Custom Wire Technologies: Shaping Industries

Custom wire technologies are revolutionizing industries by offering tailored solutions that meet specific needs. From aerospace and automotive to electronics and medical devices, these wires play a critical role in […]

Custom wire technologies are revolutionizing industries by offering tailored solutions that meet specific needs. From aerospace and automotive to electronics and medical devices, these wires play a critical role in ensuring optimal performance and reliability. Unlike standard wires, custom wires are engineered to withstand demanding environments, operate at precise temperatures, and deliver superior electrical conductivity. This flexibility allows for the creation of innovative products that push the boundaries of what’s possible.

The journey of custom wire technologies begins with a deep understanding of the application. Designers and engineers meticulously select materials, wire gauges, and insulation to create a solution that meets specific requirements. The manufacturing process is equally crucial, involving techniques like drawing, stranding, and coating to achieve the desired properties. This intricate process ensures that custom wires deliver the reliability and longevity needed for demanding applications.

Introduction to Custom Wire Technologies

Custom wire technologies refer to the design and manufacture of wires and cables tailored to specific applications and requirements. These technologies are crucial in various industries, enabling the creation of wires that meet unique performance, environmental, and safety standards.

Custom wire technologies offer a wide range of advantages over standard wire options, including:

Benefits of Custom Wire Technologies

Custom wire technologies provide several benefits that make them ideal for various applications. These benefits include:

- Enhanced Performance: Custom wires can be designed to meet specific performance requirements, such as increased conductivity, improved flexibility, and enhanced resistance to environmental factors. For example, a custom wire with high-temperature insulation could be used in applications like automotive wiring, where high temperatures are common.

- Improved Reliability: Custom wire technologies allow for the selection of materials and manufacturing processes that ensure optimal reliability and longevity. This is crucial in critical applications where failure could lead to significant consequences.

- Cost Optimization: While custom wires may have a higher initial cost compared to standard options, they can lead to cost savings in the long run by reducing maintenance, downtime, and replacement costs.

- Compliance with Standards: Custom wires can be designed to meet specific industry standards and regulations, ensuring compliance and safety in various applications.

Design and Engineering Considerations

Custom wire technologies demand meticulous design and engineering to ensure optimal performance, reliability, and safety. This involves a careful selection of materials, precise wire gauge calculations, and appropriate insulation choices, all guided by fundamental engineering principles.

Material Selection

Material selection is crucial in custom wire design. The choice of materials depends on factors like the application’s environment, electrical properties, and mechanical requirements.

- Conductors: Copper and aluminum are commonly used due to their excellent conductivity. However, specific applications may require other materials like silver, gold, or nickel-plated copper for improved conductivity or resistance to corrosion.

- Insulation: Insulation materials protect the conductor and prevent short circuits. Factors like temperature resistance, chemical resistance, and dielectric strength influence insulation selection. Common insulation materials include PVC, Teflon, and silicone rubber.

Wire Gauge

Wire gauge refers to the diameter of a wire, directly impacting its current carrying capacity and resistance.

- Ampacity: The current carrying capacity of a wire is determined by its gauge. Higher gauge numbers indicate smaller wire diameters and lower ampacity.

- Voltage Drop: Thicker wires (lower gauge numbers) have lower resistance, minimizing voltage drop over long distances.

The wire gauge selection should consider the intended current flow and the acceptable voltage drop for the application.

Insulation

Insulation plays a vital role in custom wire design, ensuring electrical isolation and protection.

- Dielectric Strength: Insulation must withstand the voltage applied to the wire without breaking down. This property is crucial for safety and reliable operation.

- Temperature Resistance: The insulation must withstand the operating temperature of the wire. High-temperature applications require insulation materials like Teflon or silicone rubber.

- Chemical Resistance: The insulation must resist chemicals and solvents present in the application environment.

Engineering Principles

Engineering principles are fundamental to custom wire design. They ensure the wire’s performance, reliability, and safety.

- Ohm’s Law: This law governs the relationship between voltage, current, and resistance. It is crucial for calculating wire gauge and voltage drop.

- Kirchhoff’s Laws: These laws describe the flow of current and voltage in electrical circuits, guiding the design of complex wire systems.

- Electromagnetism: Understanding electromagnetic principles is essential for designing wires that minimize interference and ensure proper operation in electromagnetically sensitive environments.

Design Challenges

Custom wire design often presents unique challenges.

- Space Constraints: Limited space can restrict wire diameter and require innovative solutions like miniaturized wires or flexible cable designs.

- Extreme Temperatures: Applications involving high or low temperatures require specialized materials and insulation that can withstand extreme conditions.

- Environmental Factors: Harsh environments like corrosive atmospheres or high humidity require specific materials and coatings to protect the wire from damage.

