Wiper Technologies: Keeping Things Clear

Wiper technologies, essential for maintaining visibility in various environments, have evolved significantly over time. From the simple windshield wipers of early automobiles to the sophisticated sensor-based systems of modern vehicles, […]

Wiper technologies, essential for maintaining visibility in various environments, have evolved significantly over time. From the simple windshield wipers of early automobiles to the sophisticated sensor-based systems of modern vehicles, wiper technologies have played a crucial role in ensuring safety and functionality. This exploration delves into the fascinating world of wipers, uncovering their diverse applications, technological advancements, and future trends.

The purpose of wiper technologies is to remove debris, water, and other obstructions from surfaces, ensuring clear visibility. This is crucial in industries like automotive, aerospace, industrial, and marine, where visibility is paramount for safe operation. Different types of wipers exist, each tailored to specific applications and environments. From conventional blade-based wipers to advanced sensor-driven systems, wiper technologies have adapted to meet the diverse needs of various industries.

Wiper Technologies

Wiper technologies are essential components in various industries, playing a crucial role in maintaining cleanliness, efficiency, and safety. They are designed to remove unwanted substances, debris, and contaminants from surfaces, ensuring optimal performance and longevity of equipment.

Types of Wipers

Wiper technologies encompass a diverse range of designs and functionalities, each tailored to specific applications. These types of wipers offer distinct advantages, catering to different needs and environments.

- Blade Wipers: Blade wipers are widely used in automotive applications, utilizing a flexible blade to remove water and debris from windshields. These wipers are typically driven by an electric motor and feature adjustable settings for speed and angle.

- Squeegee Wipers: Squeegee wipers, commonly found in industrial settings, employ a rubber blade to effectively remove liquids from surfaces. These wipers are often used in conjunction with a cleaning solution to achieve thorough cleaning.

- Rotary Wipers: Rotary wipers, also known as circular wipers, utilize a rotating disc or brush to clean surfaces. They are commonly employed in applications where continuous cleaning is required, such as in printing presses or conveyor belts.

- Air Wipers: Air wipers utilize a high-velocity stream of air to remove debris and contaminants from surfaces. They are particularly useful in environments where water or other liquids are undesirable, such as in food processing or pharmaceutical manufacturing.

- Vacuum Wipers: Vacuum wipers combine the suction power of a vacuum with a wiper blade to remove debris and liquids. These wipers are often used in industrial settings where cleanliness is paramount, such as in semiconductor manufacturing or cleanroom environments.

