Edge Technology Indicator Holders: A Guide to Modern Design and Applications

Edge technology indicator holders are essential components in various industries, playing a crucial role in monitoring and controlling critical processes. These holders, often found in manufacturing, automation, and energy sectors, […]

Edge technology indicator holders are essential components in various industries, playing a crucial role in monitoring and controlling critical processes. These holders, often found in manufacturing, automation, and energy sectors, provide real-time data and insights, enabling efficient operations and informed decision-making. Their design and functionality are constantly evolving, incorporating advancements in materials, sensors, and communication technologies.

This guide delves into the world of edge technology indicator holders, exploring their definition, applications, design considerations, and future trends. From understanding the basic principles to examining emerging technologies, we aim to provide a comprehensive overview of this critical aspect of modern industrial operations.

What is an Edge Technology Indicator Holder?

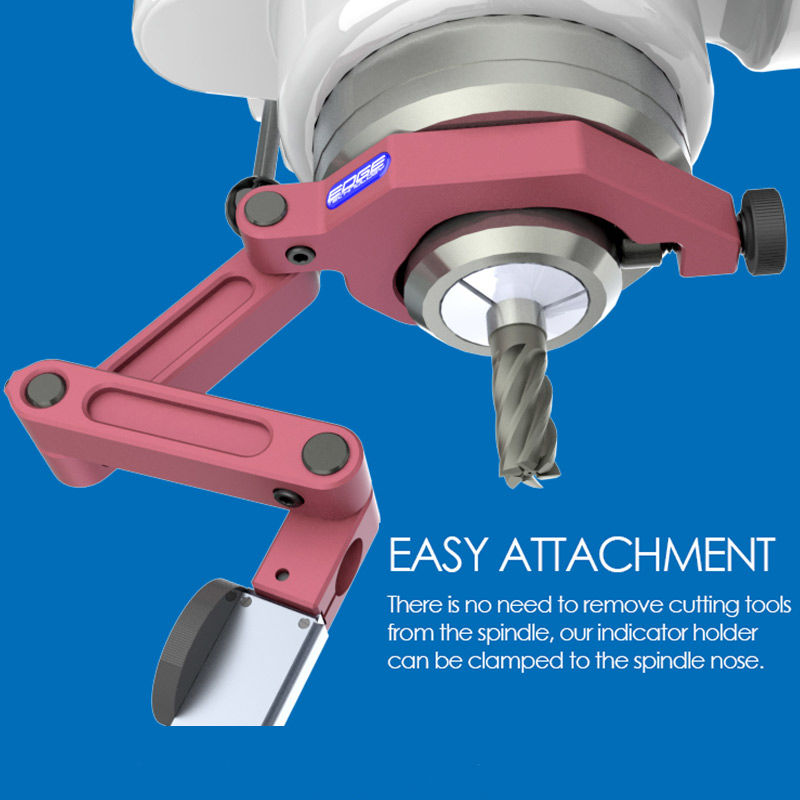

An edge technology indicator holder is a specialized component used in various industrial applications to securely hold and display indicators that convey crucial information about the operation of a machine or process. These indicators, often in the form of lights, gauges, or displays, provide visual cues to operators and technicians, allowing them to monitor and control the system effectively.

Purpose and Function

Edge technology indicator holders serve as mounting points for indicators, ensuring their visibility and accessibility. They are strategically positioned at the edge of panels, consoles, or machinery, providing a clear and unobstructed view of the information displayed. The holders are designed to withstand the rigors of industrial environments, ensuring the indicators remain secure and functional even under vibration, shock, and temperature fluctuations.

Key Components and Materials

Edge technology indicator holders are typically constructed using robust materials such as:

- Metal: Steel, aluminum, or stainless steel are common choices for their strength, durability, and resistance to corrosion.

- Plastic: High-impact plastics like polycarbonate or ABS offer lightweight alternatives with good resistance to chemicals and impact.

The design of the holder may incorporate features like:

- Mounting Brackets: Securely attach the holder to the panel or machine.

- Indicator Retention Mechanisms: Ensure the indicator is held firmly in place.

