Inspection Technologies: Advancing Quality and Safety

Inspection technologies are revolutionizing how we assess the integrity and performance of various assets, from manufacturing components to infrastructure. These technologies have evolved significantly, moving beyond traditional visual inspection and […]

Inspection technologies are revolutionizing how we assess the integrity and performance of various assets, from manufacturing components to infrastructure. These technologies have evolved significantly, moving beyond traditional visual inspection and manual testing methods. Modern inspection techniques leverage advanced sensors, imaging, and data analysis to deliver unparalleled accuracy, efficiency, and insights.

The driving force behind this technological evolution is a growing emphasis on safety, quality, and operational efficiency across industries. From ensuring the structural integrity of bridges to detecting defects in aircraft engines, inspection technologies play a crucial role in safeguarding lives, optimizing performance, and minimizing downtime.

Evolution of Inspection Technologies

Inspection technologies have evolved significantly over time, driven by the need for improved safety, quality control, and efficiency. From traditional methods like visual inspection to sophisticated modern techniques, inspection technologies have become increasingly sophisticated and integrated into various industries.

Historical Development of Inspection Technologies

The historical development of inspection technologies can be traced back to the early days of industrialization. Early inspection methods were primarily manual and relied heavily on human judgment. Visual inspection was a common practice, where skilled workers would examine products for defects. Manual testing involved using simple tools to assess the functionality and performance of components.

- Early 20th Century: The introduction of mechanical testing equipment, such as tensile testers and hardness testers, marked a significant advancement in inspection technologies. These devices provided objective measurements of material properties, leading to more reliable and consistent quality control.

- Mid-20th Century: The development of non-destructive testing (NDT) techniques, such as ultrasonic testing, radiographic testing, and magnetic particle testing, revolutionized the field of inspection. These techniques allowed for the detection of internal defects without damaging the inspected object, enabling the identification of potential failures before they occurred.

- Late 20th Century: The advent of computers and digital imaging significantly impacted inspection technologies. Automated inspection systems emerged, integrating sensors, cameras, and software to perform inspections faster and more accurately than manual methods.

- 21st Century: Advances in artificial intelligence (AI), machine learning, and robotics have further transformed inspection technologies. AI-powered systems can analyze vast amounts of data from inspections, identify patterns, and predict potential failures. Robotic inspection systems can access hard-to-reach areas and perform inspections in hazardous environments.

Comparison of Traditional and Modern Inspection Methods, Inspection technologies

Traditional inspection methods, such as visual inspection and manual testing, were often subjective and prone to human error. They also required significant time and effort, limiting the scope and frequency of inspections. Modern inspection techniques, on the other hand, offer several advantages over traditional methods:

- Objectivity: Modern inspection technologies rely on sensors, cameras, and software to collect data and perform analysis, reducing the subjectivity of human judgment.

- Accuracy: Modern inspection systems are designed to provide precise measurements and detect defects that might be missed by human eyes.

- Speed: Automated inspection systems can perform inspections much faster than manual methods, allowing for increased inspection frequency and coverage.

- Efficiency: Modern inspection technologies can automate many inspection tasks, freeing up human inspectors to focus on more complex tasks.

- Data Analysis: Modern systems can collect and analyze vast amounts of data from inspections, providing insights into trends, potential failures, and areas for improvement.

Driving Forces Behind Advancements in Inspection Technologies

Several factors have driven the advancements in inspection technologies:

- Safety Regulations: Increasingly stringent safety regulations in various industries have driven the development of more effective and reliable inspection technologies to ensure the safety of workers and the public.

- Quality Control: The demand for higher quality products and services has led to the adoption of advanced inspection techniques to detect defects early in the production process, minimizing costly rework and product recalls.

- Efficiency Demands: The need for increased efficiency and productivity has encouraged the development of automated inspection systems that can perform inspections faster and more efficiently than manual methods.

- Cost Reduction: Advanced inspection technologies can help reduce costs by identifying potential failures early, preventing costly repairs and downtime.

- Innovation: Continuous innovation in fields like AI, robotics, and sensor technology has paved the way for the development of new and improved inspection technologies.

Types of Inspection Technologies

Inspection technologies encompass a diverse range of methods and tools used to assess the condition, integrity, and performance of assets, structures, and systems. These technologies play a crucial role in ensuring safety, reliability, and efficiency across various industries.

