Laser Marking Technologies LLC: Precision Marking for Modern Industries

Laser Marking Technologies LLC is a pioneer in the field of laser marking, offering innovative solutions that revolutionize product identification and traceability. With a deep understanding of laser technology and […]

Laser Marking Technologies LLC is a pioneer in the field of laser marking, offering innovative solutions that revolutionize product identification and traceability. With a deep understanding of laser technology and a commitment to precision, the company provides cutting-edge services to diverse industries, from automotive and aerospace to medical and electronics.

Laser marking utilizes focused beams of light to permanently etch designs, logos, or codes onto various materials. This technology surpasses traditional marking methods by delivering exceptional accuracy, durability, and versatility. Whether it’s serializing components, branding products, or creating intricate designs, laser marking provides a reliable and efficient solution.

Laser Marking Technologies LLC

Laser Marking Technologies LLC is a leading provider of laser marking solutions for a wide range of industries. The company was founded in 2005 with the goal of providing high-quality, reliable laser marking systems that meet the specific needs of its customers. Since its inception, Laser Marking Technologies LLC has grown to become a trusted partner for businesses of all sizes, offering a comprehensive range of products and services.

Company Overview

Laser Marking Technologies LLC is committed to providing innovative and reliable laser marking solutions that meet the evolving needs of its customers. The company’s core values are centered around customer satisfaction, quality, innovation, and integrity.

“Our mission is to be the leading provider of laser marking solutions by delivering exceptional customer service, innovative products, and unwavering commitment to quality.”

Laser Marking Technologies LLC offers a wide range of products and services to meet the diverse needs of its customers. The company’s product portfolio includes:

* Laser Marking Systems: Laser Marking Technologies LLC offers a variety of laser marking systems, including fiber lasers, CO2 lasers, and UV lasers. These systems are designed for a wide range of applications, including part identification, traceability, and branding.

* Laser Marking Software: The company also provides user-friendly software that allows customers to easily create and manage laser marking projects. The software is designed to be intuitive and easy to use, even for users with limited experience in laser marking.

* Laser Marking Accessories: Laser Marking Technologies LLC offers a wide range of accessories to enhance the functionality of its laser marking systems. These accessories include marking heads, lenses, and safety equipment.

Target Market and Customer Base

Laser Marking Technologies LLC serves a diverse customer base across various industries. The company’s target market includes:

* Manufacturing: Laser marking systems are widely used in manufacturing for part identification, traceability, and quality control.

* Automotive: Laser marking is used in the automotive industry for marking components, VIN numbers, and other identification information.

* Aerospace: Laser marking is used in the aerospace industry for marking aircraft parts, engine components, and other critical components.

* Medical Device: Laser marking is used in the medical device industry for marking implants, surgical instruments, and other medical devices.

* Electronics: Laser marking is used in the electronics industry for marking circuit boards, integrated circuits, and other electronic components.

Laser Marking Technologies LLC works closely with its customers to understand their specific needs and develop customized solutions. The company’s team of experienced engineers and technicians provides comprehensive support throughout the entire process, from initial consultation to system installation and ongoing maintenance.

Laser Marking Technologies

Laser marking technologies have revolutionized the way we mark and identify products across a wide range of industries. This technology offers numerous advantages over traditional marking methods, including increased precision, durability, and efficiency.

Industries Benefiting from Laser Marking

Laser marking technologies are widely adopted in various industries due to their versatility and ability to meet specific marking requirements. Here are some key industries that benefit from laser marking:

- Automotive: Laser marking is used for marking components, parts, and vehicle identification numbers (VINs). It ensures permanent and legible markings on metal surfaces, including engine blocks, chassis, and other components.

- Electronics: The electronics industry relies heavily on laser marking for marking circuit boards, integrated circuits, and other electronic components. The high precision of laser marking allows for accurate and detailed markings on delicate electronic surfaces.

- Medical Devices: Medical devices require precise and permanent markings for traceability and regulatory compliance. Laser marking provides a non-contact method for marking implants, surgical instruments, and other medical devices, ensuring durability and sterility.

- Aerospace: The aerospace industry utilizes laser marking for marking aircraft parts, engines, and other critical components. Laser marking ensures high-quality markings that can withstand harsh environmental conditions and maintain the integrity of the components.

- Manufacturing: Laser marking finds widespread applications in manufacturing, including marking tools, dies, molds, and other industrial components. It enables the creation of permanent and legible markings for identification, traceability, and quality control.

- Pharmaceuticals: The pharmaceutical industry relies on laser marking for marking drug vials, packaging, and other pharmaceutical products. Laser marking ensures tamper-proof and traceable markings, enhancing product safety and security.

