Window Tint Technology: Benefits, Types, and Applications

Window tint technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Window […]

Window tint technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

Window tint technology has evolved significantly over the years, offering a myriad of benefits beyond simply reducing glare. From enhancing vehicle aesthetics to protecting occupants from harmful UV rays, window tint has become an integral part of modern life. This article delves into the fascinating world of window tint, exploring its history, applications, and future trends.

Introduction to Window Tint Technology

Window tint technology involves applying a thin, semi-transparent film to the interior of a vehicle’s windows. This film acts as a barrier, filtering out a portion of the sun’s harmful ultraviolet (UV) rays and infrared (IR) radiation. The primary function of window tint is to reduce heat, glare, and UV exposure, offering various benefits to occupants and the vehicle itself.

Window tint films are constructed using various materials and processes, resulting in diverse properties and applications. Understanding the different types of window tint films and their characteristics is crucial for making informed decisions based on individual needs and preferences.

Types of Window Tint Films

Window tint films can be broadly categorized into three main types: dyed, metallic, and ceramic. Each type possesses unique properties and characteristics that make them suitable for different applications.

- Dyed Films: These films are the most basic type and are created by adding dye to a polyester base. They offer good heat rejection and UV protection but are less durable than other types. Dyed films can fade over time, particularly in areas with high UV exposure.

- Metallic Films: These films incorporate metal particles into the polyester base, providing enhanced heat rejection and glare reduction compared to dyed films. Metallic films are more durable and less prone to fading but can interfere with radio signals and GPS reception.

- Ceramic Films: Ceramic films are the most advanced type, using ceramic nanoparticles for heat and UV protection. They offer excellent heat rejection, glare reduction, and UV protection while maintaining high clarity and signal transmission. Ceramic films are also known for their durability and resistance to fading.

History and Evolution of Window Tint Technology

Window tint technology has evolved significantly since its inception in the early 20th century. Initially, window tints were primarily used for aesthetic purposes, adding a darker look to vehicles. However, as the understanding of UV radiation and its harmful effects grew, window tint technology advanced to focus on heat rejection and UV protection.

- Early Developments: In the early 1900s, window tints were mainly made from dyes applied directly to the glass. These early tints were not very effective and often faded quickly.

- Introduction of Films: The development of polyester-based films in the 1960s revolutionized window tint technology. These films offered improved heat rejection and UV protection, along with greater durability and ease of application.

- Advancements in Materials: The introduction of metallic and ceramic materials in the 1980s and 1990s further enhanced window tint technology, providing superior heat rejection, glare reduction, and UV protection.

- Nanotechnology: In recent years, nanotechnology has played a significant role in the development of advanced ceramic films, offering exceptional heat and UV protection with minimal impact on signal transmission and visibility.

Types of Window Tint Films

Window tint films come in various types, each with unique properties and applications. Understanding the differences between these films is crucial for choosing the right one for your needs.

Types of Window Tint Films

Window tint films are broadly categorized into two main types:

- Dyed Films: These films are made by dyeing a thin polyester film with a colorant. They are the most basic and affordable type of tint.

- Metalized Films: These films are made by sputtering a thin layer of metal onto a polyester film. They offer better heat rejection and UV protection than dyed films.

Within these two categories, there are several sub-types, each with its own set of characteristics:

Comparison of Window Tint Films

Here is a table comparing different types of window tint films based on their properties:

| Type | Visible Light Transmittance (VLT) | Infrared (IR) Rejection | Ultraviolet (UV) Protection | Durability | Cost |

|---|---|---|---|---|---|

| Dyed Film | 5-35% | Low | Good | Low | Low |

| Metalized Film | 5-70% | High | Excellent | High | High |

| Ceramic Film | 5-70% | Very High | Excellent | Very High | Very High |

| Hybrid Film | 5-70% | High | Excellent | High | High |

Dyed Films

Dyed films are the most basic type of window tint film. They are made by dyeing a thin polyester film with a colorant. This type of film is typically the most affordable option, but it also has the lowest level of heat rejection and UV protection. Dyed films can also fade over time, especially if they are exposed to prolonged sunlight.

Metalized Films

Metalized films are made by sputtering a thin layer of metal onto a polyester film. This process gives the film a reflective quality, which helps to reject heat and UV rays. Metalized films are generally more durable than dyed films and can last for several years. However, they can also cause interference with radio signals and GPS systems.

Ceramic Films

Ceramic films are a relatively new type of window tint film. They are made by using ceramic nanoparticles instead of metal. This makes them non-metallic and less likely to interfere with radio signals or GPS systems. Ceramic films offer excellent heat rejection and UV protection, and they are very durable. However, they are also the most expensive type of window tint film.

