Thermal Spray Technologies Inc: Coating Solutions for Industry

Thermal Spray Technologies Inc. is a leading provider of advanced thermal spray coatings, specializing in innovative solutions for a wide range of industries. The company’s commitment to research and development […]

Thermal Spray Technologies Inc. is a leading provider of advanced thermal spray coatings, specializing in innovative solutions for a wide range of industries. The company’s commitment to research and development ensures that their offerings are at the forefront of technology, addressing the ever-evolving needs of their clients.

Thermal Spray Technologies Inc. offers a comprehensive suite of thermal spray processes, each tailored to specific application requirements. From wear-resistant coatings for heavy machinery to corrosion-resistant coatings for infrastructure, the company’s expertise spans a diverse spectrum of industrial applications.

Thermal Spray Technologies Inc. Overview

Thermal Spray Technologies Inc. (TST) is a leading provider of thermal spray solutions, a technology used to create protective and functional coatings on various materials. Founded in 2005 by a team of experienced engineers and scientists, TST has since established itself as a trusted partner for industries seeking innovative and reliable coating solutions.

History and Founding

TST was founded in 2005 by a group of experienced engineers and scientists with a shared passion for thermal spray technology. The company’s founders recognized the immense potential of thermal spray coatings in various industries and set out to develop innovative solutions that could meet the evolving needs of their clients. TST’s initial focus was on providing custom thermal spray services for the aerospace and automotive industries, where high-performance coatings are critical for ensuring safety and longevity. Over the years, TST has expanded its operations and now serves a wide range of industries, including energy, medical, and electronics.

Mission, Vision, and Core Values

TST’s mission is to provide its clients with innovative and reliable thermal spray solutions that enhance the performance and longevity of their products. The company’s vision is to be recognized as a global leader in thermal spray technology, known for its commitment to quality, innovation, and customer satisfaction. TST’s core values are:

- Customer Focus: TST prioritizes understanding its clients’ needs and delivering solutions that exceed their expectations.

- Innovation: TST continuously invests in research and development to create cutting-edge thermal spray technologies.

- Quality: TST is committed to providing high-quality products and services that meet the highest industry standards.

- Integrity: TST operates with honesty and transparency in all its business dealings.

Products and Services

TST offers a wide range of thermal spray products and services, including:

- Custom Thermal Spray Coatings: TST designs and applies custom thermal spray coatings tailored to the specific requirements of each client’s application.

- Thermal Spray Equipment: TST provides a variety of thermal spray equipment, including wire arc spray guns, plasma spray torches, and high-velocity oxy-fuel (HVOF) systems.

- Thermal Spray Training: TST offers comprehensive training programs on thermal spray technology, covering topics such as coating design, application techniques, and quality control.

- Thermal Spray Consulting: TST provides expert consulting services to help clients select the optimal thermal spray solution for their specific needs.

Target Market and Customer Base

TST’s target market includes a wide range of industries that rely on thermal spray coatings for enhanced performance, durability, and functionality. Some of TST’s key customer segments include:

- Aerospace: TST provides thermal spray coatings for aircraft components, including engine parts, turbine blades, and airframe structures.

- Automotive: TST provides thermal spray coatings for automotive components, such as engine blocks, cylinder heads, and exhaust systems.

- Energy: TST provides thermal spray coatings for energy industry components, including power plant turbines, pipelines, and drilling equipment.

- Medical: TST provides thermal spray coatings for medical devices, such as implants, surgical instruments, and prosthetic components.

- Electronics: TST provides thermal spray coatings for electronic components, such as circuit boards, connectors, and sensors.

