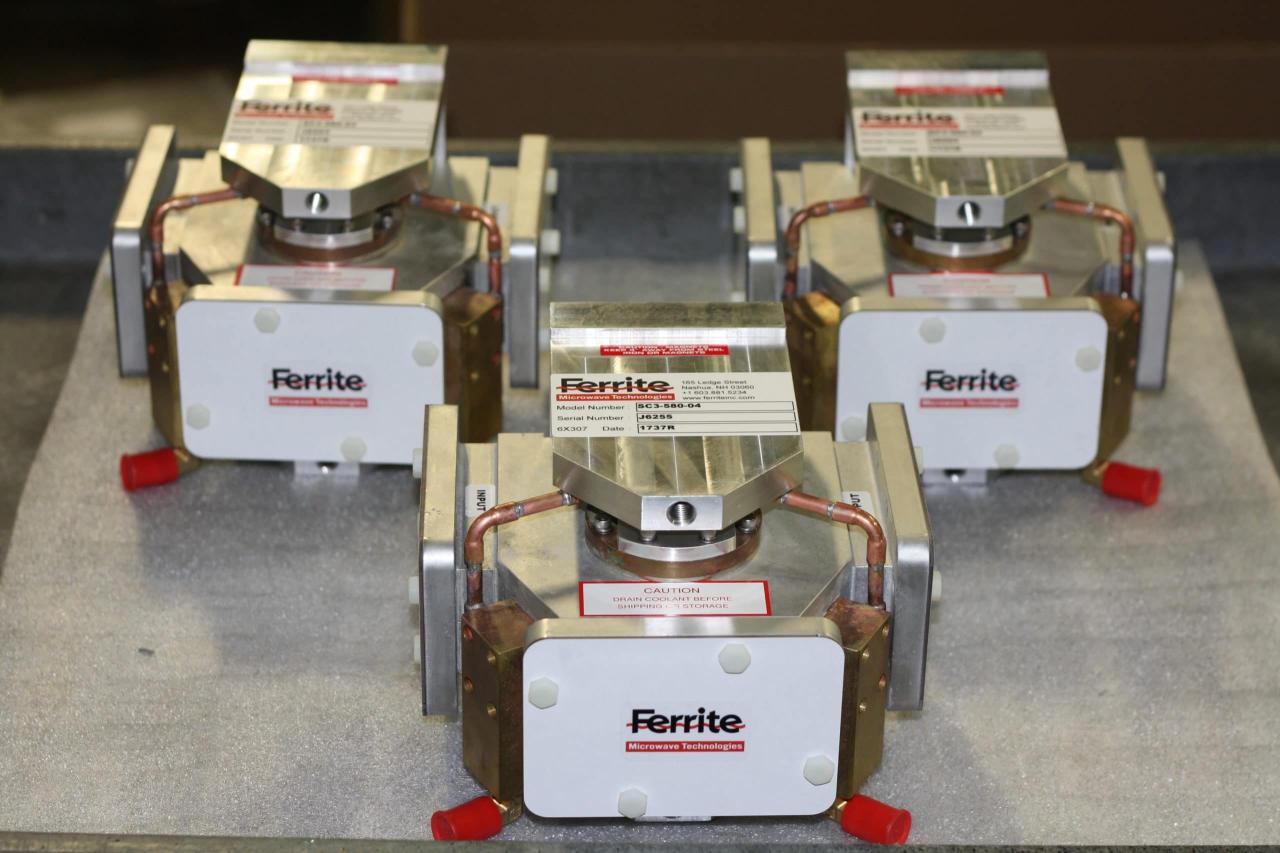

| Circulators | Circulators are passive devices that direct microwave signals in a specific direction. | Non-reciprocal properties, high isolation, and low insertion loss. | Improved signal routing, reduced reflections, and enhanced system efficiency. |

