Online Process Technology Degree: Your Path to Industry Success

An online process technology degree opens doors to a world of exciting career opportunities in various industries. This flexible and affordable path equips you with the essential skills and knowledge […]

An online process technology degree opens doors to a world of exciting career opportunities in various industries. This flexible and affordable path equips you with the essential skills and knowledge to excel as a process technology professional. You’ll gain a deep understanding of process control, instrumentation, and automation, while also exploring specialized areas that align with your interests.

The curriculum is designed to provide a comprehensive foundation in process technology principles, preparing you to confidently tackle real-world challenges. From understanding the intricate workings of industrial processes to mastering the latest automation technologies, you’ll develop the expertise to make a meaningful impact in a dynamic field.

Introduction to Online Process Technology Degrees

The demand for skilled process technology professionals is steadily increasing across various industries, including manufacturing, pharmaceuticals, energy, and food processing. These professionals play a crucial role in optimizing production processes, ensuring safety, and maximizing efficiency. An online process technology degree offers a flexible and affordable pathway to enter this exciting field.

Benefits of Online Process Technology Degrees

Pursuing an online process technology degree provides several advantages, making it an attractive option for individuals seeking to enhance their career prospects.

- Flexibility: Online programs offer the convenience of learning at your own pace and on your own schedule, accommodating work commitments and personal responsibilities. This flexibility allows students to continue working while pursuing their education.

- Affordability: Online programs often have lower tuition fees compared to traditional on-campus programs, making them more accessible to a wider range of individuals. Additionally, online learning eliminates the need for relocation or commuting, further reducing costs.

- Accessibility: Online programs break down geographical barriers, allowing individuals from diverse locations to access quality education and pursue their desired careers. This accessibility expands opportunities for career advancement and professional development.

Key Skills and Knowledge Acquired

Online process technology programs equip students with the essential skills and knowledge required to succeed in this field.

- Process Control and Automation: Students gain a comprehensive understanding of process control systems, automation technologies, and their application in various industrial settings. They learn to design, implement, and maintain automated systems to optimize production processes.

- Process Safety and Environmental Compliance: Safety and environmental regulations are paramount in process technology. Students develop a strong foundation in process safety principles, hazard identification, and risk assessment. They also learn about environmental regulations and best practices for sustainable operations.

