Watson Marlow Fluid Technology Solutions: Precision Engineering for Fluid Handling

Watson Marlow Fluid Technology Solutions stands as a beacon of innovation in the world of precision fluid handling. With a rich history rooted in meticulous engineering, the company has become […]

Watson Marlow Fluid Technology Solutions stands as a beacon of innovation in the world of precision fluid handling. With a rich history rooted in meticulous engineering, the company has become synonymous with reliability, accuracy, and cutting-edge solutions that cater to diverse industries.

From pharmaceutical manufacturing to chemical processing, Watson Marlow’s products and services are meticulously designed to meet the specific needs of each application. Their commitment to research and development has led to the creation of a wide range of pumps, meters, and systems that deliver unmatched performance, efficiency, and safety.

Introduction to Watson Marlow Fluid Technology Solutions

Watson Marlow is a leading global provider of precision fluid handling solutions, specializing in the design and manufacture of pumps, metering systems, and other fluid management equipment. The company’s history spans over 70 years, during which time it has established a reputation for reliability, accuracy, and innovation in the fluid technology industry.

Watson Marlow’s focus on precision fluid handling stems from its commitment to delivering solutions that meet the demanding needs of various industries. These industries include pharmaceutical, chemical, food and beverage, and life sciences, where accurate and reliable fluid transfer is crucial for production processes and product quality.

Core Values and Mission Statement

Watson Marlow’s core values underpin its commitment to excellence and customer satisfaction. These values are reflected in the company’s mission statement, which emphasizes:

- Providing innovative and reliable fluid handling solutions

- Delivering exceptional customer service

- Operating with integrity and ethical business practices

- Promoting a culture of continuous improvement

Key Products and Services

Watson Marlow Fluid Technology Solutions provides a comprehensive range of products and services designed to meet the diverse needs of various industries. Their offerings are tailored to deliver precise fluid handling, control, and measurement solutions, ensuring efficiency, reliability, and safety across a wide range of applications.

Product Categories

Watson Marlow’s product portfolio encompasses a variety of pump technologies, each designed for specific applications and fluid handling requirements.

| Category | Description | Applications | Benefits |

|---|---|---|---|

| Peristaltic Pumps | Precise fluid transfer, low pulsation, gentle handling of sensitive fluids. | Chemical processing, pharmaceutical manufacturing, food and beverage, biotechnology, laboratory applications. | Reliability, low maintenance, accurate flow control, minimal contamination risk, dry-running capability. |

| Diaphragm Pumps | High-pressure applications, handling viscous fluids, robust and reliable performance. | Chemical processing, industrial cleaning, wastewater treatment, oil and gas, mining. | High pressure capability, self-priming, low pulsation, long service life, handling abrasive fluids. |

| Metering Pumps | Accurate dosing of fluids, precise flow control, reliable and consistent performance. | Chemical processing, water treatment, pharmaceutical manufacturing, food and beverage, industrial applications. | Accurate dosing, flow control, reliable operation, low maintenance, wide range of flow rates. |

| Fluid Handling Systems | Complete integrated solutions for fluid transfer, control, and monitoring. | Chemical processing, pharmaceutical manufacturing, food and beverage, wastewater treatment, industrial applications. | Simplified system integration, enhanced efficiency, improved control, reduced downtime, customized solutions. |

Industry Applications

Watson Marlow’s products and services find applications in a wide range of industries, addressing specific needs and challenges.

- Chemical Processing: Peristaltic pumps are widely used in chemical processing for transferring corrosive, abrasive, or sensitive fluids. They offer reliable performance and minimize contamination risks, ensuring efficient and safe operations. For example, in the production of polymers, Watson Marlow pumps are used to transfer highly viscous and reactive monomers, ensuring precise control and preventing contamination.

- Pharmaceutical Manufacturing: Watson Marlow’s pumps are essential in pharmaceutical manufacturing, where precise fluid handling and contamination control are critical. Their peristaltic pumps are used for transferring sensitive active pharmaceutical ingredients (APIs) and sterile solutions, ensuring product quality and safety.

- Food and Beverage: Watson Marlow’s pumps are designed to meet the stringent hygiene standards of the food and beverage industry. Their pumps are used for transferring delicate ingredients, sanitizing equipment, and bottling products, ensuring product integrity and consumer safety.

