Air Flow Technology: Understanding and Applying the Science of Movement

Air flow technology, a fascinating field that explores the principles and applications of moving air, plays a vital role in various industries, from HVAC to aerospace. Understanding how air moves, […]

Air flow technology, a fascinating field that explores the principles and applications of moving air, plays a vital role in various industries, from HVAC to aerospace. Understanding how air moves, its characteristics, and the factors influencing its behavior is crucial for designing efficient, comfortable, and safe environments. This exploration delves into the fundamentals of airflow, its diverse applications, and the latest advancements shaping the future of this critical technology.

From the simple act of breathing to the complex dynamics of aircraft flight, air flow technology permeates our lives. Its principles govern the movement of air in buildings, vehicles, and even our bodies. Understanding these principles allows us to manipulate airflow for a variety of purposes, such as controlling temperature, optimizing ventilation, and enhancing performance.

Fundamentals of Airflow Technology

Airflow technology encompasses the study and application of principles governing the movement of air, which is essential in various fields, including HVAC systems, ventilation, and industrial processes. Understanding the fundamentals of airflow is crucial for designing and optimizing systems that efficiently transport air, ensuring comfort, safety, and optimal performance.

Basic Principles of Airflow

Airflow is the movement of air from one point to another, driven by pressure differences. The basic principles governing airflow include pressure, velocity, and volume.

- Pressure: Air pressure is the force exerted by air molecules on a given area. Air flows from areas of high pressure to areas of low pressure. The pressure difference, known as the pressure gradient, drives the airflow. For example, in a typical HVAC system, a fan creates a pressure difference between the supply and return air ducts, forcing air to flow through the system.

- Velocity: Air velocity is the speed at which air is moving. The velocity of airflow is directly proportional to the pressure difference. Higher pressure differences result in higher air velocities. For instance, in a wind tunnel, the velocity of airflow is controlled by adjusting the pressure difference between the inlet and outlet sections.

- Volume: Air volume is the amount of air moving through a given area per unit time. It is typically measured in cubic feet per minute (cfm) or cubic meters per second (m3/s). Air volume is directly proportional to both velocity and the cross-sectional area of the flow path. For example, a larger duct with the same air velocity will have a higher air volume compared to a smaller duct.

Types of Airflow

Airflow can be categorized into different types based on its flow characteristics. The three main types of airflow are laminar, turbulent, and transitional flow.

- Laminar flow: Laminar flow is characterized by smooth, orderly movement of air particles in parallel layers. This type of flow occurs at low velocities and in smooth flow paths with minimal turbulence. An example of laminar flow is the movement of air through a long, straight pipe at low speeds. It is often desirable in applications where smooth, predictable airflow is required, such as in cleanrooms or ventilation systems.

- Turbulent flow: Turbulent flow is characterized by chaotic, irregular movement of air particles, with mixing and eddies occurring throughout the flow path. This type of flow occurs at high velocities, in complex flow paths with obstacles, or when there are sudden changes in direction. An example of turbulent flow is the airflow around a moving car or through a fan with rotating blades. It is often undesirable in applications where smooth, predictable airflow is required, as it can lead to increased energy consumption and noise levels.

- Transitional flow: Transitional flow is a flow regime that exists between laminar and turbulent flow. It is characterized by both smooth and chaotic flow patterns, with some degree of turbulence present. This type of flow occurs in situations where the flow velocity or flow path geometry is transitioning between laminar and turbulent conditions. An example of transitional flow is the airflow through a partially obstructed pipe or a duct with a gradual change in cross-sectional area.

Factors Influencing Airflow

Several factors can influence the characteristics of airflow, including temperature, humidity, and obstacles.

- Temperature: Temperature affects the density of air, which in turn influences airflow. Warm air is less dense than cold air, meaning it will rise and create upward airflow. Conversely, cold air is denser and will sink, creating downward airflow. This principle is used in HVAC systems to create air circulation patterns.

- Humidity: Humidity, or the amount of moisture in the air, also affects air density. Humid air is denser than dry air, leading to slower airflow rates. This is why humidifiers are often used to increase air density and improve airflow in certain applications, such as in industrial processes involving drying or evaporation.

