Metal Technologies Ravenna: A Legacy of Innovation

Metal Technologies Ravenna stands as a testament to the enduring legacy of craftsmanship and innovation. The city has long been a hub for metalworking, its history interwoven with the rise […]

Metal Technologies Ravenna stands as a testament to the enduring legacy of craftsmanship and innovation. The city has long been a hub for metalworking, its history interwoven with the rise and fall of empires. Today, Ravenna’s metal technology sector thrives, boasting a diverse range of industries, cutting-edge research, and a commitment to sustainability. From ancient shipyards to modern manufacturing plants, the city’s metalworking heritage continues to shape its future.

This exploration delves into the rich tapestry of metal technologies in Ravenna, examining its historical roots, current state, and future prospects. We’ll uncover the key players, explore the innovations driving progress, and analyze the trends shaping the industry’s trajectory.

Metal Technologies in Ravenna: Metal Technologies Ravenna

Ravenna, a city steeped in history and culture, boasts a rich heritage in metalworking that spans centuries. From ancient Roman times to the present day, the city has been a hub for skilled artisans and innovative industries, leaving an enduring mark on the landscape of metal technologies.

Historical Overview of Metalworking in Ravenna

Ravenna’s metalworking legacy dates back to the Roman era, when the city was a major center for trade and manufacturing. Skilled artisans produced a wide range of metal objects, from everyday tools to intricate jewelry and decorative items. The city’s strategic location on the Adriatic coast facilitated the import of raw materials and the export of finished goods, contributing to its economic prosperity.

During the Byzantine period, Ravenna’s metalworking traditions continued to flourish. The city’s artisans were renowned for their expertise in goldsmithing, creating exquisite works of art that adorned churches and palaces. The legacy of this period is evident in the intricate mosaics and gold-leaf decorations that adorn Ravenna’s iconic monuments.

The Middle Ages saw the emergence of specialized workshops and guilds, further solidifying Ravenna’s position as a center for metalworking. The city’s artisans played a vital role in the production of weapons, armor, and other essential goods for local communities and beyond.

Current State of Metal Technologies in Ravenna

Ravenna’s metal technology sector continues to thrive in the 21st century, with a strong focus on innovation and specialization. The city is home to a diverse range of companies operating in various sectors, including:

- Automotive: Ravenna’s proximity to the automotive hub of Bologna has fostered a strong presence of metalworking companies specializing in the production of components for cars, motorcycles, and other vehicles. These companies employ advanced technologies to create high-precision parts, contributing to the efficiency and performance of modern vehicles.

- Aerospace: The city’s metalworking expertise has also found application in the aerospace industry. Companies in Ravenna specialize in the production of lightweight and durable components for aircraft, satellites, and other aerospace applications. This sector leverages cutting-edge technologies and stringent quality control standards to ensure the safety and reliability of these critical components.

- Mechanical Engineering: Ravenna’s metalworking companies also play a crucial role in the broader mechanical engineering sector. They provide a wide range of services, including design, manufacturing, and assembly of machinery, equipment, and tooling for various industries. This sector benefits from the city’s skilled workforce and its expertise in precision engineering and metal fabrication.

Research Institutions and Specialized Industries

Ravenna is also home to several research institutions and specialized industries that contribute to the advancement of metal technologies. These institutions foster innovation and collaboration, ensuring that the city remains at the forefront of technological development.

- The University of Bologna’s Ravenna campus plays a key role in research and development related to metal technologies. The university’s engineering faculty conducts research on advanced materials, manufacturing processes, and sustainable production methods, contributing to the development of new and innovative metal technologies.

- The National Research Council (CNR) has a research center in Ravenna that focuses on materials science and engineering. The center conducts research on the properties and behavior of metals, developing new alloys and processing techniques that enhance the performance and durability of metal components.

- The Emilia-Romagna Region’s Technological Innovation Agency (ARTES 4.0) supports the development and adoption of advanced technologies in the region, including metalworking. ARTES 4.0 provides resources and expertise to companies in Ravenna, helping them to implement Industry 4.0 technologies and enhance their competitiveness.

