Zipper Technology: A History of Innovation

Zipper technology, a seemingly simple invention, has revolutionized the way we fasten and secure our clothing, luggage, and countless other items. From its humble beginnings to its sophisticated modern iterations, […]

Zipper technology, a seemingly simple invention, has revolutionized the way we fasten and secure our clothing, luggage, and countless other items. From its humble beginnings to its sophisticated modern iterations, the zipper has become an indispensable part of our daily lives.

This journey delves into the fascinating history of zipper technology, exploring its evolution from its earliest origins to the present day. We’ll uncover the key milestones and the ingenious minds behind its development, comparing early designs with the advanced models we use today. We’ll then delve into the intricate workings of zippers, dissecting their mechanics and understanding the forces that drive their smooth operation.

History of Zipper Technology

The zipper, a ubiquitous and seemingly simple fastening device, has a fascinating history spanning over a century. Its evolution from a rudimentary invention to a sophisticated and versatile technology is a testament to human ingenuity and the constant pursuit of improved functionality.

Early Innovations and the Invention of the Zipper

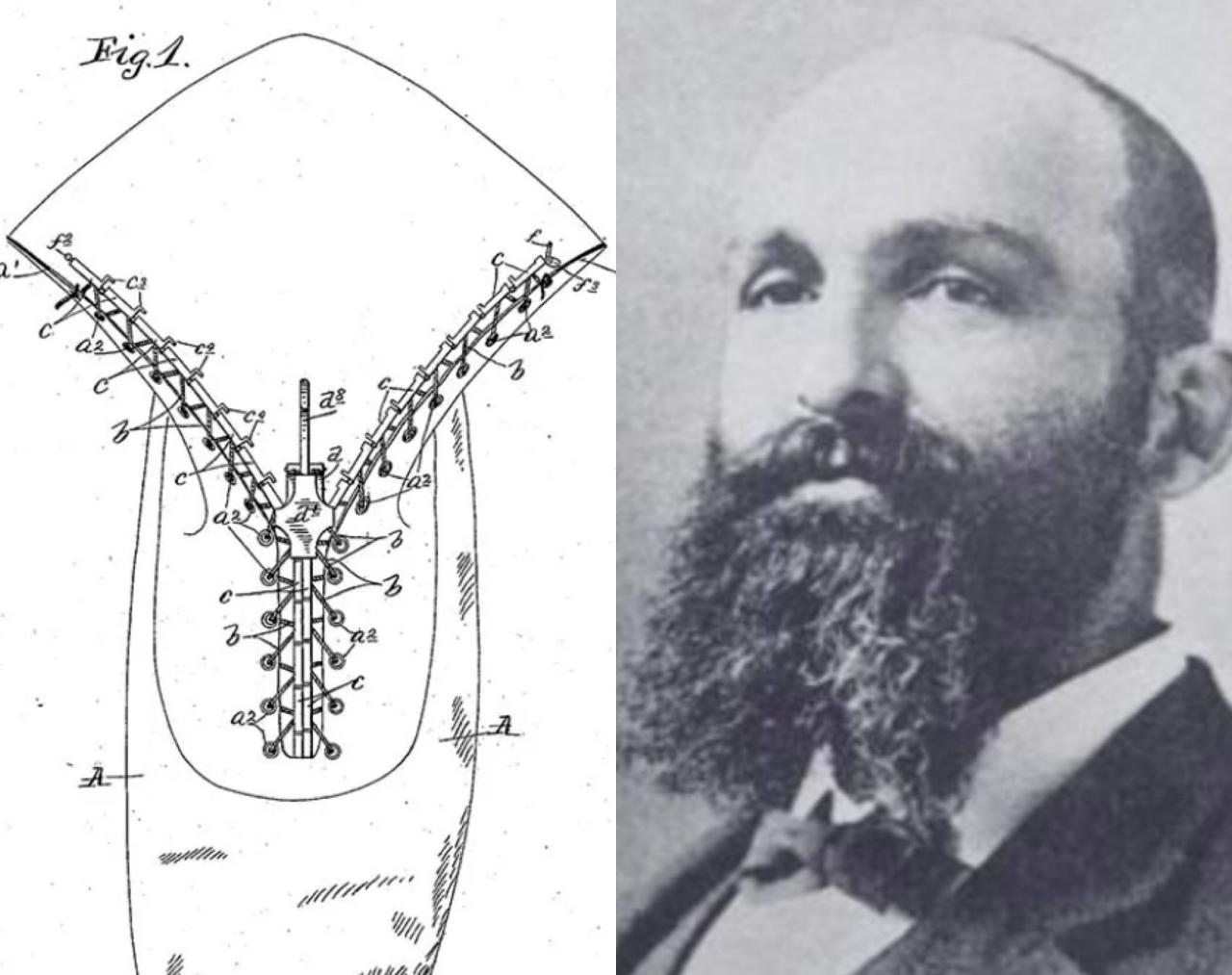

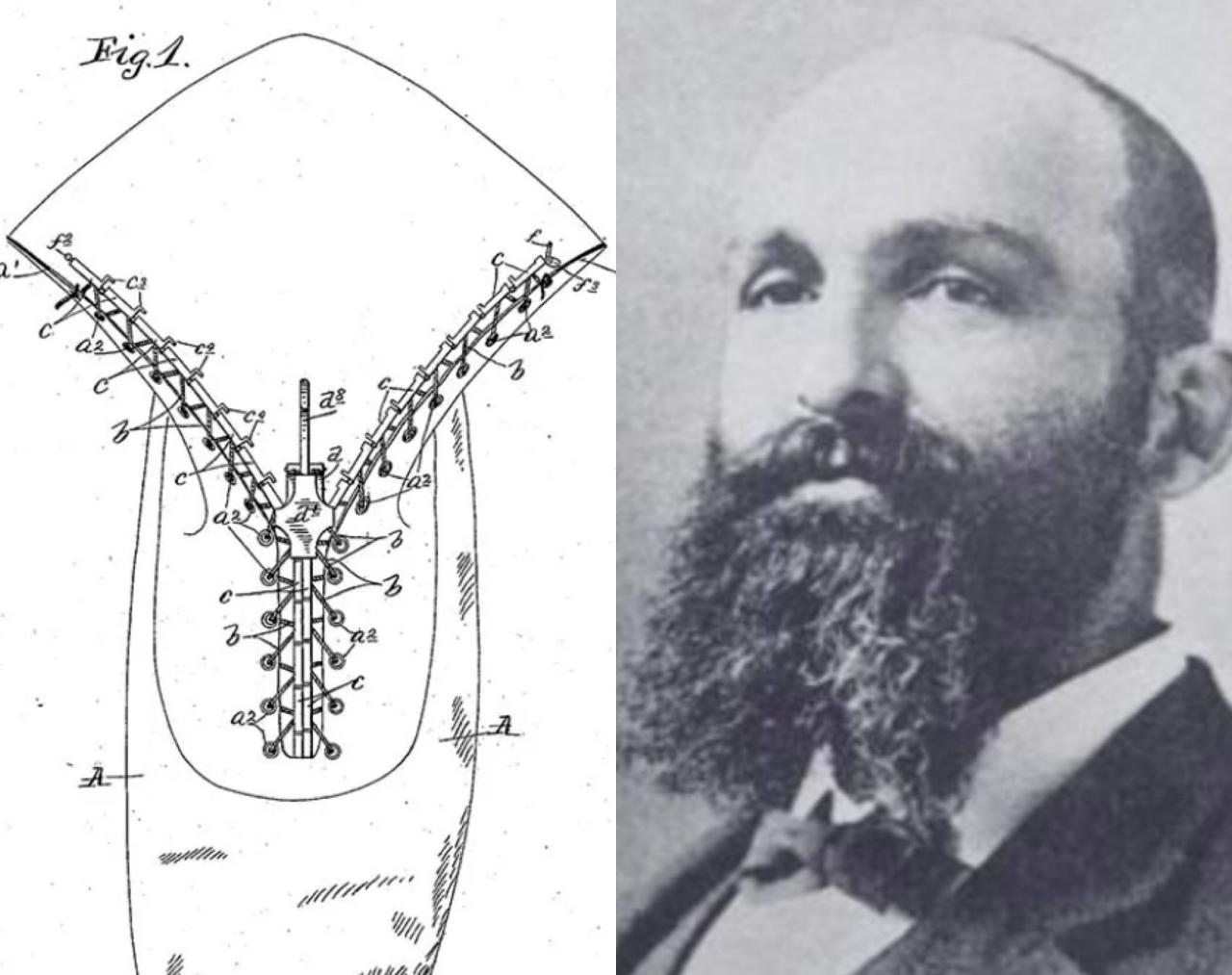

The concept of a continuous, interlocking fastener predates the zipper. In the late 19th century, several inventors explored the idea of using hooks and eyes or interlocking teeth to create a secure closure. However, it was in 1893 that Whitcomb Judson, an American inventor, patented a device he called the “Clasp Locker” which is considered the first recognizable zipper. The Clasp Locker, though functional, was bulky and difficult to operate.