- Water Treatment: Watson Marlow’s metering pumps are used in water treatment plants for precise dosing of chemicals, ensuring efficient and effective water purification. Their pumps are also used in wastewater treatment facilities for handling corrosive and abrasive fluids, contributing to sustainable water management.

- Industrial Applications: Watson Marlow’s products are used in various industrial applications, including oil and gas, mining, and manufacturing. Their pumps are designed to handle abrasive, corrosive, and viscous fluids, ensuring reliable operation in demanding environments. For example, in oil and gas exploration, Watson Marlow pumps are used for transferring drilling fluids and chemicals, ensuring efficient and safe operations.

Implementation Examples

Watson Marlow’s solutions have been implemented in various applications, demonstrating their effectiveness and adaptability.

- Pharmaceutical Manufacturing: A leading pharmaceutical company implemented Watson Marlow’s peristaltic pumps in their sterile filling line for transferring highly sensitive APIs. The pumps’ precise flow control and minimal contamination risk ensured product quality and safety, contributing to the company’s success in producing life-saving medications.

- Chemical Processing: A chemical processing plant used Watson Marlow’s diaphragm pumps for handling corrosive and abrasive fluids in their production process. The pumps’ high-pressure capability and long service life ensured efficient and reliable operation, minimizing downtime and maximizing productivity.

- Food and Beverage: A food and beverage company implemented Watson Marlow’s peristaltic pumps for transferring delicate ingredients in their beverage production line. The pumps’ gentle handling and minimal pulsation ensured product quality and integrity, contributing to the company’s reputation for producing high-quality beverages.

Technological Innovations

Watson Marlow’s commitment to innovation is evident in its continuous development of cutting-edge fluid handling solutions. The company has been at the forefront of integrating advanced technologies to improve efficiency, safety, and sustainability in various industries.

