Refrigeration and Air Conditioning Technology 8th Edition: Mastering Cooling Systems

Refrigeration and Air Conditioning Technology 8th Edition delves into the fascinating world of cooling systems, exploring the science behind how we keep things cool and comfortable. From the fundamental principles […]

Refrigeration and Air Conditioning Technology 8th Edition delves into the fascinating world of cooling systems, exploring the science behind how we keep things cool and comfortable. From the fundamental principles of thermodynamics to the latest advancements in energy efficiency, this comprehensive guide provides a deep understanding of the technologies that shape our modern world.

This book takes readers on a journey through the history of refrigeration and air conditioning, showcasing the evolution of these technologies and their impact on various industries. It examines the intricate workings of refrigeration and air conditioning systems, from the components that make them function to the different types of systems used in homes, businesses, and industries.

Introduction to Refrigeration and Air Conditioning

Refrigeration and air conditioning are essential technologies that have revolutionized our lives, making it possible to preserve food, create comfortable living and working environments, and enable various industrial processes. This chapter delves into the fundamental principles, historical development, and diverse applications of these technologies.

Fundamental Principles of Refrigeration and Air Conditioning

Refrigeration and air conditioning systems rely on the principles of thermodynamics, particularly the transfer of heat between different substances. The core principle is based on the concept of a refrigerant, a fluid that absorbs heat during evaporation and releases it during condensation. This continuous cycle of absorption and release of heat allows for the cooling of a specific space or substance.

The basic components of a refrigeration system include a compressor, condenser, expansion valve, and evaporator. The compressor pumps the refrigerant through the system, increasing its pressure and temperature. The condenser then releases the heat absorbed by the refrigerant to the surrounding environment, causing the refrigerant to condense. The expansion valve reduces the pressure of the refrigerant, causing it to evaporate and absorb heat from the space being cooled. Finally, the evaporator absorbs heat from the surrounding environment, lowering its temperature. This cycle repeats continuously, providing a continuous cooling effect.

Historical Evolution of Refrigeration and Air Conditioning Technologies

Refrigeration and air conditioning technologies have evolved significantly throughout history, driven by technological advancements and changing societal needs.

- Early Refrigeration Methods: Early refrigeration methods relied on natural processes like ice harvesting and the use of evaporative cooling. Ice was harvested from lakes and rivers during the winter and stored in insulated structures for later use. Evaporative cooling systems utilized the principle of water evaporation to cool air, often employed in arid regions.

- Mechanical Refrigeration: The invention of the mechanical compressor in the late 19th century marked a significant breakthrough in refrigeration technology. Early mechanical refrigerators used toxic and flammable refrigerants like ammonia and methyl chloride. The development of safer and more efficient refrigerants, such as Freon, in the 20th century revolutionized the industry.

- Air Conditioning: The development of air conditioning systems followed closely behind the advancements in refrigeration. Early air conditioning systems were bulky and expensive, primarily used in commercial and industrial settings. The invention of the window air conditioner in the mid-20th century made air conditioning more accessible to residential consumers.

- Modern Technologies: Modern refrigeration and air conditioning systems have become increasingly sophisticated, incorporating advanced technologies like variable-speed compressors, electronic controls, and energy-efficient refrigerants. The focus has shifted towards sustainability and energy efficiency, with advancements in inverter technology and smart home integration.

Applications of Refrigeration and Air Conditioning Systems, Refrigeration and air conditioning technology 8th edition

Refrigeration and air conditioning systems find wide-ranging applications in various sectors, including:

- Food Preservation: Refrigeration is crucial for preserving food, extending its shelf life, and preventing spoilage. Refrigerators and freezers are ubiquitous in homes, restaurants, grocery stores, and other food-related industries.

- Commercial and Industrial Applications: Refrigeration systems are essential in various commercial and industrial sectors, including food processing, pharmaceutical manufacturing, and chemical production. They are used for storing and transporting temperature-sensitive products, ensuring quality control and safety.

- Residential Comfort: Air conditioning systems provide thermal comfort in homes, offices, and other residential settings, creating a pleasant and productive environment. They are especially crucial in hot and humid climates, where they help to regulate temperature and humidity levels.

- Commercial and Public Spaces: Air conditioning systems are widely used in commercial buildings, such as shopping malls, hotels, restaurants, and theaters, to create a comfortable environment for customers and employees.

