Aircraft Engineering and Aerospace Technology: A Journey of Innovation

Aircraft engineering and aerospace technology have always been at the forefront of innovation, pushing the boundaries of human ingenuity and shaping our world. From the first rudimentary gliders to the […]

Aircraft engineering and aerospace technology have always been at the forefront of innovation, pushing the boundaries of human ingenuity and shaping our world. From the first rudimentary gliders to the sophisticated spacecraft of today, the journey of flight has been a testament to the power of scientific exploration and engineering excellence.

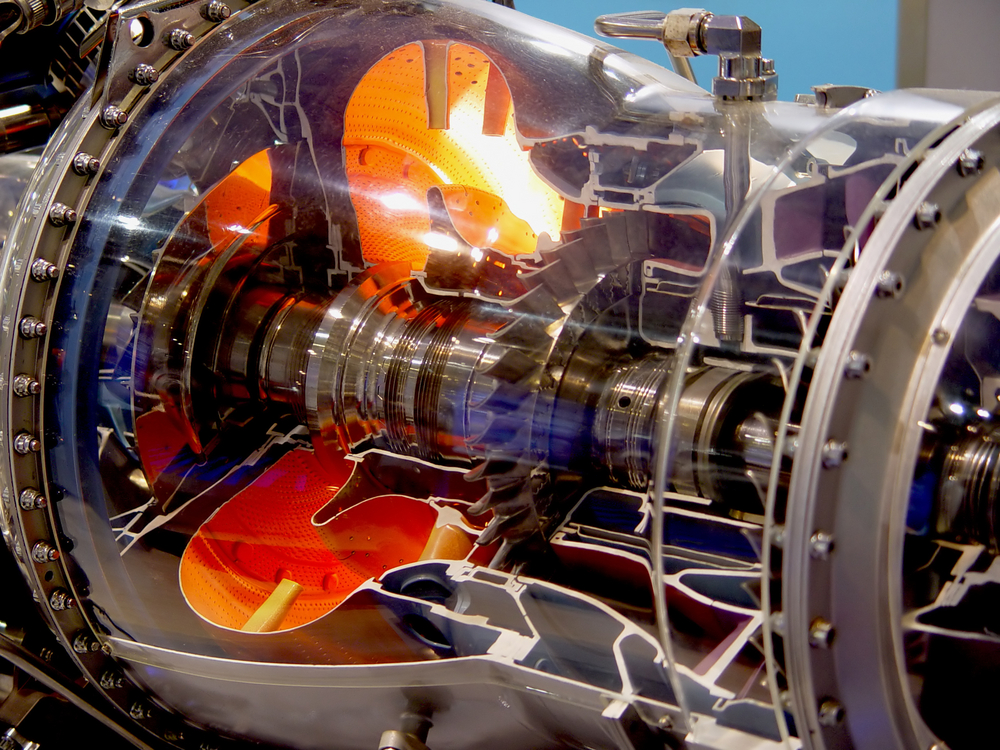

This field encompasses a diverse range of disciplines, including aerodynamics, propulsion, structures, avionics, and materials science, each playing a crucial role in the design, development, and operation of aircraft. The principles of aerodynamics, for instance, are fundamental to understanding how aircraft generate lift and maneuver through the air, while propulsion systems provide the power to propel these marvels of engineering through the sky.

Aircraft Structures and Materials: Aircraft Engineering And Aerospace Technology

Aircraft structures are designed to withstand the extreme stresses and loads they experience during flight. Understanding the fundamental principles of structural mechanics is crucial for ensuring the safety and efficiency of aircraft.

Structural Mechanics in Aircraft Design

Structural mechanics is a branch of mechanics that deals with the behavior of rigid bodies under the action of forces. It involves the analysis of stresses, strains, and deformations in materials. In aircraft design, structural mechanics plays a vital role in determining the strength, stiffness, and stability of aircraft components.

The basic principles of structural mechanics include:

- Stress and Strain: Stress is the force per unit area acting on a material, while strain is the deformation of the material under stress. The relationship between stress and strain is known as the material’s constitutive law.