Unique Characteristics and Strengths of Ravenna’s Metal Technology Sector

Ravenna’s metal technology sector is characterized by a number of unique strengths and advantages, contributing to its continued success and growth. These include:

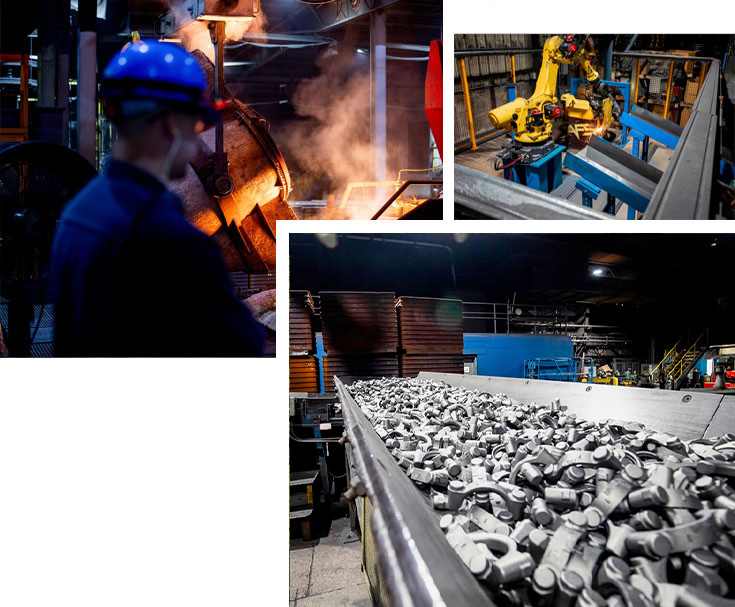

- A strong tradition of craftsmanship and expertise: Ravenna’s long history of metalworking has fostered a skilled workforce with a deep understanding of traditional techniques and modern technologies. This combination of experience and innovation enables the city’s metalworking companies to produce high-quality products that meet the demanding requirements of various industries.

- A focus on specialization and niche markets: Rather than competing in mass production, Ravenna’s metalworking companies have chosen to specialize in specific sectors and niche markets. This strategy allows them to develop expertise and offer customized solutions that cater to the unique needs of their clients.

- A commitment to innovation and technological advancement: Ravenna’s metalworking companies are constantly seeking ways to improve their processes and products. They invest in research and development, collaborate with universities and research institutions, and adopt new technologies to stay ahead of the curve. This commitment to innovation ensures that Ravenna’s metal technology sector remains competitive and relevant in the global marketplace.

Key Metalworking Industries in Ravenna

Ravenna, a city steeped in history and culture, also boasts a thriving metalworking industry. This sector plays a pivotal role in the local economy, contributing significantly to employment and technological advancement.

Metalworking Industries in Ravenna

The metalworking industry in Ravenna is diverse, encompassing various sectors, each with its own unique characteristics and contributions.

- Automotive: This sector is a significant contributor to Ravenna’s economy, with several major players specializing in the production of automotive components. These companies utilize advanced manufacturing techniques and technologies to produce high-quality parts for both domestic and international markets.

- Machinery: Ravenna is home to a range of machinery manufacturers, specializing in the production of equipment for various industries, including agriculture, construction, and manufacturing. These companies often integrate cutting-edge technologies to enhance the efficiency and performance of their products.

- Aerospace: This sector, while smaller in size compared to others, is gaining momentum in Ravenna. Companies specializing in aerospace components are leveraging their expertise and advanced manufacturing capabilities to meet the growing demand for high-precision parts in the aerospace industry.

- Shipbuilding: Ravenna’s strategic location on the Adriatic Sea has fostered a significant shipbuilding industry. Companies in this sector specialize in the construction and repair of various types of vessels, including cargo ships, tankers, and ferries.