- Transportation: Refrigeration and air conditioning systems are also integral to transportation, including refrigerated trucks and trains used for transporting perishable goods, and passenger vehicles equipped with air conditioning systems for comfort and safety.

Thermodynamics and Refrigeration Cycles

Refrigeration is the process of removing heat from a space or object to lower its temperature. This process is based on the principles of thermodynamics, which govern the transfer of heat and work. Understanding these principles is crucial for comprehending the operation of refrigeration systems.

Basic Thermodynamic Concepts

Thermodynamics deals with the relationship between heat, work, and temperature. The following concepts are fundamental to refrigeration:

- Heat: The transfer of thermal energy between objects at different temperatures. Heat flows from a higher temperature to a lower temperature. In refrigeration, heat is removed from the refrigerated space and transferred to the surroundings.

- Work: The energy required to move an object or change its state. In refrigeration, work is performed by the compressor, which pumps refrigerant through the system.

- Temperature: A measure of the average kinetic energy of the molecules in a substance. Lower temperatures indicate lower kinetic energy.

- Specific Heat: The amount of heat required to raise the temperature of one unit mass of a substance by one degree Celsius. Different substances have different specific heats.

- Enthalpy: A thermodynamic property that represents the total energy of a system. It includes the internal energy, pressure, and volume of the system.

- Entropy: A measure of the disorder or randomness of a system. Entropy increases as heat is transferred from a higher temperature to a lower temperature.

Refrigeration Cycles

A refrigeration cycle is a closed system that uses a working fluid (refrigerant) to transfer heat from a cold source to a hot source. The most common type of refrigeration cycle is the vapor-compression cycle.

Vapor-Compression Refrigeration Cycle

The vapor-compression refrigeration cycle consists of four main components:

- Compressor: Compresses the refrigerant vapor, increasing its temperature and pressure.

- Condenser: Cools the high-pressure, high-temperature refrigerant vapor, causing it to condense into a liquid.

- Expansion Valve: Reduces the pressure and temperature of the refrigerant liquid, causing it to partially vaporize.

- Evaporator: Absorbs heat from the refrigerated space, causing the remaining liquid refrigerant to vaporize completely.

The refrigerant circulates through the cycle, absorbing heat from the refrigerated space in the evaporator and releasing it to the surroundings in the condenser. The compressor provides the energy needed to drive the cycle.

Other Refrigeration Cycles

While the vapor-compression cycle is the most prevalent, other refrigeration cycles are used in specific applications:

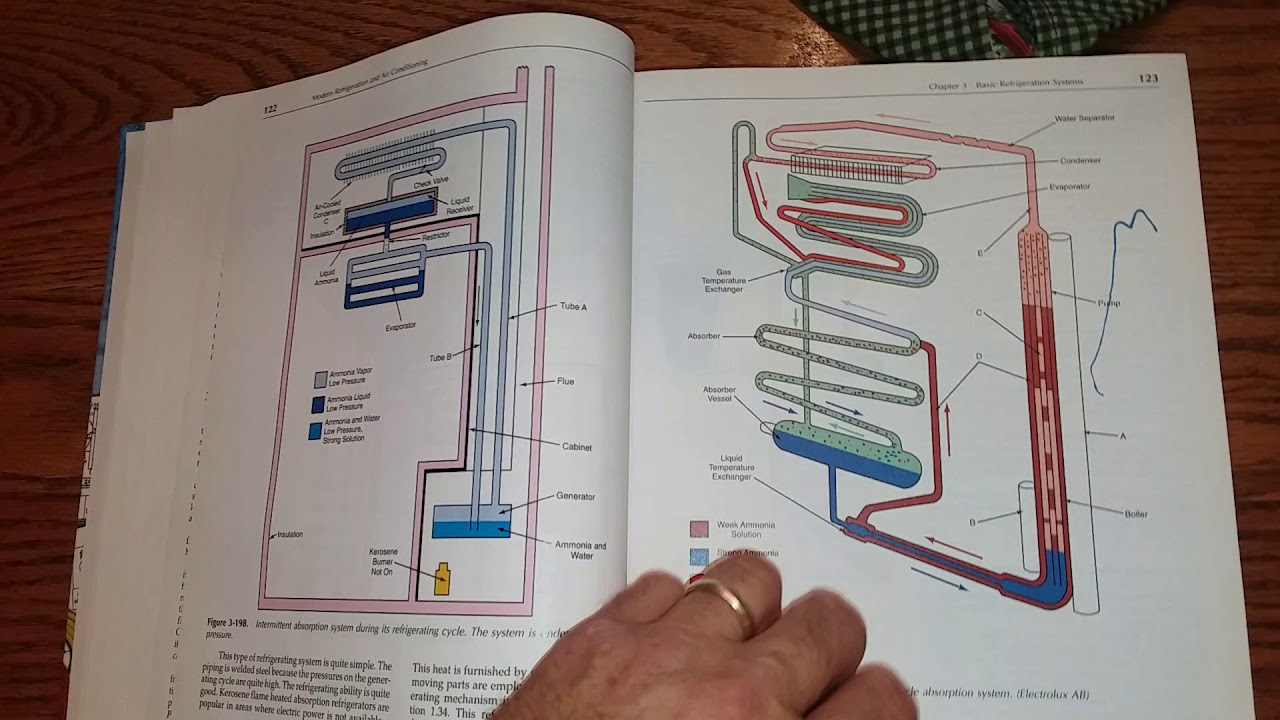

- Absorption Refrigeration Cycle: This cycle uses a solution (typically water and lithium bromide) to absorb the refrigerant vapor. It is commonly used in applications where heat is readily available, such as in industrial processes or solar-powered systems.

- Air Refrigeration Cycle: This cycle uses air as the working fluid. It is less efficient than vapor-compression cycles but is often used in small-scale applications, such as in automotive air conditioners.

- Stirling Refrigeration Cycle: This cycle uses a closed-loop system with a displacer piston and a power piston to transfer heat. It is known for its high efficiency but is more complex and expensive than other cycles.

Comparison of Refrigeration Cycles

The choice of refrigeration cycle depends on factors such as the desired cooling capacity, operating temperature range, energy efficiency, and cost.

| Cycle | Efficiency | Suitability |

|---|---|---|

| Vapor-Compression | High | Wide range of applications, including residential, commercial, and industrial refrigeration. |

| Absorption | Moderate | Applications where heat is readily available, such as industrial processes or solar-powered systems. |

| Air | Low | Small-scale applications, such as in automotive air conditioners. |

| Stirling | High | Applications requiring high efficiency, but more complex and expensive than other cycles. |

The coefficient of performance (COP) is a measure of the efficiency of a refrigeration system. It is defined as the ratio of the cooling capacity to the power input. Higher COP values indicate higher efficiency.

The COP of a refrigeration system is influenced by factors such as the type of cycle, operating conditions, and refrigerant properties.

Refrigeration Components and Systems

Refrigeration systems are designed to remove heat from a specific space or substance, thereby lowering its temperature. They are essential in various applications, from keeping food fresh in homes to maintaining optimal conditions in industrial processes. The key components of a refrigeration system work together to achieve this cooling effect.

Refrigeration System Components

Refrigeration systems typically consist of four main components: the compressor, condenser, evaporator, and expansion valve. These components are interconnected in a closed loop, facilitating the transfer of heat and refrigerant.

- Compressor: The compressor is the heart of the refrigeration system. It is responsible for compressing the refrigerant vapor, increasing its pressure and temperature. This compression process raises the refrigerant’s energy level, enabling it to release heat in the condenser.

- Condenser: The condenser is a heat exchanger where the high-pressure, high-temperature refrigerant vapor releases heat to the surrounding environment. As the refrigerant cools down, it transitions from a vapor to a liquid state. This process typically involves the use of air or water as the cooling medium.

- Expansion Valve: The expansion valve controls the flow of refrigerant from the high-pressure liquid state to the low-pressure evaporator. It allows the refrigerant to expand rapidly, causing a significant drop in its pressure and temperature.

- Evaporator: The evaporator is another heat exchanger where the low-pressure, low-temperature refrigerant absorbs heat from the refrigerated space or substance. This process causes the refrigerant to evaporate, absorbing the heat and lowering the temperature of the surrounding environment.

Types of Refrigeration Systems

Refrigeration systems can be classified into various types based on their application, size, and operating principles.

- Residential Refrigeration Systems: These systems are commonly found in homes and are primarily used for food preservation. They typically utilize a vapor-compression refrigeration cycle and are designed for small-scale cooling needs.