Wiper Technology Components

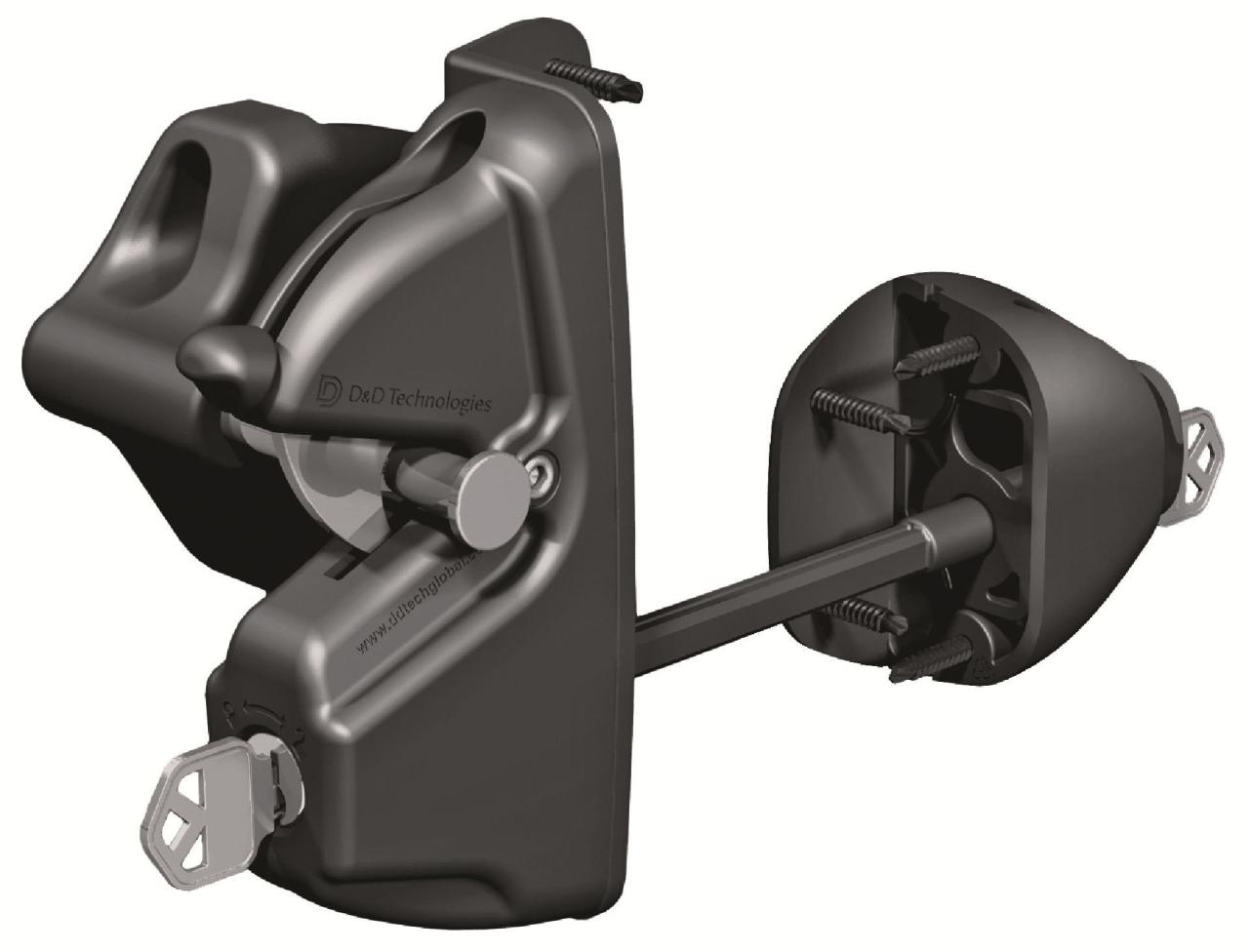

A wiper system is a crucial safety feature in vehicles, ensuring clear visibility during inclement weather conditions. It consists of several interconnected components that work together to effectively remove rain, snow, and debris from the windshield.

Components of a Wiper System

The following are the essential components of a typical wiper system:

- Blade: The blade is the rubber or synthetic material that directly contacts the windshield. It is responsible for removing water and debris. The blade’s design and material significantly impact its performance, such as its ability to evenly distribute pressure and prevent streaking.

- Arm: The arm is a metal or plastic structure that connects the blade to the motor. It pivots on a central point, allowing the blade to move across the windshield. The arm’s length and shape influence the coverage area and pressure distribution.

- Motor: The motor provides the power to drive the wiper arm. It converts electrical energy into mechanical energy, rotating the arm and blade. The motor’s speed and torque determine the wiper’s speed and force.

- Linkage: The linkage connects the motor to the arm and transmits the motor’s rotation to the arm. It often consists of a series of rods and pivots that allow the arm to move in a specific path across the windshield.

Materials Used in Wiper Components

The materials used in wiper components have a significant impact on their performance and durability.

- Blades: Modern blades often use synthetic rubber or a blend of rubber and other materials, such as silicone, to provide optimal wiping performance. These materials are designed to resist wear and tear, maintain flexibility in cold temperatures, and prevent streaking.

- Arms: Arms are typically made of steel or plastic. Steel arms offer durability and resistance to bending, while plastic arms provide flexibility and are lighter in weight. The choice of material depends on the specific design and application.

- Motor: Wiper motors are typically made of durable materials such as steel and aluminum. The motor’s housing and internal components are designed to withstand vibration and heat.

- Linkage: The linkage components are often made of steel or plastic, depending on the design and size of the system.

Wiper Technology Advancements: Wiper Technologies

The automotive industry has witnessed significant advancements in wiper technology, driven by the pursuit of enhanced safety, comfort, and driver convenience. These innovations have led to the development of more sophisticated and intelligent wiper systems that adapt to varying weather conditions and driving situations.

Sensor-Based Wiper Systems

Sensor-based wiper systems utilize sensors to detect precipitation levels, such as rain or snow, and automatically activate the wipers accordingly. These systems eliminate the need for manual adjustment, ensuring optimal visibility and enhancing safety, especially in challenging weather conditions.

- Rain Sensors: These sensors use infrared light to detect water droplets on the windshield and adjust the wiper speed based on the intensity of the rainfall.

- Light Sensors: Some wiper systems integrate light sensors that can detect changes in ambient light levels and activate the wipers when it starts to rain or snow, even if the driver hasn’t noticed the precipitation.

The benefits of sensor-based wiper systems include:

- Enhanced Safety: By automatically activating the wipers, these systems ensure optimal visibility, reducing the risk of accidents caused by poor visibility.