Visual Inspection

Visual inspection is the most basic and widely used inspection method, relying on the human eye to observe and evaluate the condition of an asset. It involves direct visual examination of the asset’s surface, components, and surrounding environment to identify any visible defects, damage, or anomalies.

- Principles: Visual inspection relies on the human eye’s ability to perceive visual cues, such as color changes, cracks, corrosion, wear, and deformation. It often involves the use of magnifying glasses, lighting tools, and mirrors to enhance visibility.

- Applications: Visual inspection is commonly used for a wide range of applications, including:

- Assessing the condition of bridges, buildings, and other structures.

- Inspecting pipelines, tanks, and other industrial equipment for corrosion, leaks, and other defects.

- Evaluating the condition of aircraft, ships, and other vehicles for damage and wear.

- Performing routine maintenance checks on machinery and equipment.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) refers to a group of techniques used to evaluate the properties and integrity of materials and components without causing damage. NDT methods use various physical principles to detect flaws, defects, and other anomalies that may not be visible to the naked eye.

- Principles: NDT methods utilize different physical principles, such as sound waves, electromagnetic radiation, or magnetic fields, to interact with the material and detect internal defects or changes in material properties.

- Applications: NDT techniques are widely used in various industries, including:

- Aerospace: Detecting cracks, voids, and other defects in aircraft components.

- Construction: Assessing the integrity of concrete structures, welds, and reinforcing bars.

- Energy: Inspecting pipelines, pressure vessels, and other critical infrastructure for corrosion, cracks, and other defects.

- Manufacturing: Evaluating the quality of welds, castings, and other manufactured components.