- Commercial Refrigeration Systems: Commercial refrigeration systems are employed in various businesses, including supermarkets, restaurants, and convenience stores. They are larger and more powerful than residential systems, capable of handling significant cooling loads.

- Industrial Refrigeration Systems: Industrial refrigeration systems are used in large-scale applications such as food processing, chemical manufacturing, and cold storage facilities. These systems are designed for high-capacity cooling and often incorporate advanced technologies for efficient operation.

Refrigeration System Types Comparison

The following table compares the characteristics and applications of various refrigeration system types:

| Type | Characteristics | Applications |

|---|---|---|

| Vapor-Compression Refrigeration | Most common type, uses a compressor to circulate refrigerant | Residential, commercial, industrial |

| Absorption Refrigeration | Uses heat to drive the refrigeration cycle, suitable for applications with readily available heat sources | Industrial, commercial, some residential |

| Air-Cycle Refrigeration | Utilizes air as the refrigerant, suitable for high-altitude applications | Aircraft, some industrial applications |

Air Conditioning Systems and Components

Air conditioning systems are designed to control the temperature, humidity, and air quality within a space. They are widely used in homes, businesses, and public spaces to provide comfort and improve productivity. The fundamental principle behind air conditioning is the process of heat transfer, where heat is removed from a space and transferred to another location. This process typically involves the use of a refrigerant, which absorbs heat from the air and releases it outside.

Air conditioning systems consist of various components, each playing a crucial role in the overall operation. Understanding the function of each component is essential for troubleshooting and maintaining these systems effectively.

Components of an Air Conditioning System

The components of an air conditioning system work together to achieve the desired temperature and humidity levels within a space. Each component performs a specific function, and their proper operation is essential for the efficient and effective functioning of the entire system.

- Blower: The blower is responsible for circulating air through the system. It draws air from the space being cooled, passes it over the evaporator coil, and then delivers the cooled air back into the space. The blower is typically powered by an electric motor.

- Evaporator Coil: The evaporator coil is a heat exchanger where the refrigerant absorbs heat from the air. As the refrigerant flows through the evaporator coil, it changes from a liquid to a gas, absorbing heat in the process. The air passing over the evaporator coil is cooled as it absorbs heat from the refrigerant.

- Condenser Coil: The condenser coil is another heat exchanger, where the refrigerant releases heat to the outside environment. As the refrigerant flows through the condenser coil, it changes from a gas to a liquid, releasing heat in the process. The heat is typically transferred to the outside air by a fan or other means.

- Thermostat: The thermostat acts as the control center for the air conditioning system. It senses the temperature of the space and sends signals to the system to adjust the cooling output accordingly. When the temperature falls below the set point, the thermostat turns off the system, and when it rises above the set point, the thermostat turns the system back on.

- Compressor: The compressor is the heart of the air conditioning system. It compresses the refrigerant gas, increasing its pressure and temperature. This process allows the refrigerant to release heat to the condenser coil and return to the evaporator coil, completing the refrigeration cycle.

- Expansion Valve: The expansion valve controls the flow of refrigerant through the system. It reduces the pressure of the refrigerant as it enters the evaporator coil, allowing it to absorb heat more effectively.

Types of Air Conditioning Systems

There are various types of air conditioning systems available, each with its own advantages and disadvantages. The type of system that is best suited for a particular application depends on factors such as the size of the space, the desired level of comfort, and the budget.

- Central Air Conditioning: Central air conditioning systems are typically used in larger homes and buildings. They consist of a central unit located outside the building, which houses the compressor, condenser, and other components. The central unit is connected to a series of ducts that distribute the cooled air throughout the building.

- Window Units: Window units are smaller, self-contained air conditioners that are typically installed in individual rooms. They are a simple and affordable option for cooling smaller spaces. Window units typically have a lower cooling capacity than central air systems, but they can be effective for small rooms.

- Split Systems: Split systems are similar to central air systems but consist of two units: an indoor unit and an outdoor unit. The indoor unit is typically mounted on a wall or ceiling, and it contains the evaporator coil and blower. The outdoor unit contains the compressor and condenser. Split systems offer greater flexibility in installation and are often more efficient than window units.

Refrigeration and Air Conditioning Applications: Refrigeration And Air Conditioning Technology 8th Edition

Refrigeration and air conditioning systems are ubiquitous in modern life, playing crucial roles in various industries and settings. These technologies ensure the preservation of food, maintain comfortable environments, and facilitate a wide range of industrial processes.

