NK Technologies Current Transducer: A Comprehensive Guide

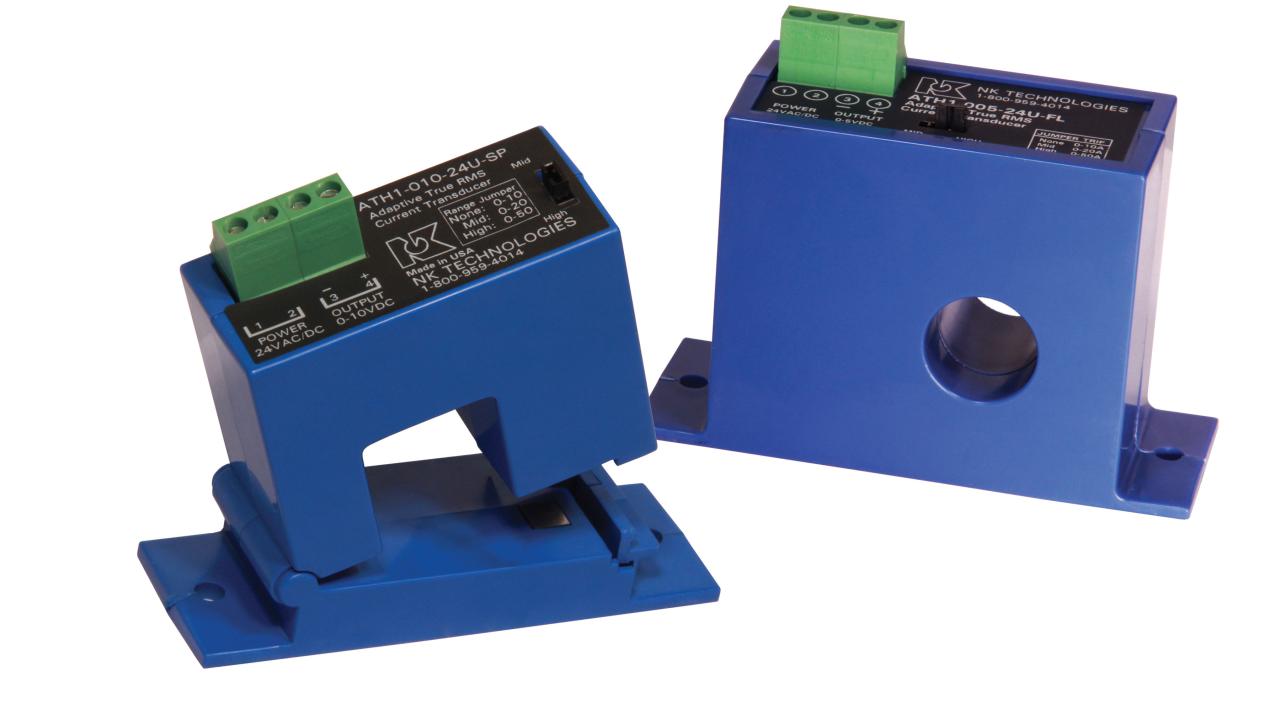

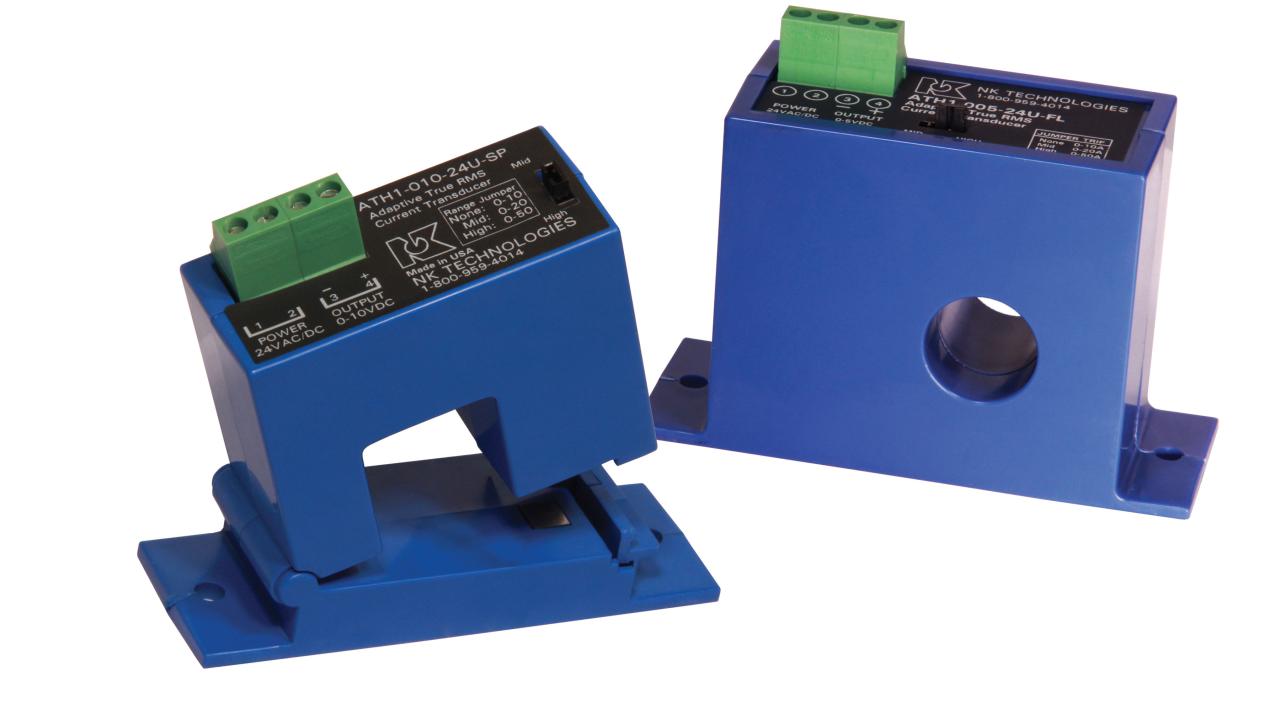

NK Technologies current transducers play a vital role in various industries, enabling precise measurement and control of electrical currents. These devices, engineered with advanced technology and meticulous design, have become […]

NK Technologies current transducers play a vital role in various industries, enabling precise measurement and control of electrical currents. These devices, engineered with advanced technology and meticulous design, have become indispensable for monitoring and optimizing performance in applications ranging from industrial automation to medical equipment.

NK Technologies has established itself as a leading manufacturer of transducers, offering a wide range of products designed to meet diverse industry requirements. Their transducers are renowned for their accuracy, reliability, and durability, making them a trusted choice for engineers and technicians worldwide.

NK Technologies Transducer Overview

NK Technologies is a leading manufacturer of high-quality transducers, known for their reliability, durability, and innovative designs. The company has a rich history in the field, dating back several decades.

History and Background

NK Technologies was founded in the 1970s with a focus on developing innovative solutions for industrial applications. Their initial focus was on pressure transducers, but they quickly expanded their product line to include other types of sensors, including load cells, accelerometers, and displacement transducers. The company’s commitment to quality and customer satisfaction has been a key driver of its success, leading to a strong reputation in the industry.

Core Product Lines

NK Technologies offers a wide range of transducers, catering to various industrial needs. Their product lines can be broadly categorized as follows:

- Pressure Transducers: NK Technologies offers a comprehensive selection of pressure transducers, covering a wide range of pressure ranges, accuracies, and output types. These transducers are suitable for various applications, including hydraulic systems, pneumatic systems, and process control.