- Jewelry: Laser marking is used in the jewelry industry for marking precious metals, gemstones, and other jewelry items. It allows for intricate and personalized markings, adding value and authenticity to jewelry pieces.

Applications of Laser Marking in Different Industries

Laser marking offers a wide range of applications across various industries, catering to specific marking needs. Here are some examples of specific applications:

- Product Identification: Laser marking is used for marking product serial numbers, barcodes, and QR codes for easy identification and traceability. This helps businesses track inventory, manage supply chains, and prevent counterfeiting.

- Data Encoding: Laser marking allows for the encoding of complex data, such as manufacturing dates, batch numbers, and other critical information, directly onto product surfaces. This enhances product traceability and facilitates efficient data management.

- Logo and Branding: Laser marking can be used to mark company logos, brand names, and other branding elements onto products. This enhances brand visibility, product recognition, and customer loyalty.

- Quality Control: Laser marking is used for marking quality control information, such as inspection stamps, acceptance marks, and other quality assurance indicators. This ensures product quality and facilitates efficient quality control processes.

- Customization: Laser marking allows for the creation of personalized markings, such as names, initials, and custom designs. This enhances product value and provides a unique touch for customers.

Advantages of Laser Marking

Laser marking offers significant advantages over traditional marking methods, making it a preferred choice in many industries. Here are some key advantages:

- High Precision: Laser marking offers exceptional precision, allowing for intricate and detailed markings. This is particularly important for applications requiring accurate and legible markings on small or delicate surfaces.

- Durability: Laser markings are highly durable and resistant to wear, tear, and environmental factors. This ensures that markings remain legible over time, even in harsh conditions.

- Versatility: Laser marking can be used on a wide range of materials, including metals, plastics, ceramics, and glass. This versatility makes it suitable for marking a diverse range of products.

- Non-Contact: Laser marking is a non-contact method, eliminating the risk of damage or contamination to the product surface. This is particularly important for delicate or sensitive products.

- Speed and Efficiency: Laser marking is a fast and efficient process, allowing for high-volume marking with minimal downtime. This improves productivity and reduces overall marking costs.

- Environmental Friendliness: Laser marking is an environmentally friendly process, as it does not involve the use of harmful chemicals or solvents. This aligns with sustainability goals and reduces environmental impact.

Impact of Laser Marking Technologies on Product Quality and Efficiency

Laser marking technologies have significantly impacted product quality and efficiency in various industries. The high precision and durability of laser markings ensure consistent and reliable product identification, traceability, and quality control. This reduces errors, improves product consistency, and enhances overall product quality.

Furthermore, the speed and efficiency of laser marking processes have streamlined manufacturing operations, reducing production time and costs. This allows businesses to meet market demands more effectively and optimize their overall production processes.

Laser Marking Technologies

Laser marking is a versatile and widely used technology for permanently marking various materials. It involves using a focused laser beam to alter the material’s surface, creating a visible mark. The process is precise, efficient, and offers numerous advantages over traditional marking methods.

Types of Laser Marking Technologies

Laser marking technologies are categorized based on the type of laser used and the marking process. The most common types include:

- Laser Engraving: This method uses a high-power laser beam to remove material from the surface, creating a permanent mark. It’s often used for creating deep, intricate designs on materials like metals, plastics, and wood.

- Laser Ablation: Similar to engraving, ablation uses a laser to vaporize a thin layer of material, leaving behind a mark. This method is effective for creating fine details and precise markings on various materials, including metals, ceramics, and glass.

- Laser Etching: This technique uses a laser to chemically alter the surface of a material, creating a permanent mark. Etching is often used for marking plastics, metals, and glass, producing marks that are durable and aesthetically pleasing.

- Laser Marking (Annealing): This method uses a laser to heat a material’s surface, causing a change in its color or texture. It’s commonly used for marking metals, producing marks that are resistant to wear and tear.

- Laser Marking (Melting): This technique uses a laser to melt a material’s surface, creating a raised mark. It’s often used for marking plastics, producing marks that are tactile and easily identifiable.

Principles of Laser Marking Processes

The principle behind laser marking lies in the interaction between the laser beam and the material’s surface. The laser beam, concentrated and focused, delivers energy to the material, causing a change in its properties. This change can manifest as a removal of material (engraving, ablation), a chemical alteration (etching), or a change in color or texture (annealing, melting).

The specific process employed depends on the desired mark, the material being marked, and the available laser technology.

