Strip Technology: Revolutionizing Industries

Strip technology, a versatile and innovative approach, has emerged as a game-changer across various industries. This technology, characterized by its unique design and manufacturing processes, offers numerous advantages over traditional […]

Strip technology, a versatile and innovative approach, has emerged as a game-changer across various industries. This technology, characterized by its unique design and manufacturing processes, offers numerous advantages over traditional methods, leading to enhanced efficiency, improved performance, and cost savings. From electronics and automotive to construction and aerospace, strip technology has found its way into countless applications, shaping the future of modern manufacturing and engineering.

The core concept of strip technology revolves around the creation of thin, elongated components, often with intricate designs and precise dimensions. These strips are produced using specialized manufacturing processes, ensuring high levels of precision and consistency. The versatility of strip technology allows for its application in a wide range of industries, with each sector leveraging its unique advantages to optimize production and enhance product quality.

Strip Technology

Strip technology, encompassing various applications from magnetic stripes on cards to the intricate circuitry of flexible electronics, is poised for significant advancements. This technology is constantly evolving, driven by innovations in materials science, manufacturing processes, and design principles.

Emerging Trends and Advancements

The future of strip technology is marked by exciting advancements in materials, manufacturing, and applications. This section explores key trends shaping the landscape of this technology.

- Flexible and Stretchable Materials: The development of flexible and stretchable materials, such as graphene, carbon nanotubes, and conductive polymers, is enabling the creation of strip-based devices that can conform to curved surfaces and withstand bending and stretching. These materials are revolutionizing the design of wearable electronics, sensors, and medical devices.

- 3D Printing and Additive Manufacturing: 3D printing techniques are transforming the fabrication of strip-based devices, allowing for complex geometries and customized designs. This approach enables the creation of intricate structures with integrated functionalities, paving the way for more sophisticated and adaptable strip technologies.

- Nano-scale Engineering: Advancements in nano-scale engineering are enabling the development of strip-based devices with enhanced performance and miniaturization. For example, the use of nanowires and quantum dots in strip sensors is improving sensitivity and accuracy, leading to applications in healthcare, environmental monitoring, and security.

- Biocompatible and Biodegradable Materials: The increasing focus on biocompatibility and biodegradability is driving the development of strip-based devices for medical applications. Biocompatible materials ensure minimal tissue rejection and biodegradability allows for temporary devices that dissolve after their purpose is fulfilled.

Impact on Existing Applications

These advancements in strip technology are set to transform existing applications and create new possibilities across diverse industries.

- Smart Packaging: Flexible and stretchable strip sensors can be integrated into packaging materials to monitor temperature, humidity, and pressure, providing real-time information about the condition of goods during transportation and storage. This technology enhances product safety and reduces waste.

- Wearable Electronics: Strip technology is crucial for the development of wearable electronics, enabling the creation of flexible and comfortable devices that can be seamlessly integrated into clothing or worn on the skin. These devices offer numerous applications in health monitoring, fitness tracking, and entertainment.

- Medical Devices: Strip-based sensors and actuators are revolutionizing medical devices, enabling the development of minimally invasive procedures, personalized treatments, and real-time health monitoring. For example, flexible strips with embedded sensors can be used to monitor vital signs, deliver medication, or even stimulate nerve cells.

- Energy Harvesting: Strip technology plays a vital role in energy harvesting, enabling the creation of flexible and lightweight solar cells, thermoelectric generators, and piezoelectric devices. These technologies can convert ambient energy sources, such as sunlight, heat, and mechanical vibrations, into electricity, powering wearable devices and sensors.

Timeline of Key Milestones and Future Projections

The evolution of strip technology has been marked by several key milestones, and future projections suggest continued innovation and widespread adoption.

| Year | Milestone |

|---|---|

| 1950s | Introduction of magnetic stripe cards for payment and identification. |

| 1970s | Development of flexible printed circuits, paving the way for strip-based electronics. |

| 1990s | Advancements in microelectronics and materials science lead to the creation of more sophisticated strip-based devices. |

| 2000s | Emergence of organic electronics and the development of flexible and stretchable materials. |

| 2010s | Rapid growth of wearable electronics, smart packaging, and medical devices incorporating strip technology. |

| 2020s and Beyond | Continued innovation in materials, manufacturing, and applications, leading to widespread adoption of strip technology in various sectors. |