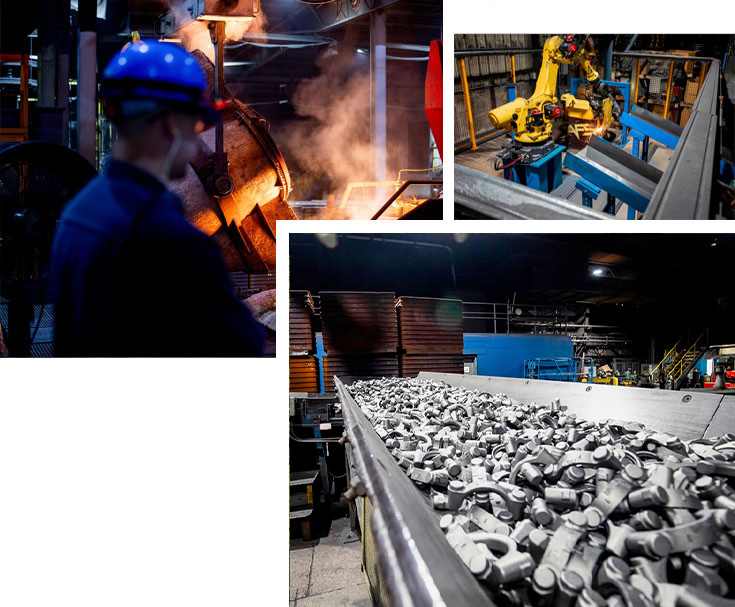

- Metal Processing: This sector encompasses a wide range of activities, including metal casting, forging, and machining. Companies in this sector provide essential services to other industries, supplying raw materials and components for various applications.

Key Players in the Metalworking Industry

| Industry | Key Players | Size (Employees) | Areas of Specialization |

|---|---|---|---|

| Automotive |

|

|

|

| Machinery |

|

|

|

| Aerospace |

|

|

|

| Shipbuilding |

|

|

|

| Metal Processing |

|

|

|

Technological Advancements and Market Share

Ravenna’s metalworking industries are known for their adoption of advanced technologies, which has allowed them to remain competitive in the global market. Companies in this sector invest heavily in research and development, focusing on areas such as automation, robotics, and digital manufacturing. These technological advancements have enabled them to improve efficiency, reduce costs, and enhance product quality.

Environmental Impact

The metalworking industry in Ravenna is committed to sustainable practices, recognizing the importance of minimizing its environmental impact. Companies in this sector are actively implementing initiatives to reduce energy consumption, minimize waste generation, and improve resource efficiency. They are also investing in cleaner technologies and processes to reduce emissions and pollution.

Innovation and Research in Metal Technologies

Ravenna’s metal technology sector is not only thriving on its established industries but also actively engaging in innovation and research, pushing the boundaries of metalworking. Research institutions and universities play a pivotal role in this advancement, fostering a culture of innovation and driving the development of cutting-edge technologies.

Research Institutions and Universities

Ravenna boasts a strong network of research institutions and universities dedicated to advancing metal technologies. These institutions serve as hubs for collaboration between academia, industry, and government, driving innovation and development.

- The University of Bologna’s Ravenna campus, with its Department of Industrial Engineering, is a key player in research related to advanced manufacturing processes, materials science, and sustainability in metalworking.

- The National Research Council (CNR) has a research institute in Ravenna focusing on materials science and technology, with a specific focus on developing new alloys and coatings for improved performance and durability in metal components.

- The Polytechnic University of Marche, with its strong engineering programs, collaborates with local metalworking companies on research projects, particularly in the field of additive manufacturing and digitalization of production processes.

Cutting-Edge Research Projects

Research institutions and universities in Ravenna are actively involved in a wide range of cutting-edge research projects, pushing the boundaries of metalworking technologies.

- Materials Science: Researchers are developing new alloys with enhanced properties, such as high strength-to-weight ratios, improved corrosion resistance, and better thermal conductivity. These advancements are crucial for applications in aerospace, automotive, and energy sectors. For example, the CNR institute in Ravenna is developing novel titanium alloys for use in aerospace applications, focusing on reducing weight and improving fatigue resistance.

- Manufacturing Processes: Research focuses on developing innovative manufacturing processes, such as additive manufacturing (3D printing) and laser-based processing, to create complex metal components with improved precision and efficiency. Researchers are also exploring the use of robotics and automation to enhance productivity and reduce costs in metalworking. The University of Bologna’s Ravenna campus is actively researching the application of laser-based processing for creating intricate metal components, particularly for use in medical devices and tooling.

- Sustainability: Research efforts are directed towards developing sustainable metalworking practices, reducing environmental impact, and promoting resource efficiency. This includes research on recycling and reusing metal materials, developing cleaner production processes, and exploring the use of renewable energy sources in metalworking operations. The Polytechnic University of Marche is actively researching the development of sustainable metalworking processes, including the use of recycled materials and the implementation of energy-efficient technologies in manufacturing.

Impact of Innovation and Research

Innovation and research have a significant impact on the competitiveness of Ravenna’s metal technology sector.

- Enhanced Product Performance: Research and development of new materials and manufacturing processes lead to the creation of high-performance metal components with improved durability, strength, and functionality, giving Ravenna’s metalworking companies a competitive edge in global markets.

- Increased Efficiency and Productivity: Innovative manufacturing processes, such as additive manufacturing and automation, contribute to increased efficiency and productivity, reducing production costs and lead times. This allows Ravenna’s metalworking companies to respond quickly to market demands and remain competitive.

