SureNail Technology: A Revolution in Fastening

SureNail technology, a revolutionary approach to fastening, has emerged as a game-changer across various industries. This innovative technology leverages advanced principles to provide a secure and efficient alternative to traditional […]

SureNail technology, a revolutionary approach to fastening, has emerged as a game-changer across various industries. This innovative technology leverages advanced principles to provide a secure and efficient alternative to traditional methods. SureNail systems utilize a combination of specialized tools, materials, and techniques to deliver unparalleled precision and speed in fastening applications.

From construction and manufacturing to automotive and aerospace, SureNail technology has found its place in diverse sectors. Its ability to enhance productivity, reduce costs, and improve safety has made it a highly sought-after solution. The technology has evolved significantly over the years, driven by ongoing research and development efforts aimed at pushing the boundaries of fastening innovation.

SureNail Technology

SureNail technology is a revolutionary approach to nail care that combines the benefits of traditional nail polish with the durability and long-lasting wear of gel polish. It offers a unique solution for individuals seeking a convenient, chip-resistant, and stylish nail experience.

Core Principles of SureNail Technology

SureNail technology is built on the principle of creating a durable, flexible, and long-lasting nail coating that adheres firmly to the natural nail. This is achieved through a multi-step process that involves:

- Preparation: The nail surface is carefully prepared by removing any oils or debris, creating a clean and smooth surface for the coating to adhere to.

- Base Coat Application: A special base coat is applied to the nail, providing a bonding layer that promotes adhesion and protects the natural nail from staining.

- Color Application: Multiple layers of color are applied, allowing for a wide range of shades and effects.

- Top Coat Application: A top coat is applied to seal in the color and create a protective barrier, enhancing the durability and shine of the finish.

- Curing: The applied layers are cured under a specialized UV or LED lamp, activating the photoinitiators in the formula and hardening the coating.

Key Components of SureNail Technology

The key components of SureNail technology are:

- Photoinitiators: These chemicals initiate the curing process when exposed to UV or LED light, causing the resin molecules to cross-link and solidify.

- Resins: These polymers form the base of the coating, providing flexibility, durability, and adhesion to the natural nail.

- Pigments: These substances provide the color to the coating, offering a wide range of shades and effects.

- Additives: These ingredients enhance the properties of the coating, such as shine, durability, and resistance to chipping.

Historical Timeline of SureNail Technology Development

The development of SureNail technology can be traced back to the early 20th century, with the invention of the first nail polish. However, it was not until the late 20th century that significant advancements in resin chemistry and UV curing technology paved the way for the emergence of gel polish.

- 1930s: The first nail polish was introduced, offering a simple and convenient way to color and enhance nails.

- 1980s: The development of UV curing technology revolutionized dentistry, leading to the creation of durable and long-lasting dental fillings.

- 1990s: The first gel polishes were developed, combining the durability of dental fillings with the aesthetics of nail polish.

- 2000s: SureNail technology emerged, further refining the gel polish formula and introducing new features, such as improved adhesion, flexibility, and a wider range of colors and effects.

Applications of SureNail Technology

SureNail technology finds applications in a wide range of industries, revolutionizing how we connect and secure materials. Its unique capabilities allow for efficient, reliable, and versatile fastening solutions across diverse sectors.