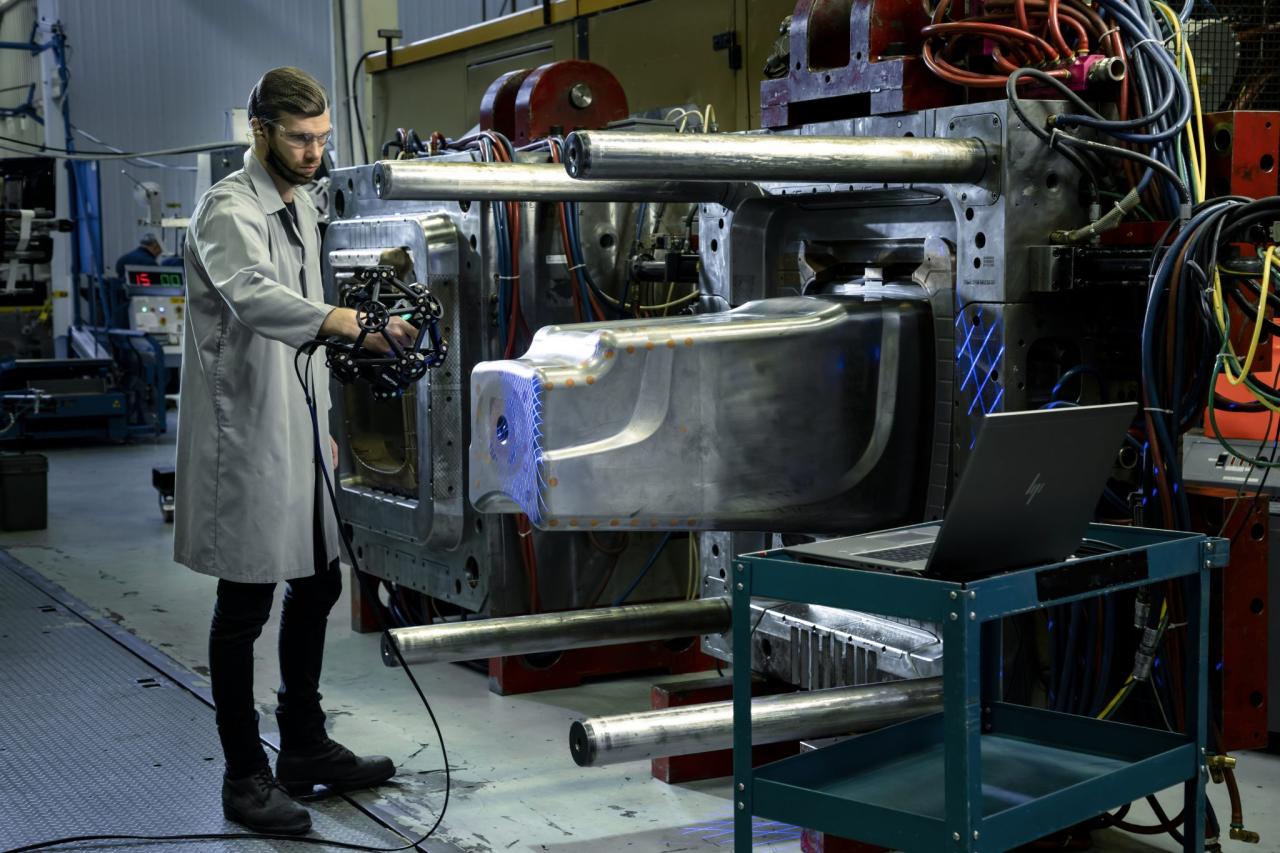

Manufacturing Processes and Techniques

The creation of custom wire technologies involves a diverse range of manufacturing processes, each tailored to specific wire types and desired properties. Understanding these processes is crucial for selecting the appropriate method for a given application. This section explores the different manufacturing processes involved in custom wire production, highlighting their unique characteristics and suitability for various wire types. Additionally, we will compare and contrast traditional and advanced manufacturing techniques used in custom wire production.

Traditional Wire Drawing

Traditional wire drawing is a fundamental process in custom wire manufacturing. It involves pulling a metal rod through a series of dies of progressively smaller diameters, reducing the cross-sectional area and increasing the length of the wire. This process is used to produce wires with precise diameters and controlled surface finishes.

Process Description

The process begins with a metal rod, known as the billet, which is heated to a specific temperature to improve its ductility. The billet is then fed through a die, a hardened steel tool with a precisely shaped opening. As the billet passes through the die, it is pulled by a drawbench, a machine that provides the necessary force for the drawing process. The die reduces the diameter of the billet, and the process is repeated with progressively smaller dies to achieve the desired wire diameter.