Materials Suitable for Laser Marking

Laser marking technology is applicable to a wide range of materials, including:

- Metals: Steel, aluminum, brass, copper, titanium, and other metals can be effectively marked using various laser marking techniques.

- Plastics: Polypropylene, polyethylene, polycarbonate, and other plastics can be marked with lasers, producing durable and legible marks.

- Glass: Glass can be marked using lasers to create permanent markings, including logos, serial numbers, and other information.

- Ceramics: Laser marking is effective for marking ceramics, creating durable and aesthetically pleasing marks.

- Wood: Laser engraving is a popular method for marking wood, producing intricate designs and personalized engravings.

Factors Influencing Laser Marking Technology Choice

The selection of a specific laser marking technology depends on several factors:

- Material properties: The material’s composition, thickness, and surface properties play a crucial role in determining the suitable laser marking technique.

- Mark requirements: The desired mark’s size, depth, resolution, and permanence influence the choice of technology.

- Production speed: The required marking speed and throughput are important considerations for choosing a laser marking system.

- Cost: The cost of the laser marking system, including the laser itself, consumables, and maintenance, is a significant factor in decision-making.

- Application: The specific application, such as product identification, traceability, or decorative marking, dictates the most appropriate laser marking technology.

Laser Marking Technologies

Laser marking technologies have revolutionized the way we mark and identify products, providing a permanent, precise, and versatile solution for various industries. This technology utilizes a focused laser beam to alter the surface of a material, creating a mark that can be text, logos, barcodes, or intricate designs.

Advantages of Laser Marking Technologies

Laser marking offers a range of advantages that make it a superior choice compared to traditional marking methods.

- High Precision: Laser marking systems provide exceptional precision, allowing for intricate details and fine lines to be etched onto the surface of materials. This accuracy is crucial for applications requiring precise markings, such as electronic components, medical devices, and high-precision tools.

- Durability: Laser markings are highly durable and resistant to wear, tear, and environmental factors. They can withstand harsh conditions, such as extreme temperatures, chemicals, and abrasion, ensuring the mark remains legible for an extended period.

- Versatility: Laser marking technology can be applied to a wide range of materials, including metals, plastics, ceramics, and even some types of wood. This versatility allows for marking various products across different industries.

- Speed and Efficiency: Laser marking processes are generally fast and efficient, allowing for high-volume production runs. The automation of the process minimizes human error and increases productivity.

- Environmentally Friendly: Laser marking is an environmentally friendly process, as it does not involve the use of harmful chemicals or solvents. This aligns with sustainable manufacturing practices and reduces the environmental impact of marking processes.

Considerations and Limitations

While laser marking offers numerous advantages, there are some considerations and limitations to be aware of.

- Material Compatibility: Not all materials are suitable for laser marking. Some materials may be too soft or too porous, resulting in uneven or poorly defined markings.

- Cost of Equipment: Laser marking systems can be expensive to purchase and maintain. However, the long-term cost savings associated with their durability and efficiency can offset the initial investment.

- Safety Precautions: Laser marking equipment emits high-intensity beams that can be hazardous to human eyes and skin. Proper safety measures, such as protective eyewear and shielding, must be implemented to ensure the safety of operators and bystanders.

- Technical Expertise: Operating and maintaining laser marking systems requires specialized knowledge and training. Companies may need to invest in training their personnel or hire experienced technicians to ensure proper operation and maintenance.

Cost-Effectiveness of Laser Marking

Laser marking can be a cost-effective solution compared to traditional methods, such as stamping, etching, or printing. While the initial investment in equipment can be significant, the long-term savings associated with laser marking can outweigh the cost.

- Reduced Labor Costs: Laser marking is an automated process, reducing the need for manual labor and minimizing human error. This can lead to significant savings in labor costs.

- Elimination of Consumables: Unlike traditional methods that require consumables such as ink or stamps, laser marking does not involve any consumable materials, further reducing operational costs.

- Increased Efficiency: The speed and efficiency of laser marking allow for higher production volumes, leading to increased productivity and reduced downtime.

- Reduced Waste: Laser marking minimizes waste generation compared to traditional methods that may involve material scraps or ink spills.

Safety Measures and Regulations

Laser marking equipment emits high-intensity beams that can be hazardous to human eyes and skin. It is crucial to implement appropriate safety measures and comply with regulations to ensure the safety of operators and bystanders.

- Protective Eyewear: Operators must wear specialized laser safety goggles that are rated for the specific wavelength and power of the laser being used.

- Shielding: Laser marking equipment should be enclosed with appropriate shielding to prevent accidental exposure to the laser beam.