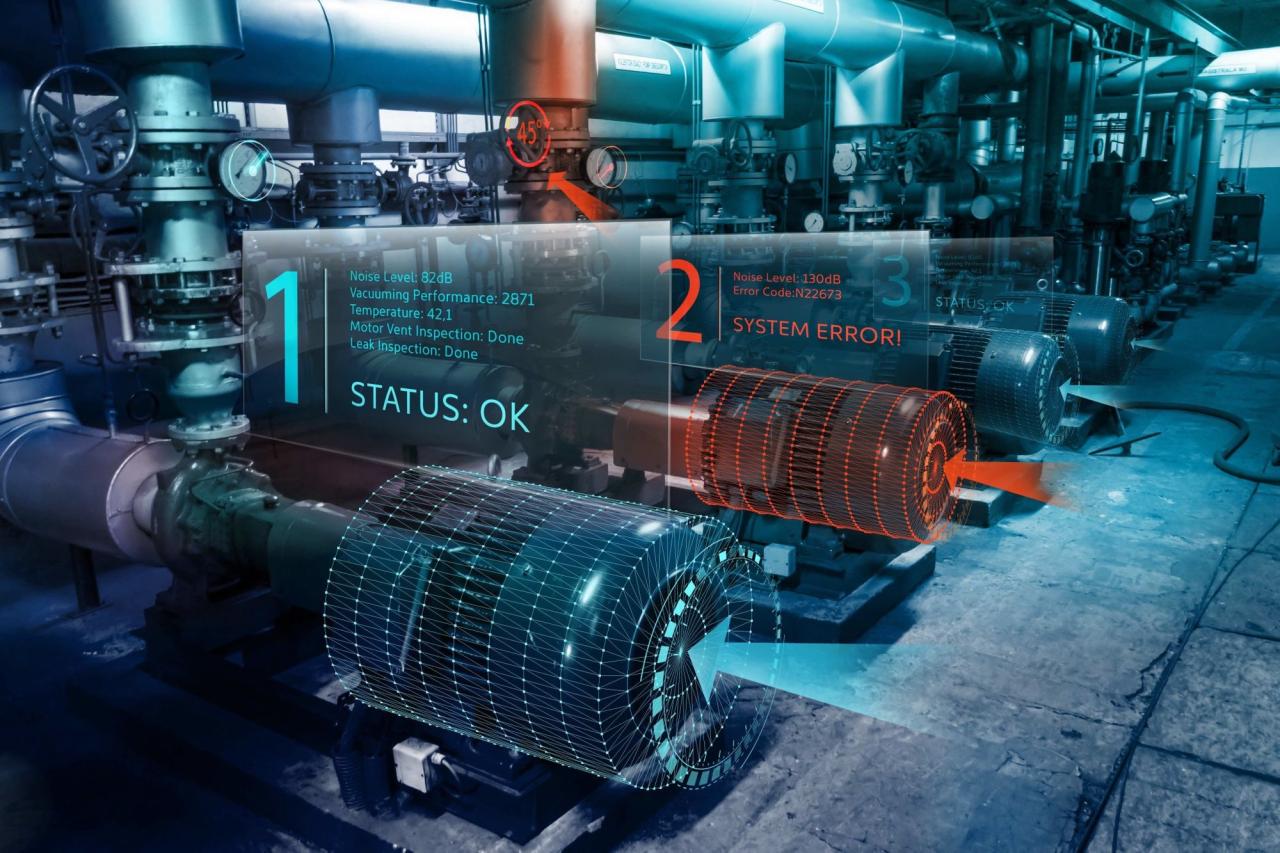

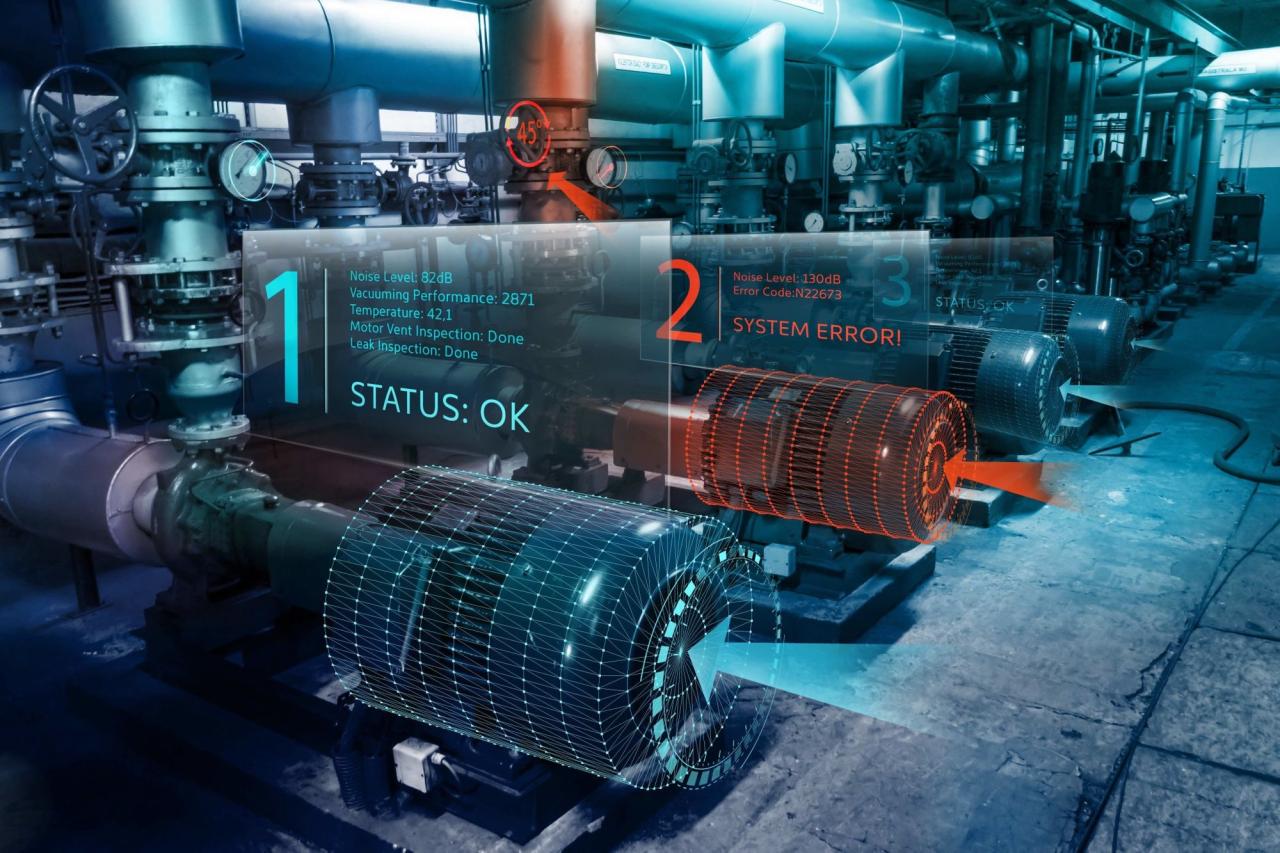

Automated Inspection Systems

Automated inspection systems utilize robotics, sensors, and software to perform inspections automatically, reducing the need for human intervention. These systems can access difficult-to-reach areas, perform inspections more quickly and efficiently, and provide more accurate and consistent results.