Refrigeration Applications

Refrigeration plays a vital role in preserving food and other perishable goods, ensuring their quality and extending their shelf life. The application of refrigeration in various industries is essential for maintaining optimal storage conditions, preventing spoilage, and minimizing waste.

- Food Storage: Refrigeration is extensively used in supermarkets, grocery stores, restaurants, and homes to store perishable foods like fruits, vegetables, meat, dairy products, and seafood. The cold temperatures slow down bacterial growth and enzymatic activity, preventing spoilage and extending the freshness of these items.

- Pharmaceuticals: Pharmaceuticals require strict temperature control for optimal storage and transportation. Refrigeration is essential for maintaining the potency and efficacy of medicines, vaccines, and other pharmaceutical products. This ensures the safety and effectiveness of these essential healthcare items.

- Chemical Processing: Refrigeration is used in chemical processing for various purposes, including temperature control of reactions, condensation of gases, and storage of sensitive materials. Chemical reactions often require specific temperature ranges for optimal yield and safety, and refrigeration systems provide precise temperature control.

Air Conditioning Applications

Air conditioning systems provide comfort and productivity by regulating temperature, humidity, and air quality in various settings. These systems are essential for maintaining comfortable living and working environments, particularly in regions with hot and humid climates.

- Residential: Residential air conditioning systems are widely used in homes to provide comfort during hot weather. They regulate temperature, humidity, and air quality, creating a pleasant and healthy living environment. This improves sleep quality, reduces heat stress, and enhances overall well-being.

- Commercial: Commercial air conditioning systems are crucial for maintaining comfortable temperatures in various commercial settings, including offices, retail stores, hotels, restaurants, and entertainment venues. These systems ensure a pleasant environment for customers, employees, and visitors, enhancing productivity and satisfaction.

- Industrial: Industrial air conditioning systems are designed to meet the specific requirements of various industrial processes. These systems provide precise temperature control, humidity regulation, and air filtration for sensitive equipment, materials, and manufacturing processes. This ensures optimal performance, product quality, and safety in industrial environments.

Refrigeration and Air Conditioning Requirements in Different Applications

The specific requirements and considerations for refrigeration and air conditioning systems vary depending on the application. The following table summarizes some key factors to consider:

| Application | Refrigeration Requirements | Air Conditioning Requirements |

|---|---|---|

| Food Storage | Low temperatures (0°C to 7°C), humidity control, rapid cooling, proper ventilation, energy efficiency | Temperature control (20°C to 25°C), humidity control, air filtration, energy efficiency |

| Pharmaceuticals | Precise temperature control (2°C to 8°C), humidity control, security, monitoring systems, energy efficiency | Temperature control (20°C to 25°C), humidity control, air filtration, security, energy efficiency |

| Chemical Processing | Temperature control (varies depending on the process), precise control, safety features, corrosion resistance, energy efficiency | Temperature control (varies depending on the process), humidity control, air filtration, safety features, energy efficiency |

| Residential | Temperature control (18°C to 24°C), humidity control, energy efficiency, quiet operation, ease of maintenance | Temperature control (20°C to 25°C), humidity control, air filtration, energy efficiency, quiet operation, ease of maintenance |

| Commercial | Temperature control (varies depending on the type of business), humidity control, energy efficiency, reliability, ease of maintenance | Temperature control (20°C to 25°C), humidity control, air filtration, energy efficiency, reliability, ease of maintenance |

| Industrial | Temperature control (varies depending on the process), precise control, safety features, corrosion resistance, energy efficiency, reliability | Temperature control (varies depending on the process), humidity control, air filtration, safety features, energy efficiency, reliability |

Energy Efficiency and Sustainability

The increasing demand for refrigeration and air conditioning, coupled with the growing awareness of environmental concerns, has made energy efficiency and sustainability crucial aspects of the industry. These systems, while essential for modern life, contribute significantly to energy consumption and greenhouse gas emissions. This chapter delves into the energy consumption and environmental impact of refrigeration and air conditioning systems, explores methods for improving energy efficiency, and examines sustainable technologies.

