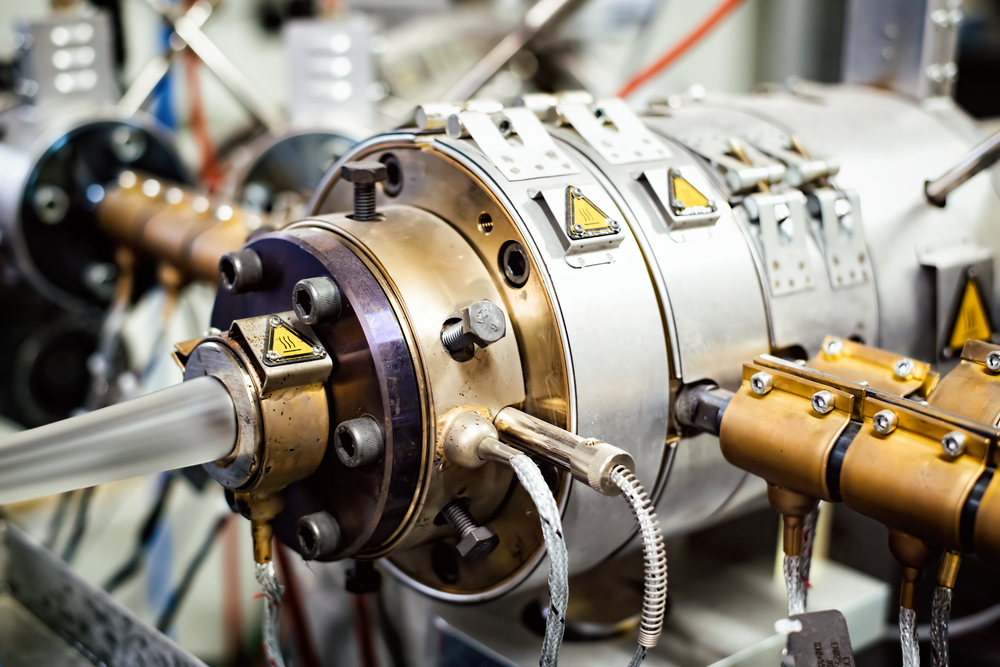

Plastic Extrusion Technologies in Middlefield, OH

Plastic extrusion technologies middlefield oh – Plastic extrusion technologies in Middlefield, OH, play a vital role in shaping the region’s economy. From everyday products to specialized components, plastic extrusion processes […]

Plastic extrusion technologies middlefield oh – Plastic extrusion technologies in Middlefield, OH, play a vital role in shaping the region’s economy. From everyday products to specialized components, plastic extrusion processes transform raw materials into a diverse range of useful items. This article delves into the intricacies of this industry, exploring its processes, equipment, and the materials that make it possible.

Middlefield, OH, boasts a robust plastic extrusion industry, with companies specializing in various extrusion techniques and applications. This thriving sector contributes significantly to the local economy, creating jobs and supporting numerous businesses. The town’s strategic location and access to skilled labor have fostered a thriving environment for plastic extrusion, making it a hub for innovation and technological advancement.

Materials Used in Plastic Extrusion

Plastic extrusion is a versatile manufacturing process that utilizes a wide range of materials to create a diverse array of products. The selection of the appropriate plastic material is crucial for achieving the desired properties and performance of the final product. This section will delve into the common types of plastics used in extrusion processes, exploring their characteristics and the factors that influence their suitability for extrusion.

Common Types of Plastics Used in Extrusion

The choice of plastic material for extrusion depends on the intended application and the desired properties of the final product. Some of the most commonly used plastics in extrusion processes include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC).

- Polyethylene (PE) is a versatile thermoplastic known for its flexibility, toughness, and chemical resistance. It is commonly used in packaging films, bags, bottles, pipes, and other applications where flexibility and durability are essential.

- Polypropylene (PP) is another widely used thermoplastic known for its stiffness, strength, and resistance to chemicals and heat. It is often used in containers, fibers, films, and other applications where strength and heat resistance are required.

- Polyvinyl Chloride (PVC) is a rigid thermoplastic known for its durability, versatility, and cost-effectiveness. It is widely used in pipes, window frames, siding, flooring, and other applications where strength and durability are essential.

Properties and Characteristics of Plastic Materials, Plastic extrusion technologies middlefield oh

The suitability of a plastic material for extrusion is influenced by several factors, including its melting point, viscosity, flow rate, and tensile strength.