- Principles: Automated inspection systems typically employ sensors, such as cameras, lasers, ultrasonic transducers, or eddy current probes, to collect data about the asset’s condition. The collected data is then processed by software algorithms to identify defects, anomalies, and other issues.

- Applications: Automated inspection systems are used in various industries, including:

- Oil and Gas: Inspecting pipelines, tanks, and other infrastructure for corrosion, leaks, and other defects.

- Power Generation: Inspecting turbines, boilers, and other equipment for wear, corrosion, and other issues.

- Manufacturing: Inspecting parts and products for defects and quality control.

- Construction: Monitoring the progress of construction projects and inspecting structural integrity.

Remote Inspection

Remote inspection technologies enable the inspection of assets from a distance, using various tools and techniques to collect data and assess the condition of the asset. These technologies can be used to inspect assets in hazardous, inaccessible, or remote locations, reducing risks and costs associated with traditional inspection methods.

- Principles: Remote inspection technologies often utilize drones, robots, or specialized cameras equipped with sensors to capture images, videos, or data from the asset. This data is then transmitted back to a remote location for analysis and interpretation.

- Applications: Remote inspection technologies are used in various industries, including:

- Infrastructure: Inspecting bridges, tunnels, and other structures for damage and deterioration.

- Energy: Inspecting wind turbines, solar panels, and other renewable energy infrastructure for performance and maintenance needs.

- Mining: Inspecting mineshafts, tunnels, and other underground infrastructure for safety and stability.

- Environmental Monitoring: Assessing environmental conditions and monitoring the health of ecosystems.

Applications of Inspection Technologies

Inspection technologies play a crucial role in enhancing efficiency, safety, and quality across various industries. By leveraging advanced sensors, imaging techniques, and data analysis, these technologies enable comprehensive assessments of assets, processes, and products, leading to informed decision-making and improved outcomes.

Applications of Inspection Technologies Across Industries

The applications of inspection technologies are diverse and span across a wide range of industries. Here’s a table highlighting some key applications:

| Industry | Application | Technology | Benefits |

|---|---|---|---|

| Manufacturing | Quality control, defect detection, and process monitoring | Computer vision, X-ray inspection, ultrasonic testing | Reduced defects, improved product quality, enhanced production efficiency |

| Construction | Structural integrity assessment, material inspection, and safety audits | Drone inspection, laser scanning, thermal imaging | Improved safety, reduced construction costs, and enhanced project efficiency |

| Aerospace | Aircraft maintenance, non-destructive testing, and component inspection | Eddy current testing, ultrasonic testing, and visual inspection | Enhanced aircraft safety, reduced maintenance costs, and extended aircraft lifespan |

| Healthcare | Medical imaging, disease diagnosis, and surgical procedures | Computed tomography (CT), magnetic resonance imaging (MRI), and endoscopy | Improved diagnosis accuracy, minimally invasive procedures, and enhanced patient care |

| Energy | Pipeline inspection, wind turbine blade inspection, and power plant maintenance | Remotely operated vehicles (ROVs), laser scanning, and thermal imaging | Improved safety, reduced downtime, and enhanced energy efficiency |

Inspection Technologies in Manufacturing

Inspection technologies play a vital role in manufacturing by ensuring product quality, identifying defects, and optimizing production processes.

- Computer vision is used to inspect products for defects, such as scratches, dents, or missing parts. It involves using cameras and software to analyze images and identify anomalies. For example, computer vision systems can be deployed on assembly lines to automatically detect defects in automotive parts or electronic components.

- X-ray inspection is a non-destructive testing method that uses X-rays to penetrate materials and reveal internal defects. This technology is commonly used in the manufacturing of electronics, aerospace components, and medical devices. For instance, X-ray inspection can be used to identify cracks, voids, or foreign objects within circuit boards or engine parts.