Energy Consumption and Environmental Impact

Refrigeration and air conditioning systems are major consumers of energy, particularly in residential and commercial buildings. The energy used to power these systems ultimately comes from fossil fuels, contributing to greenhouse gas emissions and climate change. The environmental impact of refrigeration and air conditioning extends beyond energy consumption. Refrigerants used in these systems are potent greenhouse gases, and leaks can have a significant impact on the atmosphere.

Improving Energy Efficiency

Energy efficiency in refrigeration and air conditioning systems can be improved through various measures, including:

- Optimizing System Design and Operation: Properly sizing systems for specific needs, using high-efficiency components, and optimizing system settings can significantly reduce energy consumption. For instance, using variable-speed compressors, which adjust their speed based on demand, can save energy compared to fixed-speed compressors.

- Insulation and Sealing: Proper insulation and sealing of buildings, equipment, and ductwork minimize heat loss and gain, reducing the workload on refrigeration and air conditioning systems.

- Using Energy-Efficient Components: Selecting high-efficiency compressors, fans, and other components can lead to substantial energy savings over time. For example, using electronically commutated motors (ECMs) for fans can reduce energy consumption by 20-30% compared to traditional AC motors.

- Smart Controls and Automation: Implementing smart controls and automation can optimize system operation based on real-time conditions, further reducing energy consumption. For example, thermostats with occupancy sensors can adjust temperatures based on whether a room is occupied or not.

- Refrigerant Management: Proper refrigerant management, including regular leak checks and maintenance, reduces emissions and minimizes the environmental impact. Using refrigerants with lower global warming potential (GWP) can further reduce the environmental impact.

Sustainable Refrigeration and Air Conditioning Technologies

The industry is constantly developing sustainable technologies to minimize the environmental footprint of refrigeration and air conditioning. These technologies include:

- Natural Refrigerants: Using natural refrigerants, such as ammonia, carbon dioxide, and hydrocarbons, eliminates the use of synthetic refrigerants with high GWP. These natural refrigerants have a negligible or zero impact on the ozone layer and global warming potential.

- Hybrid Systems: Hybrid systems combine different technologies to optimize energy efficiency and reduce environmental impact. For example, a hybrid system could use solar energy to power a refrigeration system or use geothermal energy for heating and cooling.

- District Cooling: District cooling systems provide centralized cooling to multiple buildings, reducing the overall energy consumption and environmental impact compared to individual systems.

- Passive Cooling Techniques: Utilizing passive cooling techniques, such as natural ventilation and shading, can significantly reduce the reliance on mechanical cooling systems, especially in regions with favorable climates.

Examples of Sustainable Refrigeration and Air Conditioning Technologies

- Supermarkets Using CO2 Refrigeration: Many supermarkets have adopted CO2 refrigeration systems, which offer high energy efficiency and low environmental impact. CO2 is a natural refrigerant with zero ozone depletion potential and a low GWP. These systems are often combined with heat recovery systems to further improve energy efficiency.

- Data Centers Using Free Cooling: Data centers, which require significant cooling capacity, are increasingly utilizing free cooling techniques. These systems use outdoor air for cooling when temperatures are low enough, reducing reliance on mechanical cooling systems and saving energy.

- Residential Buildings with Geothermal Heat Pumps: Geothermal heat pumps utilize the constant temperature of the earth to provide heating and cooling. These systems offer high energy efficiency and a reduced environmental impact compared to traditional HVAC systems.

Refrigerants and Their Properties

Refrigerants are the heart of refrigeration and air conditioning systems, responsible for absorbing heat from the refrigerated space and transferring it to the environment. Understanding the properties of different refrigerants is crucial for selecting the right one for a particular application and ensuring safe and efficient system operation.

Refrigerant Properties

Refrigerant properties play a critical role in determining their suitability for various applications. Key properties include:

- Boiling Point: The boiling point of a refrigerant determines its operating pressure and temperature range. A refrigerant with a lower boiling point will operate at lower pressures and temperatures, making it suitable for low-temperature applications like freezing.

- Specific Heat: The specific heat of a refrigerant represents its ability to absorb heat. Higher specific heat allows the refrigerant to absorb more heat per unit mass, enhancing system efficiency.

- Thermal Conductivity: Thermal conductivity measures the ability of a refrigerant to transfer heat. A higher thermal conductivity facilitates faster heat transfer, leading to better system performance.