- Melting Point: The melting point of a plastic material is the temperature at which it transitions from a solid to a liquid state. This property is important in extrusion because the material must be heated to its melting point to be processed. Plastics with lower melting points are generally easier to extrude than those with higher melting points.

- Viscosity: Viscosity is a measure of a fluid’s resistance to flow. In extrusion, the viscosity of the plastic melt influences the flow rate and the ability to fill the die. Plastics with lower viscosities are generally easier to extrude than those with higher viscosities.

- Flow Rate: The flow rate of a plastic melt is the volume of material that can be extruded per unit time. This property is important in determining the production rate of the extrusion process. Plastics with higher flow rates are generally preferred for high-volume extrusion applications.

- Tensile Strength: Tensile strength is a measure of a material’s resistance to pulling or stretching. In extrusion, the tensile strength of the plastic material is important for determining the strength and durability of the final product. Plastics with higher tensile strengths are generally preferred for applications where strength and durability are essential.

Additives and Fillers in Plastic Extrusion

Additives and fillers are often incorporated into plastic materials to modify their properties and enhance their performance. These additives can improve the material’s processability, strength, durability, color, and other characteristics.

- Plasticizers are additives that increase the flexibility and ductility of plastic materials. They are commonly used in PVC to make it more flexible and easier to process.

- Stabilizers are additives that protect plastic materials from degradation due to heat, light, or oxygen. They help to extend the lifespan of the product and prevent discoloration or embrittlement.

- Fillers are materials that are added to plastic materials to improve their strength, stiffness, or other properties. Common fillers include glass fibers, carbon black, and mineral fillers.

- Colorants are pigments or dyes that are added to plastic materials to impart color. They are used to create a wide range of colors and patterns in extruded products.

Applications of Plastic Extrusion Products in Middlefield, OH

Middlefield, Ohio, is a hub for plastic extrusion, with numerous companies specializing in the production of various extruded plastic products. These products find wide-ranging applications across different industries, contributing significantly to the regional economy.

Industries Utilizing Extruded Plastic Products

Extruded plastic products are integral to numerous industries in the Middlefield, OH region. Here are some key sectors that rely heavily on these products:

- Automotive: Plastic extrusion plays a crucial role in the automotive industry, with applications in components like bumpers, dashboards, door panels, and trim. The region’s proximity to major automotive manufacturers creates a strong demand for these products.

- Construction: Extruded plastic finds extensive use in construction, including window and door frames, siding, gutters, pipes, and insulation. These products contribute to the construction of residential and commercial buildings in the region.

- Agriculture: Plastic extrusion plays a significant role in agricultural applications, such as greenhouse structures, irrigation systems, and protective coverings for crops. The region’s agricultural sector benefits from the durability and versatility of extruded plastic products.

- Packaging: Extruded plastic products are widely used in packaging applications, including bottles, containers, films, and protective wraps. This industry relies heavily on the efficiency and cost-effectiveness of plastic extrusion.

- Medical: The medical industry also benefits from extruded plastic products, with applications in medical devices, tubing, and disposable equipment. The region’s presence of healthcare facilities creates a demand for these specialized products.

Innovative Applications of Plastic Extrusion

The plastic extrusion industry in Middlefield, OH is constantly innovating, finding new and creative applications for extruded plastic products. Some notable examples include:

- 3D Printing Filaments: Several companies in the region are developing and manufacturing high-performance plastic filaments for 3D printing. These filaments offer unique properties and are used in various industries, from prototyping to advanced manufacturing.

- Biodegradable Plastics: Some companies are focusing on the development and production of biodegradable plastic products. These environmentally friendly materials are gaining popularity in packaging and other applications, contributing to sustainable practices.

- Custom-Designed Products: The flexibility of plastic extrusion allows for the creation of custom-designed products tailored to specific industry needs. This enables companies to develop innovative solutions for unique applications.

Last Recap: Plastic Extrusion Technologies Middlefield Oh

The plastic extrusion industry in Middlefield, OH, continues to evolve, driven by advancements in technology and a growing demand for sustainable solutions. With its commitment to innovation and a focus on producing high-quality products, the industry is well-positioned to meet the challenges and opportunities of the future. As the world increasingly relies on plastic for its diverse applications, Middlefield’s plastic extrusion companies will remain at the forefront of this essential industry.

Plastic extrusion technologies in Middlefield, OH, are often employed in the production of various components and products. These processes can benefit from advanced equipment like the Source Technologies ST9817, source technologies st9817 , which offers precise control and high-quality output.

This integration of cutting-edge technology can enhance the efficiency and reliability of plastic extrusion operations in Middlefield, OH.