- Driver Convenience: Drivers can focus on the road ahead without having to manually adjust the wiper speed.

- Improved Windshield Life: By adjusting the wiper speed based on the intensity of the precipitation, these systems help to prevent excessive wear and tear on the windshield and wiper blades.

However, these systems also present some challenges:

- Cost: Sensor-based wiper systems are generally more expensive than traditional wiper systems.

- Calibration: These systems require proper calibration to ensure accurate detection and activation of the wipers.

- Sensitivity: Some sensors can be overly sensitive to small amounts of precipitation, leading to unnecessary wiper activation.

Examples of companies leading the development of sensor-based wiper systems include Bosch, Valeo, and Denso.

Variable-Speed Wipers

Variable-speed wiper systems offer drivers the ability to adjust the wiper speed based on the intensity of the precipitation and driving conditions. This feature provides greater control and adaptability, allowing drivers to choose the optimal wiper speed for their specific needs.

- Multiple Speed Settings: Most variable-speed wiper systems offer multiple speed settings, ranging from slow intermittent speeds for light rain to fast continuous speeds for heavy rain or snow.

- Intermittent Wiping: This feature allows the wipers to operate at intervals, providing a more efficient and less intrusive wiping experience during light rain or snow.

The benefits of variable-speed wiper systems include:

- Enhanced Visibility: By adjusting the wiper speed to match the precipitation intensity, drivers can maintain optimal visibility in all weather conditions.

- Reduced Windshield Wear: Using the appropriate wiper speed for the conditions helps to minimize wear and tear on the windshield and wiper blades.

- Driver Control: Variable-speed wipers give drivers greater control over the wiping process, allowing them to customize the speed based on their preferences.

However, these systems also have some limitations:

- Complexity: Variable-speed wiper systems are more complex than traditional systems, which can increase the risk of malfunctions.

- Cost: Variable-speed wiper systems are generally more expensive than traditional systems.

Companies like Bosch, Valeo, and Denso are at the forefront of developing variable-speed wiper systems.

Heated Wiper Blades

Heated wiper blades are designed to prevent ice and snow from accumulating on the blades, ensuring optimal wiping performance in cold weather conditions. These blades typically incorporate a heating element that melts away ice and snow, preventing them from obstructing the wiper’s movement.

- Improved Visibility: Heated wiper blades ensure clear visibility in cold weather by preventing ice and snow from accumulating on the blades.

- Reduced Wear and Tear: By preventing ice and snow from freezing to the blades, heated wiper blades reduce wear and tear on the blades and windshield.

- Enhanced Safety: Clear visibility in cold weather is crucial for safe driving, and heated wiper blades help to achieve this.

However, heated wiper blades also present some drawbacks:

- Cost: Heated wiper blades are generally more expensive than traditional wiper blades.

- Power Consumption: Heated wiper blades require additional power, which can increase the load on the vehicle’s electrical system.

- Limited Availability: Heated wiper blades are not widely available for all vehicle models.

Companies such as Bosch, Valeo, and Michelin are actively developing and manufacturing heated wiper blades.

Wiper Technology Applications

Wiper technologies are widely used in various industries to ensure clear visibility and optimal performance. Their applications range from automotive to aerospace, industrial, and marine sectors, each with unique requirements and challenges. This section will delve into the diverse applications of wiper technologies across these industries, highlighting specific examples of how wipers are used in each field.

Automotive

Wiper technologies are indispensable in the automotive industry, ensuring driver safety and visibility during adverse weather conditions.

- Windshield Wipers: These are the most common application of wiper technologies in vehicles. Windshield wipers use a rubber blade that sweeps across the windshield, removing rain, snow, and debris, ensuring clear visibility for the driver. They are often equipped with various features like speed control, intermittent wiping, and rain sensors for optimal performance.

- Rear Window Wipers: These wipers are essential for maintaining visibility while reversing, especially in rainy or snowy conditions. They are typically smaller than windshield wipers and operate at a slower speed.

- Headlight Wipers: In some vehicles, especially those operating in harsh environments, headlight wipers are used to keep the headlights clean and ensure optimal illumination.

Aerospace

Wiper technologies play a crucial role in the aerospace industry, particularly in aircraft and spacecraft, where maintaining clear visibility is paramount for safety and performance.

- Aircraft Windshield Wipers: These wipers are designed to withstand extreme weather conditions, including high winds, rain, and ice. They often feature specialized materials and designs to ensure reliable operation in harsh environments.

- Cockpit Canopy Wipers: Aircraft cockpits often have transparent canopies that require wipers for maintaining visibility. These wipers are typically designed to operate at high speeds and can be equipped with heated blades to prevent ice build-up.