Concept for a New Application of Strip Technology

Drawing inspiration from current trends, a novel application of strip technology could revolutionize the field of personalized medicine. Imagine a flexible, biocompatible strip that can be seamlessly integrated into a patient’s skin, acting as a microfluidic device for targeted drug delivery. This “smart patch” would incorporate sensors to monitor the patient’s physiological parameters, such as blood glucose levels, and release medication in a controlled and personalized manner. The strip could also be equipped with wireless communication capabilities, enabling real-time data transmission to healthcare providers. This concept offers a promising solution for chronic disease management, personalized treatment, and improved patient outcomes.

Strip Technology: Environmental and Societal Impacts

Strip technology, while offering numerous advantages in various fields, also carries potential environmental and societal implications that warrant careful consideration. Analyzing these impacts is crucial for promoting responsible and sustainable adoption of this innovative technology.

Environmental Impact of Strip Technology Production and Use

The environmental impact of strip technology production and use is multifaceted and depends on various factors, including the specific materials used, manufacturing processes, and operational conditions.

- Resource Extraction and Material Processing: The production of strip technology components, such as silicon wafers, requires significant energy and resources. Mining and processing of raw materials, such as silicon, can have environmental impacts, including habitat destruction, air and water pollution, and greenhouse gas emissions.

- Energy Consumption: The operation of strip technology, especially in applications like data centers, can consume substantial amounts of electricity. This can lead to increased reliance on fossil fuels and contribute to greenhouse gas emissions.

- Waste Generation: The disposal of outdated or malfunctioning strip technology devices can create electronic waste, which can pose environmental risks if not managed properly.

- Water Consumption: Some strip technology manufacturing processes require significant amounts of water for cooling and cleaning. This can strain water resources in areas with water scarcity.

Societal Benefits and Drawbacks of Widespread Strip Technology Adoption

The potential societal benefits and drawbacks of widespread strip technology adoption are interconnected and can have both positive and negative consequences.

- Economic Growth and Job Creation: The development and deployment of strip technology can stimulate economic growth and create new jobs in sectors such as manufacturing, research, and development.

- Enhanced Productivity and Efficiency: Strip technology can significantly enhance productivity and efficiency in various industries, leading to improved economic performance and reduced costs.

