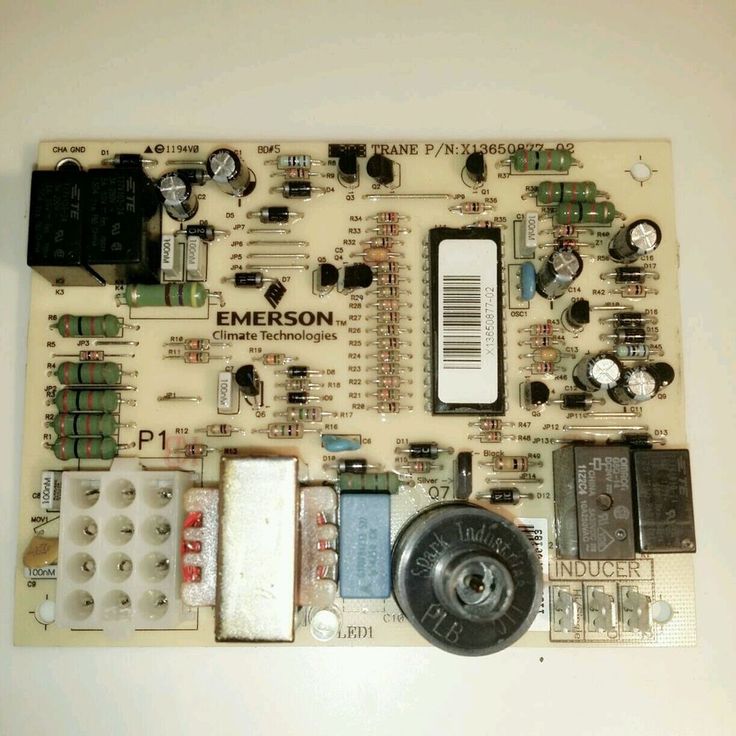

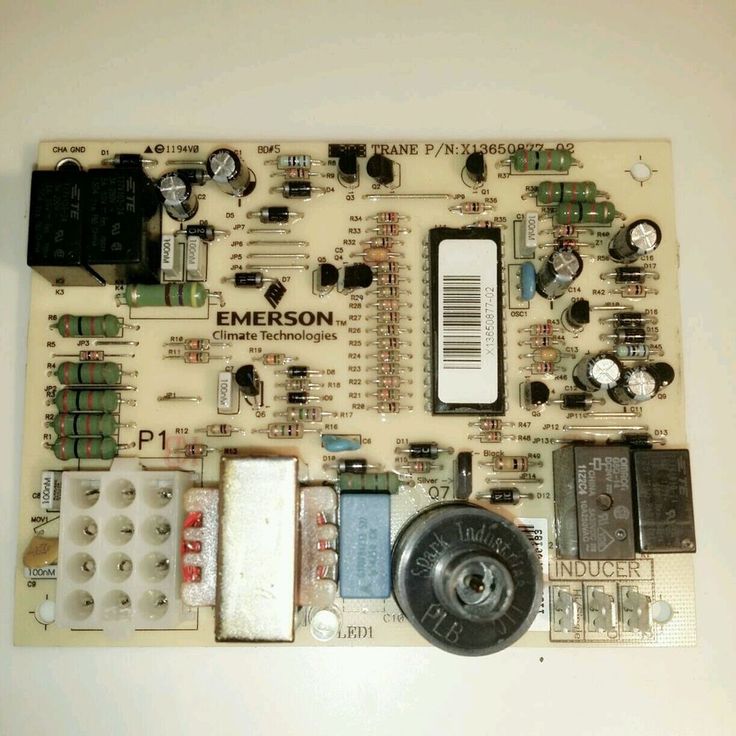

Emerson Climate Technologies Control Board: HVAC System Management

Emerson Climate Technologies control boards are the brains behind efficient and reliable HVAC systems, playing a crucial role in managing and optimizing building comfort and energy consumption. These boards act […]

Emerson Climate Technologies control boards are the brains behind efficient and reliable HVAC systems, playing a crucial role in managing and optimizing building comfort and energy consumption. These boards act as the central command center, receiving data from various sensors and actuators within the HVAC system and making real-time decisions to maintain desired temperatures, humidity levels, and air quality.

Emerson, a renowned leader in climate technologies, has a rich history of innovation in the HVAC industry. Their control boards are designed with advanced features and capabilities to meet the evolving needs of modern buildings. From residential and commercial applications to industrial and data centers, Emerson control boards provide intelligent solutions for a wide range of HVAC systems.

Control Board Programming and Configuration

Emerson control boards are sophisticated devices that require careful programming and configuration to achieve optimal performance. This process involves setting various parameters and adjusting settings to match specific application requirements. Understanding these configurations is crucial for maximizing the efficiency and reliability of your system.

Programming and Configuration Process

The programming and configuration process for Emerson control boards typically involves the following steps:

- Connect to the control board: Establish a communication link between the control board and a programming device, usually a laptop or a handheld programmer. This connection is typically established using a serial port, Ethernet, or a wireless interface.