- Obstacles: Obstacles in the flow path can disrupt airflow patterns and create turbulence. This can occur due to building structures, furniture, or equipment. The presence of obstacles can lead to increased energy consumption and noise levels, and careful consideration should be given to their impact on airflow when designing ventilation or HVAC systems.

Applications of Airflow Technology

Airflow technology plays a crucial role in various industries, influencing everything from our comfort and safety to the efficiency of industrial processes. Its applications are diverse and essential for optimizing performance, ensuring safety, and enhancing the overall user experience.

HVAC Systems

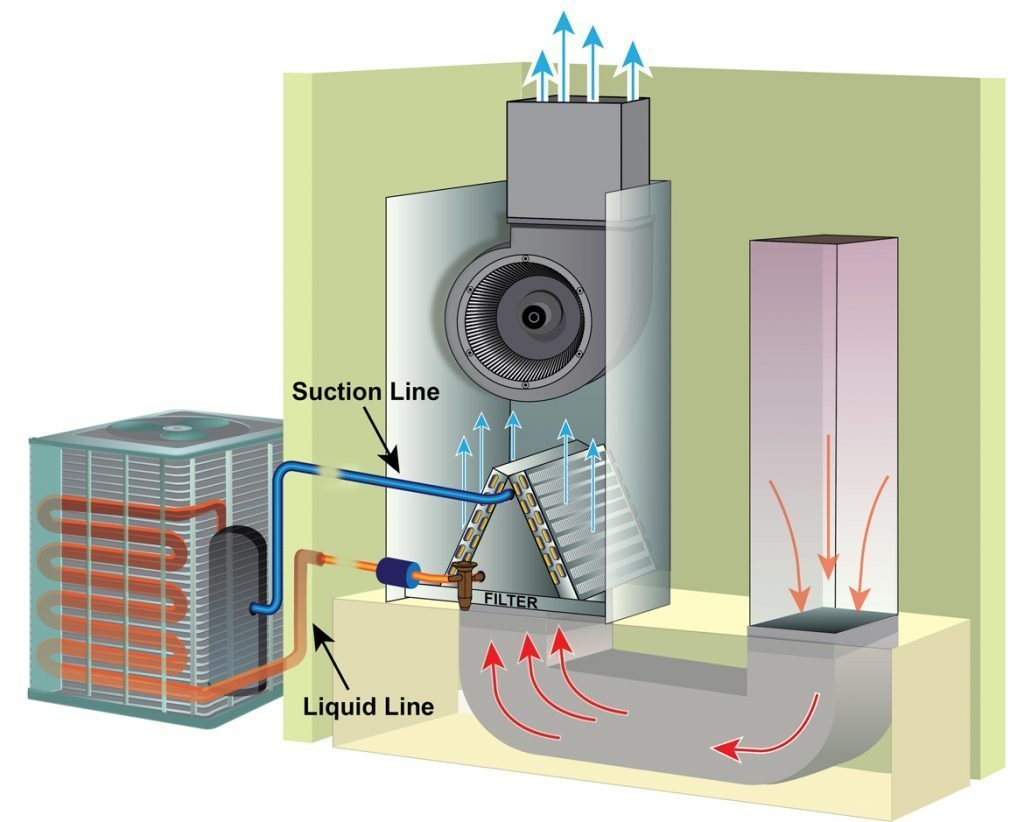

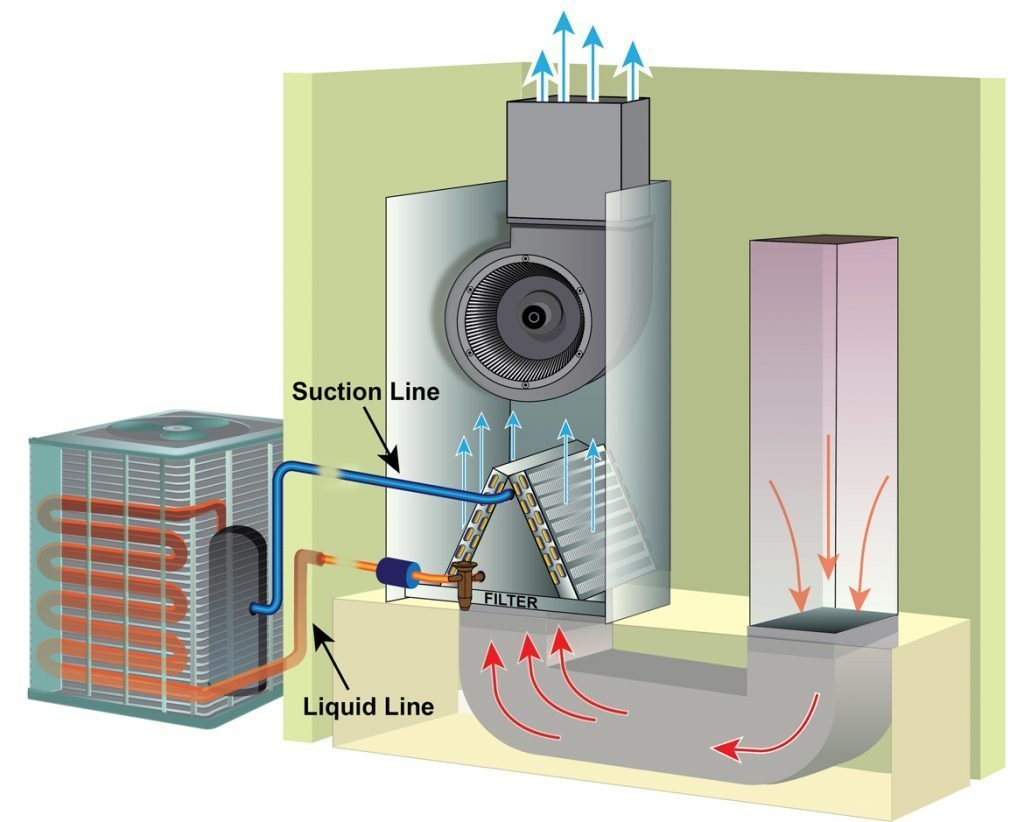

Airflow technology is fundamental to the design and operation of Heating, Ventilation, and Air Conditioning (HVAC) systems. The primary function of HVAC systems is to maintain comfortable indoor temperatures and air quality. Airflow technology plays a crucial role in this process, ensuring that air is circulated effectively, removing pollutants, and delivering conditioned air to the desired locations.

Here are some key aspects of airflow technology in HVAC:

- Air Distribution: Airflow technology is essential for effectively distributing conditioned air throughout a building. This involves designing ductwork and air diffusers that ensure even air distribution and minimize air drafts.

- Air Filtration: Airflow technology is critical for filtering out pollutants and allergens from the air. This is achieved by using filters within HVAC systems, which trap dust, pollen, and other airborne particles.

- Air Velocity Control: Airflow technology allows for the precise control of air velocity, ensuring that air is circulated efficiently and at a comfortable speed.