| Isolators | Isolators are devices that allow microwave signals to pass in one direction but block them in the opposite direction. | Non-reciprocal properties, high isolation, and low insertion loss. | Protection of sensitive components from reflected power, improved signal integrity, and enhanced system stability. |

| Phase Shifters | Phase shifters are devices that introduce a controlled phase shift to microwave signals. | Tunability, low losses, and high bandwidth. | Improved signal steering, beamforming, and radar performance. |

| Radar Systems | Ferrites are used in radar systems for various functions, including frequency tuning, signal isolation, and phase shifting. | High permeability, low losses, and tunability. | Enhanced target detection, improved range resolution, and reduced interference. |

| Communication Networks | Ferrites play a crucial role in communication networks, particularly in microwave filters, circulators, and isolators. | High permeability, low losses, and tunability. | Improved signal quality, reduced interference, and enhanced bandwidth. |

| Medical Imaging | Ferrites are used in magnetic resonance imaging (MRI) systems for generating strong magnetic fields. | High permeability, low losses, and tunability. | Improved image quality, enhanced resolution, and reduced scan time. |

Role of Ferrites in Microwave Devices

Ferrites play a vital role in various microwave devices due to their unique properties.

Microwave Filters

Ferrite materials are used in microwave filters to selectively pass or block specific frequency bands. The high permeability of ferrites allows for the creation of resonant circuits that can be tuned to specific frequencies. This tunability is achieved by varying the applied magnetic field, which alters the permeability of the ferrite material.

Circulators

Circulators are passive devices that direct microwave signals in a specific direction. They are based on the non-reciprocal properties of ferrites, which means that the signal propagation direction is different depending on the direction of the applied magnetic field. This property allows for the creation of circulators that can isolate different parts of a microwave circuit.

Isolators

Isolators are devices that allow microwave signals to pass in one direction but block them in the opposite direction. They are also based on the non-reciprocal properties of ferrites. Isolators are commonly used to protect sensitive components from reflected power, which can cause damage or instability.

Phase Shifters

Phase shifters are devices that introduce a controlled phase shift to microwave signals. They are used in various applications, including radar systems, communication networks, and medical imaging. The tunability of ferrites allows for the creation of phase shifters that can be adjusted to introduce a specific phase shift.

Ferrite Materials and Properties: Ferrite Microwave Technologies

Ferrite materials are a class of ceramic materials with magnetic properties, making them essential components in microwave technologies. They are known for their high permeability, low conductivity, and excellent magnetic properties, enabling them to manipulate electromagnetic waves effectively in the microwave frequency range. This section will explore the various types of ferrites, their unique characteristics, and the relationship between their chemical composition and magnetic properties.

Types of Ferrite Materials

The chemical composition of ferrite materials significantly influences their magnetic properties and applications. Ferrites are broadly classified into two main categories: soft ferrites and hard ferrites.

- Soft ferrites are characterized by their low coercivity and high permeability, making them suitable for applications where rapid magnetization and demagnetization are required, such as inductors, transformers, and microwave devices.

- Hard ferrites, on the other hand, exhibit high coercivity and moderate permeability, making them suitable for applications requiring permanent magnetization, such as magnets and magnetic recording media.

Furthermore, within these categories, various types of ferrites are available, each tailored for specific applications. Some common examples include:

- Nickel-Zinc (NiZn) ferrites are widely used in high-frequency applications, including antennas, filters, and circulators, due to their high permeability and low losses in the microwave frequency range.

- Manganese-Zinc (MnZn) ferrites are known for their high permeability and low cost, making them suitable for applications such as transformers, inductors, and choke coils.

- Magnesium-Manganese (MgMn) ferrites are used in high-power microwave applications, including circulators and isolators, due to their high saturation magnetization and low losses.

- Yttrium Iron Garnet (YIG) is a type of ferrimagnetic garnet with exceptionally narrow linewidth and high permeability, making it ideal for high-performance microwave devices such as filters, resonators, and oscillators.