- Sustainable Practices: Research into sustainable metalworking practices helps Ravenna’s metal technology sector reduce its environmental impact, promote resource efficiency, and comply with increasingly stringent environmental regulations. This fosters a responsible and sustainable approach to manufacturing, enhancing the sector’s reputation and competitiveness.

The Future of Metal Technologies in Ravenna

Ravenna’s metalworking industry, with its rich history and expertise, stands at the cusp of a transformative era. The future of metal technologies in Ravenna is intricately linked to global trends in manufacturing, automation, and sustainability. The city’s metalworking sector has the potential to embrace these trends and emerge as a leader in innovative and sustainable metal production.

Impact of Automation and Digitalization

Automation and digitalization are reshaping the manufacturing landscape, and Ravenna’s metalworking industry is not immune to this transformation. The adoption of robotics, artificial intelligence (AI), and advanced data analytics can enhance efficiency, productivity, and precision in metalworking processes.

- Robotics and Automation: The integration of robots in manufacturing processes can automate repetitive tasks, improve accuracy, and enhance safety. This can free up human workers to focus on more complex and strategic tasks, ultimately leading to increased productivity and efficiency.

- Digitalization and Data Analytics: The adoption of digital technologies, such as Internet of Things (IoT) sensors and data analytics platforms, can provide real-time insights into manufacturing processes, allowing for optimization and predictive maintenance. This data-driven approach can lead to improved quality control, reduced downtime, and enhanced resource utilization.

Challenges and Opportunities

The transition to a more automated and digitalized metalworking industry presents both challenges and opportunities for Ravenna.

- Upskilling and Reskilling Workforce: The adoption of automation and digital technologies will require a skilled workforce capable of operating and maintaining these advanced systems. This necessitates investment in education and training programs to upskill and reskill the existing workforce.

- Investment in Infrastructure and Technology: Implementing automation and digitalization requires significant investment in new equipment, software, and infrastructure. This can be a challenge for smaller businesses, requiring access to funding and support mechanisms.

- Collaboration and Innovation: To stay ahead of the curve, Ravenna’s metalworking industry needs to foster collaboration among businesses, research institutions, and government agencies. This collaborative approach can facilitate knowledge sharing, innovation, and the development of new technologies.

Strategies for Sustainable Growth, Metal technologies ravenna

Ravenna’s metalworking industry can achieve sustainable growth by embracing circular economy principles, promoting resource efficiency, and reducing environmental impact.

- Circular Economy Principles: The adoption of circular economy principles, such as waste reduction, material reuse, and product lifecycle management, can minimize environmental impact and create a more sustainable manufacturing model.

- Resource Efficiency: Investing in technologies and processes that improve resource efficiency, such as energy-efficient machinery and water-saving techniques, can reduce operational costs and minimize environmental footprint.

- Sustainable Materials: The use of sustainable materials, such as recycled metals and bio-based materials, can further reduce environmental impact and promote a circular economy.

Examples of Initiatives

Ravenna has already taken steps to promote innovation and sustainability in its metalworking industry.

- The establishment of research and development centers, such as the “Centro di Ricerca per le Tecnologie Metallurgiche” (Research Center for Metallurgical Technologies), has fostered collaboration and innovation in the metalworking sector.

- The development of industrial parks, such as the “Polo Tecnologico di Ravenna” (Ravenna Technological Park), has provided a platform for businesses to collaborate, share resources, and develop new technologies.

- The implementation of green manufacturing initiatives, such as the “Green Industry Pact” (Patto per l’Industria Verde), has encouraged businesses to adopt sustainable practices and reduce their environmental impact.

Final Wrap-Up

Ravenna’s metal technology sector is a vibrant ecosystem poised for continued growth. With its deep-rooted history, robust infrastructure, and unwavering commitment to innovation, Ravenna is well-positioned to lead the way in the future of metalworking. The city’s ability to adapt to changing trends, embrace emerging technologies, and prioritize sustainability ensures its enduring relevance in the global marketplace.

Metal Technologies Ravenna specializes in advanced metalworking techniques, pushing the boundaries of innovation. While their focus is on the physical realm, their work often intersects with cutting-edge biological research, like that conducted by e-lab biological science & technology co.

ltd , a company known for its groundbreaking work in biomaterials. This collaboration between the two fields highlights the potential for transformative advancements in the future.