Thermal Spray Technologies: Processes and Applications: Thermal Spray Technologies Inc

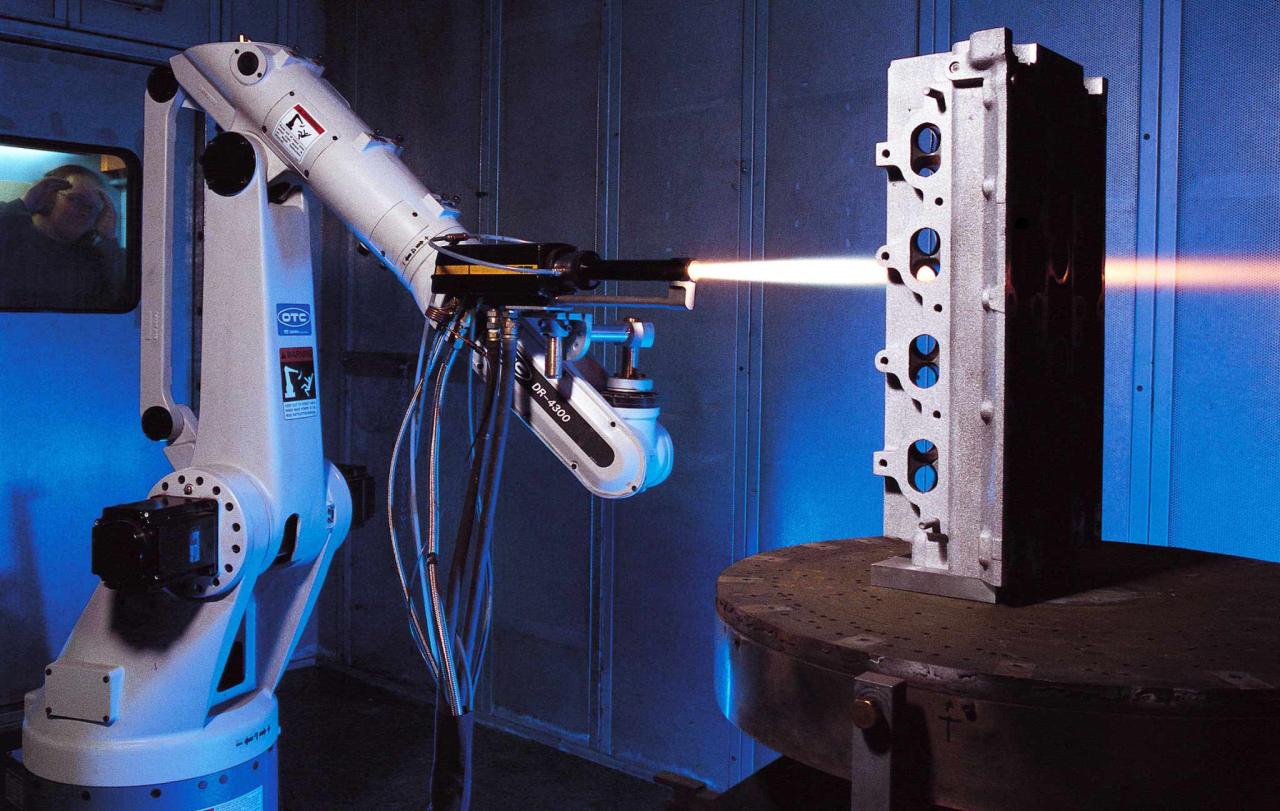

Thermal Spray Technologies Inc. employs a diverse range of thermal spray processes, each offering unique advantages and applications. These processes involve melting or heating a material, propelling it onto a substrate, and forming a coating. This section delves into the various thermal spray processes, the types of coatings offered, and the industries where these solutions find application.

Thermal Spray Processes

Thermal Spray Technologies Inc. utilizes several thermal spray processes, each with its own set of characteristics and applications. These processes are:

- High-Velocity Oxygen Fuel (HVOF): This process uses a high-velocity, high-temperature flame to propel a powdered material onto the substrate. It is known for producing dense, wear-resistant coatings with excellent adhesion. HVOF is often used in applications requiring high wear resistance, such as engine components, cutting tools, and aerospace parts.

- Wire Arc Spray (WAS): In this process, an electric arc melts a wire feedstock, which is then propelled onto the substrate using a compressed gas. WAS is known for its high deposition rate and versatility, making it suitable for large-scale applications. It is often used in applications requiring corrosion resistance, wear resistance, and thermal barrier protection.