Advantages

- High precision in wire diameter control

- Ability to produce wires with various cross-sectional shapes

- Relatively low cost compared to other processes

Disadvantages

- Limited to ductile materials

- Can introduce surface defects or imperfections

- Not suitable for producing wires with complex geometries

Extrusion

Extrusion is a process used to create wires with complex cross-sectional shapes or to produce wires from materials that are difficult to draw. In extrusion, a metal billet is forced through a die with a specific shape, creating a wire with the desired cross-section.

Process Description

The extrusion process begins with a metal billet that is heated to a specific temperature. The billet is then placed in a container called a press. A ram is then used to force the billet through a die with the desired shape. The die acts as a mold, shaping the metal as it exits the press.

Advantages

- Suitable for producing wires with complex cross-sectional shapes

- Can be used for materials that are difficult to draw

- Can produce wires with uniform properties

Disadvantages

Advanced Manufacturing Techniques

Recent advancements in manufacturing technologies have introduced new techniques for custom wire production, offering greater flexibility and control. These techniques include:

Electroforming

Electroforming is an advanced manufacturing technique used to create custom wire technologies with intricate geometries and high precision. It involves depositing a thin layer of metal onto a conductive substrate through an electrolytic process. The deposited metal layer forms the desired wire shape, allowing for the creation of complex and highly precise structures.

Process Description

The electroforming process begins with a mandrel, a non-conductive substrate with the desired wire shape. The mandrel is then coated with a thin layer of conductive material, such as a metal film. The mandrel is then immersed in an electrolytic bath containing a solution of the desired metal ions. By applying an electric current, the metal ions are attracted to the mandrel and deposit onto its surface, forming a thin layer of metal. This process is repeated until the desired thickness of the wire is achieved.

Advantages

- High precision and intricate geometry

- Suitable for producing wires with complex shapes and fine features

- Can produce wires with specific surface properties

Disadvantages

3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that has emerged as a viable option for producing custom wire technologies. It involves building up a three-dimensional object layer by layer, using a computer-aided design (CAD) model as a blueprint.

Process Description

The 3D printing process starts with a CAD model of the desired wire shape. This model is then sliced into thin layers. The printing process then uses a material deposition method to build up the wire layer by layer, following the CAD model. Different 3D printing technologies, such as fused deposition modeling (FDM) and selective laser melting (SLM), employ different material deposition methods.

Advantages

- High design flexibility and customization

- Ability to produce complex and intricate wire shapes

- Reduced material waste compared to traditional methods

Disadvantages

Applications and Industries

Custom wire technologies find applications across a wide range of industries, where their unique properties and capabilities are crucial for optimizing performance and meeting specific needs.

Custom wires are tailored to meet specific requirements and offer advantages in various applications. The following sections delve into some of the key industries where custom wire technologies play a vital role, highlighting the unique needs of each sector and how custom solutions address them.

Aerospace

Custom wires are essential in the aerospace industry due to the demanding conditions they face, including extreme temperatures, high vibration, and weight restrictions.

- High-Temperature Wires: Aircraft engines operate at extremely high temperatures, requiring wires capable of withstanding these conditions without degradation. Custom wires with high-temperature insulation materials, such as silicone rubber or Teflon, are used in engine wiring harnesses and sensors.

- Lightweight Wires: Minimizing weight is critical in aerospace applications to improve fuel efficiency and performance. Custom wires made with lightweight materials, like aluminum or silver-plated copper, are used in aircraft wiring systems and avionics.

- Vibration-Resistant Wires: Aircraft are subjected to constant vibrations during flight, necessitating wires that can withstand these forces without failure. Custom wires with reinforced insulation and shielding are employed in critical applications, ensuring reliable signal transmission.

Automotive

The automotive industry relies heavily on custom wire technologies for various components and systems, driven by the need for enhanced performance, reliability, and safety.

- High-Voltage Wires: Hybrid and electric vehicles utilize high-voltage systems for battery charging and motor operation. Custom wires with specialized insulation and shielding are required to handle the high voltages and currents involved safely.

- Sensor Wires: Modern vehicles are equipped with numerous sensors that monitor engine performance, vehicle speed, and other critical parameters. Custom wires with high-flexibility and resistance to chemicals are used to connect these sensors to the control units.

- Automotive Lighting: LED lighting is increasingly prevalent in vehicles, demanding wires with low resistance and high current-carrying capacity. Custom wires with specialized conductors and insulation are used to ensure efficient and reliable lighting operation.

Medical Devices

The medical device industry requires custom wires that meet stringent standards for biocompatibility, reliability, and safety.

- Biocompatible Wires: Implantable medical devices, such as pacemakers and defibrillators, require wires that are biocompatible and do not cause adverse reactions in the body. Custom wires made with materials like platinum, titanium, or medical-grade silicone are used in these applications.