Relationship Between Chemical Composition and Magnetic Properties, Ferrite microwave technologies

The magnetic properties of ferrites are directly related to their chemical composition. The type and concentration of metal ions in the ferrite structure influence its magnetic permeability, saturation magnetization, coercivity, and resonance frequency. For example, substituting different metal ions for iron in the spinel structure can significantly alter the magnetic properties.

The magnetic properties of ferrites are governed by the exchange interaction between the magnetic moments of the metal ions in the crystal lattice.

The strength and direction of this interaction depend on the type and arrangement of the metal ions, leading to variations in the magnetic properties of different ferrite materials.

Impact of Temperature, Frequency, and Magnetic Field

The performance of ferrite materials is influenced by various external factors, including temperature, frequency, and magnetic field.

- Temperature can significantly affect the magnetic properties of ferrites, particularly their permeability and saturation magnetization. As temperature increases, the thermal energy can disrupt the alignment of magnetic moments, leading to a decrease in permeability and saturation magnetization. This effect is known as the Curie temperature, which is the temperature above which the material loses its ferromagnetic properties.

- Frequency also plays a crucial role in the performance of ferrites. As frequency increases, the permeability of ferrites typically decreases, leading to higher losses. This is because at higher frequencies, the magnetic domains within the ferrite material cannot respond quickly enough to the changing magnetic field, resulting in energy dissipation.

- Magnetic field can influence the magnetic properties of ferrites, particularly their permeability and saturation magnetization. Applying an external magnetic field can align the magnetic moments within the ferrite material, increasing its permeability and saturation magnetization. This effect is known as magnetic anisotropy.

Understanding the impact of these factors is essential for designing and optimizing ferrite-based microwave devices.