- Vapor Pressure: Vapor pressure indicates the pressure exerted by a refrigerant in its vapor state. It influences the operating pressures within the refrigeration cycle.

- Flammability: Flammability refers to the ease with which a refrigerant can ignite and burn. Flammable refrigerants pose safety hazards and require careful handling.

- Toxicity: Toxicity describes the potential harm a refrigerant can cause if inhaled or absorbed. Non-toxic refrigerants are preferred for safety reasons.

- Ozone Depletion Potential (ODP): ODP measures a refrigerant’s potential to deplete the ozone layer. Refrigerants with high ODPs are harmful to the environment and have been phased out in many countries.

- Global Warming Potential (GWP): GWP indicates a refrigerant’s contribution to global warming. Refrigerants with high GWP values contribute significantly to climate change and are being replaced with more sustainable alternatives.

Environmental Impact of Refrigerants

The environmental impact of refrigerants has become a major concern due to their potential to contribute to ozone depletion and global warming.

- Ozone Depletion: Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were widely used in the past but were found to be major contributors to ozone depletion. These refrigerants have been phased out under the Montreal Protocol, an international treaty aimed at protecting the ozone layer.

- Global Warming: Hydrofluorocarbons (HFCs) are currently the most common refrigerants, but they have high GWP values, contributing significantly to climate change. The Kigali Amendment to the Montreal Protocol aims to phase out HFCs and transition to more climate-friendly alternatives.

Transition to Sustainable Alternatives

The transition to sustainable refrigerants is crucial for mitigating the environmental impact of refrigeration and air conditioning systems.

- Natural Refrigerants: Natural refrigerants, such as ammonia (NH3), carbon dioxide (CO2), hydrocarbons (HCs), and water (H2O), have zero or low ODP and GWP values. They are considered environmentally friendly and are increasingly being used in various applications.

- Synthetic Low-GWP Refrigerants: Some synthetic refrigerants have been developed with lower GWP values than traditional HFCs. These alternatives are still under development and their long-term environmental impact is being studied.

Comparison of Refrigerants

The following table compares the characteristics and applications of various refrigerants:

| Refrigerant | Chemical Formula | Boiling Point (°C) | ODP | GWP | Applications |

|---|---|---|---|---|---|

| R-12 (CFC) | CCl2F2 | -29.8 | 1.0 | 10900 | Phased out |

| R-22 (HCFC) | CHClF2 | -40.8 | 0.05 | 1810 | Phased out |

| R-134a (HFC) | CH2FCF3 | -26.1 | 0 | 1430 | Automotive air conditioning, residential and commercial refrigeration |

| R-410A (HFC blend) | HFC-32/HFC-125 | -51.4 | 0 | 2088 | Residential and commercial air conditioning |

| Ammonia (NH3) | NH3 | -33.3 | 0 | 0 | Industrial refrigeration, large-scale commercial refrigeration |

| Carbon Dioxide (CO2) | CO2 | -78.5 | 0 | 1 | Supermarkets, beverage cooling, industrial processes |

| Hydrocarbons (HCs) | Various | Varies | 0 | < 3 | Domestic refrigeration, heat pumps |

System Design and Installation

Designing and installing refrigeration and air conditioning systems is a crucial aspect of ensuring optimal performance, energy efficiency, and longevity. This process requires a comprehensive understanding of the system’s requirements, components, and installation procedures.

Key Considerations for System Design

The design phase involves determining the system’s capacity, selecting appropriate components, and ensuring proper layout and integration. Several factors influence system design:

- Cooling Load Calculation: This determines the system’s capacity required to maintain the desired temperature and humidity levels. It considers factors like building size, insulation, occupancy, and equipment heat loads.

- Refrigerant Selection: The chosen refrigerant should meet environmental regulations, have suitable thermodynamic properties, and be compatible with system components.

- Component Selection: The compressor, condenser, evaporator, and other components must be sized and selected based on the cooling load, operating conditions, and desired performance.

- System Layout and Piping: Proper layout and piping ensure efficient refrigerant flow, minimize pressure drops, and optimize system performance.

- Controls and Automation: The system should include controls for temperature, humidity, and other parameters, allowing for automated operation and energy optimization.

Installation Process

The installation process involves assembling and connecting system components, ensuring proper wiring, and commissioning the system for optimal operation. Here’s a step-by-step guide:

- Site Preparation: This involves clearing the installation area, preparing the foundation, and ensuring access for equipment and materials.