Hybrid Films

Hybrid films combine the benefits of both dyed and metalized films. They are typically made by using a combination of dyes and metalized layers. This gives them a good balance of affordability, heat rejection, and UV protection. Hybrid films are also generally more durable than dyed films but less durable than ceramic films.

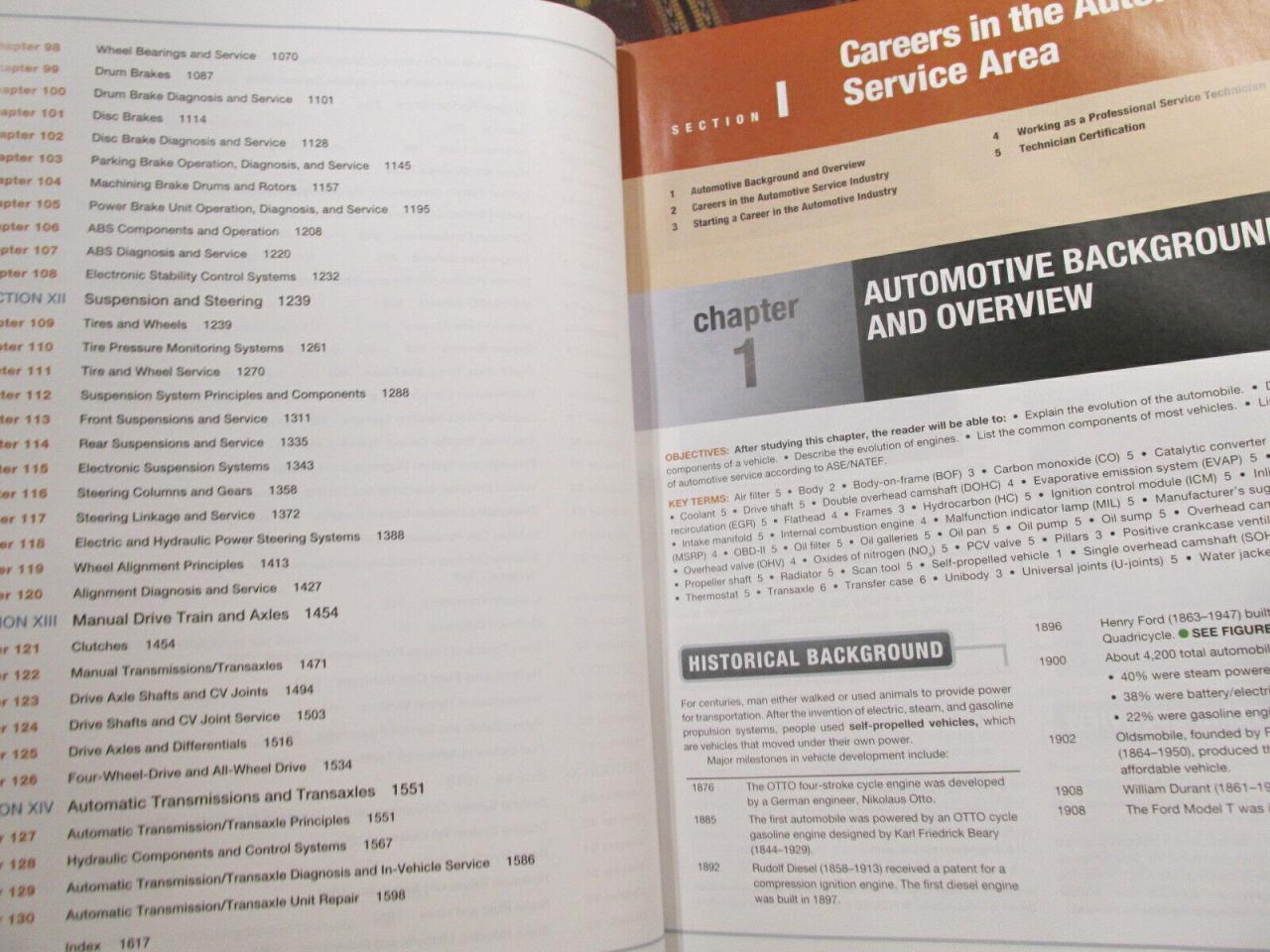

Window Tint Application Process

The window tint application process requires meticulous attention to detail and specialized tools. It involves a series of steps, from thorough preparation to careful installation and inspection. Following these steps ensures a professional and high-quality window tint installation that enhances the appearance and functionality of your vehicle.