- Cable Management Features: Organize and route wiring neatly.

Types and Applications

Edge technology indicator holders come in a variety of styles and sizes to accommodate different indicator types and application requirements. Some common examples include:

- LED Indicator Holders: Designed to house LED lights, commonly used for status indicators, alarms, and machine control signals.

- Gauge Holders: Support pressure gauges, temperature gauges, and other analog indicators, providing clear readings of critical parameters.

- Display Holders: Accommodate small LCD or LED displays for displaying text, graphics, or numerical data.

- Modular Holders: Offer flexibility by allowing multiple indicators to be combined in a single unit.

These holders are found in diverse industrial settings, including:

- Manufacturing: Monitoring production lines, machine status, and process parameters.

- Automation: Controlling robotic systems, conveyor belts, and other automated equipment.

- Transportation: Indicating vehicle status, engine parameters, and warning systems.

- Energy: Monitoring power generation, distribution, and consumption.

Applications of Edge Technology Indicator Holders

Edge technology indicator holders find widespread use across various industries, serving as a crucial component in optimizing operations and enhancing efficiency. These holders, designed to house and protect indicators that monitor real-time data, play a vital role in data collection, analysis, and decision-making.

Manufacturing

Edge technology indicator holders are essential in the manufacturing sector, enabling real-time monitoring of critical parameters like temperature, pressure, and flow rate. These holders are often integrated into production lines, providing valuable insights into the manufacturing process.

- Process Monitoring and Control: Indicator holders facilitate the continuous monitoring of crucial process variables, enabling timely adjustments to maintain optimal production conditions. For instance, in a chemical plant, temperature sensors housed in indicator holders can alert operators to potential overheating, preventing equipment damage and ensuring product quality.

