New Technology in Oil and Gas: Transforming the Industry

New technology in oil and gas industry sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality […]

New technology in oil and gas industry sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The oil and gas industry, a cornerstone of global energy production, is undergoing a dramatic transformation, fueled by a wave of technological advancements that are reshaping every facet of the sector. From exploration and production to refining and distribution, new technologies are revolutionizing how energy is extracted, processed, and delivered to consumers.

This exploration delves into the heart of this technological revolution, examining the impact of digitalization, advanced exploration and production techniques, sustainable practices, automation, and emerging technologies on the future of the industry. We will explore how these innovations are driving efficiency, reducing costs, enhancing safety, and paving the way for a more sustainable future for oil and gas.

Advanced Exploration and Production Techniques

The oil and gas industry is constantly evolving, and new technologies are playing a critical role in enhancing exploration and production activities. These advancements enable companies to locate new reserves, extract hydrocarbons more efficiently, and minimize environmental impact.

Seismic Imaging, 3D Modeling, and Machine Learning

Seismic imaging, 3D modeling, and machine learning are powerful tools that are revolutionizing the way oil and gas companies explore for new reserves.

- Seismic imaging uses sound waves to create images of underground rock formations. This data is then used to identify potential oil and gas reservoirs.

- 3D modeling takes seismic data and creates a detailed, three-dimensional representation of the subsurface. This allows geologists and engineers to better understand the structure and properties of the reservoir.

- Machine learning algorithms can analyze vast amounts of seismic data and identify patterns that might be missed by human analysts. This can help to improve the accuracy of exploration efforts and reduce the risk of dry holes.

Drilling and Well Completion Technologies

Advancements in drilling and well completion technologies have significantly increased the efficiency and effectiveness of oil and gas production.

- Horizontal drilling allows companies to drill wells that extend horizontally through the reservoir. This increases the contact area between the wellbore and the reservoir, resulting in higher production rates.

- Hydraulic fracturing, or fracking, involves injecting a mixture of water, sand, and chemicals into the reservoir to create fractures. This allows oil and gas to flow more easily to the wellbore.

“Horizontal drilling and hydraulic fracturing have unlocked vast new reserves of oil and gas, particularly in unconventional shale formations.”

Economic and Environmental Impact

These new technologies have had a profound impact on the economics and environmental footprint of oil and gas production.

- The increased efficiency of exploration and production has led to lower costs and increased profitability. This has made it possible to develop reserves that were previously uneconomical to extract.

- The use of horizontal drilling and hydraulic fracturing has led to a significant increase in domestic oil and gas production, reducing reliance on foreign imports.

- However, these technologies have also raised concerns about their environmental impact. Fracking has been linked to water contamination, air pollution, and seismic activity.

Sustainable Oil and Gas Operations

The oil and gas industry is facing increasing pressure to reduce its environmental impact and transition to more sustainable practices. New technologies are playing a crucial role in this shift, enabling the industry to operate more efficiently, reduce emissions, and minimize its footprint.

Renewable Energy Integration, New technology in oil and gas industry

Renewable energy sources, such as solar and wind power, can be integrated into oil and gas operations to reduce reliance on fossil fuels. These technologies can provide power for facilities, drilling rigs, and other operations, decreasing the industry’s overall carbon footprint.

- Solar Power: Oil and gas companies are increasingly installing solar panels at their facilities to generate clean energy. For example, ExxonMobil has deployed solar power at several of its facilities in the United States, including a large-scale solar farm in Texas.

- Wind Power: Wind turbines can be used to generate electricity for remote oil and gas operations, especially in areas with strong wind resources. Companies like BP and Shell have invested in offshore wind farms to power their operations.

Carbon Capture and Storage

Carbon capture and storage (CCS) technologies capture carbon dioxide emissions from oil and gas production and processing facilities and store them underground, preventing them from entering the atmosphere.

- Post-Combustion Capture: This technology captures CO2 from flue gases after combustion.

- Pre-Combustion Capture: This method captures CO2 before combustion, typically from natural gas or coal.