- Energy Efficiency: By optimizing airflow patterns and reducing air leakage, HVAC systems can significantly improve energy efficiency.

Automotive Applications

Airflow technology plays a critical role in automotive engineering, impacting the performance, fuel efficiency, and safety of vehicles.

- Aerodynamics: Airflow technology is used to optimize the aerodynamic design of vehicles, reducing drag and improving fuel efficiency. This involves shaping the vehicle’s body to minimize air resistance and create downforce, enhancing stability at high speeds.

- Engine Cooling: Airflow technology is crucial for cooling the engine and other components. This involves designing air intake and exhaust systems that efficiently circulate air, preventing overheating and ensuring optimal performance.

- Ventilation: Airflow technology is used to ensure proper ventilation within the vehicle cabin, providing fresh air and removing pollutants. This involves designing ventilation systems that effectively circulate air and prevent stagnation.

- Safety Features: Airflow technology is used in safety features such as airbags and windshields, ensuring optimal deployment and protection during collisions.

Aerospace Applications

Airflow technology is paramount in aerospace engineering, influencing the design, performance, and safety of aircraft.

- Aircraft Design: Airflow technology is used to design aircraft wings, fuselages, and other components to optimize lift, reduce drag, and enhance stability. This involves analyzing airflow patterns and using computational fluid dynamics (CFD) simulations to refine designs.

- Engine Performance: Airflow technology is critical for engine performance in aircraft, ensuring efficient combustion and thrust generation. This involves designing air intake and exhaust systems that maximize airflow and minimize turbulence.