- Equilibrium: The forces acting on an aircraft structure must be in equilibrium to prevent the structure from collapsing. This principle is used to analyze the loads and stresses acting on different parts of the aircraft.

- Compatibility: The deformation of different parts of the aircraft must be compatible to ensure the structure remains intact. This principle is used to analyze the behavior of the structure under different loading conditions.

These principles are applied in aircraft design through various methods, including:

- Finite Element Analysis (FEA): FEA is a numerical method used to analyze the behavior of complex structures by dividing them into smaller elements. This method allows engineers to predict the stress distribution, deformation, and stability of the aircraft under different loading conditions.

- Structural Optimization: This involves finding the optimal design of the aircraft structure to minimize weight while meeting strength and stiffness requirements. This can be achieved using various optimization techniques, such as genetic algorithms and gradient-based methods.

Aircraft Materials

The choice of materials is critical in aircraft design, as it significantly impacts the aircraft’s performance, weight, and cost. Aircraft materials must possess specific properties, including:

- High Strength-to-Weight Ratio: This is essential for minimizing aircraft weight and maximizing payload capacity.

- Good Fatigue Resistance: Aircraft structures experience cyclic loading during flight, so materials must resist fatigue failure.

- Corrosion Resistance: Aircraft operate in harsh environments, so materials must resist corrosion.

- High Stiffness: This is essential for maintaining the aircraft’s structural integrity and shape under load.

- Good Machinability: Materials must be easy to fabricate and assemble.

Common aircraft materials include:

- Aluminum Alloys: Aluminum alloys are widely used in aircraft structures due to their high strength-to-weight ratio, good corrosion resistance, and ease of fabrication. They are used in fuselage, wings, and other structural components.

- Titanium Alloys: Titanium alloys have excellent strength-to-weight ratio, high melting point, and good corrosion resistance. They are used in high-stress areas, such as landing gear, engine components, and high-temperature applications.

- Composites: Composites are materials made by combining two or more materials with different properties. They offer high strength-to-weight ratio, good fatigue resistance, and can be tailored to specific applications. Common composite materials include carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP).

Advantages and Disadvantages of Aircraft Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum Alloys | High strength-to-weight ratio, good corrosion resistance, easy to fabricate | Lower melting point compared to titanium, susceptible to fatigue under high stress |

| Titanium Alloys | Excellent strength-to-weight ratio, high melting point, good corrosion resistance | High cost, difficult to machine |

| Composites (CFRP) | High strength-to-weight ratio, good fatigue resistance, customizable properties | High cost, susceptibility to damage, difficult to repair |

Aircraft Avionics and Flight Control Systems

Avionics, a portmanteau of “aviation” and “electronics,” refers to the electronic systems used in aircraft. These systems play a crucial role in modern aircraft, handling navigation, communication, and flight control, making them indispensable for safe and efficient operations.

The Role of Avionics Systems

Avionics systems encompass a wide range of technologies, including navigation systems, communication systems, and flight control systems. These systems are integrated to provide pilots with the necessary information and tools to safely operate the aircraft.

- Navigation Systems: These systems are responsible for determining the aircraft’s position, altitude, and heading. Examples include the Global Positioning System (GPS), Inertial Navigation Systems (INS), and radio navigation aids like VOR/DME. These systems provide pilots with accurate and real-time information for route planning and safe navigation.

- Communication Systems: These systems enable communication between the aircraft and ground stations, other aircraft, and air traffic control. Examples include VHF radio, HF radio, and satellite communication systems. These systems are essential for maintaining communication with air traffic control, receiving weather updates, and coordinating with other aircraft.

- Flight Control Systems: These systems are responsible for controlling the aircraft’s flight path, including pitch, roll, and yaw. They receive inputs from the pilot’s controls and translate them into commands for the aircraft’s actuators, such as control surfaces and engines. Modern flight control systems are increasingly incorporating advanced technologies like fly-by-wire and adaptive control.