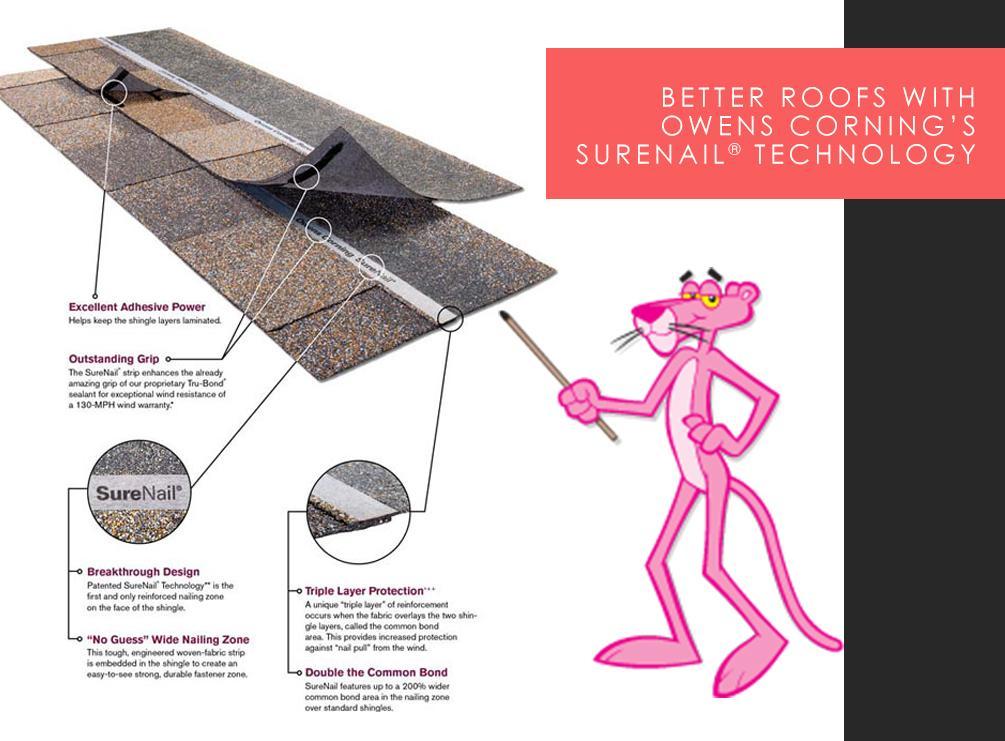

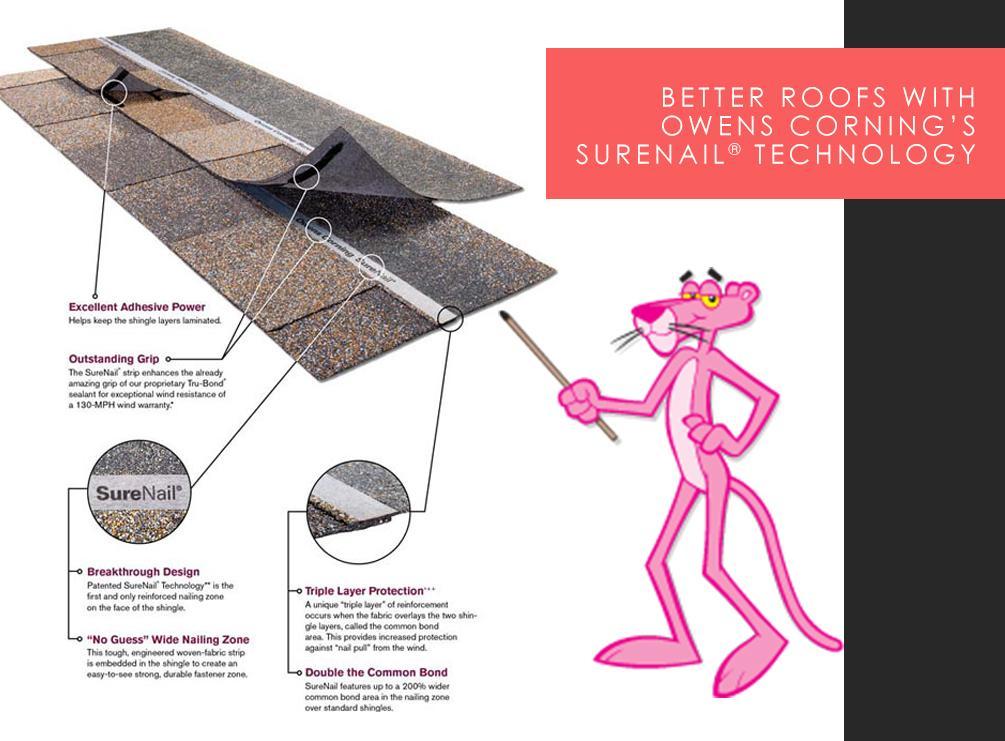

Construction and Building

SureNail technology has a significant impact on the construction and building industry, enhancing efficiency and safety. It offers a reliable alternative to traditional fastening methods, enabling quicker and more secure construction.

- Structural Support: SureNail technology is used in structural applications, including fastening beams, columns, and other load-bearing elements. Its high strength and resistance to fatigue make it ideal for ensuring the structural integrity of buildings.