- Flight Control: Airflow technology is used in flight control systems, such as flaps and spoilers, to adjust lift and drag during takeoff, landing, and maneuvering.

- Safety Features: Airflow technology is used in safety features such as emergency exits and evacuation systems, ensuring efficient and safe evacuation in case of emergencies.

Other Applications, Air flow technology

Airflow technology has applications in a wide range of other industries, including:

- Medical Devices: Airflow technology is used in medical devices such as ventilators and oxygen concentrators, delivering essential gases to patients.

- Industrial Processes: Airflow technology is used in industrial processes such as drying, cooling, and material handling, optimizing efficiency and reducing energy consumption.

- Agriculture: Airflow technology is used in greenhouses and other agricultural applications to control temperature, humidity, and airflow, improving crop yields and reducing pest infestations.

Airflow Measurement and Analysis

Understanding and quantifying airflow is crucial in various applications, from HVAC systems to aerodynamic designs. Airflow measurement and analysis techniques provide insights into airflow patterns, velocity, and pressure, enabling engineers to optimize system performance, ensure safety, and enhance efficiency.

Airflow Measurement Methods

Various methods are employed to measure airflow, each with its strengths and limitations.

- Anemometers: These devices measure the speed of air by detecting the rotation of a propeller or the change in resistance of a heated wire. Anemometers are commonly used for measuring airflow in ducts, ventilation systems, and open spaces.

- Pitot Tubes: Pitot tubes measure the stagnation pressure of airflow, which is the pressure that occurs when the air is brought to rest. By measuring the difference between stagnation pressure and static pressure, the velocity of airflow can be calculated. Pitot tubes are often used in applications requiring high accuracy, such as aircraft instrumentation and wind tunnel testing.

- Hot-Wire Anemometers: These devices measure the rate of heat loss from a heated wire, which is proportional to the speed of airflow. Hot-wire anemometers are highly sensitive and suitable for measuring turbulent and unsteady flows. They are commonly used in research and development, such as in wind tunnels and automotive testing.

- Thermal Anemometers: These devices measure airflow by detecting the change in temperature caused by the air moving past a heated element. Thermal anemometers are often used for measuring airflow in confined spaces, such as computer servers and electronic equipment.

- Ultrasonic Anemometers: These devices measure airflow by emitting and receiving ultrasonic waves. The time it takes for the waves to travel through the air is used to calculate the speed of airflow. Ultrasonic anemometers are non-intrusive and can measure airflow in a wide range of conditions, making them suitable for environmental monitoring and meteorological studies.

Airflow Analysis Techniques

Once airflow data is collected, various techniques are employed to analyze and interpret the results.

- Computational Fluid Dynamics (CFD) Simulations: CFD simulations are numerical models that solve the equations governing fluid flow. They allow engineers to predict airflow patterns, velocity, and pressure distribution in complex geometries. CFD simulations are widely used in various applications, such as aircraft design, HVAC system optimization, and wind turbine performance analysis.

Example: A CFD simulation of a building’s airflow can help architects and engineers optimize the design of ventilation systems to ensure adequate air circulation and minimize energy consumption.

- Experimental Testing: Experimental testing involves measuring airflow in real-world conditions using various instruments. This data can be used to validate CFD simulations and provide insights into the actual performance of systems. Experimental testing can involve wind tunnel experiments, field measurements, and laboratory tests.

Example: Wind tunnel experiments can be used to study the aerodynamic performance of vehicles and aircraft, providing valuable data for design optimization and performance improvement.

Key Parameters in Airflow Studies

Several key parameters are measured and analyzed in airflow studies to understand the characteristics of airflow.

- Velocity: The speed of airflow is a fundamental parameter that determines the rate of air movement. It is typically measured in meters per second (m/s) or feet per second (ft/s).

- Pressure: Airflow exerts pressure on surfaces, and this pressure can be measured using various instruments. Pressure is typically measured in Pascals (Pa) or pounds per square inch (psi).

- Flow Rate: The volume of air passing through a given area per unit time is called the flow rate. It is typically measured in cubic meters per second (m3/s) or cubic feet per minute (cfm).

- Temperature: The temperature of airflow can affect its density and viscosity, which in turn influence its flow characteristics. Temperature is typically measured in degrees Celsius (°C) or degrees Fahrenheit (°F).