- Load Cells: NK Technologies provides a range of load cells, designed for accurate measurement of force and weight. These load cells are commonly used in industrial weighing systems, material handling equipment, and process control applications.

- Accelerometers: NK Technologies offers a variety of accelerometers, used for measuring vibration, shock, and tilt. These accelerometers are employed in applications such as machine monitoring, structural health monitoring, and automotive testing.

- Displacement Transducers: NK Technologies provides a range of displacement transducers, used for measuring linear or angular displacement. These transducers are commonly used in applications such as machine control, robotics, and process automation.

Applications and Industries

NK Technologies transducers are used in a wide range of industries and applications. Some key areas include:

- Manufacturing: NK Technologies transducers are widely used in manufacturing processes for monitoring and controlling various parameters, such as pressure, force, vibration, and displacement. These transducers are essential for ensuring product quality and process efficiency.

- Process Control: NK Technologies transducers play a crucial role in process control applications, providing accurate and reliable measurement data for optimizing processes and ensuring safety. They are used in industries such as chemical processing, food and beverage, and pharmaceuticals.

- Aerospace and Defense: NK Technologies transducers are used in aerospace and defense applications, where reliability and precision are paramount. They are employed in aircraft, missiles, and other defense systems for monitoring and controlling critical parameters.

- Automotive: NK Technologies transducers are used in the automotive industry for monitoring and controlling various parameters, such as engine pressure, suspension load, and vehicle stability. They contribute to improved vehicle performance, safety, and efficiency.

- Research and Development: NK Technologies transducers are also used in research and development activities, providing accurate and reliable data for scientific experiments, testing, and analysis.

Types of Transducers Offered by NK Technologies

NK Technologies offers a wide range of transducers designed to measure various physical parameters. These transducers are used in diverse applications, including industrial automation, process control, and research.