Autopilot Systems

Autopilot systems are a key component of modern aircraft avionics. These systems use sensors and actuators to automatically control the aircraft’s flight path, relieving the pilot from manual control. Autopilots contribute to flight safety by:

- Reducing Pilot Workload: Autopilots allow pilots to focus on other tasks, such as monitoring systems, communicating with air traffic control, and managing fuel. This reduces pilot fatigue and the risk of errors.

- Enhancing Precision and Accuracy: Autopilots are capable of maintaining a precise flight path and altitude, even in challenging conditions. This improves flight efficiency and reduces fuel consumption.

- Improving Flight Safety: Autopilots can automatically correct for unexpected events, such as turbulence or engine failure. This can help to prevent accidents and improve overall flight safety.

Advanced Flight Control Technologies

Modern aircraft are increasingly incorporating advanced flight control technologies, such as fly-by-wire and adaptive control, to further enhance safety and efficiency.

- Fly-by-Wire: This technology uses electronic signals instead of mechanical linkages to control the aircraft’s flight surfaces. This allows for more precise control and enables the implementation of advanced flight control features, such as stability augmentation and automated flight control.

- Adaptive Control: This technology uses sensors to monitor the aircraft’s flight conditions and automatically adjust the control system parameters to optimize performance. This can help to improve aircraft stability, reduce fuel consumption, and enhance overall flight safety.

Aerospace Technology and Innovation

The aerospace industry is constantly evolving, driven by advancements in technology, changing societal needs, and a relentless pursuit of pushing the boundaries of human exploration. This section explores key trends and challenges shaping the future of aerospace, delving into the role of emerging technologies and highlighting significant milestones in aerospace history.

Sustainability in Aerospace

The aerospace industry is facing increasing pressure to reduce its environmental impact. Sustainability is no longer a mere aspiration but a critical necessity. Key trends include:

- Development of Sustainable Aviation Fuels (SAF): These fuels, derived from renewable sources like biomass or waste, significantly reduce carbon emissions compared to traditional jet fuel. Examples include sustainable aviation fuel produced from cooking oil, agricultural waste, or algae.

- Electric and Hybrid-Electric Aircraft: The development of electric and hybrid-electric aircraft is gaining momentum, offering the potential for zero-emission flight, particularly for shorter-range routes.

- Improved Aircraft Efficiency: Ongoing research and development focus on optimizing aircraft design, reducing weight, and improving aerodynamic performance to minimize fuel consumption.

Challenges include the need for large-scale production of SAF, the development of robust and lightweight batteries for electric aircraft, and the integration of sustainable technologies into existing infrastructure.

Hypersonic Flight, Aircraft engineering and aerospace technology

Hypersonic flight, defined as travel at speeds exceeding Mach 5 (five times the speed of sound), is a highly challenging but potentially transformative area of aerospace technology.

- Military Applications: Hypersonic vehicles offer significant strategic advantages in military operations, including rapid deployment and the ability to strike targets with greater speed and precision.

- Commercial Applications: The potential for faster and more efficient transcontinental travel is driving interest in developing hypersonic passenger aircraft, although the technical and safety challenges are substantial.

Key challenges include the extreme temperatures and aerodynamic forces experienced at hypersonic speeds, the need for advanced materials and propulsion systems, and the development of reliable and safe hypersonic vehicles.

Space Exploration

Space exploration continues to push the boundaries of human knowledge and technological innovation.

- Private Spaceflight: The emergence of private spaceflight companies like SpaceX and Blue Origin has democratized access to space, fostering competition and driving innovation in areas like reusable launch vehicles and spacecraft design.

- Lunar and Martian Exploration: Missions to the Moon and Mars are central to ongoing space exploration efforts, with the goal of establishing long-term human presence on these celestial bodies.

- Space Tourism: The prospect of space tourism is becoming increasingly viable, with companies offering suborbital flights and longer-duration space experiences.

Challenges include the high costs associated with space exploration, the development of technologies for long-duration space missions, and the need to address the potential environmental impacts of space activities.

Role of Emerging Technologies

Artificial intelligence (AI) and machine learning (ML) are transforming the aerospace industry, driving advancements in areas like:

- Autonomous Flight: AI-powered systems are being developed to automate various aspects of flight, including navigation, collision avoidance, and even landing.