Waste Management Solutions

Oil and gas operations generate significant amounts of waste, including produced water, drilling cuttings, and sludge. New technologies are being developed to manage these waste streams sustainably.

- Wastewater Treatment: Advanced wastewater treatment technologies are being used to remove pollutants from produced water, enabling its reuse or safe disposal.

- Recycling and Reuse: Companies are finding ways to recycle and reuse waste materials, such as drilling cuttings and sludge, reducing the amount of waste sent to landfills.

Impact on Greenhouse Gas Emissions

The adoption of these technologies has a significant impact on reducing greenhouse gas emissions and minimizing the environmental impact of oil and gas operations.

- Reduced Carbon Footprint: Renewable energy integration and CCS technologies directly contribute to reducing CO2 emissions.

- Improved Air Quality: Waste management solutions help to reduce air pollution by minimizing the release of harmful pollutants from waste streams.

Automation and Robotics in Oil and Gas

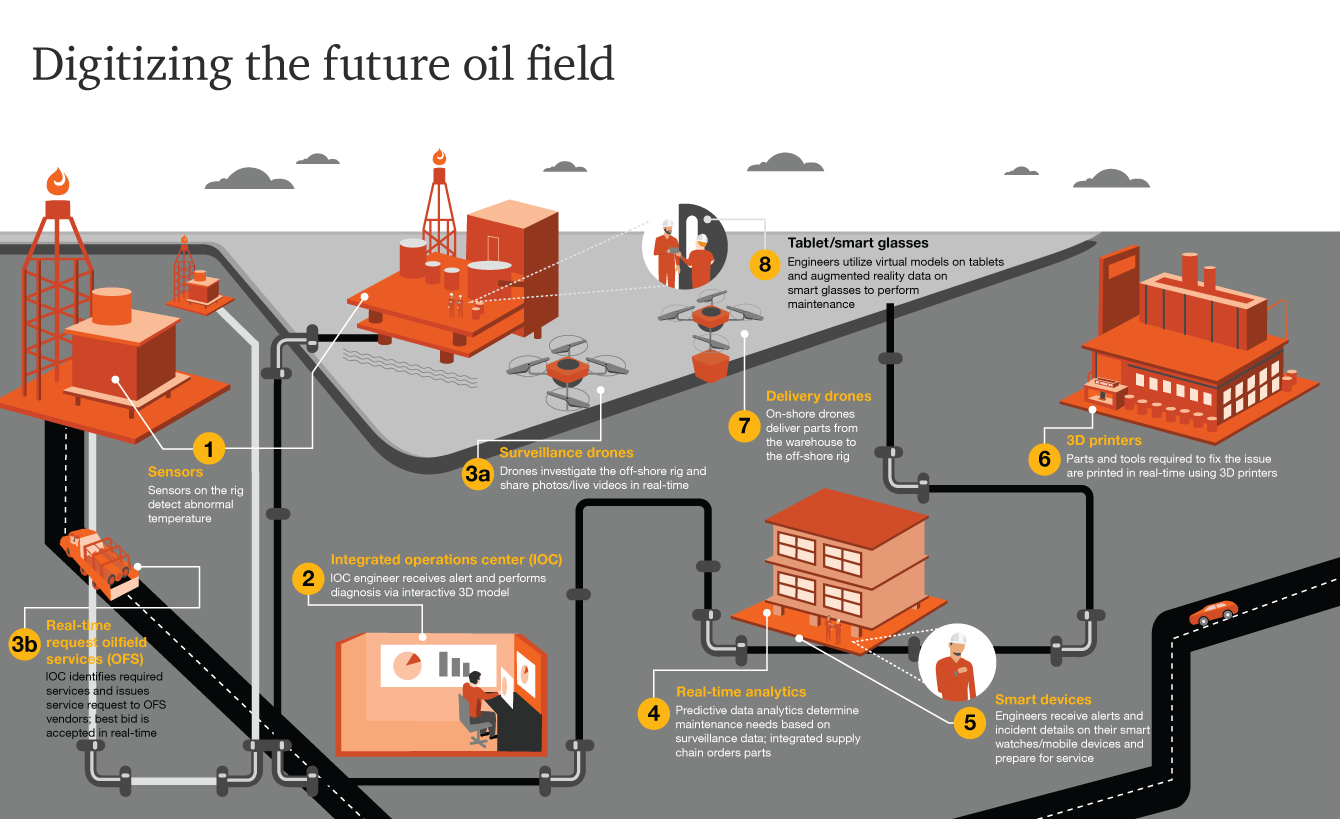

The oil and gas industry is embracing automation and robotics to enhance efficiency, improve safety, and reduce costs. These technologies are transforming various aspects of operations, from drilling and maintenance to inspection and data analysis.