- Ultrasonic testing uses sound waves to detect defects in materials. This method is particularly effective for inspecting welds, castings, and other components where internal defects may be present. Ultrasonic testing is widely used in the manufacturing of aircraft, pipelines, and pressure vessels.

The benefits of using inspection technologies in manufacturing include:

- Reduced defects: By detecting defects early on, inspection technologies can help to reduce the number of defective products that are shipped to customers.

- Improved product quality: Inspection technologies can help to ensure that products meet quality standards and specifications.

- Enhanced production efficiency: By automating inspection processes, inspection technologies can help to improve production efficiency and reduce the time required to inspect products.

Inspection Technologies in Construction

Inspection technologies are increasingly being used in the construction industry to improve safety, efficiency, and quality.

- Drone inspection is a cost-effective and efficient way to inspect bridges, buildings, and other structures. Drones equipped with high-resolution cameras can capture images and videos of hard-to-reach areas, providing valuable insights into the condition of structures.

- Laser scanning is a technology that uses lasers to create 3D models of structures. This technology can be used to accurately measure the dimensions of structures, detect defects, and create detailed plans for renovations or repairs.

- Thermal imaging is used to detect temperature differences in structures, which can indicate problems such as leaks, insulation issues, or electrical faults. Thermal imaging can be used to identify potential safety hazards and to assess the energy efficiency of buildings.

The benefits of using inspection technologies in construction include:

- Improved safety: Inspection technologies can help to identify potential safety hazards, such as structural defects or leaks, which can prevent accidents.

- Reduced construction costs: By detecting problems early on, inspection technologies can help to reduce the costs associated with repairs and rework.

- Enhanced project efficiency: Inspection technologies can help to speed up the construction process by providing accurate and timely information about the condition of structures.

Inspection Technologies in Aerospace

Inspection technologies play a critical role in the aerospace industry, ensuring the safety and reliability of aircraft and spacecraft.

- Eddy current testing is a non-destructive testing method that uses electromagnetic fields to detect defects in conductive materials. This technology is commonly used to inspect aircraft components, such as fuselage panels, wings, and landing gear.

- Ultrasonic testing is also widely used in the aerospace industry to detect defects in aircraft components. Ultrasonic testing can be used to identify cracks, voids, or other defects in materials, such as aluminum, titanium, and composites.

- Visual inspection is still an important part of aircraft maintenance, but it is often supplemented by advanced imaging technologies, such as borescopes and endoscopes, which allow inspectors to see inside components that are difficult to access.

The benefits of using inspection technologies in aerospace include:

- Enhanced aircraft safety: Inspection technologies help to ensure that aircraft are safe to fly by detecting defects early on.

- Reduced maintenance costs: By detecting problems early on, inspection technologies can help to prevent costly repairs and downtime.

- Extended aircraft lifespan: Inspection technologies can help to extend the lifespan of aircraft by identifying and addressing potential problems before they become serious.

Key Features and Benefits of Inspection Technologies

Modern inspection technologies offer a wide range of advantages that significantly enhance various inspection tasks across diverse industries. These technologies are designed to improve accuracy, efficiency, and safety while reducing costs and downtime.

Increased Accuracy and Precision

Inspection technologies leverage advanced sensors, algorithms, and data analysis techniques to achieve unparalleled levels of accuracy and precision. This translates to more reliable and detailed inspection results, minimizing the risk of human error and ensuring a comprehensive understanding of the asset’s condition.

Improved Efficiency and Speed

These technologies streamline inspection processes, reducing the time required to complete inspections and enabling faster turnaround times. This is achieved through automation, remote monitoring capabilities, and real-time data analysis, allowing for quicker identification of potential issues and efficient decision-making.

Enhanced Safety and Reliability

Inspection technologies play a crucial role in enhancing safety and reliability by minimizing human intervention in hazardous environments. They allow for remote inspections of high-risk areas, reducing the risk of accidents and injuries. Moreover, the ability to detect potential issues early on contributes to improved reliability and reduced downtime.

Reduced Costs and Downtime

By optimizing inspection processes and minimizing downtime, inspection technologies contribute to significant cost savings. Early detection of potential issues through proactive inspections allows for timely repairs and maintenance, preventing major breakdowns and costly repairs.