- Plasma Spray (PS): This process utilizes a plasma torch to heat and melt a powder feedstock, which is then propelled onto the substrate. Plasma spray is capable of producing coatings with high melting points and excellent thermal properties. It is often used in applications requiring thermal barrier protection, wear resistance, and electrical insulation.

- Detonation Spray (DS): In detonation spray, a detonation wave is used to accelerate and melt a powder feedstock, which is then propelled onto the substrate. This process produces dense, fine-grained coatings with high adhesion and wear resistance. DS is often used in applications requiring high performance, such as aerospace components, turbine blades, and tooling.

- Cold Spray (CS): This process uses a high-velocity gas stream to accelerate and impact particles onto the substrate. CS is a relatively new process that operates at low temperatures, allowing for the coating of sensitive substrates without heat damage. It is often used in applications requiring wear resistance, corrosion resistance, and surface modification.

Types of Coatings

Thermal Spray Technologies Inc. offers a wide range of coatings, each designed for specific applications and properties. These coatings can be categorized as follows:

- Ceramic Coatings: These coatings are composed of ceramic materials, such as alumina, zirconia, and titanium carbide. Ceramic coatings are known for their high hardness, wear resistance, and thermal stability. They are often used in applications requiring high-temperature resistance, wear resistance, and electrical insulation.

- Metallic Coatings: These coatings are composed of metallic materials, such as aluminum, nickel, and stainless steel. Metallic coatings are known for their corrosion resistance, wear resistance, and electrical conductivity. They are often used in applications requiring protection against corrosion, wear, and erosion.

- Composite Coatings: These coatings combine different materials, such as ceramics and metals, to achieve specific properties. Composite coatings offer a wide range of properties, including high hardness, wear resistance, thermal stability, and corrosion resistance. They are often used in applications requiring multiple properties, such as high-performance engine components and tooling.

Applications and Industries

Thermal spray technologies are used in a wide range of industries and applications. Some of the key areas where Thermal Spray Technologies Inc.’s solutions find application include:

- Aerospace: Thermal spray coatings are used in aerospace applications for wear resistance, thermal barrier protection, and corrosion resistance. Examples include turbine blades, engine components, and aircraft components.

- Automotive: Thermal spray coatings are used in automotive applications for wear resistance, corrosion resistance, and thermal barrier protection. Examples include engine components, exhaust systems, and brake components.

- Energy: Thermal spray coatings are used in energy applications for wear resistance, corrosion resistance, and thermal barrier protection. Examples include power plant components, turbine blades, and oil and gas pipelines.

- Tooling and Manufacturing: Thermal spray coatings are used in tooling and manufacturing applications for wear resistance, corrosion resistance, and surface modification. Examples include cutting tools, molds, and dies.

- Medical: Thermal spray coatings are used in medical applications for biocompatibility, wear resistance, and surface modification. Examples include implants, surgical instruments, and prosthetic devices.

Benefits and Limitations of Thermal Spray Processes, Thermal spray technologies inc

The following table summarizes the benefits and limitations of each thermal spray process:

| Process | Benefits | Limitations |

|---|---|---|

| High-Velocity Oxygen Fuel (HVOF) | High wear resistance, excellent adhesion, dense coatings | Lower deposition rate compared to other processes, limited coating thickness |

| Wire Arc Spray (WAS) | High deposition rate, versatile, cost-effective | Porous coatings, limited control over coating microstructure |

| Plasma Spray (PS) | High melting point coatings, excellent thermal properties, versatile | High energy consumption, limited coating thickness |

| Detonation Spray (DS) | Dense coatings, high adhesion, high wear resistance | High capital investment, limited coating thickness |

| Cold Spray (CS) | Low-temperature process, suitable for sensitive substrates, high adhesion | Limited material compatibility, lower wear resistance compared to other processes |

Thermal Spray Technologies Inc.

Thermal Spray Technologies Inc. is a company dedicated to pushing the boundaries of thermal spray technology. Their commitment to innovation is evident in their continuous research and development efforts, aimed at improving existing processes and developing novel solutions for various industries.