- Access the programming software: Once connected, launch the dedicated programming software provided by Emerson. This software provides a user-friendly interface for accessing and modifying control board settings.

- Load the factory default settings: Begin by loading the factory default settings. This ensures a clean slate for your configuration and prevents unintended changes.

- Configure basic settings: Set up essential parameters such as the communication protocol, data logging options, and alarm thresholds. These settings ensure proper communication and data management.

- Configure control loops: Define the control loops that govern the operation of your system. This involves setting PID (Proportional-Integral-Derivative) control parameters, loop limits, and setpoints.

- Program logic and sequences: Implement specific logic and sequences using the programming software. This allows you to automate tasks, create interlocks, and implement advanced control strategies.

- Test and validate the configuration: After programming, thoroughly test the control board’s operation to ensure it functions as intended. This may involve simulating real-world conditions or running a series of tests.

- Document the configuration: Maintain detailed documentation of the control board’s configuration. This documentation is essential for troubleshooting, future modifications, and system maintenance.

Control Board Parameters and Settings

Emerson control boards offer a wide range of parameters and settings that can be adjusted to optimize performance. These settings fall into various categories:

- Communication settings: These settings define the communication protocol, baud rate, and other parameters for data exchange between the control board and external devices.

- Input/Output (I/O) configuration: Configure the types of sensors and actuators connected to the control board, including their scaling, ranges, and alarm thresholds.

- Control loop parameters: Set the PID control parameters, loop limits, and setpoints for each control loop. These parameters govern the response of the control system to changes in process variables.

- Alarm settings: Define alarm thresholds, notification methods, and other parameters for managing system events and alerts.

- Data logging and reporting: Configure the data logging frequency, storage capacity, and reporting options for monitoring and analyzing system performance.

- Security settings: Implement access control and password protection to prevent unauthorized access to the control board’s configuration.

- Advanced settings: Explore advanced features like cascade control, feedforward control, and adaptive control strategies for complex applications.

Common Programming Tasks and Troubleshooting Scenarios

Here are some common programming tasks and troubleshooting scenarios that you may encounter when working with Emerson control boards:

- Adding a new sensor or actuator: This involves configuring the I/O settings, including the sensor type, scaling, and alarm thresholds.

- Modifying a control loop: Adjusting PID parameters, loop limits, and setpoints can fine-tune the control system’s response.

- Implementing a new control strategy: This may involve programming logic and sequences to automate tasks or implement advanced control strategies.

- Troubleshooting communication errors: Verify communication settings, cable connections, and device compatibility to resolve communication issues.

- Investigating alarm conditions: Analyze alarm logs, sensor readings, and control loop parameters to identify the cause of alarms.

- Updating firmware: Emerson releases firmware updates to address bugs, improve performance, and introduce new features. Regularly updating the firmware ensures optimal operation.

Control Board Maintenance and Troubleshooting: Emerson Climate Technologies Control Board

Regular maintenance and proper troubleshooting techniques are essential for ensuring the longevity and optimal performance of Emerson control boards. By following recommended practices, you can minimize downtime, prevent costly repairs, and extend the lifespan of your equipment.

Recommended Maintenance Practices

Regular maintenance practices play a crucial role in extending the life of your Emerson control board and ensuring its optimal performance. These practices help prevent potential issues and minimize downtime.

- Visual Inspection: Regularly inspect the control board for any signs of damage, such as loose connections, burnt components, or corrosion. This visual inspection helps identify potential issues before they escalate.

- Cleaning: Dust and debris can accumulate on the control board, leading to overheating and malfunctions. Use a soft brush or compressed air to clean the board regularly. Avoid using any liquids or harsh chemicals that could damage the components.

- Temperature Monitoring: Ensure the control board operates within its recommended temperature range. Overheating can significantly shorten the lifespan of the components. Monitor the temperature using a thermal camera or infrared thermometer.

- Power Supply: Verify that the control board receives a stable and consistent power supply. Fluctuations in voltage can cause damage to the board’s sensitive electronics.

- Firmware Updates: Regularly check for firmware updates from Emerson. These updates often include bug fixes, performance enhancements, and security patches that can improve the control board’s functionality and stability.

- Documentation: Maintain detailed records of all maintenance activities, including dates, procedures performed, and any observed issues. This documentation can be helpful for future troubleshooting and analysis.

Common Control Board Issues and Troubleshooting Techniques

Control boards, despite their robust design, can experience issues over time. Understanding common problems and troubleshooting techniques is essential for resolving these issues efficiently.

- Power Issues: A common issue is a lack of power or unstable power supply. Check the power cord, circuit breaker, and fuse for any faults. Ensure the power supply voltage is within the control board’s specifications.

- Communication Problems: Communication errors between the control board and other devices can cause malfunctions. Check the communication cables for damage or loose connections. Verify the communication protocols and settings are correctly configured.

- Sensor Malfunctions: Faulty sensors can provide incorrect data to the control board, leading to incorrect control actions. Check the sensor connections, calibrate the sensors, and ensure they are compatible with the control board.