Data Collection and Analysis Capabilities

Inspection technologies are equipped with powerful data collection and analysis capabilities, enabling the generation of comprehensive reports and insights. This data can be used to track asset performance, identify trends, and optimize maintenance schedules, ultimately leading to improved asset management and reduced operational costs.

Challenges and Future Trends in Inspection Technologies

While inspection technologies offer numerous benefits, their implementation and integration come with certain challenges. These challenges are crucial to address to ensure the successful adoption and advancement of these technologies. Moreover, exploring future trends in inspection technologies is essential to understand the direction of innovation and its potential impact on various industries.

Challenges in Implementing and Integrating Inspection Technologies

Implementing and integrating inspection technologies require careful consideration of several challenges. These challenges, if not addressed effectively, can hinder the successful adoption and realization of the benefits of these technologies.

- Cost Considerations: The initial investment in inspection technologies, including hardware, software, and training, can be substantial. This cost factor can be a significant barrier for smaller companies or those with limited budgets. However, the long-term cost savings and efficiency gains achieved through inspection technologies can offset the initial investment. For example, predictive maintenance enabled by inspection technologies can significantly reduce downtime and maintenance costs.

- Training and Expertise: Operating and interpreting data from inspection technologies require specialized training and expertise. This need for skilled personnel can be challenging, especially in industries where expertise in advanced technologies is limited. Training programs and partnerships with educational institutions can help bridge this gap.

- Data Management and Analysis: Inspection technologies generate vast amounts of data that require efficient management and analysis. This data can be complex and require specialized software and tools for interpretation. Establishing robust data management systems and employing data analytics techniques are crucial for extracting valuable insights from the collected data.

- Integration with Existing Systems: Integrating inspection technologies with existing systems, such as enterprise resource planning (ERP) or asset management systems, can be complex and require significant effort. Ensuring compatibility and seamless data flow between different systems is essential for achieving optimal results and avoiding data silos.

Future Trends in Inspection Technologies

Inspection technologies are continuously evolving, driven by advancements in artificial intelligence (AI), sensor technologies, robotics, and automation. These trends hold the potential to revolutionize how inspections are conducted and the insights gained from them.

- Advancements in Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are transforming inspection technologies by enabling automated defect detection, anomaly identification, and predictive maintenance. AI-powered algorithms can analyze vast amounts of data, identify patterns, and predict potential failures before they occur. For example, AI-based image recognition algorithms are being used to detect corrosion in pipelines, preventing potential leaks and accidents.

- Development of New Sensor Technologies: Advancements in sensor technologies are leading to the development of more sensitive, accurate, and versatile sensors. These sensors can collect data from various environments and conditions, providing more comprehensive and detailed insights. For instance, the development of fiber optic sensors allows for real-time monitoring of infrastructure, detecting stress and strain before they lead to structural failures.

- Integration of Robotics and Automation: Robotics and automation are increasingly integrated into inspection technologies, enabling faster, more efficient, and safer inspections. Robots can access hazardous or difficult-to-reach areas, performing tasks that would be dangerous or impossible for humans. For example, drones are being used for inspecting bridges and power lines, reducing the risk of accidents and improving the efficiency of inspections.

- Emerging Applications in Areas Like Predictive Maintenance and Asset Management: Inspection technologies are playing a crucial role in predictive maintenance and asset management. By analyzing data from inspections, companies can anticipate potential failures and schedule maintenance proactively, reducing downtime and extending the lifespan of assets. For example, AI-powered systems can analyze data from vibration sensors in industrial equipment to predict when maintenance is needed, preventing costly breakdowns and ensuring optimal performance.

Ultimate Conclusion

Inspection technologies are not just about identifying problems; they are about proactively managing risks and optimizing performance. As these technologies continue to evolve, driven by advancements in artificial intelligence, sensor technology, and automation, we can expect even greater benefits in terms of safety, reliability, and cost savings. The future of inspection technologies holds exciting possibilities for transforming industries and ensuring a safer, more efficient world.

Inspection technologies are essential for ensuring the safety and efficiency of various industries. From infrastructure to manufacturing, these technologies play a crucial role in identifying potential problems and maintaining quality standards. One company that specializes in providing cutting-edge inspection solutions is aries clean technologies linden nj.

Their expertise in environmental and industrial services allows them to offer a comprehensive range of inspection services that help businesses meet their regulatory requirements and achieve their sustainability goals.