Innovation and Research

Thermal Spray Technologies Inc. recognizes the importance of research and development in driving technological advancements. The company has established a dedicated research and development team, equipped with state-of-the-art facilities and resources. This team focuses on:

- Developing new thermal spray materials with enhanced properties like wear resistance, corrosion resistance, and high-temperature performance.

- Optimizing existing thermal spray processes to improve efficiency, reduce costs, and enhance the quality of coatings.

- Exploring new applications for thermal spray technologies in emerging industries like aerospace, energy, and biomedical.

The company’s dedication to innovation has resulted in the development of several proprietary technologies, including:

- A novel plasma spray process that enables the deposition of highly dense and uniform coatings with superior adhesion and performance.

- A unique material formulation for thermal spray coatings that offers exceptional wear resistance and corrosion protection in harsh environments.

- A software platform that optimizes thermal spray process parameters based on specific application requirements, ensuring consistent and reliable coating quality.

Thermal Spray Technologies Inc. actively engages in industry collaborations and partnerships to foster innovation and knowledge sharing. The company has established collaborations with leading research institutions, universities, and industry partners to:

- Conduct joint research projects to develop novel thermal spray technologies and applications.

- Share expertise and best practices to advance the field of thermal spray technology.

- Access cutting-edge research facilities and equipment to accelerate the development of new solutions.

Thermal Spray Technologies Inc. has a strong track record of research publications and presentations at industry conferences. Recent research projects include:

- Developing a new thermal spray coating for turbine blades, offering enhanced high-temperature performance and extended service life.

- Investigating the use of thermal spray technology for biomedical applications, such as creating customized implants with improved biocompatibility.

- Exploring the potential of thermal spray for energy storage applications, such as coating electrodes for high-performance batteries.

These research efforts demonstrate Thermal Spray Technologies Inc.’s commitment to pushing the boundaries of thermal spray technology and developing innovative solutions for diverse industries.

Thermal Spray Technologies Inc.: Industry Impact and Future

Thermal Spray Technologies Inc. has emerged as a significant player in the thermal spray industry, leaving an undeniable mark on its landscape. The company’s impact extends beyond its technological prowess, influencing the industry’s direction and shaping its future trajectory.

Industry Impact

Thermal Spray Technologies Inc. has significantly impacted the thermal spray industry through its innovative solutions, commitment to research and development, and dedication to customer satisfaction. The company’s advanced thermal spray technologies have revolutionized various sectors, including aerospace, automotive, and energy, by enhancing the performance, durability, and lifespan of components. Its unwavering commitment to research and development has led to the creation of groundbreaking thermal spray processes and materials, setting new standards for the industry. Thermal Spray Technologies Inc. has also earned a reputation for its exceptional customer service, providing comprehensive support throughout the entire thermal spray process, from design to implementation. This customer-centric approach has fostered strong relationships with clients, solidifying the company’s position as a trusted partner in the industry.

Future Outlook and Growth Potential

Thermal Spray Technologies Inc. is poised for continued growth and success in the future. The global thermal spray market is projected to experience significant expansion, driven by increasing demand from various industries. The company’s focus on innovation, coupled with its strategic investments in research and development, will enable it to capitalize on emerging trends and technological advancements in the thermal spray industry. Thermal Spray Technologies Inc. is well-positioned to leverage the growing adoption of advanced thermal spray technologies in sectors such as aerospace, automotive, and energy, further expanding its market reach and customer base.

Challenges and Opportunities

While the future outlook for Thermal Spray Technologies Inc. is promising, the company faces certain challenges and opportunities that will shape its trajectory. One key challenge is the intense competition in the thermal spray industry, with numerous players vying for market share. Another challenge is the need to stay ahead of technological advancements, ensuring that its products and services remain competitive in a rapidly evolving market. However, these challenges also present opportunities for growth and expansion. The increasing demand for thermal spray solutions in emerging markets presents a significant opportunity for Thermal Spray Technologies Inc. to expand its global reach and penetrate new customer segments. The company can also leverage its technological expertise to develop innovative solutions that address specific industry needs, further solidifying its position as a leader in the thermal spray industry.