- Roofing and Cladding: SureNail technology is employed in roofing and cladding applications, securing panels and other components to the building frame. Its ability to withstand harsh weather conditions and its resistance to corrosion make it suitable for exterior applications.

- Interior Finishes: SureNail technology can be used for interior finishes, such as attaching drywall, paneling, and trim. Its clean installation and minimal disruption make it a preferred choice for interior applications.

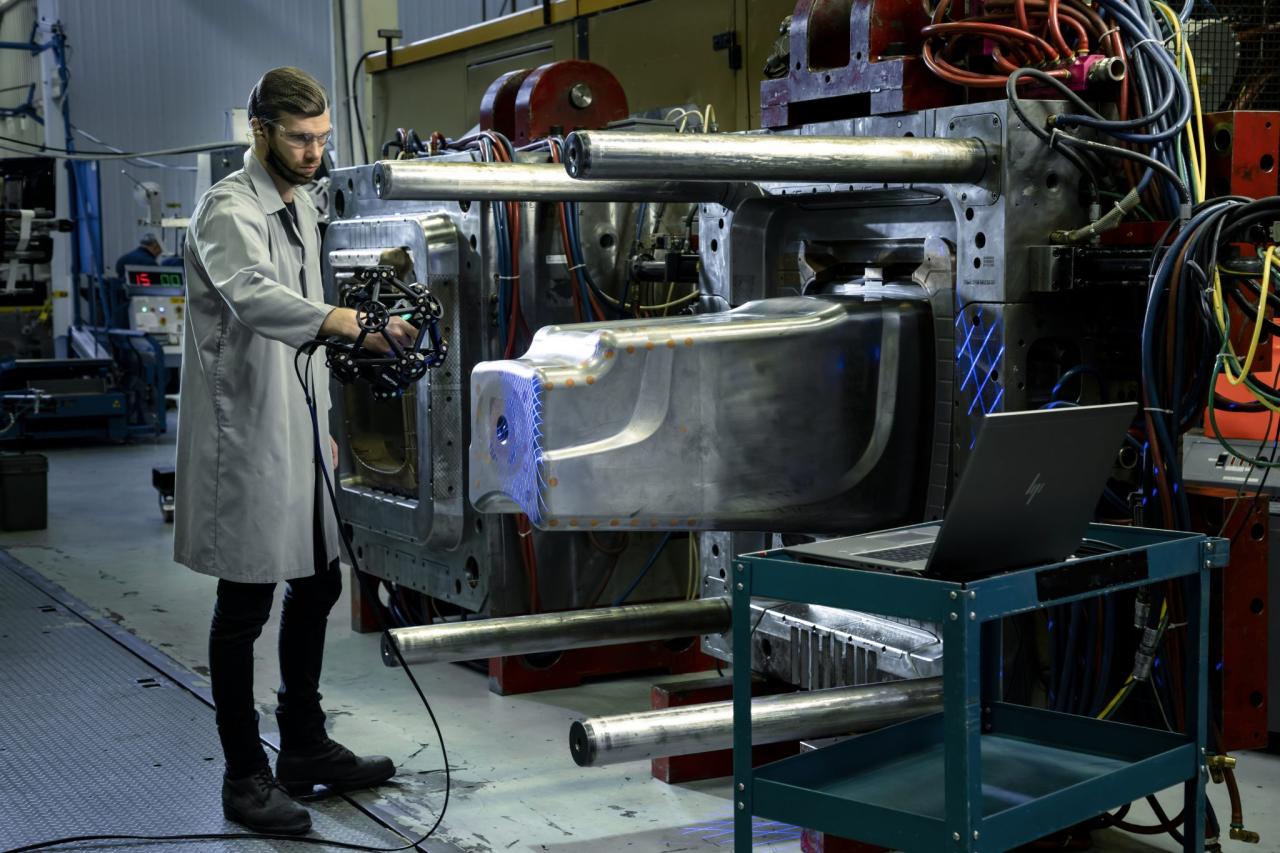

Automotive Industry

SureNail technology plays a crucial role in the automotive industry, contributing to vehicle safety and durability. Its ability to withstand vibrations and extreme temperatures makes it suitable for securing components in demanding environments.