- Training and Certification: Operators should receive comprehensive training on laser safety procedures and regulations.

- Regular Inspections: Laser marking equipment should undergo regular inspections and maintenance to ensure proper functionality and safety.

- Compliance with Regulations: Laser marking equipment must comply with relevant safety regulations and standards set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO).

Laser Marking Technologies

Laser marking technologies are constantly evolving, driven by advancements in laser sources, optics, and software. These innovations are shaping the future of marking, etching, and engraving applications across various industries.

Emerging Trends and Advancements

The landscape of laser marking technologies is witnessing a surge in innovative trends, driven by advancements in laser sources, optics, and software. These advancements are revolutionizing the precision, efficiency, and versatility of laser marking, impacting industries and applications across the board.

- Ultrafast Lasers: These lasers, emitting pulses in femtosecond or picosecond durations, offer exceptional precision and minimal heat affected zones (HAZ), making them ideal for delicate materials and intricate designs. This allows for high-resolution marking on sensitive materials like plastics, ceramics, and metals, without compromising the material’s integrity.

- Fiber Lasers: These lasers, known for their high efficiency, long lifespan, and compact design, are becoming increasingly popular in industrial settings. Their high beam quality and flexibility enable precise marking on various materials, including metals, plastics, and ceramics, making them versatile tools for diverse applications.

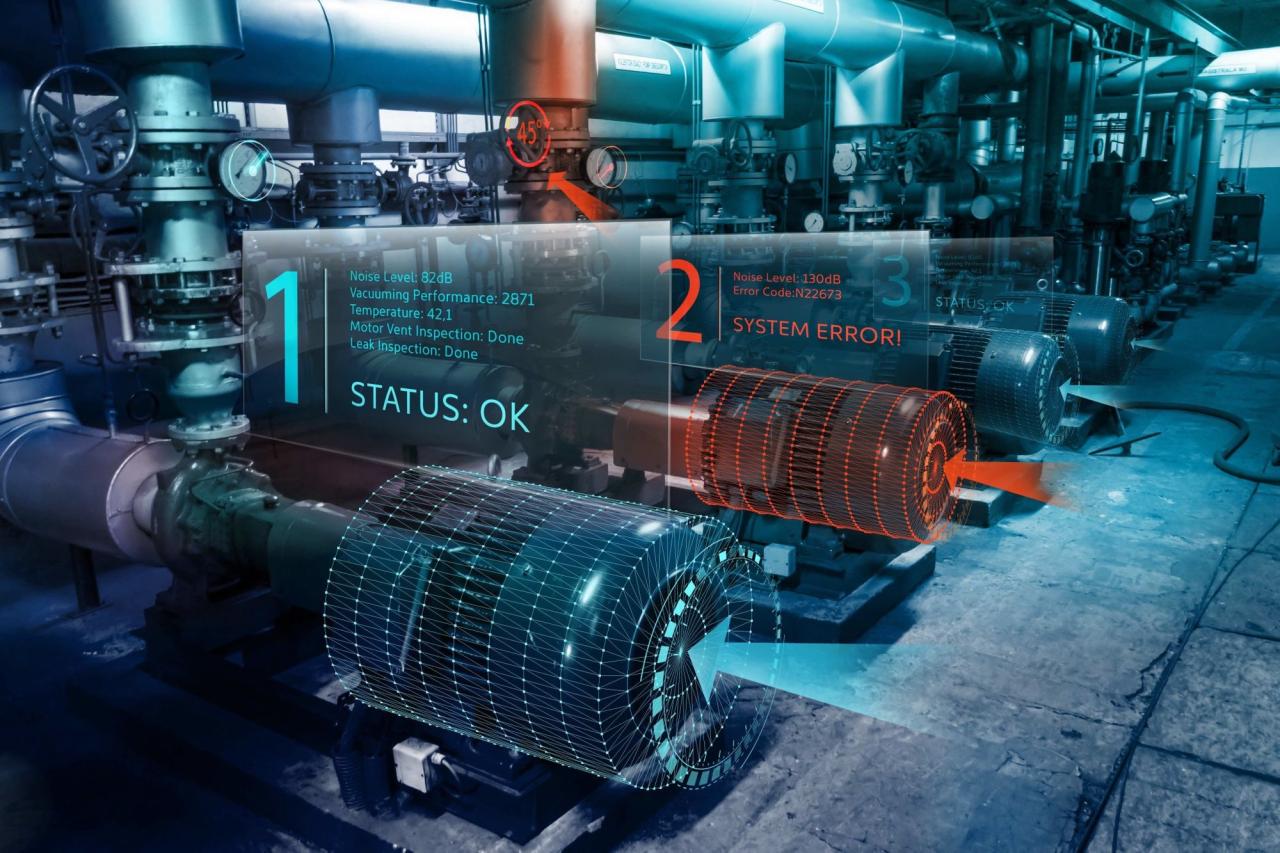

- Automated Marking Systems: Advancements in robotics and automation are integrating laser marking systems into production lines, streamlining processes and enhancing efficiency. These systems enable high-speed, high-throughput marking, optimizing production workflows and minimizing human intervention.