Types of Transducers Offered by NK Technologies

| Transducer Type | Measurement Principle | Application | Key Features |

|---|---|---|---|

| Pressure Transducers | Conversion of pressure into an electrical signal | Fluid pressure monitoring, process control, industrial automation | High accuracy, wide pressure range, robust construction |

| Load Cells | Conversion of force into an electrical signal | Weight measurement, force measurement, industrial automation | High accuracy, high load capacity, stable performance |

| Temperature Sensors | Conversion of temperature into an electrical signal | Temperature monitoring, process control, industrial automation | High accuracy, wide temperature range, fast response time |

| Displacement Sensors | Conversion of displacement into an electrical signal | Position monitoring, vibration analysis, industrial automation | High resolution, long-term stability, compact size |

| Acceleration Sensors | Conversion of acceleration into an electrical signal | Vibration monitoring, shock detection, industrial automation | High sensitivity, wide frequency range, rugged construction |

Transducer Technology and Design

NK Technologies transducers are engineered to deliver precise and reliable measurements across a wide range of applications. The design and technology employed in these transducers are crucial to their performance and accuracy.

Transducer Principles and Technologies

The core of NK Technologies transducers lies in the principle of converting one form of energy into another. This conversion is typically achieved through a sensing element that responds to the measured parameter. For instance, in a pressure transducer, the sensing element might be a diaphragm that deflects under pressure, and this deflection is then converted into an electrical signal.

The specific technology used in a transducer depends on the parameter being measured and the desired accuracy and range. Some common technologies employed by NK Technologies include:

- Piezoresistive Technology: This technology uses the change in electrical resistance of a semiconductor material under stress to measure pressure or force. Piezoresistive transducers are known for their high sensitivity and wide operating temperature range.

- Piezoelectric Technology: This technology utilizes the piezoelectric effect, where certain materials generate an electrical charge when subjected to mechanical stress. Piezoelectric transducers are widely used in applications requiring high frequency response and low power consumption.

- Capacitive Technology: This technology measures the change in capacitance between two conductive plates as a result of the measured parameter. Capacitive transducers are known for their high accuracy and stability over time.

- Inductive Technology: This technology utilizes the principle of electromagnetic induction to measure the change in inductance of a coil due to the measured parameter. Inductive transducers are often employed in applications requiring high sensitivity and low noise.

Transducer Materials and Construction

The choice of materials for transducer construction is critical to its performance and reliability. NK Technologies uses a variety of materials, including:

- Stainless Steel: This material is widely used for its strength, corrosion resistance, and durability. Stainless steel is often used in transducers operating in harsh environments.

- Titanium: This material offers excellent corrosion resistance and biocompatibility, making it suitable for medical and marine applications.

- Silicon: This material is used in piezoresistive transducers for its high sensitivity and ability to be precisely etched and patterned.

- Ceramic: This material is commonly used in piezoelectric transducers for its ability to generate a strong electrical charge under stress.

The construction of a transducer involves assembling these materials in a specific configuration that optimizes its performance. This may involve processes such as:

- Etching: This process is used to create precise patterns on silicon wafers for piezoresistive transducers.

- Sputtering: This process deposits thin films of materials onto substrates, such as ceramic for piezoelectric transducers.

- Welding: This process joins different materials together, such as stainless steel and silicon, to create a robust transducer.

Transducer Performance Characteristics

NK Technologies transducers are designed to meet specific performance requirements depending on the application. Key performance characteristics include:

- Accuracy: This refers to the closeness of the measured value to the true value. Transducer accuracy is typically expressed as a percentage of the full-scale output.

- Sensitivity: This represents the change in output signal for a given change in the measured parameter. High sensitivity transducers provide a greater output signal for small changes in the measured parameter.

- Range: This defines the limits of the measured parameter that the transducer can accurately measure.

- Frequency Response: This indicates the ability of the transducer to accurately measure rapidly changing parameters. High frequency response transducers are suitable for applications involving dynamic measurements.

- Temperature Stability: This describes the ability of the transducer to maintain its accuracy over a range of temperatures.

- Durability: This refers to the transducer’s ability to withstand harsh environments and repeated use.

The performance characteristics of different transducer types can vary significantly. For example, piezoelectric transducers typically have a higher frequency response than piezoresistive transducers, but they may have lower accuracy. Capacitive transducers are known for their high accuracy and stability, but they may have a lower frequency response than other types. The selection of the appropriate transducer type depends on the specific requirements of the application.

Transducer Applications and Use Cases: Nk Technologies Current Transducer

NK Technologies transducers are versatile and play a crucial role in various industries. Their applications span a wide range of fields, contributing to efficiency, safety, and innovation. This section delves into specific examples of how NK Technologies transducers are used, showcasing their effectiveness through real-world applications.

Industrial Automation and Process Control

NK Technologies transducers are instrumental in industrial automation and process control systems. Their ability to convert physical parameters into electrical signals enables precise monitoring and control of critical processes.

