Xebec Deburring Technologies: Shaping Precision Manufacturing

Xebec deburring technologies are revolutionizing manufacturing processes by offering efficient and precise solutions for removing sharp edges and burrs from a wide range of materials. This innovative approach, rooted in […]

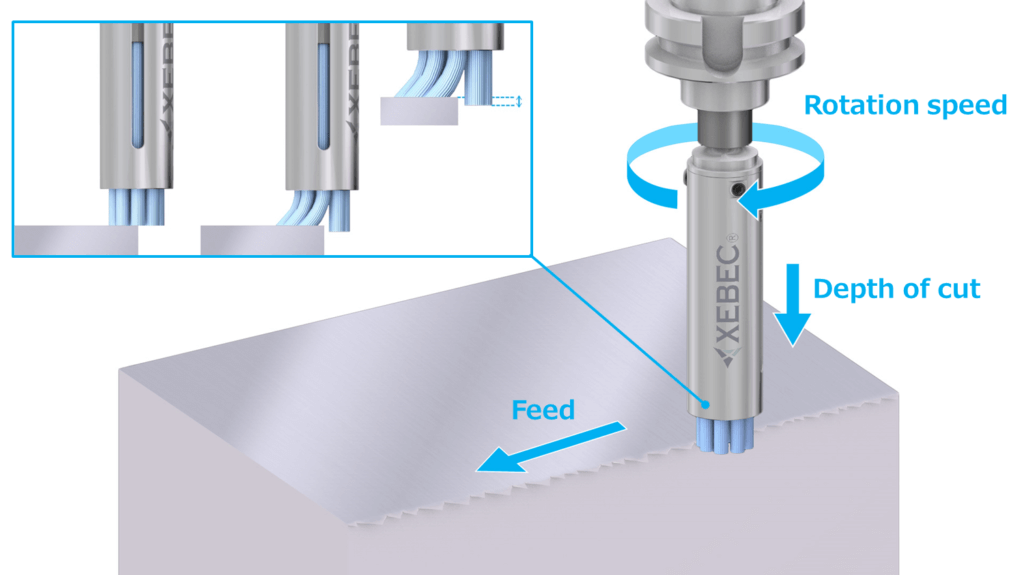

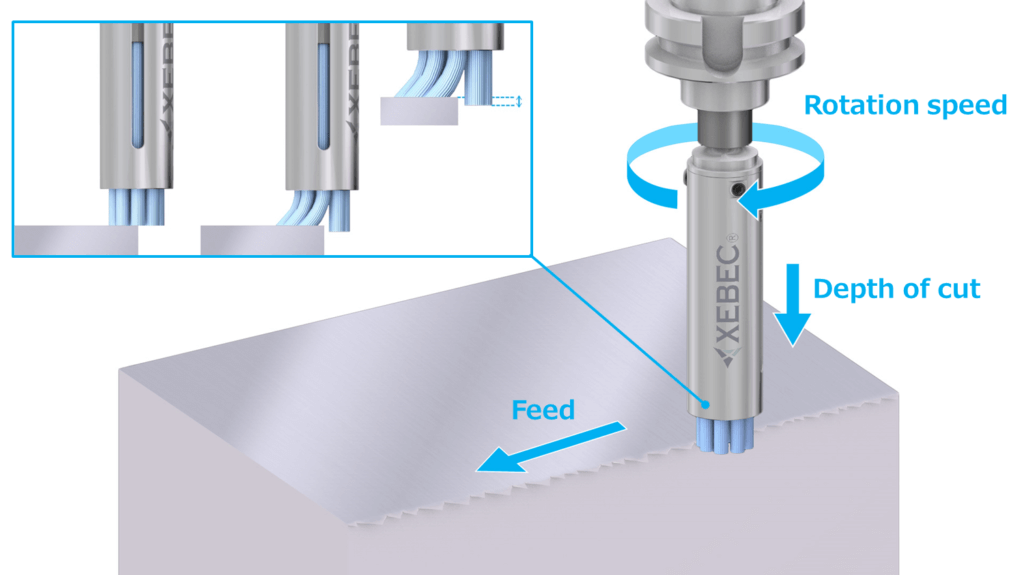

Xebec deburring technologies are revolutionizing manufacturing processes by offering efficient and precise solutions for removing sharp edges and burrs from a wide range of materials. This innovative approach, rooted in advanced engineering and automation, delivers exceptional surface finishes, enhancing product quality and minimizing production downtime.