Automation in Drilling Operations

Automation is revolutionizing drilling operations by improving efficiency, reducing human error, and enhancing safety. Automated drilling systems, such as robotic drilling rigs and automated mud pumps, are capable of performing complex tasks with precision and accuracy. These systems are programmed to optimize drilling parameters, monitor well conditions, and react to changes in real-time. This automation allows for faster and more efficient drilling, reducing downtime and maximizing production.

Robotics in Maintenance and Inspection

Robots are increasingly being used for maintenance and inspection tasks in oil and gas fields. These robots can access hazardous areas, perform complex inspections, and carry out maintenance tasks with minimal human intervention. For instance, robotic crawlers equipped with cameras and sensors can inspect pipelines and other infrastructure, identifying potential leaks, corrosion, and other issues. This allows for proactive maintenance, reducing the risk of accidents and costly repairs.

Benefits of Automation and Robotics

The adoption of automation and robotics in the oil and gas industry offers several advantages:

- Increased Efficiency: Automated systems can work continuously, without the need for breaks or rest, leading to increased productivity and reduced downtime.

- Reduced Labor Costs: Automation reduces the reliance on human labor, lowering operational costs and freeing up skilled personnel for more complex tasks.

- Improved Safety: Robots can perform hazardous tasks in dangerous environments, reducing the risk of injuries to human workers.

- Enhanced Data Collection and Analysis: Automated systems can collect vast amounts of data, which can be analyzed to optimize operations, predict potential problems, and improve decision-making.

Examples of Robotic Systems in Oil and Gas

Several robotic systems are being deployed in oil and gas fields, each with specific applications:

- Autonomous Underwater Vehicles (AUVs): These robots can be used to inspect pipelines, conduct surveys, and collect data in underwater environments. They are equipped with sensors, cameras, and sonar systems to provide detailed information about the underwater infrastructure.

- Remotely Operated Vehicles (ROVs): ROVs are controlled from the surface and can be used for a variety of tasks, including underwater inspections, maintenance, and repairs. They are equipped with manipulators, cameras, and sensors to perform complex tasks in challenging environments.

- Robotic Welding Systems: These robots are used for welding pipelines and other infrastructure, ensuring precise and consistent welds. They can work in hazardous environments and perform complex welding tasks with high accuracy.

Challenges and Opportunities of Automation and Robotics

The increasing use of automation and robotics in the oil and gas industry presents both challenges and opportunities:

- High Initial Investment: Implementing automation and robotics requires significant upfront investment in technology, training, and infrastructure.

- Job Displacement: Automation may lead to job displacement as machines replace some human tasks. However, it also creates new opportunities in areas like robotics engineering and data analysis.

- Cybersecurity Concerns: Automated systems are vulnerable to cyberattacks, which could disrupt operations and compromise data security. Robust cybersecurity measures are essential to mitigate these risks.

- Integration with Existing Infrastructure: Integrating new automation and robotics technologies with existing infrastructure can be challenging and require careful planning.

The Future of Oil and Gas Technology: New Technology In Oil And Gas Industry

The oil and gas industry is at a crossroads. While it remains a vital source of energy, it also faces increasing pressure to reduce its environmental impact and adapt to a changing energy landscape. The future of this industry hinges on its ability to embrace innovation and adopt emerging technologies that can enhance efficiency, reduce emissions, and unlock new resources.