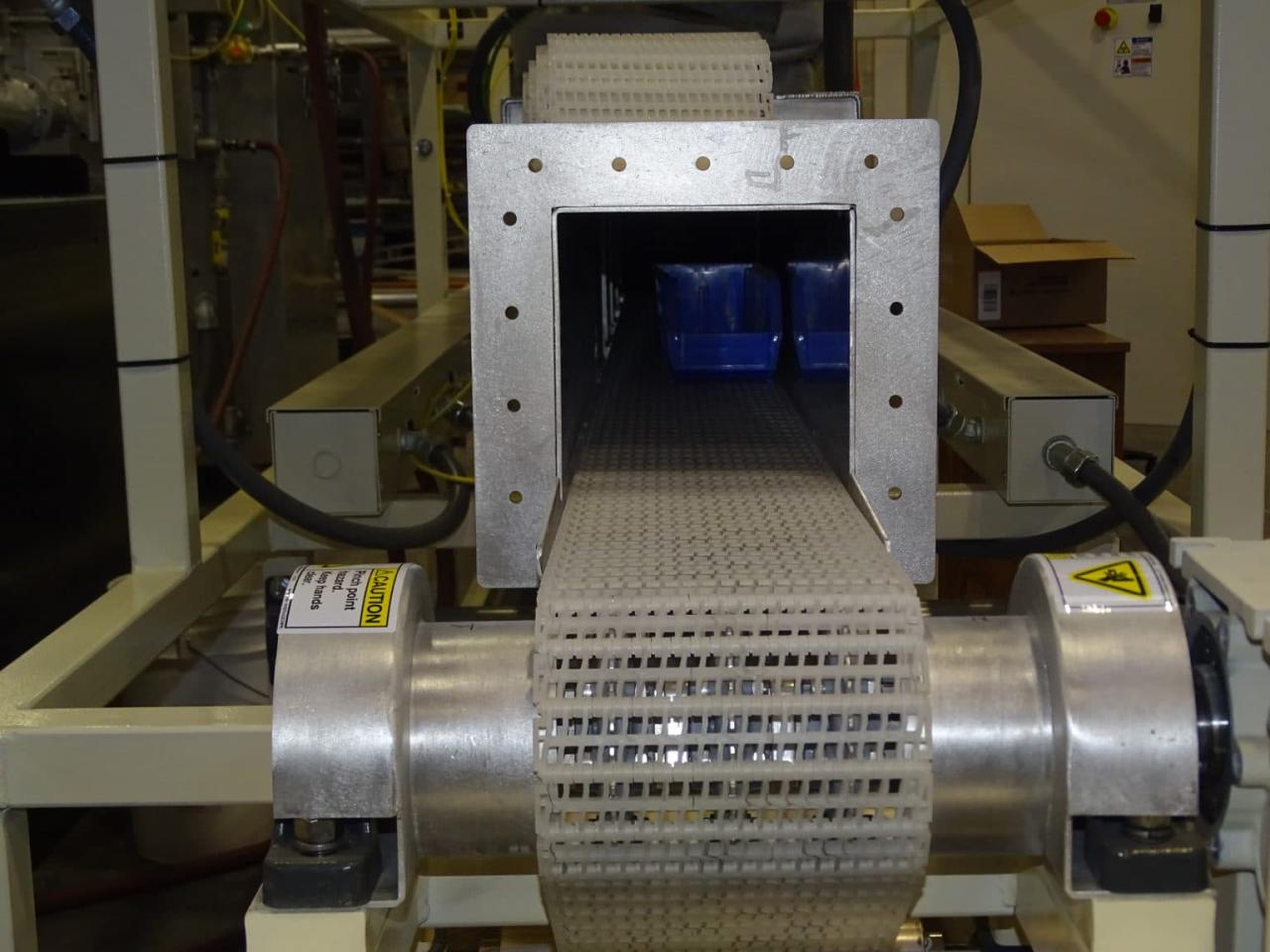

Microwave Device Design and Fabrication

The design and fabrication of microwave devices using ferrites involve a careful selection of materials, geometries, and fabrication processes to achieve the desired microwave performance. These devices play a crucial role in various applications, including telecommunications, radar, and medical imaging.

Design Considerations

The design of ferrite microwave devices requires a comprehensive understanding of the material properties, operating frequencies, and desired functionalities. The design process typically involves the following steps:

- Material Selection: The choice of ferrite material is critical for achieving the desired performance characteristics. Factors to consider include saturation magnetization, permeability, dielectric constant, and loss tangent. Different ferrite materials exhibit varying properties, making it essential to select the most suitable material for the specific application. For example, nickel-zinc ferrites are commonly used in high-frequency applications due to their high permeability and low loss tangent.

- Geometry Optimization: The geometry of the ferrite device, including the shape, size, and dimensions, significantly influences its microwave properties. The design process often involves simulations and modeling to optimize the geometry for specific applications. For instance, the shape of a ferrite resonator can be adjusted to achieve the desired resonant frequency and bandwidth.

- Impedance Matching: Proper impedance matching is essential to ensure efficient power transfer between the device and the surrounding circuitry. This involves designing the device to have an impedance that is compatible with the characteristic impedance of the transmission lines or other components. Impedance matching can be achieved using techniques such as quarter-wave transformers or impedance matching networks.

Fabrication Techniques

The fabrication of ferrite microwave devices involves a series of steps, including material preparation, shaping, and assembly.

- Material Preparation: Ferrite materials are typically prepared using powder metallurgy techniques. This involves mixing and sintering the ferrite powder at high temperatures to create a dense and homogeneous ceramic material. The sintering process is crucial for achieving the desired magnetic and dielectric properties.

- Shaping: The shaped ferrite material is then processed using various techniques, such as machining, grinding, or pressing. These techniques allow for the creation of specific geometries, such as resonators, filters, and isolators.

- Assembly: The fabricated ferrite components are then assembled with other microwave components, such as transmission lines, connectors, and packaging materials. The assembly process must ensure proper electrical connections and mechanical stability.

Modeling and Simulation

Accurate modeling and simulation are crucial for the design and optimization of ferrite microwave devices. These tools allow engineers to predict the performance of the device before fabrication, enabling them to identify potential issues and optimize the design.