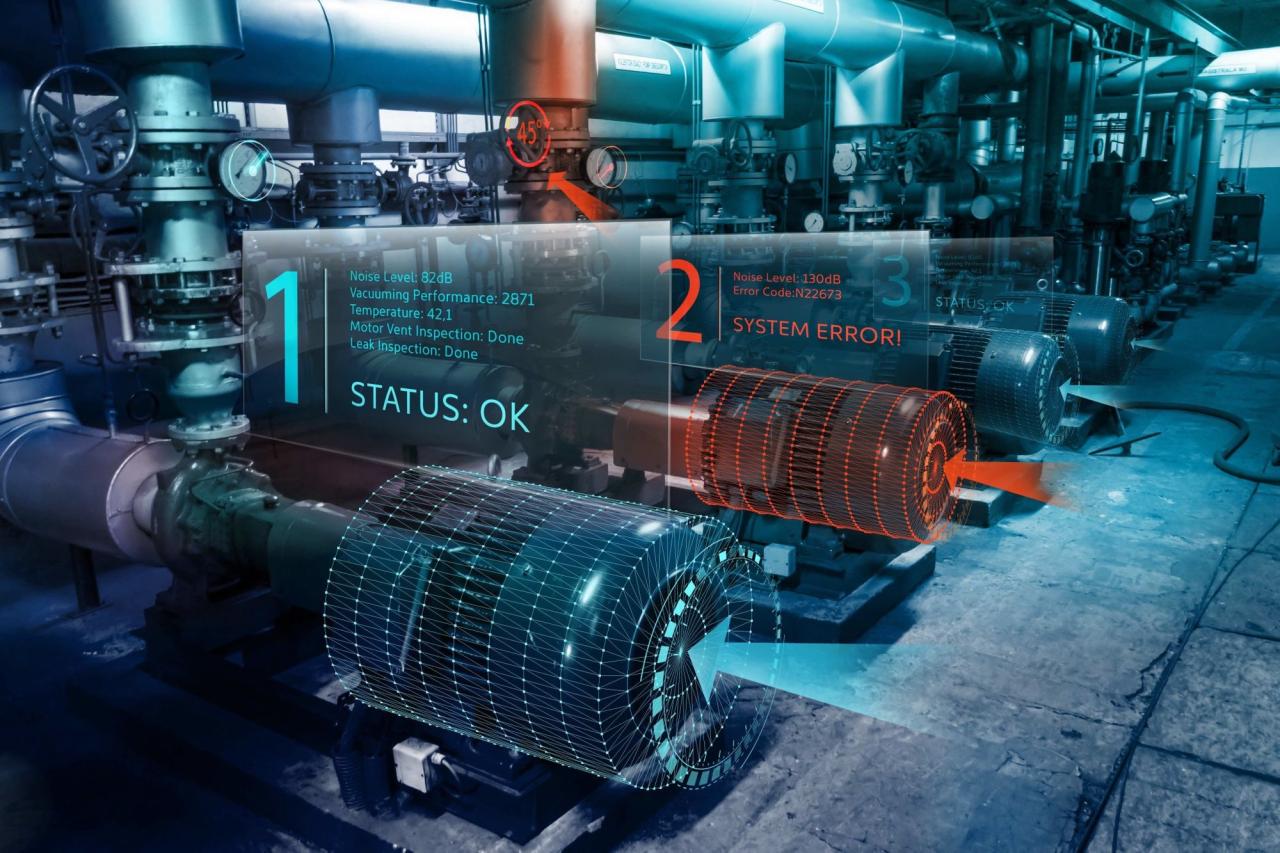

- Predictive Maintenance: By capturing real-time data on equipment performance, indicator holders enable predictive maintenance strategies. For example, vibration sensors placed in indicator holders can detect early signs of wear and tear in machinery, allowing for scheduled maintenance before failures occur, minimizing downtime and production disruptions.

- Quality Control: Edge technology indicator holders play a critical role in maintaining product quality. Sensors housed in these holders can monitor parameters like pH levels, viscosity, and particle size, ensuring that products meet stringent quality standards.

Healthcare

Edge technology indicator holders are transforming healthcare by enabling remote patient monitoring, real-time data collection, and improved diagnostic accuracy.

- Remote Patient Monitoring: Indicator holders equipped with sensors can collect vital signs such as heart rate, blood pressure, and oxygen saturation levels, enabling remote patient monitoring. This allows healthcare providers to track patients’ health status remotely, facilitating early intervention and improving patient outcomes.

- Point-of-Care Diagnostics: Indicator holders are used in point-of-care diagnostics, enabling rapid and accurate testing for various conditions. For example, glucose meters housed in indicator holders allow for quick blood sugar readings, empowering patients to manage their diabetes effectively.

- Surgical Monitoring: Indicator holders are integrated into surgical equipment to monitor vital signs and provide real-time data to surgeons during procedures. This enables precise control over surgical parameters, improving patient safety and surgical outcomes.

Energy

Edge technology indicator holders are crucial in the energy sector, facilitating efficient energy generation, distribution, and consumption.

- Renewable Energy Monitoring: Indicator holders equipped with sensors can monitor wind speed and direction, solar irradiance, and other parameters related to renewable energy sources. This data is essential for optimizing energy generation and maximizing efficiency.

- Smart Grid Management: Edge technology indicator holders play a vital role in smart grid management, enabling real-time monitoring of power flow, voltage levels, and other grid parameters. This data is used to optimize grid operations, improve reliability, and reduce energy losses.

- Energy Efficiency Optimization: Indicator holders can monitor energy consumption in buildings and industrial facilities, providing insights into energy usage patterns and identifying areas for improvement. This data can be used to implement energy-saving measures and reduce energy costs.

Transportation

Edge technology indicator holders are transforming the transportation industry by enhancing safety, efficiency, and sustainability.

- Vehicle Telematics: Indicator holders equipped with sensors can collect data on vehicle speed, location, fuel consumption, and other parameters. This data is used to optimize fleet management, improve driver safety, and reduce fuel costs.

- Traffic Management: Indicator holders are deployed along roads and highways to collect data on traffic flow, congestion levels, and other parameters. This data is used to optimize traffic management systems, reduce congestion, and improve road safety.