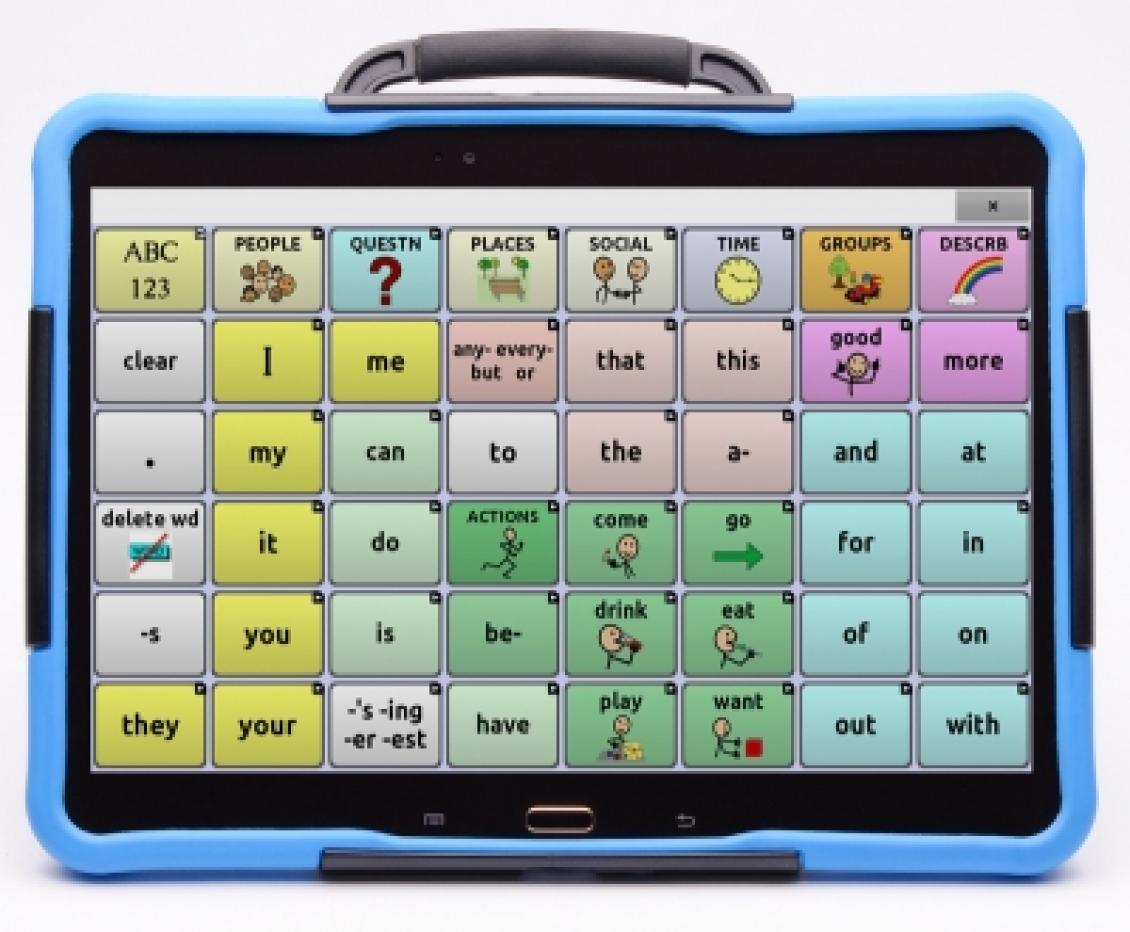

- Improved Healthcare and Education: Strip technology plays a crucial role in advancing healthcare and education through applications such as medical imaging, drug discovery, and personalized learning.

- Digital Divide: The widespread adoption of strip technology could exacerbate the digital divide, particularly in underserved communities with limited access to technology and infrastructure.

- Privacy Concerns: The increasing reliance on strip technology raises concerns about privacy and data security, as personal information can be collected and analyzed without explicit consent.

- Job Displacement: The automation capabilities of strip technology could lead to job displacement in certain sectors, requiring retraining and upskilling of the workforce.

Examples of How Strip Technology Can Contribute to Sustainable Practices

Despite the potential environmental concerns, strip technology can contribute to sustainable practices in various ways.

- Energy Efficiency: Strip technology can be used to develop energy-efficient devices and systems, reducing overall energy consumption and greenhouse gas emissions.

- Renewable Energy Integration: Strip technology can facilitate the integration of renewable energy sources, such as solar and wind power, into the grid, promoting clean energy adoption.

- Smart Cities and Infrastructure: Strip technology can be utilized in smart cities and infrastructure projects to optimize resource usage, improve transportation efficiency, and reduce environmental impact.

- Precision Agriculture: Strip technology can enable precision agriculture practices, optimizing crop yields, reducing water and fertilizer usage, and minimizing environmental impact.

Recommendations for Mitigating Potential Negative Impacts Associated with Strip Technology

To mitigate the potential negative impacts associated with strip technology, several recommendations can be implemented.

- Sustainable Manufacturing Practices: Encouraging the adoption of sustainable manufacturing practices, such as reducing waste, using recycled materials, and minimizing energy consumption, can significantly reduce the environmental footprint of strip technology production.

- Energy Efficiency Measures: Implementing energy efficiency measures in strip technology devices and data centers can reduce electricity consumption and greenhouse gas emissions.

- Responsible Disposal and Recycling: Establishing robust e-waste management systems and promoting recycling initiatives can minimize the environmental impact of outdated or malfunctioning strip technology devices.

- Addressing the Digital Divide: Implementing policies and initiatives to bridge the digital divide, such as providing affordable access to technology and infrastructure, can ensure equitable access to the benefits of strip technology.

- Data Privacy and Security Measures: Enacting strong data privacy and security regulations, as well as promoting ethical data practices, can address concerns about privacy and data misuse associated with strip technology.

- Workforce Development and Reskilling Programs: Implementing workforce development and reskilling programs can help individuals adapt to the changing job market and acquire the skills needed for emerging technologies.