Automation and Digitalization

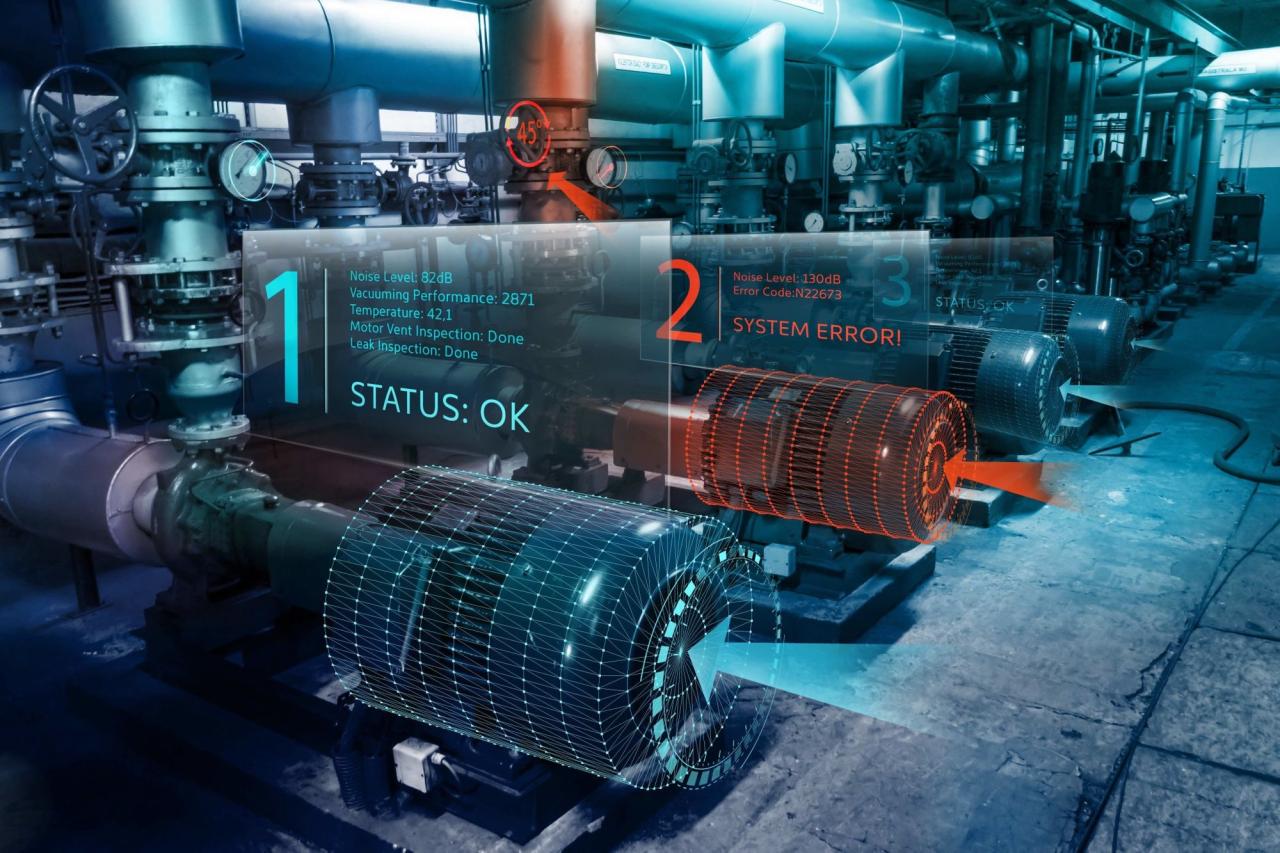

Watson Marlow has recognized the growing importance of automation and digitalization in modern manufacturing and process industries. The company has invested heavily in developing intelligent and automated systems that streamline fluid handling operations.

- Smart Pumps and Controllers: Watson Marlow’s pumps are equipped with advanced sensors and controllers that provide real-time data on pump performance, fluid flow rates, and system pressure. This data can be used to optimize pump operation, reduce downtime, and improve overall efficiency.

- Remote Monitoring and Control: Watson Marlow offers remote monitoring and control capabilities that allow users to access and manage their fluid handling systems from anywhere in the world. This enables proactive maintenance, troubleshooting, and performance optimization, even for geographically dispersed facilities.

- Data Analytics and Predictive Maintenance: Watson Marlow leverages data analytics to identify potential issues and predict maintenance needs before they occur. This helps prevent unexpected downtime and ensure the continuous operation of critical fluid handling systems.

Smart Technology Integration

Watson Marlow actively integrates smart technologies to enhance the capabilities and functionality of its fluid handling solutions.

- Internet of Things (IoT): Watson Marlow’s pumps and controllers can be integrated with IoT platforms to provide real-time data and insights into fluid handling operations. This enables better decision-making, improved process control, and enhanced operational efficiency.

- Artificial Intelligence (AI): Watson Marlow is exploring the use of AI algorithms to optimize pump performance, predict maintenance needs, and improve overall system reliability. AI-powered solutions can analyze vast amounts of data and identify patterns that would be difficult for humans to detect.

- Cloud Computing: Watson Marlow leverages cloud computing platforms to provide secure and scalable data storage and processing capabilities for its fluid handling systems. This enables remote access, real-time monitoring, and data analytics, further enhancing operational efficiency and decision-making.

Industry Applications and Case Studies

Watson Marlow fluid technology solutions are widely used across various industries, addressing critical challenges and delivering tangible results. These solutions are tailored to meet the specific needs of each industry, ensuring optimal performance, efficiency, and safety.

Pharmaceutical and Biotechnology

Watson Marlow’s fluid handling solutions play a crucial role in pharmaceutical and biotechnology manufacturing, where precision, sterility, and compliance are paramount. These solutions are designed to handle delicate and sensitive fluids, ensuring product integrity and safety throughout the process.

- Sterile Fluid Transfer: Watson Marlow peristaltic pumps are widely used in sterile applications, such as aseptic filling, media preparation, and bioreactor feeding. Their ability to handle fluids without contact with internal pump components ensures sterility and eliminates the risk of contamination.

- Precise Dosing and Dispensing: Watson Marlow’s peristaltic pumps and dosing systems provide accurate and repeatable dosing of critical ingredients in pharmaceutical formulations. This ensures consistent product quality and reduces waste.

- High-Purity Fluid Handling: Watson Marlow’s solutions are designed to handle high-purity fluids, meeting stringent regulatory requirements for pharmaceutical manufacturing. Their pumps and tubing are made from materials that are compatible with sensitive pharmaceutical products, ensuring purity and integrity.