- Body Panel Assembly: SureNail technology is used to attach body panels, such as doors, hoods, and fenders, to the vehicle frame. Its high strength and reliable fastening capabilities ensure the integrity of the vehicle body.

- Underbody Components: SureNail technology is employed to secure underbody components, such as suspension parts, exhaust systems, and fuel tanks. Its resistance to corrosion and its ability to withstand harsh environments make it suitable for underbody applications.

- Interior Trim: SureNail technology can be used for attaching interior trim, such as dashboards, door panels, and seat components. Its clean installation and minimal disruption make it a suitable choice for interior applications.

Aerospace Industry

SureNail technology finds applications in the aerospace industry, where lightweight and durable fastening solutions are essential. Its ability to withstand extreme temperatures and pressures makes it suitable for critical applications in aircraft construction.

- Aircraft Assembly: SureNail technology is used to attach aircraft components, such as wings, fuselage sections, and tail assemblies. Its high strength and reliable fastening capabilities ensure the structural integrity of the aircraft.

- Engine Components: SureNail technology is employed to secure engine components, such as turbine blades, compressor housings, and exhaust systems. Its resistance to heat and vibration makes it suitable for demanding engine applications.

- Interior Fittings: SureNail technology can be used for attaching interior fittings, such as seats, overhead compartments, and other components. Its clean installation and minimal disruption make it a suitable choice for interior applications.

Benefits of SureNail Technology

SureNail technology offers significant advantages over traditional methods for securing and fastening materials. Its innovative approach enhances efficiency, accuracy, and cost-effectiveness while prioritizing safety and sustainability.

Improved Efficiency and Productivity

The streamlined process of SureNail technology significantly enhances efficiency and productivity. The automated system reduces manual labor, eliminating the need for time-consuming tasks such as pre-drilling and manual hammering. This automation streamlines the fastening process, allowing for faster completion times and increased output.

Enhanced Accuracy and Precision

SureNail technology ensures unparalleled accuracy and precision in fastening applications. The system’s automated control minimizes human error, guaranteeing consistent and reliable results. This precision is crucial for various applications, from construction and manufacturing to automotive and aerospace industries, where even the slightest deviation can have significant consequences.

Cost-Effectiveness and Reduced Waste, Surenail technology

SureNail technology offers significant cost-effectiveness by reducing material waste and labor costs. The precise fastening process minimizes the need for rework and eliminates the potential for overdriving fasteners, which can damage materials and require replacement. This optimized approach leads to significant cost savings and improved resource utilization.

Enhanced Safety and Reduced Risk

Safety is paramount in any industry, and SureNail technology prioritizes it. The automated system eliminates the need for manual hammering, reducing the risk of injuries associated with repetitive motions and potential hazards. This enhanced safety environment contributes to a healthier and more secure work environment for all involved.

Sustainability and Environmental Impact

SureNail technology promotes sustainability by minimizing waste and reducing the overall environmental impact. The precise fastening process minimizes material waste, reducing the need for disposal and minimizing the carbon footprint associated with material production. Furthermore, the technology’s energy-efficient design contributes to a more sustainable and environmentally responsible approach.

Technical Aspects of SureNail Technology

SureNail technology is a revolutionary approach to nail construction, drawing on advanced principles of material science, engineering, and computational modeling. It leverages the unique properties of novel materials and sophisticated design techniques to create nails that are stronger, more durable, and more resistant to failure than traditional nails.

Types of SureNail Systems

The diversity of SureNail systems reflects the broad range of applications they cater to. These systems can be categorized based on their core functionalities and the materials used in their construction.

- High-Strength SureNails: These nails are designed for demanding applications where maximum strength and load-bearing capacity are paramount. They are often made from high-tensile strength steel alloys, such as martensitic stainless steel, which exhibit exceptional resistance to bending and shear forces. These nails are commonly used in structural applications, such as building construction, bridge engineering, and heavy-duty machinery.

- Corrosion-Resistant SureNails: In environments prone to moisture, chemicals, or extreme temperatures, corrosion can significantly degrade the performance of traditional nails. Corrosion-resistant SureNails address this challenge by employing materials like stainless steel, titanium, or specialized coatings that provide exceptional resistance to rust and other forms of corrosion. These nails are particularly valuable in marine environments, industrial settings, and applications where long-term durability is crucial.