- Pressure Measurement in Manufacturing: NK Technologies pressure transducers are employed in various manufacturing processes, ensuring accurate pressure readings for optimal product quality and process efficiency. For example, in the food and beverage industry, they monitor pressure levels in packaging machines to ensure consistent product filling.

- Level Sensing in Chemical Plants: NK Technologies level transducers are essential for monitoring fluid levels in tanks and vessels within chemical plants. They provide real-time data for safe and efficient operation, preventing overflows and ensuring optimal production.

- Temperature Control in HVAC Systems: NK Technologies temperature transducers are used in HVAC systems to monitor and regulate temperatures in buildings, ensuring comfortable and energy-efficient environments. They play a crucial role in maintaining optimal indoor temperatures for residential and commercial spaces.

Aerospace and Defense

NK Technologies transducers are integral to aerospace and defense applications, where precision and reliability are paramount. They provide accurate measurements for critical systems, ensuring safe and efficient operation.

- Aircraft Engine Monitoring: NK Technologies transducers are used in aircraft engines to monitor pressure, temperature, and vibration levels, providing critical data for engine health and performance. This information is vital for flight safety and maintenance planning.

- Missile Guidance Systems: NK Technologies transducers are employed in missile guidance systems to measure and control critical parameters like acceleration and orientation. This ensures accurate targeting and trajectory control for effective missile performance.

- Spacecraft Instrumentation: NK Technologies transducers are used in spacecraft instrumentation to measure environmental parameters like temperature, pressure, and radiation levels. This data is crucial for monitoring spacecraft health and ensuring mission success.

Medical and Healthcare

NK Technologies transducers play a vital role in medical and healthcare applications, contributing to patient care and diagnostics. Their accuracy and reliability ensure precise measurements for various medical procedures.

- Blood Pressure Monitoring: NK Technologies pressure transducers are used in medical devices for blood pressure monitoring, providing accurate readings for diagnosis and treatment. They are crucial for managing hypertension and other cardiovascular conditions.

- Medical Imaging: NK Technologies transducers are employed in medical imaging equipment like ultrasound machines, providing accurate signals for generating detailed images of internal organs and tissues. This aids in diagnosis and treatment planning.

- Patient Monitoring Systems: NK Technologies transducers are used in patient monitoring systems to measure vital signs like heart rate, respiration rate, and oxygen saturation. They provide real-time data for patient care and early detection of potential complications.

Automotive and Transportation, Nk technologies current transducer

NK Technologies transducers are widely used in the automotive and transportation industries, enhancing vehicle performance, safety, and efficiency.

- Engine Management Systems: NK Technologies transducers are employed in engine management systems to monitor various parameters like air pressure, fuel flow, and engine speed. This information is used to optimize engine performance and fuel efficiency.

- Vehicle Safety Systems: NK Technologies transducers are used in vehicle safety systems like anti-lock braking systems (ABS) and electronic stability control (ESC). They measure parameters like wheel speed and vehicle stability, providing data for these systems to function effectively.

- Autonomous Vehicles: NK Technologies transducers play a crucial role in autonomous vehicles, providing data for various sensors like lidar, radar, and cameras. This information is essential for autonomous navigation and decision-making.

Advantages and Considerations of NK Technologies Transducers

NK Technologies transducers offer a range of benefits across various applications, making them a popular choice for engineers and technicians. However, like any technology, they also have certain considerations that need to be addressed. This section explores the advantages and potential limitations of NK Technologies transducers, comparing them with those from competing manufacturers.

Advantages of NK Technologies Transducers

NK Technologies transducers offer a number of advantages that make them a compelling choice for a wide range of applications. Here are some key benefits:

- High Accuracy and Precision: NK Technologies transducers are known for their high accuracy and precision, ensuring reliable measurements and data collection. This is crucial for applications where precise measurements are essential, such as in industrial automation, aerospace, and medical devices.

- Durability and Reliability: NK Technologies transducers are designed to withstand harsh environments and demanding conditions. Their robust construction and high-quality materials ensure long-term reliability and performance, reducing downtime and maintenance costs.

- Wide Range of Options: NK Technologies offers a diverse selection of transducers, catering to various measurement needs. From pressure, temperature, and displacement to force, acceleration, and vibration, there is a transducer for almost any application.

- Competitive Pricing: NK Technologies transducers offer a good balance between performance and price. Their competitive pricing makes them a cost-effective solution for various applications, especially when compared to premium brands.

- Strong Technical Support: NK Technologies provides excellent technical support to its customers. Their team of experts is available to assist with product selection, troubleshooting, and application guidance, ensuring a smooth integration and optimal performance.