Judson’s invention caught the attention of Gideon Sundback, a Swedish-American engineer working for the Universal Fastener Company. Sundback recognized the potential of Judson’s design and dedicated himself to improving its functionality and ease of use. In 1913, Sundback introduced a significantly improved version of the zipper, which he called the “Hookless Fastener.” This design featured interlocking teeth that could be easily manipulated by a slider, making it more user-friendly.

The Zipper Gains Popularity

Sundback’s invention initially found limited success. It was primarily used in specialized applications such as boots and workwear. However, the zipper gained significant popularity during World War I. Its durability and ease of use made it an ideal fastening mechanism for military uniforms and equipment.

Modernization and Versatility

The zipper underwent significant modernization and diversification in the 20th century. The introduction of nylon in the 1930s led to lighter, more durable zippers. Further advancements in materials and manufacturing techniques resulted in zippers of varying sizes, colors, and finishes.

Early Zipper Designs vs. Contemporary Models

Early zipper designs were often bulky and difficult to operate. They were typically made of metal, which could be prone to rust and corrosion. Contemporary zippers are significantly lighter and more durable, thanks to the use of materials like nylon and polyester. They are also available in a wide range of colors and finishes, making them suitable for a wide range of applications.

Working Principles of Zippers: Zipper Technology

The zipper, a seemingly simple yet ingenious invention, relies on a complex interplay of interlocking components to achieve its functionality. The fundamental principle behind its operation is the precise engagement and disengagement of interlocking teeth, guided by a slider that traverses along the zipper tape.

Components and their Roles

The zipper’s operation hinges on the interaction of several key components:

- Zipper Tape: The foundation of the zipper is the tape, typically made of fabric or plastic, which serves as the base for the interlocking teeth. It provides structural support and ensures smooth movement of the slider.

- Teeth: The teeth are the core of the zipper’s functionality. They are typically made of metal or plastic and are arranged in opposing rows on each side of the tape. These teeth interlock with each other, creating a secure closure.

- Slider: The slider is the mechanism that moves along the zipper tape, engaging and disengaging the teeth. It is typically made of metal or plastic and has a channel that guides the teeth into and out of interlocking positions.

- Pull Tab: The pull tab is attached to the slider and provides a convenient handle for manipulating the zipper. It allows users to easily pull the slider along the tape, closing or opening the zipper.

Zipper Closure and Opening

The process of closing a zipper involves the slider moving along the tape, engaging the teeth on opposite sides. As the slider moves, the teeth interlock, creating a secure closure. This interlocking action is facilitated by the shape of the teeth and the design of the slider. The slider’s channel ensures that the teeth align correctly and interlock smoothly.

The opening process is essentially the reverse of closing. The slider is pulled in the opposite direction, disengaging the teeth. The slider’s channel guides the teeth out of their interlocking positions, allowing the zipper to open.

The smooth operation of a zipper is ensured by a combination of factors:

- Friction: A controlled amount of friction between the teeth and the slider is essential for maintaining a secure closure. This friction is typically achieved through the materials used and the design of the components.

- Lubrication: In some cases, lubrication may be applied to the zipper to reduce friction and enhance smooth operation. This is particularly common in zippers used in high-wear applications, such as clothing.

- Tension: The tension of the zipper tape plays a crucial role in the overall operation. Too much tension can make it difficult to close the zipper, while too little tension can result in a loose and insecure closure.

Types of Zippers and Their Applications

Zippers come in a variety of types, each designed for specific applications and requirements. The type of zipper used depends on factors such as the weight and type of fabric, the intended use, and the desired aesthetic.

Types of Zippers Based on Construction and Materials

Zippers can be classified based on their construction, materials, and intended applications. This classification helps in choosing the most suitable zipper for a particular garment or product.