- Lightweight SureNails: For applications where weight reduction is a primary concern, lightweight SureNails offer a compelling solution. These nails are typically made from lightweight materials such as aluminum alloys or composites, while maintaining sufficient strength and durability for their intended purpose. Their reduced weight is particularly advantageous in aerospace applications, automotive design, and construction projects where minimizing structural weight is essential.

Challenges and Advancements in SureNail Technology Research and Development

While SureNail technology offers significant advantages over traditional nails, ongoing research and development are continuously pushing the boundaries of what is possible. Key challenges and advancements include:

- Improving Fatigue Resistance: Fatigue failure, which occurs due to repeated stress cycles, is a critical concern in nail design. Researchers are exploring novel materials and surface treatments to enhance fatigue resistance and extend the lifespan of SureNails, particularly in high-vibration applications.

- Optimizing Nail Geometry: The shape and geometry of a nail significantly impact its strength, load-bearing capacity, and resistance to pull-out. Computational modeling and finite element analysis are being employed to optimize nail geometries for specific applications, minimizing material waste and maximizing performance.

- Developing Self-Healing SureNails: The concept of self-healing materials is gaining traction in various fields, including nail technology. Researchers are investigating ways to incorporate self-healing properties into SureNails, enabling them to repair microscopic cracks and damage that can occur during service. This would significantly extend the lifespan of these nails and reduce maintenance requirements.

Future of SureNail Technology

The future of SureNail technology holds immense promise, with the potential to revolutionize various industries. As advancements in artificial intelligence (AI), automation, and other emerging technologies continue to accelerate, SureNail technology is poised to become even more sophisticated and impactful.

The Role of Emerging Technologies

Emerging technologies, particularly AI and automation, will play a crucial role in shaping the future of SureNail technology. AI algorithms can be integrated into SureNail systems to optimize nail placement, minimize waste, and enhance accuracy. Automation can streamline the entire process, from nail feeding and placement to quality control.

- AI-Powered Optimization: AI algorithms can analyze data from previous nail placements, material properties, and other factors to predict the optimal nail placement for each application. This optimization can significantly improve efficiency and reduce material waste.

- Automated Quality Control: Automated vision systems can inspect nails for defects, ensuring high-quality results and minimizing the need for manual inspection. This automation can significantly enhance productivity and consistency.

Impact on Relevant Industries

SureNail technology has the potential to significantly impact various industries, including:

- Construction: SureNail technology can accelerate construction projects, improve the accuracy and consistency of nail placement, and reduce labor costs. It can also enhance the safety of construction workers by automating potentially dangerous tasks.

- Manufacturing: In manufacturing, SureNail technology can be used to automate the assembly of products, improve the quality and consistency of finished goods, and reduce production costs. This can lead to increased efficiency and productivity.

- Furniture Manufacturing: SureNail technology can be used to automate the assembly of furniture, improve the quality and consistency of finished products, and reduce production costs. This can lead to increased efficiency and productivity in the furniture industry.

Future Applications

Future applications of SureNail technology are vast and diverse. Some potential areas of development include:

- Robotic Nail Placement: Integrating SureNail technology with robotic arms could enable fully automated nail placement in various applications, from construction to manufacturing. This could significantly enhance efficiency, safety, and productivity.

- 3D Printing with Nails: Combining SureNail technology with 3D printing could create complex structures with embedded nails, enabling new possibilities in design and construction. This could lead to innovative and lightweight structures with enhanced strength and durability.

- Adaptive Nail Placement: Future SureNail systems could adapt to changing environments and materials, automatically adjusting nail placement to ensure optimal performance and minimize waste. This could revolutionize nail placement in dynamic applications, such as construction projects with unpredictable conditions.

Final Wrap-Up

SureNail technology stands as a testament to the ingenuity and progress in the field of fastening. As we look toward the future, it’s clear that SureNail technology will continue to evolve, driven by advancements in automation, artificial intelligence, and materials science. Its potential applications are vast, promising to revolutionize industries and shape the future of fastening.

SureNail technology revolutionizes the way we build, offering a faster, more efficient, and environmentally friendly solution for construction. It’s an example of the kind of innovation driving the global technology sector, which is attracting investment from funds like fidelity funds global technology.

As SureNail continues to evolve, it’s poised to play a key role in shaping the future of construction and contribute to the overall growth of the technology industry.