- Component Installation: The compressor, condenser, evaporator, and other components are installed in their designated locations, ensuring proper leveling and support.

- Piping and Wiring: Refrigerant lines and electrical wiring are installed according to the system design, ensuring proper connections and insulation.

- System Commissioning: This involves starting the system, checking for leaks, and verifying proper operation.

- Performance Testing: The system is tested to ensure it meets the design specifications and provides the desired cooling capacity.

System Maintenance and Troubleshooting

Regular maintenance is essential for ensuring optimal performance, extending system life, and preventing costly repairs. Troubleshooting helps identify and resolve any operational issues.

- Preventive Maintenance: This includes regular inspections, cleaning, and lubrication of system components, such as filters, coils, and fans.

- Troubleshooting Techniques: Common troubleshooting methods include checking refrigerant levels, identifying leaks, examining control settings, and verifying electrical connections.

- Maintenance Records: Keeping detailed records of maintenance activities helps track system performance and identify potential issues.

Emerging Technologies and Future Trends

The field of refrigeration and air conditioning is constantly evolving, driven by the need for greater energy efficiency, environmental sustainability, and enhanced comfort. Recent advancements in technology are shaping the future of the industry, leading to innovative solutions that address these challenges. This chapter explores the latest trends in refrigeration and air conditioning technology, including the integration of smart technologies and renewable energy sources.

Integration of Smart Technologies

The integration of smart technologies is transforming the way refrigeration and air conditioning systems are designed, operated, and maintained. These technologies enhance system efficiency, improve comfort, and provide valuable data for optimizing performance.

- Smart Controllers: These controllers utilize advanced algorithms and sensors to monitor and adjust system performance in real-time, optimizing energy consumption and maintaining desired temperatures. They can also learn user preferences and adapt to changing conditions, such as outdoor temperature fluctuations. For example, smart controllers can automatically adjust the thermostat based on occupancy levels, ensuring optimal comfort while minimizing energy waste.

- Internet of Things (IoT): The IoT allows refrigeration and air conditioning systems to connect to the internet, enabling remote monitoring and control. This provides technicians with real-time data on system performance, allowing for proactive maintenance and early detection of potential issues. This data can also be used to identify areas for improvement and optimize system efficiency.

- Artificial Intelligence (AI): AI algorithms are being used to analyze data from sensors and predict system behavior, enabling proactive maintenance and reducing downtime. For instance, AI can be used to anticipate equipment failures and schedule maintenance before they occur, preventing costly repairs and disruptions. AI-powered systems can also optimize energy consumption by analyzing historical data and adjusting system settings based on real-time conditions.

Renewable Energy Sources

The use of renewable energy sources is becoming increasingly important in the refrigeration and air conditioning industry, as it reduces reliance on fossil fuels and minimizes environmental impact.

- Solar Power: Solar panels can be used to generate electricity to power refrigeration and air conditioning systems, reducing reliance on the grid and lowering energy costs. This is particularly beneficial in areas with abundant sunlight, where solar power can provide a significant portion of the energy needs.

- Geothermal Energy: Geothermal heat pumps use the stable temperature of the earth to provide heating and cooling. These systems are highly efficient and environmentally friendly, as they utilize a renewable energy source. Geothermal energy can be used to power refrigeration and air conditioning systems in both residential and commercial buildings.

- Wind Power: In areas with strong winds, wind turbines can generate electricity to power refrigeration and air conditioning systems. This is a sustainable option for reducing carbon emissions and lowering energy costs.

Outcome Summary

Refrigeration and Air Conditioning Technology 8th Edition offers a comprehensive and engaging exploration of the principles, components, applications, and future trends in this essential field. By understanding the complexities of cooling systems, readers gain valuable insights into the technologies that shape our modern world and the crucial role they play in our daily lives. Whether you are a student, a professional, or simply curious about the science behind keeping things cool, this book provides a wealth of knowledge and insights.

Refrigeration and air conditioning technology is a rapidly evolving field, and the 8th edition of the textbook reflects the latest advancements. As you delve into the intricacies of this field, you might find yourself needing to reward your students or colleagues with a thoughtful gift.

Consider technology corporate gifts that align with their interests, such as a smart thermostat or a portable air purifier, to further enhance their understanding and appreciation of the world of refrigeration and air conditioning.