Case Study: Pharmaceutical Manufacturing

A leading pharmaceutical manufacturer faced challenges with traditional pump systems in their aseptic filling line. The pumps were prone to contamination, leading to product spoilage and costly production downtime. Watson Marlow’s peristaltic pumps were implemented to address these issues. The pumps’ contact-free fluid handling eliminated the risk of contamination, ensuring product sterility and reducing downtime. The result was a significant improvement in production efficiency and a reduction in product loss.

Food and Beverage

Watson Marlow’s fluid handling solutions are essential in the food and beverage industry, where product safety, quality, and hygiene are paramount. Their solutions are designed to handle a wide range of fluids, from delicate fruit juices to thick sauces, ensuring accurate dispensing, efficient processing, and consistent product quality.

- Accurate Dosing and Dispensing: Watson Marlow’s peristaltic pumps and dosing systems are used for precise dispensing of ingredients in food and beverage formulations. This ensures consistent product quality and reduces waste.

- Hygienic Fluid Handling: Watson Marlow’s solutions are designed to meet the stringent hygiene standards of the food and beverage industry. Their pumps and tubing are made from materials that are food-grade and easy to clean, minimizing the risk of contamination.

- Gentle Fluid Handling: Watson Marlow’s peristaltic pumps are gentle on delicate fluids, preventing damage and preserving product quality. This is particularly important in applications involving fruit juices, sauces, and other sensitive ingredients.

Case Study: Beverage Production

A major beverage manufacturer was experiencing challenges with their traditional pump system for dispensing fruit juice concentrate. The pumps were causing damage to the delicate juice, leading to product quality issues and customer complaints. Watson Marlow’s peristaltic pumps were implemented to address these issues. The pumps’ gentle fluid handling preserved the juice’s quality, eliminating product damage and reducing customer complaints. The result was a significant improvement in product quality and customer satisfaction.

Chemical and Petrochemical, Watson marlow fluid technology solutions

Watson Marlow’s fluid handling solutions are widely used in the chemical and petrochemical industries, where harsh environments and corrosive fluids pose significant challenges. Their solutions are designed to withstand these demanding conditions, ensuring reliable operation and minimizing downtime.

- Chemical-Resistant Pumps: Watson Marlow’s peristaltic pumps are made from materials that are resistant to a wide range of chemicals and solvents. This ensures reliable operation in harsh environments and prevents pump failure due to corrosion.

- Precise Fluid Transfer: Watson Marlow’s pumps are capable of accurately transferring corrosive fluids, ensuring precise dosing and minimizing waste. This is crucial in chemical processes where accurate metering is essential.

- Low Maintenance Requirements: Watson Marlow’s peristaltic pumps have a simple design and require minimal maintenance, reducing downtime and operational costs. This is particularly important in demanding chemical and petrochemical environments.

Case Study: Chemical Manufacturing

A chemical manufacturer was struggling with their traditional pump system for transferring corrosive chemicals. The pumps were prone to failure due to corrosion, leading to frequent downtime and production delays. Watson Marlow’s peristaltic pumps were implemented to address these issues. The pumps’ chemical resistance and low maintenance requirements ensured reliable operation and minimized downtime. The result was a significant improvement in production efficiency and a reduction in operational costs.

Sustainability and Environmental Impact: Watson Marlow Fluid Technology Solutions

At Watson Marlow, sustainability is deeply embedded in our operations and forms the cornerstone of our commitment to responsible fluid handling solutions. We believe in minimizing our environmental footprint while delivering innovative and reliable solutions to our customers.

Energy Efficiency

Watson Marlow actively seeks to reduce energy consumption throughout our operations. We implement energy-efficient practices in our manufacturing facilities, including the use of LED lighting, energy-efficient equipment, and optimized building management systems. Our pumps are designed with efficiency in mind, minimizing energy consumption while maintaining high performance.

- For instance, our peristaltic pumps are known for their low energy consumption, significantly reducing operational costs and environmental impact.

- Watson Marlow’s commitment to energy efficiency is evident in our participation in initiatives like the ISO 50001 energy management system, ensuring continuous improvement in our energy performance.

Waste Reduction

We strive to minimize waste generation across our entire value chain. Our manufacturing processes are optimized for waste reduction, with a focus on recycling and reusing materials. We also promote responsible waste management practices within our operations, ensuring proper disposal and minimizing our environmental impact.

- Our commitment to waste reduction is demonstrated through our use of recycled materials in packaging and our participation in initiatives aimed at reducing plastic waste.