Conclusive Thoughts

As strip technology continues to evolve, we can expect even more groundbreaking applications and innovations in the years to come. The ability to tailor strip technology to specific needs, coupled with its inherent efficiency and cost-effectiveness, makes it a promising solution for a wide range of challenges. From reducing environmental impact to driving advancements in various industries, strip technology stands poised to play a pivotal role in shaping the future of manufacturing and engineering.

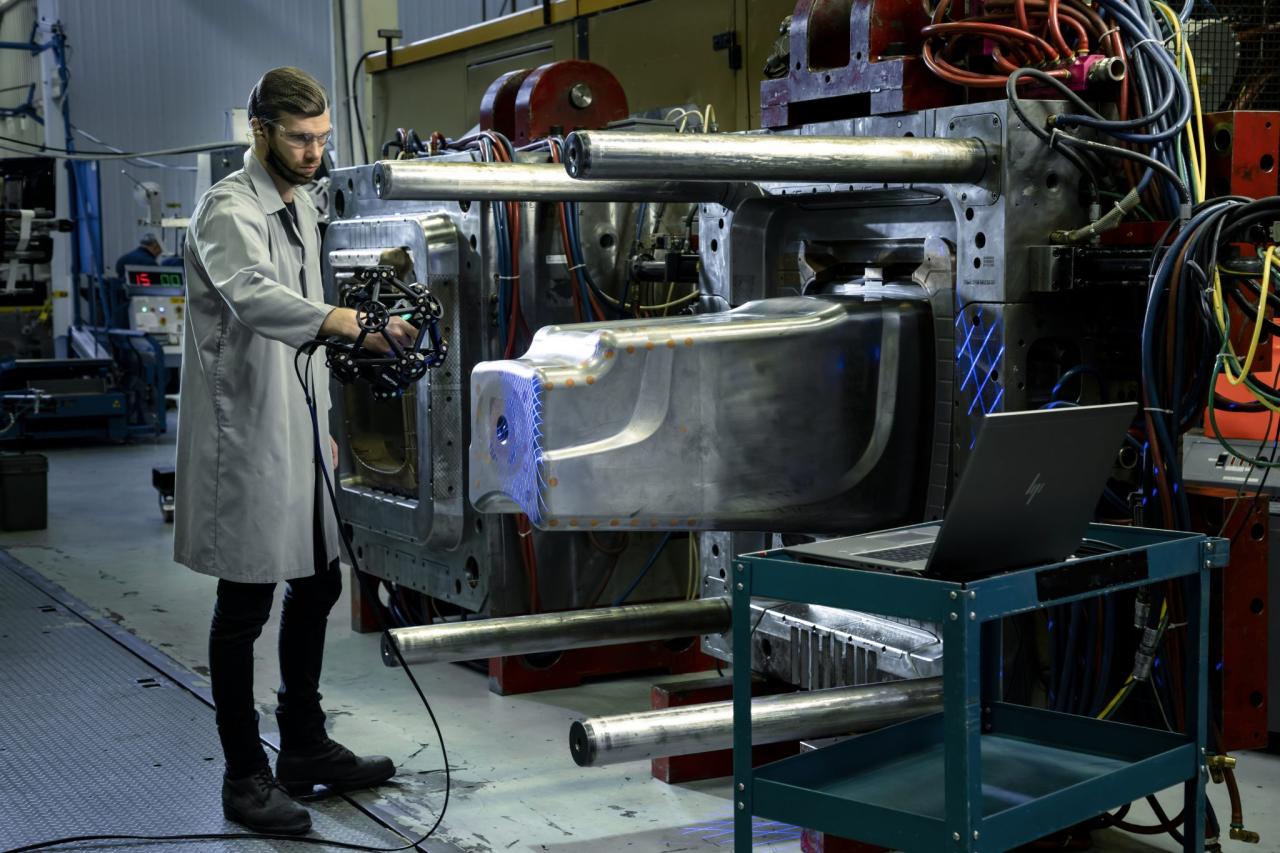

Strip technology, a key component in various industries, often requires a dedicated workspace. A technology table can provide the perfect platform for assembling, testing, and manipulating these delicate strips. The table’s sturdy design and specialized features ensure a stable and organized environment, optimizing the process of strip technology development and application.