Limitations of NK Technologies Transducers

While NK Technologies transducers offer many advantages, there are also certain limitations to consider:

- Limited Customization Options: While NK Technologies offers a wide range of standard transducers, their customization options may be limited compared to some competitors. This could pose a challenge for applications requiring highly specialized transducers.

- Lead Time: The lead time for NK Technologies transducers can vary depending on the model and availability. In some cases, the lead time may be longer than that of other manufacturers, potentially delaying projects.

- Limited Availability: While NK Technologies has a broad product portfolio, certain specialized transducers may not be readily available. This could necessitate sourcing from alternative manufacturers for specific applications.

Comparison with Competitors

NK Technologies transducers compete with a range of manufacturers in the market, each offering its unique strengths and weaknesses. Here’s a brief comparison with some prominent competitors:

- Omega Engineering: Omega Engineering offers a vast range of transducers, known for their high accuracy and wide selection. However, their pricing may be higher than NK Technologies.

- Honeywell: Honeywell is a well-established player in the transducer market, offering high-quality products with excellent technical support. However, their products tend to be more expensive than NK Technologies.

- Sensata Technologies: Sensata Technologies specializes in sensors and transducers, providing innovative solutions for various industries. Their transducers are known for their reliability and performance, but their pricing may be higher than NK Technologies.

Transducer Selection and Integration

Choosing the right NK Technologies transducer for your application is crucial for achieving accurate and reliable measurements. Integrating these transducers into your existing systems or equipment is equally important for seamless operation.

Transducer Selection

Selecting the appropriate NK Technologies transducer involves considering several factors, including the specific application, measurement range, environmental conditions, and desired accuracy.

- Application Type: Identify the type of measurement you need, such as pressure, force, displacement, acceleration, or temperature. This will help you narrow down the transducer options.

- Measurement Range: Determine the minimum and maximum values you need to measure. This will ensure the transducer has the appropriate sensitivity and capacity for your application.

- Environmental Conditions: Consider the temperature, humidity, vibration, and other environmental factors that the transducer will be exposed to. Choose a transducer that can withstand these conditions.

- Accuracy Requirements: Define the level of accuracy needed for your application. Transducers with higher accuracy levels typically come at a higher cost.

- Output Type: Determine the type of output signal you require, such as analog voltage, current, or digital signals. Ensure the transducer’s output is compatible with your system’s requirements.