- Miniaturized Wires: Medical devices are often miniaturized to reduce invasiveness and improve patient comfort. Custom wires with small diameters and flexible insulation are used in applications like catheters, endoscopes, and surgical instruments.

- High-Frequency Wires: Some medical devices, such as MRI machines and diagnostic equipment, operate at high frequencies. Custom wires with low impedance and minimal signal loss are required to ensure accurate data transmission.

Electronics

The electronics industry uses custom wires extensively for connecting various components and systems, driven by the need for high performance, miniaturization, and reliability.

- High-Speed Data Wires: Modern electronic devices rely on high-speed data transmission for applications like internet browsing, video streaming, and gaming. Custom wires with low capacitance and inductance are used to minimize signal distortion and ensure fast data transfer.

- Flexible Wires: Portable electronic devices, such as smartphones and tablets, require wires that are flexible and durable. Custom wires with thin insulation and high-flexibility are used in these applications.

- Shielded Wires: Electronic devices are susceptible to electromagnetic interference (EMI) from external sources. Custom wires with shielding layers are used to minimize EMI and ensure signal integrity.

Future Trends and Innovations: Custom Wire Technologies

The realm of custom wire technologies is constantly evolving, driven by advancements in materials science, manufacturing processes, and emerging applications. This dynamism paves the way for exciting innovations that are poised to reshape various industries and redefine the possibilities of wire-based solutions.

Advancements in Materials Science

The development of novel materials with enhanced properties is a key driver of innovation in custom wire technologies. These advancements enable the creation of wires with superior electrical conductivity, thermal resistance, strength, flexibility, and corrosion resistance.

- High-Temperature Superconductors: Superconducting wires, capable of conducting electricity with zero resistance at extremely low temperatures, are poised to revolutionize power transmission and energy storage. These materials hold immense potential for applications in high-speed trains, magnetic levitation systems, and advanced medical imaging.

- Nanowires: Nanowires, with their exceptional surface area and unique electrical and optical properties, are finding applications in electronics, sensors, and energy harvesting. The miniaturization enabled by nanowires opens up new possibilities for smaller, more efficient devices.

- Shape Memory Alloys: Shape memory alloys (SMAs) exhibit the remarkable ability to return to their original shape after deformation. This property makes them ideal for use in actuators, sensors, and biomedical devices. SMAs can be incorporated into custom wires to create self-healing or adaptive structures.

Advanced Manufacturing Processes

The evolution of manufacturing processes is playing a pivotal role in pushing the boundaries of custom wire technologies. These advancements enable the production of wires with greater precision, complexity, and efficiency.

- Additive Manufacturing (3D Printing): 3D printing is revolutionizing the production of custom wires by allowing for the creation of complex geometries and intricate designs. This technology enables the fabrication of wires with integrated sensors, actuators, and other functionalities, opening up new possibilities for smart and responsive systems.

- Micro-Extrusion: Micro-extrusion techniques allow for the production of wires with extremely small diameters and precise cross-sections. This capability is crucial for the development of microelectronics, nanotechnology, and advanced medical devices.

- Laser-Based Processing: Laser-based techniques are employed for precise wire cutting, welding, and surface modification. These processes enhance the performance and reliability of custom wires, enabling the creation of high-precision components for demanding applications.

Emerging Applications, Custom wire technologies

The innovations in custom wire technologies are driving the development of groundbreaking applications across diverse industries. These advancements are transforming the way we live, work, and interact with the world around us.

- Smart Grids: Custom wires with integrated sensors and communication capabilities are essential for the development of smart grids. These systems enable real-time monitoring and control of power distribution, enhancing efficiency and reliability while reducing energy waste.

- Wearable Electronics: The miniaturization and flexibility of custom wires are key to the development of wearable electronics. These devices, including smartwatches, fitness trackers, and medical sensors, are revolutionizing healthcare, fitness, and communication.

- Robotics and Automation: Custom wires with high strength, flexibility, and conductivity are critical components of advanced robotics and automation systems. These wires enable the development of robots with greater dexterity, precision, and responsiveness.

Wrap-Up

As industries continue to evolve, the demand for custom wire technologies will only increase. The ability to create bespoke solutions that meet specific needs is essential for driving innovation and pushing the boundaries of what’s possible. From advancements in materials science to the development of new manufacturing techniques, the future of custom wire technologies is bright, promising even more innovative solutions for a wide range of industries.

Custom wire technologies are essential in a wide range of applications, from intricate electronics to everyday devices. One area where custom wire solutions are particularly valuable is in the development of pet technology products , ensuring reliable and safe connections for innovative features like automated feeders and interactive toys.

By tailoring wire specifications to specific needs, custom wire technologies contribute to the advancement of pet technology and enhance the lives of both pets and their owners.