- Watson Marlow actively seeks to reduce waste generation in our operations through efficient material utilization, optimized production processes, and responsible disposal practices.

Responsible Material Sourcing

Watson Marlow prioritizes the use of sustainable and responsibly sourced materials in our products. We work closely with our suppliers to ensure compliance with ethical sourcing practices and environmental standards. We are committed to using materials that minimize environmental impact throughout their lifecycle.

- Watson Marlow’s commitment to responsible material sourcing extends to the use of recycled plastics and bio-based materials in our products, contributing to a circular economy.

- We actively engage with suppliers to ensure responsible sourcing practices, promoting transparency and environmental responsibility in our supply chain.

Future Trends and Developments

The fluid handling industry is constantly evolving, driven by advancements in technology, changing regulatory landscapes, and growing demand for sustainable solutions. Watson Marlow is committed to staying ahead of the curve by investing in research and development, collaborating with industry partners, and anticipating future trends.

Adaptation to Emerging Trends

Watson Marlow is actively adapting to the changing landscape of fluid handling technology. This includes embracing digitalization, integrating artificial intelligence (AI), and prioritizing sustainability.

- Digitalization and Industry 4.0: Watson Marlow is leveraging digital technologies to enhance its products and services. This includes integrating data analytics, remote monitoring, and predictive maintenance capabilities into its fluid handling systems. This allows for real-time data collection, improved process optimization, and reduced downtime.

- Artificial Intelligence (AI): Watson Marlow is exploring the potential of AI to automate tasks, optimize fluid handling processes, and improve decision-making. This includes developing AI-powered predictive maintenance models, optimizing pump performance, and improving process control.

- Sustainability: Watson Marlow is committed to developing sustainable fluid handling solutions. This includes focusing on energy efficiency, reducing waste, and using environmentally friendly materials. For example, the company offers a range of pumps that utilize energy-efficient motors and minimize energy consumption.

Predictions for the Future of Fluid Technology

The future of fluid technology is expected to be shaped by several key trends. These trends will influence the design, functionality, and applications of fluid handling systems.

- Increased Automation: Automation is expected to play a larger role in fluid handling. This includes the use of robots, autonomous systems, and intelligent control systems to automate tasks and improve efficiency. For example, Watson Marlow is developing automated systems for precise fluid dispensing and handling in pharmaceutical and laboratory settings.

- Advanced Materials: Advancements in materials science will lead to the development of new materials for fluid handling applications. These materials will offer improved performance, durability, and resistance to harsh environments. This includes materials like high-performance polymers, ceramics, and composites that are resistant to corrosion, wear, and temperature extremes.

- Personalized Medicine: The growing field of personalized medicine will drive demand for precise and accurate fluid handling solutions. Watson Marlow is developing pumps and systems that are specifically designed for handling small volumes of fluids, such as in microfluidic applications, for personalized drug delivery and diagnostics.

Watson Marlow’s Role in Shaping the Future

Watson Marlow is well-positioned to play a significant role in shaping the future of fluid technology. The company’s focus on innovation, sustainability, and customer-centric solutions will enable it to meet the evolving needs of the industry.

- Continued Investment in R&D: Watson Marlow will continue to invest heavily in research and development to create innovative fluid handling solutions. This includes developing new technologies, improving existing products, and expanding into new applications.

- Strategic Partnerships: Watson Marlow will collaborate with industry partners to develop and implement cutting-edge solutions. This includes working with universities, research institutions, and technology companies to share knowledge and expertise.

- Customer-Centric Approach: Watson Marlow will continue to prioritize customer needs and provide tailored solutions. This includes working closely with customers to understand their specific requirements and providing customized products and services.

Ending Remarks

Watson Marlow’s dedication to innovation, sustainability, and customer satisfaction has cemented its position as a leading force in the fluid technology industry. As the industry continues to evolve, Watson Marlow remains at the forefront, shaping the future of fluid handling with its unwavering commitment to precision, reliability, and environmental responsibility.

Watson Marlow fluid technology solutions are known for their precision and reliability, offering a wide range of pumps and accessories for various applications. When it comes to noise reduction, their systems can be further enhanced by incorporating the Quiet Technologies Halo , a cutting-edge acoustic enclosure designed to significantly minimize operating noise levels.

This integration allows Watson Marlow to provide even quieter and more user-friendly solutions for demanding environments.