Transducer Integration

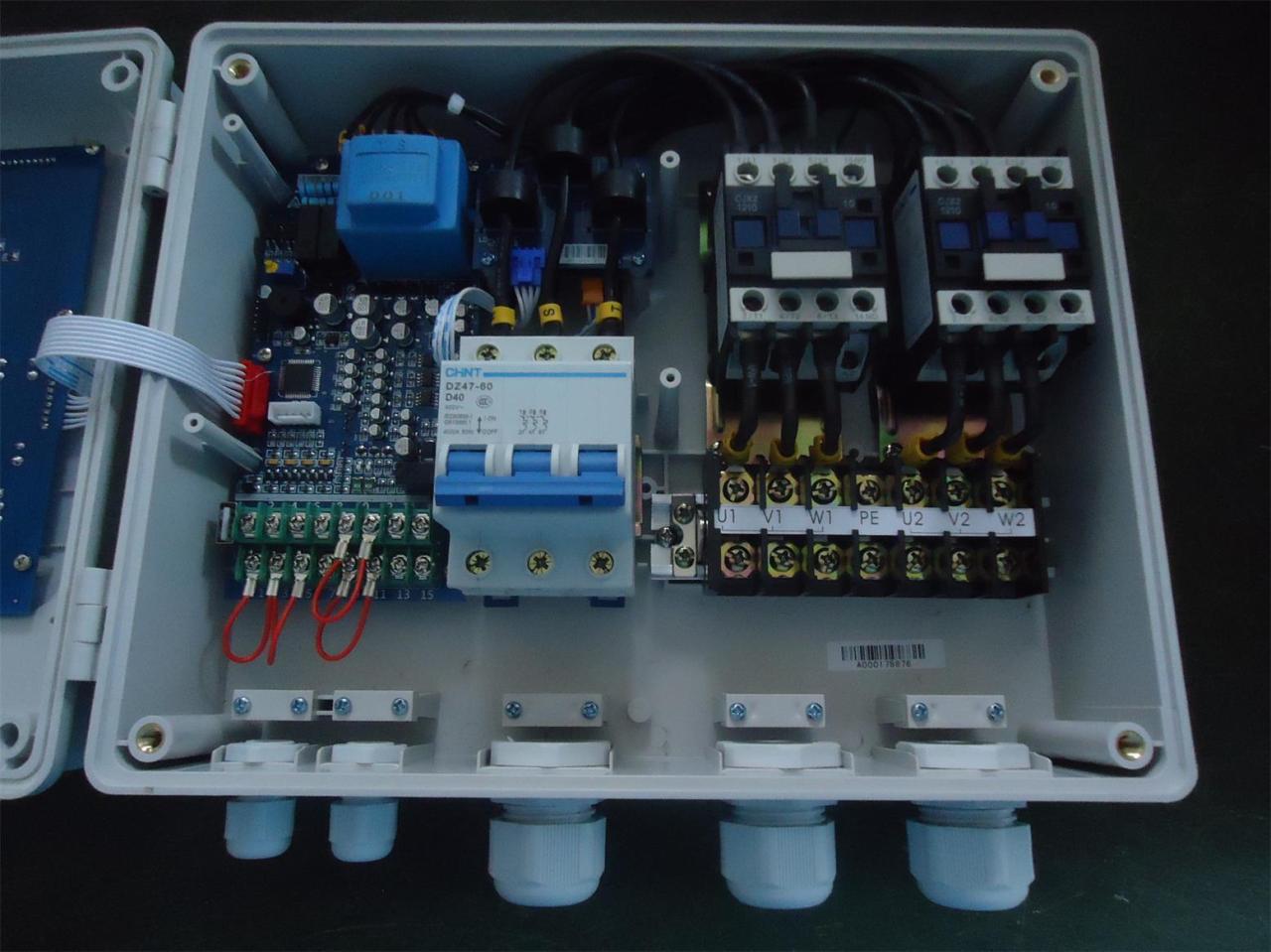

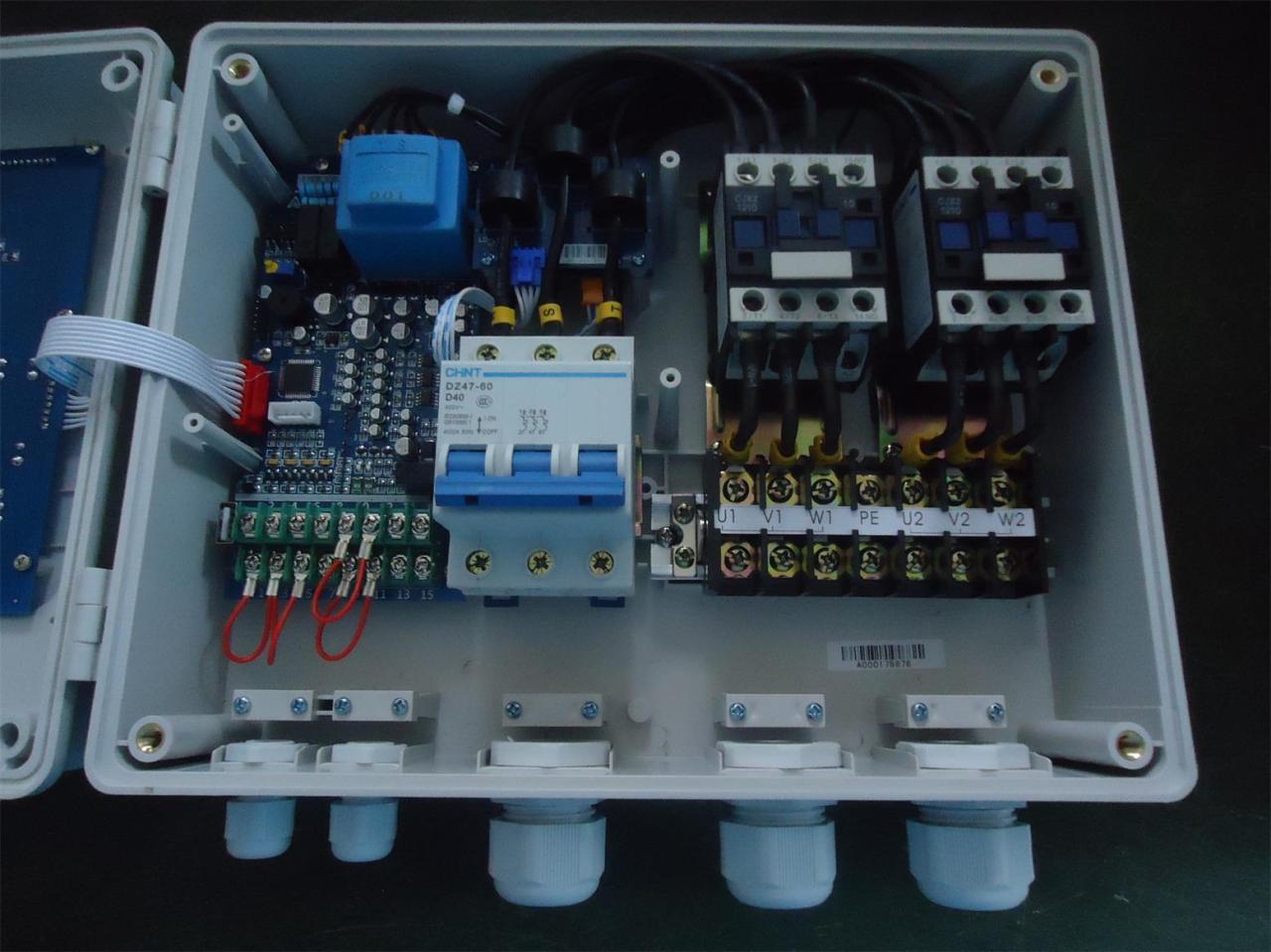

Integrating NK Technologies transducers into your systems or equipment involves understanding the transducer’s specifications, ensuring proper electrical connections, and calibrating the transducer for accurate readings.