- Autonomous Vehicles: Edge technology indicator holders are essential for the development of autonomous vehicles. Sensors housed in these holders provide real-time data on the vehicle’s surroundings, enabling autonomous navigation and collision avoidance.

Agriculture

Edge technology indicator holders are revolutionizing agriculture by enabling precision farming, improved resource management, and increased crop yields.

- Precision Farming: Indicator holders equipped with sensors can monitor soil moisture, temperature, nutrient levels, and other parameters. This data is used to optimize irrigation, fertilization, and other agricultural practices, leading to increased crop yields and reduced resource consumption.

- Livestock Monitoring: Indicator holders can monitor livestock health, providing real-time data on animal temperature, weight, and other vital signs. This data enables early detection of health issues, reducing livestock losses and improving animal welfare.

- Environmental Monitoring: Edge technology indicator holders are used to monitor environmental conditions in agricultural fields, such as air quality, water quality, and pest infestations. This data is essential for managing environmental risks and promoting sustainable agricultural practices.

Trends and Future Developments

The field of edge technology is constantly evolving, with new trends and advancements shaping the design and application of indicator holders. The convergence of automation, artificial intelligence, and machine learning is driving innovation in this domain, leading to more intelligent, efficient, and adaptable indicator holders.

The Role of Automation, Artificial Intelligence, and Machine Learning

Automation, AI, and ML are playing a pivotal role in enhancing the functionality and performance of edge technology indicator holders. These technologies enable:

- Real-time Data Analysis and Decision-Making: AI algorithms can analyze sensor data in real-time, enabling indicator holders to make informed decisions based on changing conditions. This can optimize performance, reduce downtime, and improve overall efficiency.

- Predictive Maintenance: Machine learning models can predict potential failures based on historical data, allowing for proactive maintenance and reducing downtime. This ensures continuous operation and minimizes disruption to processes.

- Adaptive Control: AI-powered indicator holders can adapt to changing environmental conditions and optimize their performance accordingly. This ensures optimal operation in dynamic environments and improves overall efficiency.

Future Developments and Innovations, Edge technology indicator holder

The future of edge technology indicator holders is promising, with several potential developments and innovations on the horizon:

- Integration with the Internet of Things (IoT): Indicator holders can be seamlessly integrated into IoT networks, enabling real-time data sharing and remote monitoring. This facilitates better decision-making, remote control, and improved operational efficiency.

- Advanced Sensor Technology: The development of more sophisticated sensors will enhance the accuracy and reliability of data collected by indicator holders. This will lead to more precise measurements and improved decision-making.

- Miniaturization and Integration: Indicator holders are becoming smaller and more compact, allowing for easier integration into existing systems. This reduces space requirements and simplifies installation processes.

Applications in Emerging Technologies

Edge technology indicator holders are finding applications in various emerging technologies, including:

- Industry 4.0: In manufacturing, indicator holders are crucial for monitoring and controlling production processes, ensuring quality control, and optimizing efficiency. This supports the development of smart factories and the automation of industrial processes.

- Smart Cities: Indicator holders are being used in smart cities to monitor environmental conditions, traffic flow, and public safety. This data is used to improve urban planning, optimize resource allocation, and enhance the quality of life for citizens.

- Precision Agriculture: In agriculture, indicator holders can monitor soil conditions, crop health, and weather patterns, enabling farmers to optimize irrigation, fertilization, and pest control. This contributes to increased crop yields and sustainable farming practices.

Conclusion

Edge technology indicator holders are integral to optimizing operations, enhancing efficiency, and driving innovation across various industries. Their ability to provide real-time data, combined with their integration with advanced technologies, positions them as key players in the future of manufacturing, automation, and energy. As technology continues to evolve, we can expect even more sophisticated and versatile indicator holders, further shaping the landscape of industrial operations and driving progress in diverse fields.

Edge technology indicator holders are a crucial component in many industries, providing a clear and precise display of vital data. These holders are often used in conjunction with high-quality spray guns, like those offered by c.a. technologies , which ensure accurate and efficient application of coatings.

By utilizing a robust edge technology indicator holder and a reliable spray gun, professionals can achieve exceptional results in their respective fields.