Deburring, a critical step in many manufacturing processes, ensures the safety and functionality of finished products. Xebec’s technologies leverage various methods, from mechanical deburring to abrasive blasting, to address diverse material types and complex geometries. These technologies are not only highly effective but also contribute to increased productivity, reduced material waste, and improved worker safety.

Xebec Deburring in the Future: Xebec Deburring Technologies

Xebec deburring technologies are constantly evolving, driven by advancements in automation, robotics, and materials science. These innovations are paving the way for a future where deburring processes are faster, more efficient, and environmentally friendly.

Future Advancements in Xebec Deburring Technologies

Xebec deburring technologies are poised for significant advancements in the coming years. The focus will be on enhancing automation, precision, and sustainability.

- Increased Automation: Xebec deburring technologies are expected to become increasingly automated, leveraging robotics and artificial intelligence (AI) to perform deburring tasks with greater precision and efficiency. This will lead to faster cycle times, reduced labor costs, and improved consistency in deburring quality.

- Advanced Robotics: Robots equipped with advanced sensors and machine learning algorithms will be able to adapt to varying part geometries and materials, ensuring optimal deburring performance. This will enable Xebec deburring technologies to handle complex parts and intricate geometries with greater accuracy.

- Smart Deburring Systems: The integration of sensors and data analytics will enable real-time monitoring and optimization of deburring processes. This will allow manufacturers to track deburring performance, identify potential issues, and adjust process parameters for optimal results.

- Sustainable Deburring Solutions: The future of Xebec deburring technologies will focus on minimizing environmental impact. This will involve developing processes that use less energy, reduce waste, and employ eco-friendly materials.

Emerging Trends and Innovations in Deburring, Xebec deburring technologies

The deburring industry is witnessing a surge in innovative technologies that are transforming traditional deburring practices. These innovations are driven by the need for increased efficiency, precision, and sustainability.

- Laser Deburring: Laser deburring is a non-contact method that uses a focused laser beam to remove burrs. This technology offers high precision, minimal heat affected zone, and the ability to deburr complex geometries.

- Electrochemical Deburring: Electrochemical deburring uses an electrolytic process to remove burrs. This method is highly efficient, environmentally friendly, and suitable for deburring delicate parts.

- Plasma Deburring: Plasma deburring utilizes a high-energy plasma jet to remove burrs. This technology offers high precision, minimal heat distortion, and the ability to deburr hard-to-reach areas.

- Automated Deburring Systems: Automated deburring systems are becoming increasingly popular, offering significant benefits in terms of efficiency, consistency, and safety. These systems integrate robots, sensors, and software to perform deburring tasks with minimal human intervention.

The Role of Xebec Deburring Technologies in Future Manufacturing

Xebec deburring technologies are expected to play a crucial role in shaping the future of manufacturing. They will be essential for producing high-quality products with minimal defects, ensuring efficient and sustainable manufacturing processes.

“Xebec deburring technologies will be instrumental in enabling manufacturers to meet the growing demands for precision, efficiency, and sustainability in the future.” – Industry Expert

Ultimate Conclusion

Xebec deburring technologies represent a significant advancement in the manufacturing landscape, empowering businesses to achieve greater efficiency, precision, and product quality. By harnessing the power of automation and innovation, Xebec continues to push the boundaries of deburring, ensuring a future where manufacturing processes are optimized for both performance and sustainability.

Xebec deburring technologies are essential for creating high-quality, precision parts. By removing sharp edges and burrs, these technologies ensure smooth surfaces and prevent damage to other components. For businesses looking to optimize their communications, unified communications technologies in Valdosta, GA can be a game-changer.

Implementing these technologies can improve efficiency, collaboration, and customer service, all of which can be essential for a successful deburring operation.