Preparation

Preparation is crucial for a successful window tint application. It involves cleaning and prepping the window surfaces to ensure a smooth and even application of the tint film.

- Thorough Cleaning: Begin by thoroughly cleaning the windows with a glass cleaner and microfiber cloth. Ensure all dirt, debris, and grease are removed, as these can affect the adhesion of the tint film.

- Tape Application: Masking tape is used to protect the surrounding areas of the window, including the trim and paint, from accidental damage during the application process.

- Window Measurement: Accurately measure the window dimensions to determine the exact size of the tint film needed.

Film Cutting and Installation

The next step involves cutting the tint film to the precise size and shape of the window and carefully applying it to the window surface.

- Film Cutting: The tint film is cut using a sharp utility knife and a cutting mat, ensuring precise dimensions to fit the window perfectly.

- Film Application: Once the film is cut, it is carefully applied to the window surface using a squeegee. The squeegee helps to remove air bubbles and ensure proper adhesion.

- Squeegee Technique: The squeegee is moved in a consistent and controlled manner, starting from the center of the film and working outwards to the edges. This technique helps to smooth out any wrinkles or bubbles.

Drying and Inspection

The final step involves allowing the tint film to dry completely and inspecting the installation for any imperfections.

- Drying Time: The tint film typically takes several days to fully dry and cure. It is important to avoid rolling down the windows or exposing the film to direct sunlight during this time.

- Inspection: Once the film is dry, it is inspected for any bubbles, wrinkles, or imperfections. If any are found, they can be addressed using a razor blade or a heat gun.

Professional window tint installers use specialized tools and techniques to ensure a high-quality installation.

Window Tint Technology in Various Applications

Window tint technology has become increasingly prevalent across various industries, offering numerous benefits. Its versatility allows for customized applications tailored to specific needs, from enhancing privacy and reducing glare to controlling heat and improving energy efficiency.

Automotive Applications

Window tint technology plays a crucial role in the automotive industry, enhancing both aesthetics and functionality. It provides a range of benefits, including:

- Enhanced Privacy: Window tint films create a barrier, obscuring the view from the outside, offering privacy for passengers and valuables within the vehicle.

- Reduced Glare: By blocking a significant portion of sunlight, window tint films minimize glare, improving visibility and reducing eye strain for drivers.

- Heat Reduction: Window tint films effectively block infrared radiation, which is the primary source of heat from the sun. This reduces the interior temperature of the vehicle, enhancing comfort and reducing reliance on air conditioning.

- UV Protection: Window tint films act as a barrier against harmful ultraviolet (UV) rays, protecting passengers from sunburn and skin damage.

- Increased Security: Some window tint films are designed to be more robust, offering increased resistance to shattering and providing additional security in case of accidents or break-ins.

Residential Applications

Window tint technology has gained popularity in residential settings, offering a range of benefits for homeowners:

- Heat Control: Window tint films can significantly reduce heat gain during the summer months, lowering energy consumption and reducing reliance on air conditioning.

- Glare Reduction: Window tint films effectively minimize glare, enhancing comfort and improving visibility within the home.

- UV Protection: By blocking harmful UV rays, window tint films protect furniture, carpets, and artwork from fading and discoloration caused by sunlight.

- Privacy Enhancement: Window tint films provide a degree of privacy, allowing homeowners to control visibility into their homes while maintaining natural light.

- Increased Security: Some window tint films offer increased resistance to shattering, providing an extra layer of security and protection in case of break-ins or storms.