- Predictive Maintenance: AI algorithms can analyze sensor data to predict potential aircraft failures, enabling proactive maintenance and reducing downtime.

- Design Optimization: AI and ML are being used to optimize aircraft design, reducing weight, improving fuel efficiency, and enhancing performance.

- Air Traffic Management: AI-based systems can improve air traffic management by optimizing flight paths, reducing delays, and enhancing safety.

Career Opportunities in Aircraft Engineering and Aerospace Technology

A career in aircraft engineering and aerospace technology offers a wide range of opportunities for individuals with a passion for innovation, problem-solving, and pushing the boundaries of what’s possible. From designing cutting-edge aircraft to developing advanced propulsion systems, this field provides a dynamic and intellectually stimulating environment.

Career Paths in Aircraft Engineering and Aerospace Technology

The aircraft engineering and aerospace technology field encompasses a variety of career paths, each with its own unique set of challenges and rewards. These career paths can be broadly categorized into research, design, manufacturing, and operations.

| Career Path | Description | Skills and Qualifications |

|---|---|---|

| Research | Conducting research and development in areas such as aerodynamics, materials science, propulsion, and avionics. | Strong analytical and problem-solving skills, a deep understanding of scientific principles, and advanced degrees in aerospace engineering or related fields. |

| Design | Designing and developing aircraft, spacecraft, and related systems, including airframes, engines, and avionics. | Strong technical skills, proficiency in computer-aided design (CAD) software, and a thorough understanding of aircraft design principles. |

| Manufacturing | Overseeing the production of aircraft and aerospace components, ensuring quality control, and managing production processes. | Experience in manufacturing processes, knowledge of materials and fabrication techniques, and strong organizational and leadership skills. |

| Operations | Working in areas such as flight operations, maintenance, and air traffic control. | Strong communication and interpersonal skills, knowledge of aviation regulations, and experience in flight operations or maintenance. |

Skills and Qualifications

Success in aircraft engineering and aerospace technology requires a unique blend of technical skills, problem-solving abilities, and soft skills. Some of the essential skills and qualifications include:

- Strong analytical and problem-solving skills: The ability to identify and solve complex technical challenges is crucial in this field.

- Proficiency in engineering software: Aircraft engineers and aerospace professionals need to be proficient in software tools such as CAD, FEA, and CFD.

- Knowledge of aircraft design principles: A deep understanding of aerodynamics, structural mechanics, propulsion systems, and avionics is essential.

- Strong communication and interpersonal skills: The ability to communicate effectively with colleagues, clients, and stakeholders is critical for success in this field.

- Teamwork and collaboration: Many projects in aircraft engineering and aerospace technology involve large teams of engineers, designers, and technicians working together.

- Adaptability and continuous learning: The field of aircraft engineering and aerospace technology is constantly evolving, so professionals need to be adaptable and willing to learn new skills.

Job Market Outlook

The job market outlook for aircraft engineers and aerospace professionals is generally positive, with continued demand for skilled professionals in this field. The growth of the aerospace industry, driven by factors such as increasing air travel demand, advancements in technology, and the development of new aircraft and spacecraft, is expected to create new job opportunities in the coming years.

However, competition for these positions can be intense, and employers are seeking candidates with strong technical skills, relevant experience, and a commitment to lifelong learning.

Conclusive Thoughts

The future of aircraft engineering and aerospace technology holds immense promise, with advancements in areas like sustainable aviation, hypersonic flight, and space exploration. The integration of emerging technologies, such as artificial intelligence and machine learning, is poised to revolutionize the industry, leading to more efficient, safer, and environmentally responsible aircraft. As we continue to explore the frontiers of flight, the impact of this field on our lives will only grow more profound.

Aircraft engineering and aerospace technology are constantly evolving, pushing the boundaries of what’s possible in terms of flight. One company leading the charge in this field is linkzone technology co. limited , a company dedicated to developing innovative solutions for the aerospace industry.

Their expertise in areas like avionics and flight control systems contributes to the advancement of aircraft engineering and helps shape the future of aerospace technology.