- Overheating: Overheating can cause damage to the control board’s components. Ensure adequate ventilation around the board and check for any blockages in the cooling system. Monitor the board’s temperature and take corrective actions if necessary.

- Software Glitches: Software errors can lead to unexpected behavior or malfunctions. Check for available firmware updates and consider restoring the control board to its factory settings if necessary.

- Component Failure: Over time, components within the control board can fail. If you suspect a component failure, replace the faulty component with a compatible part from a reputable supplier.

Resources for Technical Support and Documentation

Emerson provides comprehensive resources for technical support and documentation, ensuring users have access to the necessary information for troubleshooting and maintenance.

- Emerson Website: The Emerson website offers a wealth of resources, including user manuals, troubleshooting guides, and product specifications. You can also find information on firmware updates and technical support contact details.

- Emerson Support: Emerson provides dedicated technical support channels for assistance with control board issues. Contact their support team via phone, email, or online chat for expert guidance.

- Online Forums: Online forums dedicated to Emerson control boards offer a platform for users to share experiences, troubleshooting tips, and solutions. These forums can be a valuable resource for finding answers to common issues.

Future Trends and Innovations

The HVAC industry is constantly evolving, driven by technological advancements, environmental concerns, and changing customer expectations. Emerson Climate Technologies is at the forefront of this evolution, developing innovative control solutions that enhance efficiency, reliability, and sustainability.

Emerging Trends in HVAC Control Technology, Emerson climate technologies control board

The future of HVAC control technology is marked by the integration of advanced technologies, such as artificial intelligence (AI), the Internet of Things (IoT), and cloud computing.

- AI-Powered Optimization: AI algorithms can analyze real-time data from HVAC systems to optimize performance, predict maintenance needs, and personalize comfort settings. For instance, AI can adjust thermostat settings based on occupancy patterns, weather conditions, and energy prices, resulting in significant energy savings.

- IoT Connectivity: The integration of IoT enables seamless communication between HVAC systems, building management systems, and mobile devices. This connectivity allows for remote monitoring, control, and diagnostics, providing greater flexibility and control over HVAC operations. For example, homeowners can remotely adjust their thermostats through mobile apps, optimizing energy consumption and comfort levels.

- Cloud-Based Solutions: Cloud-based platforms provide a centralized hub for data storage, analysis, and management of HVAC systems. These platforms enable remote access, data visualization, and advanced analytics, facilitating informed decision-making and improved operational efficiency.

Potential Advancements in Emerson Control Board Functionality

Emerson is continuously innovating its control board technology to address emerging trends and enhance system capabilities.

- Predictive Maintenance: Emerson control boards are being developed with predictive maintenance capabilities. By analyzing sensor data, these boards can identify potential issues before they become major problems, reducing downtime and maintenance costs. For example, Emerson control boards can monitor motor vibrations and predict when a motor needs replacement, allowing for scheduled maintenance before a failure occurs.

- Enhanced Energy Efficiency: Emerson control boards are incorporating advanced algorithms to optimize energy consumption. These algorithms can dynamically adjust system settings based on real-time data, such as occupancy levels, weather conditions, and energy prices, minimizing energy waste and maximizing efficiency.

- Improved User Interface: Emerson is enhancing the user interfaces of its control boards, making them more intuitive and user-friendly. These interfaces provide clear visualizations of system performance, simplifying monitoring and control for both technicians and building occupants.

Emerson’s Adaptation to the Evolving Industry Landscape

Emerson is actively adapting to the evolving HVAC industry by embracing new technologies and collaborating with industry partners.

- Strategic Partnerships: Emerson is forming strategic partnerships with leading technology companies to integrate advanced solutions into its control boards. These partnerships enable Emerson to leverage cutting-edge technologies and accelerate the development of innovative HVAC solutions.

- Focus on Sustainability: Emerson is committed to developing sustainable HVAC solutions that reduce environmental impact. The company is investing in research and development to enhance energy efficiency, reduce refrigerant emissions, and promote responsible resource management.

- Data-Driven Insights: Emerson is leveraging data analytics to gain valuable insights into HVAC system performance. These insights inform product development, optimize system operations, and improve customer service.

Final Wrap-Up

As HVAC systems continue to evolve, Emerson Climate Technologies control boards remain at the forefront of innovation, offering advanced features and capabilities that enhance system efficiency, reliability, and user experience. By seamlessly integrating with other HVAC components and leveraging data analytics, these control boards empower building managers to optimize energy consumption, reduce operational costs, and create comfortable and healthy indoor environments. Understanding the functionality, programming, and maintenance of Emerson control boards is essential for maximizing the performance and longevity of HVAC systems, ensuring optimal comfort and energy efficiency for years to come.

Emerson Climate Technologies control boards are known for their reliability and advanced features, ensuring optimal performance in various climate control systems. But did you know that advancements in technology aren’t limited to HVAC? The dental industry has also seen incredible innovation, with latest denture technology offering comfort and functionality that were once unimaginable.

Just like Emerson’s control boards optimize climate, these new dentures optimize oral health and function, making a world of difference for individuals seeking a better quality of life.