- Humidity: The moisture content of air can affect its density and viscosity, influencing airflow characteristics. Humidity is typically measured as a percentage of relative humidity.

Airflow Control and Management: Air Flow Technology

Effective airflow control is crucial for maintaining optimal performance, energy efficiency, and safety in various applications. Airflow control devices and management strategies are employed to regulate the direction, volume, and velocity of air movement within systems.

Types of Airflow Control Devices

Airflow control devices are essential components that regulate and direct air movement within systems. These devices are strategically placed to manage airflow parameters, ensuring optimal performance and efficiency.

- Dampers: Dampers are adjustable vanes or plates that control the flow of air through ducts or openings. They can be manually or automatically operated, allowing for precise regulation of airflow. For example, in a ventilation system, dampers can be used to adjust the amount of air entering a room, based on occupancy or temperature requirements.

- Valves: Valves are similar to dampers but are typically used for controlling the flow of air in pipes or other enclosed systems. They can be used to isolate sections of a system, regulate pressure, or control the flow rate. For example, in a compressed air system, valves are used to control the flow of air to pneumatic tools or other equipment.

- Filters: Filters are used to remove contaminants from the air, such as dust, pollen, or bacteria. They are essential for maintaining air quality in applications where clean air is critical, such as hospitals, laboratories, and manufacturing facilities. Filters are typically made of materials such as fiberglass, paper, or fabric, with different pore sizes to capture specific contaminants. The type and efficiency of the filter used will depend on the application and the desired level of air purity.

Principles of Airflow Management

Airflow management involves optimizing, balancing, and distributing airflow to achieve specific objectives. These principles ensure efficient and effective air movement within a system.

- Optimization: Airflow optimization aims to maximize efficiency by minimizing energy consumption and maximizing air delivery. This involves adjusting airflow parameters, such as velocity and pressure, to achieve the desired results. For example, in a ventilation system, optimization involves adjusting the fan speed and damper positions to deliver the required airflow while minimizing energy consumption.

- Balancing: Airflow balancing ensures that the desired airflow is delivered to each zone or area of a system. This involves adjusting airflow control devices to ensure equal distribution of air. For example, in a multi-zone HVAC system, airflow balancing ensures that each zone receives the correct amount of air, regardless of variations in ductwork or load.

- Distribution: Airflow distribution involves controlling the direction and path of air movement within a system. This ensures that air reaches the intended areas and avoids unwanted drafts or stagnation. For example, in a cleanroom, airflow distribution is critical for maintaining a controlled environment, preventing contamination, and ensuring uniform air quality.

Challenges and Solutions in Airflow Control

Controlling airflow in complex systems presents unique challenges, requiring careful consideration of factors such as system complexity, environmental conditions, and operational requirements.

- System Complexity: Complex systems with multiple zones, branching ductwork, and various airflow control devices can make airflow management challenging. Solutions involve using sophisticated airflow modeling software and employing experienced engineers to design and implement effective control strategies.

- Environmental Conditions: Environmental factors such as temperature, humidity, and air pressure can influence airflow patterns and require adjustments to control devices. Solutions include incorporating sensors to monitor environmental conditions and adjusting control devices automatically to maintain optimal airflow.

- Operational Requirements: Different applications have specific airflow requirements, such as maintaining a certain air velocity in a cleanroom or controlling the air pressure in a pharmaceutical manufacturing facility. Solutions involve customizing airflow control systems to meet the specific requirements of each application.

Emerging Trends in Airflow Technology

The field of airflow technology is constantly evolving, driven by advancements in materials science, computational modeling, and a growing focus on energy efficiency and sustainability. This has led to the emergence of innovative airflow solutions that are transforming various industries and applications.

Smart Ventilation Systems

Smart ventilation systems are revolutionizing building design and operation by integrating sensors, data analytics, and automation to optimize airflow and indoor air quality. These systems continuously monitor environmental factors such as temperature, humidity, CO2 levels, and air pollutants.

- Based on real-time data, they adjust ventilation rates, filter efficiency, and airflow patterns to maintain optimal indoor conditions.

- Smart ventilation systems can be integrated with building management systems (BMS) to provide centralized control and monitoring.