- Electromagnetic Simulation Software: Various electromagnetic simulation software packages, such as CST Microwave Studio and HFSS, are available for modeling and simulating ferrite microwave devices. These tools use numerical methods to solve Maxwell’s equations and provide detailed information about the device’s electromagnetic fields, impedance, and power transmission characteristics.

- Modeling Techniques: Different modeling techniques, including finite element analysis (FEA) and finite difference time domain (FDTD), are used in electromagnetic simulation software. These techniques provide accurate predictions of the device’s performance under different operating conditions, including frequency, temperature, and external magnetic fields.

- Optimization: Simulation results can be used to optimize the design parameters, such as the geometry, material properties, and impedance matching network. This iterative process involves adjusting the design parameters and re-running the simulations until the desired performance is achieved.

Emerging Trends and Future Directions

The field of ferrite microwave technologies is constantly evolving, driven by the relentless pursuit of higher performance, miniaturization, and integration with other emerging technologies. Research and development efforts are focused on addressing key challenges and exploring novel materials, fabrication techniques, and applications.

New Ferrite Materials and Fabrication Techniques

The development of new ferrite materials with tailored properties is crucial for advancing microwave applications. Researchers are exploring various approaches to synthesize ferrites with enhanced magnetic properties, such as higher saturation magnetization, lower losses, and broader operating frequency ranges.

- Nanostructured Ferrites: Reducing the size of ferrite particles to the nanoscale can significantly enhance their magnetic properties. This is due to the increased surface area and quantum effects that arise at the nanoscale. Nanostructured ferrites exhibit higher saturation magnetization, lower coercivity, and improved microwave absorption characteristics.

- Multiferroic Ferrites: Combining ferromagnetic and ferroelectric properties in a single material offers exciting possibilities for developing multifunctional microwave devices. Multiferroic ferrites can exhibit magnetoelectric coupling, enabling the control of magnetic properties with electric fields or vice versa. This opens up avenues for creating novel devices with enhanced functionalities, such as tunable microwave filters and sensors.

- Composite Ferrites: Combining different ferrite materials or incorporating non-ferrite materials into the ferrite matrix can result in composite materials with tailored properties. For instance, embedding metallic nanoparticles in a ferrite matrix can enhance microwave absorption properties.

Advanced fabrication techniques are also essential for creating high-performance ferrite microwave devices.

- 3D Printing: 3D printing, also known as additive manufacturing, offers a powerful tool for fabricating complex ferrite structures with intricate geometries. This technique allows for the creation of custom-designed devices with tailored properties, enabling the realization of miniaturized and highly integrated microwave components.

- Pulsed Laser Deposition (PLD): PLD is a thin-film deposition technique that enables the growth of high-quality ferrite films with precise control over their thickness and composition. PLD is particularly suitable for fabricating thin-film microwave devices, such as filters, resonators, and antennas.

- Sputtering: Sputtering is a versatile thin-film deposition technique that allows for the deposition of various ferrite materials onto different substrates. Sputtering offers good control over the film thickness and uniformity, making it suitable for the fabrication of high-performance microwave devices.

Last Point

Ferrite microwave technologies continue to push the boundaries of innovation, paving the way for even more advanced applications. As research and development progress, we can expect to see even smaller, more efficient, and cost-effective ferrite devices, further enhancing our ability to communicate and interact with the world around us. The integration of ferrite technologies with emerging fields like metamaterials and plasmonics promises to unlock new possibilities for manipulating electromagnetic waves, driving further advancements in communication and beyond.

Ferrite microwave technologies are crucial for applications ranging from telecommunications to medical imaging. While these technologies operate in the microwave spectrum, advancements in quantum lighting technologies, like those found at quantum lighting technologies , are pushing the boundaries of light manipulation and control.

These advancements in quantum lighting technologies could potentially inspire new avenues for ferrite microwave technologies, leading to even more efficient and powerful applications in the future.