- Review Transducer Specifications: Carefully review the transducer’s datasheet, which provides information about its operating principles, electrical characteristics, environmental limitations, and calibration procedures.

- Establish Electrical Connections: Connect the transducer’s output signal to your system’s input using the appropriate cables and connectors. Refer to the transducer’s datasheet for specific wiring diagrams and connector types.

- Calibrate the Transducer: Calibration is essential for ensuring accurate measurements. Follow the transducer’s calibration instructions, which may involve using a known standard or reference point to adjust the transducer’s output.

- Consider Environmental Factors: Ensure the transducer is mounted and protected from environmental factors that could affect its performance, such as vibration, temperature extremes, or moisture.

Resources and Documentation

NK Technologies provides comprehensive resources and documentation to support transducer selection and integration.

- Product Catalogs: Browse the NK Technologies product catalogs to explore the wide range of transducers available, including detailed specifications and application examples.

- Datasheets: Access datasheets for specific transducers to obtain detailed information about their operating characteristics, electrical specifications, environmental limitations, and calibration procedures.

- Application Notes: Explore application notes that provide guidance on using NK Technologies transducers in specific applications, including installation tips, troubleshooting techniques, and best practices.

- Technical Support: Contact NK Technologies’ technical support team for assistance with transducer selection, integration, or troubleshooting. They can provide expert advice and guidance based on your specific needs.

Future Trends in Transducer Technology

The field of transducer technology is constantly evolving, driven by advancements in materials science, microelectronics, and artificial intelligence. These innovations are shaping the future of NK Technologies’ transducer offerings, leading to enhanced performance, expanded applications, and greater integration with emerging technologies.

Advancements in Materials

The development of new materials is a key driver of progress in transducer technology. These materials offer improved sensitivity, durability, and operating conditions, expanding the range of applications for transducers.

- Nanomaterials: Nanomaterials, such as graphene and carbon nanotubes, possess exceptional electrical and mechanical properties. Their use in transducers can lead to increased sensitivity, improved signal-to-noise ratios, and enhanced durability. For example, graphene-based transducers have demonstrated superior performance in sensing applications, particularly in the detection of low-frequency vibrations and acoustic waves.

- Smart Materials: Smart materials, such as piezoelectric and shape memory alloys, can respond to changes in temperature, pressure, or electrical fields. These materials are being incorporated into transducers to create self-sensing and self-actuating devices, enabling adaptive and intelligent systems. For instance, piezoelectric transducers integrated with smart materials can be used in structural health monitoring, where they can detect and respond to stress and strain variations in real-time.

- Biocompatible Materials: The development of biocompatible materials, such as polymers and ceramics, has opened up new possibilities for biomedical applications. These materials allow for the creation of implantable transducers for monitoring physiological signals, delivering targeted therapies, and enhancing prosthetics. For example, biocompatible polymer-based transducers are being used in wearable sensors for continuous monitoring of heart rate, blood pressure, and other vital signs.

Miniaturization and Integration

The trend towards miniaturization and integration is driving the development of smaller, more versatile transducers. This trend is facilitated by advances in microfabrication techniques and the integration of sensors, actuators, and electronics on a single chip.

- Micro-Electro-Mechanical Systems (MEMS): MEMS technology allows for the fabrication of miniature transducers with complex geometries and integrated functionalities. MEMS transducers are being used in a wide range of applications, including accelerometers, pressure sensors, and microphones. For instance, MEMS-based accelerometers are commonly found in smartphones and other portable devices, enabling motion detection and navigation.

- System-on-a-Chip (SoC): SoC technology integrates multiple components, including sensors, actuators, and processing units, on a single chip. This approach enables the development of highly integrated and compact transducer systems, simplifying integration and reducing costs. For example, SoC-based transducers are being used in smart home applications, where they can monitor temperature, humidity, and other environmental parameters.

- Printed Electronics: Printed electronics offers a low-cost and scalable method for fabricating flexible and conformable transducers. This technology allows for the creation of transducers that can be integrated into surfaces and objects, enabling novel applications in areas such as wearable electronics, smart packaging, and flexible displays. For example, printed piezoelectric transducers are being explored for use in flexible sensors and actuators for wearable devices.