- Spacecraft Windows: Some spacecraft, like the International Space Station, have windows that require wipers to remove dust and debris accumulated during spacewalks or from micrometeoroid impacts.

Industrial

Wiper technologies find extensive applications in various industrial settings, where maintaining clear visibility is crucial for safety, efficiency, and productivity.

- Heavy Equipment Wipers: Construction equipment, mining vehicles, and agricultural machinery often operate in dusty or muddy environments. Wipers are used to keep the windows and windshields clean, improving operator visibility and safety.

- Industrial Machinery Wipers: Many industrial machines, like lathes, milling machines, and robots, have protective windows or screens that require wipers to maintain visibility and prevent debris from entering the working area.

- Automated Guided Vehicles (AGVs): AGVs, used in warehouses and factories, often have cameras or sensors that require wipers to maintain clear visibility for navigation and obstacle avoidance.

Marine

Wiper technologies are essential for vessels of all sizes, ensuring clear visibility for navigation and safety in maritime environments.

- Ship Bridge Wipers: These wipers are crucial for the captain and crew to maintain visibility from the bridge, especially during inclement weather or fog.

- Radar and Navigation Equipment Wipers: Radar and navigation equipment often have protective covers or domes that require wipers to maintain clear visibility and optimal performance.

- Submarine Periscopes: Submarines use wipers to keep the periscope lenses clean, allowing the crew to observe the surface without compromising their underwater position.

Future Trends in Wiper Technology

The automotive industry is constantly evolving, and wiper technology is no exception. Emerging trends are pushing the boundaries of what’s possible, leading to more efficient, intelligent, and adaptable wiper systems. These advancements are not only improving the driving experience but also enhancing safety and driver assistance.

Integration of Artificial Intelligence

The integration of AI into wiper systems is revolutionizing how they operate. AI-powered wipers can analyze various factors like weather conditions, road conditions, and even driver behavior to optimize performance.

- AI algorithms can analyze real-time data from sensors like rain detectors, cameras, and even lidar systems to predict the intensity and type of precipitation.

- This information allows for more precise control of wiper speed and blade movement, ensuring optimal visibility regardless of weather conditions.

- AI can also learn driver preferences and adapt wiper settings accordingly, providing a personalized driving experience.

Autonomous Wiper Systems

Autonomous wiper systems represent the next level of automation in vehicle technology. These systems are designed to operate independently, eliminating the need for manual intervention.

- Autonomous wipers utilize advanced sensors and algorithms to detect precipitation and automatically adjust wiper speed and blade position.

- They can even anticipate upcoming weather changes, ensuring the windshield remains clear before the rain starts.

- This technology is particularly valuable for autonomous vehicles, as it ensures optimal visibility for self-driving systems.

Advanced Materials

The use of advanced materials is significantly enhancing the performance and durability of wiper blades.

- Materials like silicone and graphene offer superior resistance to wear and tear, extending blade lifespan and improving cleaning performance.

- These materials also provide better water repellency and resistance to ice and snow, ensuring optimal visibility in harsh weather conditions.

- The development of lighter and more flexible materials is also improving the efficiency and quietness of wiper systems.

Hypothetical Scenario: Future of Wiper Technology in Autonomous Vehicles, Wiper technologies

Imagine a future where autonomous vehicles navigate complex urban environments, seamlessly adapting to changing weather conditions.

- AI-powered wipers would analyze real-time data from sensors, predicting precipitation and adjusting wiper speed and blade position in advance.

- Autonomous wiper systems would operate independently, ensuring optimal visibility for self-driving systems even in heavy rain or snow.

- Advanced materials would enhance blade durability and performance, minimizing maintenance and ensuring a clear view for the autonomous vehicle’s perception systems.

Last Recap

Wiper technologies have come a long way, driven by the need for enhanced visibility and safety. As we look towards the future, the integration of artificial intelligence, autonomous systems, and advanced materials promises to further revolutionize wiper technology. From self-adjusting wipers that anticipate weather conditions to nanomaterial blades that resist wear and tear, the future of wiper technology holds exciting possibilities for enhanced performance and efficiency across industries.

Wiper technologies are crucial for ensuring clear visibility in various applications, from automotive windshields to industrial machinery. These technologies are constantly evolving, with advancements in materials, design, and automation. Companies like brenco equipment supply & technology play a vital role in supplying the equipment and expertise needed to implement these innovations.

Whether it’s providing advanced wiper blades for heavy-duty vehicles or specialized cleaning solutions for industrial settings, Brenco’s contributions to the wiper technology landscape are significant.