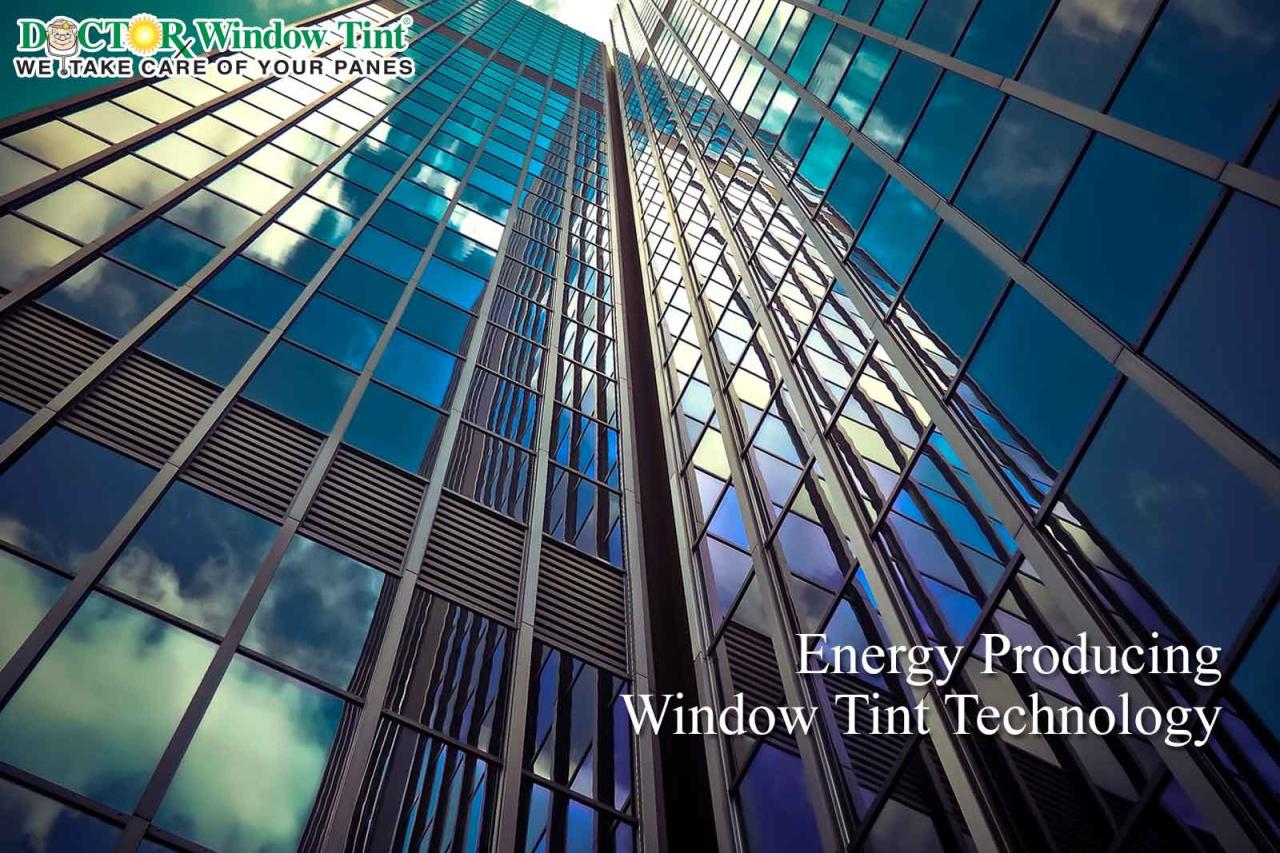

Commercial Applications

Window tint technology finds diverse applications in commercial settings, providing benefits for businesses and organizations:

- Energy Savings: Window tint films can significantly reduce heat gain, lowering energy consumption for air conditioning and reducing overall energy costs.

- Glare Control: Window tint films minimize glare, enhancing visibility and productivity for employees and customers.

- UV Protection: Window tint films protect interior furnishings and merchandise from fading and discoloration caused by sunlight.

- Privacy and Security: Window tint films can enhance privacy, controlling visibility into commercial spaces while providing an extra layer of security.

- Branding and Aesthetics: Window tint films can be used to create custom designs and branding elements, enhancing the visual appeal of commercial buildings.

Aerospace Applications, Window tint technology

Window tint technology finds specialized applications in the aerospace industry, offering critical benefits for aircraft:

- Heat Reduction: Window tint films can significantly reduce heat gain within aircraft cabins, enhancing passenger comfort and reducing reliance on air conditioning.

- Glare Control: Window tint films minimize glare, improving visibility for pilots and enhancing flight safety.

- UV Protection: Window tint films protect passengers and crew from harmful UV rays, reducing the risk of sunburn and skin damage.

- Increased Durability: Window tint films can enhance the durability of aircraft windows, providing resistance to scratches and damage caused by environmental factors.

Conclusive Thoughts: Window Tint Technology

In conclusion, window tint technology has come a long way, offering a wide range of benefits for various applications. From automotive to residential and even aerospace, window tint continues to evolve, incorporating innovative materials and functionalities. As we look towards the future, we can expect even more sophisticated window tint solutions that enhance our comfort, safety, and sustainability.

Window tint technology has come a long way, offering benefits like reduced glare, heat rejection, and even enhanced privacy. One innovative company pushing the boundaries in this field is ss technology , known for their advanced film formulations that deliver superior performance.

By utilizing cutting-edge materials and manufacturing processes, ss technology allows for window tints that are both aesthetically pleasing and highly functional, setting a new standard in the industry.