- They offer significant benefits, including improved energy efficiency, reduced operating costs, enhanced occupant comfort, and improved health outcomes.

Bio-inspired Designs

Nature provides a rich source of inspiration for designing efficient and effective airflow systems. Bio-inspired designs mimic the aerodynamic principles found in animals and plants, leading to innovations in fan blades, air filters, and ventilation systems.

- For example, the humpback whale’s fin has inspired the design of wind turbine blades, resulting in increased energy efficiency and reduced noise levels.

- The intricate structure of leaves has been used to develop highly efficient air filters with increased surface area and improved filtration capabilities.

- Bio-inspired designs are often characterized by their lightweight, low-energy consumption, and high performance, making them suitable for a wide range of applications.

Computational Fluid Dynamics (CFD)

CFD is a powerful tool for simulating and analyzing airflow patterns. It allows engineers to optimize airflow designs, reduce energy consumption, and improve performance.

- CFD simulations provide detailed insights into airflow dynamics, pressure distribution, and heat transfer, enabling the identification of potential problems and optimization opportunities.

- The use of CFD is becoming increasingly widespread in various industries, including automotive, aerospace, and HVAC.

- It helps to reduce the need for physical prototypes, leading to faster development cycles and lower costs.

Table: Key Features and Benefits of Emerging Airflow Technologies

| Technology | Key Features | Benefits |

|---|---|---|

| Smart Ventilation Systems | Sensors, data analytics, automation | Improved energy efficiency, reduced operating costs, enhanced occupant comfort, improved health outcomes |

| Bio-inspired Designs | Mimicking natural aerodynamic principles | Increased efficiency, reduced noise levels, improved filtration capabilities |

| CFD | Simulating and analyzing airflow patterns | Optimized airflow designs, reduced energy consumption, improved performance |

Case Studies of Airflow Technology

Airflow technology plays a crucial role in various industries, from healthcare to manufacturing. These case studies highlight successful implementations of airflow technology in real-world scenarios, demonstrating its impact and showcasing the challenges, solutions, and outcomes achieved.

Case Studies of Airflow Technology in Different Industries

This section presents case studies of airflow technology applications across different industries, illustrating its diverse applications and the benefits it brings.

| Industry | Application | Challenges | Solutions | Results |

|---|---|---|---|---|

| Healthcare | Operating Room Ventilation | Maintaining a sterile and controlled environment for surgical procedures, minimizing the risk of airborne infections. | High-efficiency particulate air (HEPA) filtration systems, laminar airflow technology, and positive pressure rooms. | Reduced infection rates, improved patient safety, and enhanced surgical outcomes. |

| Manufacturing | Industrial Ventilation | Removing dust, fumes, and other contaminants from the work environment, ensuring worker safety and product quality. | Exhaust ventilation systems, air filtration units, and localized extraction systems. | Improved air quality, reduced worker exposure to hazardous materials, and enhanced product quality. |

| Data Centers | Cooling and Ventilation | Maintaining optimal operating temperatures for servers and other IT equipment, preventing overheating and downtime. | Air conditioning systems, raised floors, and hot aisle/cold aisle configurations. | Improved server performance, reduced energy consumption, and increased data center reliability. |

| Agriculture | Greenhouse Ventilation | Controlling temperature, humidity, and airflow to create optimal growing conditions for crops. | Ventilation fans, air circulation systems, and environmental control systems. | Increased crop yields, improved plant health, and reduced energy consumption. |

Outcome Summary

As we’ve seen, air flow technology is a dynamic and evolving field with far-reaching implications. From the foundational principles of airflow to its diverse applications, the science of moving air continues to drive innovation and improve our lives. As we continue to explore the intricacies of airflow, we can expect even more groundbreaking advancements in the future, further enhancing efficiency, comfort, and safety in various industries.

Air flow technology plays a crucial role in various industries, from automotive to HVAC. Implementing these systems often requires additional components and software, which can be categorized as “bolt-on” technologies. Understanding the pricing of these bolt-on technologies is crucial for businesses looking to integrate them seamlessly.

Check out this guide to bolt-on technology pricing for insights into different pricing models and factors to consider. Ultimately, the right air flow technology solution will depend on your specific needs and budget, so it’s important to weigh the costs and benefits carefully.