Emerging Technologies in Oil and Gas

The oil and gas industry is ripe for disruption by a wave of emerging technologies. These technologies have the potential to revolutionize exploration, production, and refining operations, leading to significant improvements in efficiency, safety, and environmental performance.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are transforming the oil and gas industry by enabling better data analysis, predictive maintenance, and automated decision-making. AI algorithms can analyze vast amounts of data from sensors, seismic surveys, and production wells to identify patterns and anomalies, optimize production, and predict equipment failures. This can lead to improved resource recovery, reduced downtime, and increased safety.

- Internet of Things (IoT): The IoT connects physical assets to the internet, enabling real-time monitoring and control of operations. In oil and gas, IoT sensors can be deployed in pipelines, wells, and production facilities to collect data on pressure, temperature, flow rate, and other critical parameters. This data can be used to optimize production, detect leaks, and prevent equipment failures.

- Blockchain: Blockchain technology is gaining traction in the oil and gas industry due to its potential to improve transparency, security, and efficiency in supply chain management. Blockchain can track the origin and movement of oil and gas products, ensuring authenticity and reducing fraud. It can also facilitate secure and transparent transactions between buyers and sellers, streamlining the supply chain.

- Quantum Computing: Quantum computing has the potential to revolutionize the oil and gas industry by enabling faster and more efficient simulations of complex processes. Quantum computers can solve complex optimization problems, such as reservoir simulation and production optimization, which are currently too computationally intensive for classical computers.

- Advanced Materials: Advancements in materials science are leading to the development of new materials with enhanced properties that can improve the efficiency and sustainability of oil and gas operations. For example, new polymers can be used to create lighter and more durable pipelines, while advanced composites can be used to build more efficient and corrosion-resistant drilling equipment.

Impact of Emerging Technologies on the Oil and Gas Industry

The adoption of emerging technologies is expected to have a profound impact on the oil and gas industry, leading to both disruptions and new opportunities.

- Increased Efficiency and Productivity: Emerging technologies can significantly enhance the efficiency and productivity of oil and gas operations. AI-powered optimization algorithms can improve resource recovery rates, while IoT sensors can enable real-time monitoring and control, reducing downtime and waste.

- Reduced Costs: By automating tasks and optimizing operations, emerging technologies can help reduce costs in the oil and gas industry. This can improve profitability and make the industry more competitive.

- Enhanced Safety: Emerging technologies can improve safety in the oil and gas industry by enabling better risk assessment, predictive maintenance, and remote monitoring. AI algorithms can analyze data from sensors and historical records to identify potential hazards and recommend preventive measures.

- Environmental Sustainability: Emerging technologies can help reduce the environmental impact of oil and gas operations. AI-powered optimization algorithms can reduce emissions and energy consumption, while new materials can improve the efficiency and durability of equipment.

- New Business Models: Emerging technologies are creating new opportunities for innovation and business model development in the oil and gas industry. Blockchain technology, for example, can facilitate the emergence of decentralized energy markets and peer-to-peer energy trading platforms.

The Future of Oil and Gas Technology

The future of oil and gas technology is bright, with the potential to transform the industry and its role in meeting global energy demands. As these technologies mature and become more widely adopted, they will enable the industry to operate more efficiently, safely, and sustainably. The industry will need to embrace these changes and invest in research and development to stay ahead of the curve. By leveraging the power of emerging technologies, the oil and gas industry can continue to play a vital role in providing energy to the world while reducing its environmental footprint.

Ending Remarks

The oil and gas industry stands at the cusp of a new era, defined by technological innovation and a commitment to sustainability. The integration of digital technologies, advanced exploration techniques, and sustainable practices is not only enhancing operational efficiency but also enabling the industry to address the growing global energy demands while minimizing environmental impact. As we look towards the future, the continued adoption of new technologies will be crucial in shaping a more resilient, sustainable, and technologically advanced oil and gas sector.

The oil and gas industry is constantly evolving, with new technologies emerging to improve efficiency and safety. One company leading the way in this innovation is shenzhen tong bo wei technology co. ltd , known for their expertise in advanced drilling and production techniques.

Their focus on research and development has resulted in groundbreaking solutions that are transforming the industry, from real-time data analytics to automated well control systems.