- Metal Zippers: Metal zippers are known for their durability and strength. They are commonly used in heavy-duty applications, such as jackets, luggage, and tents. Metal zippers are also available in a variety of finishes, including nickel, brass, and antique gold, which adds to their aesthetic appeal.

- Plastic Zippers: Plastic zippers are lighter and more flexible than metal zippers. They are often used in garments, accessories, and other lightweight applications. Plastic zippers are available in a wide range of colors and finishes, making them a popular choice for fashion and design purposes.

- Coil Zippers: Coil zippers are a type of plastic zipper that features a continuous coil of plastic teeth. Coil zippers are known for their smooth operation and durability. They are commonly used in garments, bags, and other applications where a smooth and reliable zipper is required.

- Invisible Zippers: Invisible zippers are designed to be concealed when closed. They are commonly used in garments, such as dresses, skirts, and pants, where a discreet closure is desired. Invisible zippers are typically made of plastic or metal and are often sewn into a seam to make them virtually invisible.

Applications of Different Zipper Types

| Zipper Type | Features | Advantages | Typical Applications |

|---|---|---|---|

| Metal Zippers | Durable, strong, available in various finishes | High strength, long-lasting, aesthetically versatile | Jackets, luggage, tents, heavy-duty garments |

| Plastic Zippers | Lightweight, flexible, available in various colors and finishes | Lightweight, easy to handle, aesthetically diverse | Garments, accessories, bags, lightweight applications |

| Coil Zippers | Continuous coil of plastic teeth, smooth operation, durable | Smooth operation, reliable, durable, lightweight | Garments, bags, backpacks, applications requiring smooth closure |

| Invisible Zippers | Concealed when closed, discreet closure | Aesthetics, seamless integration, hidden closure | Dresses, skirts, pants, garments where a hidden closure is desired |

Future Trends in Zipper Technology

The world of zippers is constantly evolving, driven by advancements in materials, design, and functionality. As technology progresses, we can expect to see even more innovative and sophisticated zipper designs in the future.

Smart Zippers, Zipper technology

Smart zippers are a fascinating area of development, integrating technology to enhance functionality and user experience. These zippers can incorporate sensors, actuators, and communication capabilities, offering a range of possibilities.

- Self-locking zippers: These zippers can automatically lock in place, eliminating the need for manual closure. This feature could be particularly useful in applications where security is a concern, such as luggage or clothing.

- Remote-controlled zippers: Imagine controlling your zipper with a smartphone app. This technology could allow for easy access to pockets or compartments, especially for individuals with mobility limitations.

- Zippers with embedded sensors: Sensors integrated into zippers can monitor various parameters, such as temperature, pressure, or even biometrics. This information can be used to enhance safety, comfort, or performance in different applications.

Self-Repairing Zippers

Self-repairing zippers are a futuristic concept that could revolutionize the zipper industry. These zippers would have the ability to automatically repair minor damages, extending their lifespan and reducing the need for replacements.

- Self-healing polymers: Advanced polymers with self-healing properties could be used to create zipper teeth that can repair minor cracks or tears. These polymers would have the ability to reform their bonds when exposed to heat or pressure.

- Micro-robots for repair: Tiny robots could be integrated into the zipper structure, capable of identifying and repairing damage. These robots would use sensors to detect flaws and then deploy a repair mechanism to restore the zipper’s integrity.

Other Futuristic Concepts

Beyond smart and self-repairing zippers, several other innovative concepts are being explored.

- Biodegradable zippers: The use of biodegradable materials in zipper manufacturing would significantly reduce the environmental impact of zippers, making them more sustainable.

- 3D-printed zippers: 3D printing technology allows for the creation of customized and intricate zipper designs. This opens up possibilities for personalized zippers tailored to specific needs and applications.

Last Point

Zipper technology continues to evolve, with innovations in materials, design, and functionality pushing the boundaries of what this simple yet powerful invention can achieve. As we look to the future, we can expect even more remarkable advancements in zipper technology, shaping the way we interact with the world around us.

Zipper technology has come a long way since its invention, becoming an essential part of our everyday lives. From clothing to luggage, zippers are everywhere, ensuring a secure and reliable closure. Companies like real time technologies llc are constantly innovating, pushing the boundaries of zipper technology with advanced materials and designs, ensuring the zippers we use are durable and efficient.

These advancements continue to improve the functionality and longevity of zippers, ensuring they remain a vital part of our world.