- Multi-Axis Marking: Advanced multi-axis marking systems offer increased flexibility and precision, allowing for complex three-dimensional marking on intricate surfaces. This capability opens up new possibilities for product customization, design intricacy, and functional marking.

Impact on Industries and Applications, Laser marking technologies llc

The impact of these innovations extends across numerous industries, revolutionizing production processes, product quality, and customer experience.

- Manufacturing: Laser marking is enhancing product traceability, enabling manufacturers to permanently mark products with unique identification codes, barcodes, and other data. This ensures product authenticity, facilitates inventory management, and enhances supply chain transparency.

- Electronics: The electronics industry is leveraging laser marking for precision etching and engraving on microchips, circuit boards, and other components. This enables complex circuit designs, improves component performance, and facilitates miniaturization in electronics.

- Medical Devices: Laser marking plays a crucial role in medical device manufacturing, ensuring accurate identification and traceability. This technology is also used for marking medical implants, allowing for precise placement and facilitating future identification.

- Automotive: The automotive industry is utilizing laser marking for permanent identification of parts, enabling efficient assembly line tracking and reducing errors. This technology is also used for marking vehicle identification numbers (VINs) and other critical data, ensuring compliance with regulations.

- Aerospace: Laser marking is essential in the aerospace industry for marking components with complex geometries and intricate details. This technology enables high-precision marking on sensitive materials, ensuring durability and reliability in demanding environments.

Future of Laser Marking Technologies

The future of laser marking technologies holds immense potential, driven by continued advancements in laser sources, optics, and software.

- Artificial Intelligence (AI): AI is poised to revolutionize laser marking by optimizing parameters, automating processes, and enhancing marking accuracy. AI-powered systems can analyze data from previous marking jobs, identify patterns, and predict optimal settings for new tasks.

- Advanced Materials: The development of new materials, including advanced polymers, ceramics, and composites, is expanding the scope of laser marking applications. Laser marking technologies are being adapted to effectively mark these materials, enabling new functionalities and designs.

- 3D Laser Marking: The integration of laser marking with 3D printing technologies is creating new possibilities for complex and customized designs. This combination allows for the creation of three-dimensional objects with intricate markings, enhancing product aesthetics and functionality.

- Laser-Induced Forward Transfer (LIFT): This technology uses laser pulses to transfer materials onto substrates, enabling precise deposition of functional materials. This technique holds promise for creating microelectronic devices, sensors, and other advanced applications.

Potential Future Applications and Benefits

| Application | Benefits |

|---|---|

| Personalized medicine | Precise marking of medical devices and implants with patient-specific information, enabling customized treatment plans and enhanced patient safety. |

| Smart packaging | Laser marking of packaging with interactive elements, such as QR codes and NFC tags, providing consumers with product information, tracking, and authentication capabilities. |

| Security and authentication | Laser marking of high-value products and documents with unique identification codes and security features, preventing counterfeiting and enhancing product authenticity. |

| Art and design | Laser marking for creating intricate and detailed artwork on various materials, expanding the possibilities of artistic expression and enabling new forms of art. |

| Microfluidics and lab-on-a-chip devices | Laser marking for creating microfluidic channels and structures on chips, enabling the development of portable and efficient diagnostic and analytical tools. |

Last Word

In an era of increasing demand for high-quality, traceable products, laser marking technologies have emerged as a vital tool for manufacturers and businesses across the globe. Laser Marking Technologies LLC plays a crucial role in this transformation, empowering industries with advanced solutions that enhance efficiency, quality, and brand recognition. As technology continues to evolve, laser marking will undoubtedly play an even greater role in shaping the future of product identification and traceability.

Laser Marking Technologies LLC specializes in precision marking solutions for various industries. Their expertise in laser technology is often intertwined with advancements in digital information technology, which is crucial for controlling and optimizing their systems. To learn more about the fascinating world of digital information technology, check out this digital information technology class.

Understanding the fundamentals of digital information technology allows for a deeper appreciation of how Laser Marking Technologies LLC operates and innovates.