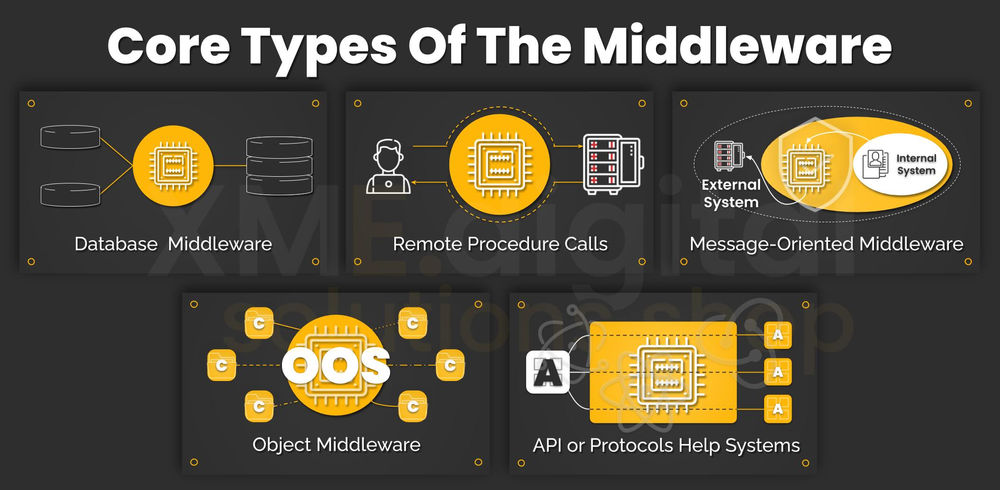

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) algorithms into transducer systems is revolutionizing data analysis and interpretation. These technologies enable transducers to learn from data, adapt to changing conditions, and provide more insightful information.

- Smart Data Analysis: AI and ML algorithms can be used to analyze data from transducers, identify patterns, and extract meaningful insights. This capability enhances the accuracy and reliability of transducer measurements, enabling better decision-making. For example, AI-powered algorithms can be used to analyze data from vibration sensors to detect early signs of machine failure.

- Adaptive Transducers: AI and ML algorithms can be used to create adaptive transducers that can learn and adjust their performance based on environmental conditions or user preferences. This capability allows for the development of more intelligent and responsive transducers. For example, AI-driven transducers can be used in healthcare applications to personalize treatment plans based on individual patient data.

- Predictive Maintenance: AI and ML algorithms can be used to predict potential failures in machines and systems based on data from transducers. This capability enables proactive maintenance and reduces downtime, improving overall system efficiency. For example, AI-powered predictive maintenance systems can analyze data from vibration sensors and temperature sensors to anticipate potential failures in industrial equipment.

Emerging Applications

The advancements in transducer technology are driving the development of new and innovative applications in various industries.

- Internet of Things (IoT): Transducers play a crucial role in the IoT by enabling the collection of data from physical objects and environments. The integration of transducers with wireless communication technologies and cloud computing platforms allows for real-time monitoring, control, and data analysis. For example, IoT sensors can be used to monitor environmental conditions in smart cities, optimize energy consumption in buildings, and enhance safety in industrial settings.

- Healthcare: Transducers are increasingly being used in healthcare applications for diagnosis, monitoring, and treatment. Advancements in biocompatible materials, miniaturization, and wireless communication technologies are enabling the development of implantable and wearable sensors for continuous health monitoring, drug delivery, and personalized medicine. For example, wearable sensors can monitor heart rate, blood pressure, and other vital signs, providing valuable insights into patient health and enabling early intervention.

- Robotics and Automation: Transducers are essential for robotic systems, providing feedback on position, force, and other parameters. The development of more accurate, robust, and integrated transducers is enabling the creation of more sophisticated and intelligent robots for a wide range of applications, including manufacturing, logistics, and healthcare. For example, force sensors integrated into robotic arms allow for precise manipulation and interaction with objects, enhancing the capabilities of robots in industrial and surgical settings.

Epilogue

As we delve into the world of NK Technologies current transducers, it becomes clear that these devices are more than just measurement tools. They are essential components that enable innovation and efficiency in countless applications. By understanding the principles behind their operation, the various types available, and their integration into systems, we can harness the power of these transducers to drive progress in our modern world.

NK Technologies’ current transducer line offers a variety of options for measuring force and pressure, making them valuable tools in various industries. This technology is finding new applications in the healthcare field, particularly in new chiropractic technology , where precise measurements are crucial for assessing spinal health and guiding treatment plans.

The versatility of NK Technologies’ transducers makes them a compelling choice for chiropractors seeking to enhance their practice and provide more accurate diagnoses.