Key Factors Influencing the Future

The future of Thermal Spray Technologies Inc. will be influenced by several key factors, including:

| Factor | Description |

|---|---|

| Technological Advancements | The continuous development of new thermal spray processes, materials, and equipment will drive innovation and growth in the industry. |

| Market Demand | The increasing demand for thermal spray solutions across various industries will create opportunities for expansion and market penetration. |

| Regulatory Landscape | Changes in environmental regulations and safety standards can impact the adoption and development of thermal spray technologies. |

| Competition | The presence of numerous competitors in the thermal spray industry will require Thermal Spray Technologies Inc. to differentiate itself through innovation, quality, and customer service. |

| Economic Conditions | Global economic conditions can influence investment decisions and the demand for thermal spray solutions. |

Case Studies and Examples

Thermal Spray Technologies Inc. boasts a rich history of delivering innovative solutions that have transformed industries and addressed critical customer challenges. This section showcases the company’s expertise through real-world case studies, customer testimonials, and visual representations of successful projects.

Illustrative Case Study: Enhancing Turbine Blade Durability in Aerospace

This case study demonstrates how Thermal Spray Technologies Inc. helped a leading aerospace manufacturer enhance the durability of turbine blades, a critical component in aircraft engines. The manufacturer faced the challenge of premature blade failure due to high operating temperatures and corrosive environments.

Thermal Spray Technologies Inc. proposed a solution involving the application of a specialized thermal spray coating to the turbine blades. The coating, composed of a high-temperature-resistant ceramic material, provided exceptional thermal insulation and resistance to corrosion.

The results were remarkable. The coated blades exhibited significantly extended service life, leading to reduced maintenance costs and improved aircraft reliability. The aerospace manufacturer achieved a 20% increase in blade lifespan, translating to substantial cost savings and improved operational efficiency.

Customer Testimonials

Thermal Spray Technologies Inc. has earned a reputation for delivering high-quality solutions and exceptional customer service. The following testimonials highlight the positive experiences of satisfied clients:

- “Thermal Spray Technologies Inc. provided us with a tailored solution that exceeded our expectations. Their expertise and commitment to quality have been invaluable to our operations.” – CEO, Automotive Manufacturing Company

- “We were impressed with Thermal Spray Technologies Inc.’s ability to understand our specific needs and develop a cost-effective solution. Their team was highly responsive and professional throughout the entire project.” – Plant Manager, Energy Production Facility

Visual Representation of a Successful Project: Coating a Power Plant Boiler

Imagine a large power plant boiler, its intricate network of tubes and chambers vital for efficient energy generation. The boiler operates under extreme conditions, facing high temperatures, corrosive gases, and abrasive particles.

Thermal Spray Technologies Inc. was tasked with protecting the boiler’s critical components from wear and tear. The company employed a specialized thermal spray coating process to apply a durable and protective layer to the boiler’s internal surfaces.

The visual representation of this project would depict a cross-section of the boiler, showcasing the intricate network of tubes and chambers. The thermal spray coating would be highlighted in a contrasting color, emphasizing its protective role.

The flowchart would depict the steps involved in the coating process, including surface preparation, coating application, and quality inspection. The diagram would also include key performance indicators, such as coating thickness and adhesion strength, demonstrating the effectiveness of the solution.

Summary

Thermal Spray Technologies Inc. stands as a testament to the transformative power of thermal spray technology. Their dedication to innovation, coupled with a deep understanding of customer needs, has solidified their position as a trusted partner in numerous industries. As the company continues to push the boundaries of thermal spray technology, its solutions will undoubtedly play an even greater role in shaping the future of materials science and industrial applications.

Thermal Spray Technologies Inc. is a company that utilizes advanced coating techniques to enhance the performance and lifespan of various products. For those interested in a career in this field, a business management technology degree can provide the essential skills in managing operations, financial resources, and strategic planning.

This degree can equip individuals with the knowledge and tools needed to succeed in a dynamic industry like thermal spray technologies.