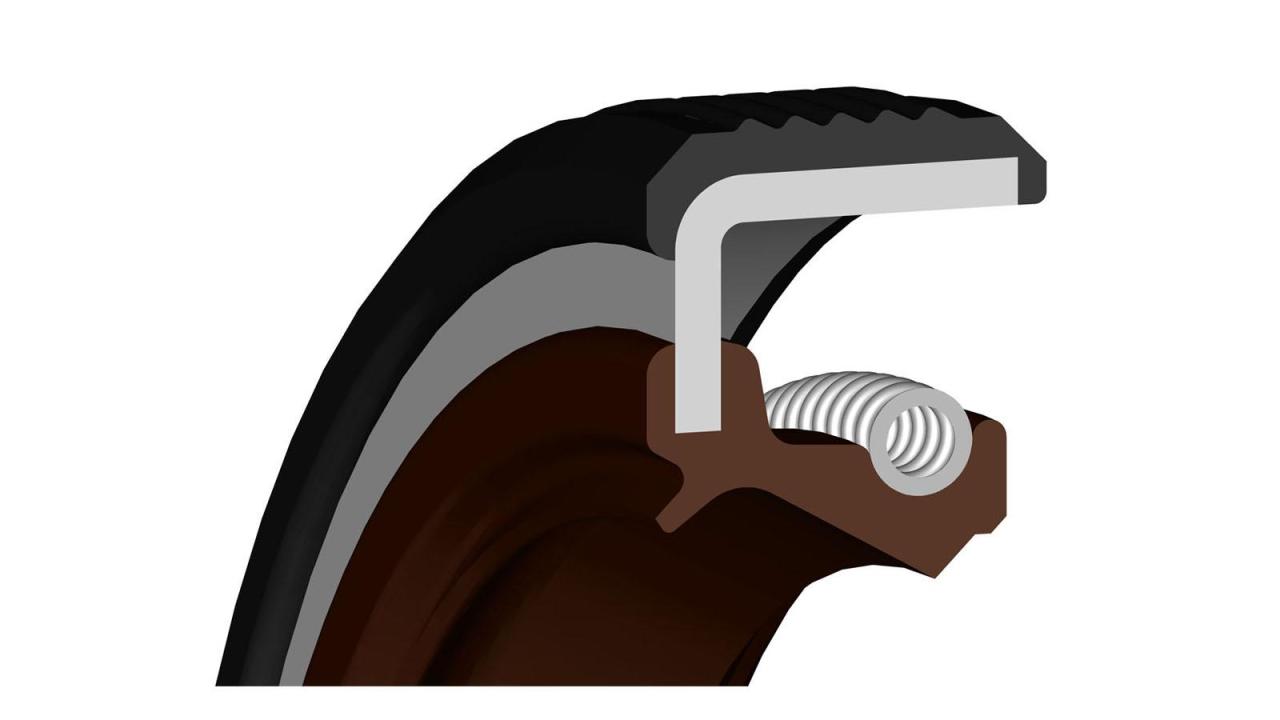

- Troubleshooting and Maintenance: Process technology professionals are responsible for troubleshooting equipment malfunctions and ensuring the smooth operation of production processes. Students acquire the skills to diagnose problems, perform preventative maintenance, and implement corrective actions.

- Data Analysis and Interpretation: Data analysis plays a crucial role in optimizing process performance. Students learn to collect, analyze, and interpret process data to identify trends, optimize parameters, and improve efficiency.

Curriculum and Coursework

An online process technology degree program is designed to provide students with a comprehensive understanding of the principles, practices, and technologies used in process industries. The curriculum is structured to equip graduates with the necessary knowledge and skills to excel in various roles within the industry.

The curriculum typically encompasses a wide range of subjects, including core courses that provide a foundation in process technology and specialized elective courses that allow students to tailor their education to specific industry needs.

Core Courses

Core courses are fundamental to the process technology curriculum, providing students with a solid understanding of the principles and practices that underpin the industry.

- Process Control: This course covers the principles and techniques used to control and optimize industrial processes. It includes topics such as feedback control systems, process dynamics, and control system design. Students will learn how to analyze process data, design control strategies, and implement control systems using various technologies.

- Instrumentation: This course focuses on the measurement and analysis of process variables. It covers topics such as sensors, transmitters, actuators, and data acquisition systems. Students will learn how to select, install, calibrate, and troubleshoot instrumentation used in process industries.

- Automation: This course explores the application of automation technologies in process industries. It covers topics such as programmable logic controllers (PLCs), distributed control systems (DCS), and industrial communication protocols. Students will learn how to program and configure automation systems, as well as integrate them into process control systems.

- Process Safety: This course emphasizes the importance of safety in process industries. It covers topics such as hazard identification, risk assessment, safety management systems, and incident investigation. Students will learn how to identify and mitigate potential hazards, and implement safety procedures to ensure a safe working environment.

- Process Design: This course focuses on the design and optimization of industrial processes. It covers topics such as process simulation, process modeling, and process optimization techniques. Students will learn how to design and analyze process flowsheets, optimize process parameters, and implement process improvements.

- Process Economics: This course explores the economic aspects of process industries. It covers topics such as cost analysis, project evaluation, and profitability analysis. Students will learn how to assess the financial viability of process projects, and make informed decisions regarding process design and operation.

Specialized Elective Courses

Specialized elective courses allow students to deepen their knowledge and skills in areas that align with their career goals.

- Advanced Process Control: This course delves into advanced control techniques such as model predictive control, adaptive control, and nonlinear control. Students will learn how to apply these techniques to optimize process performance and address complex control challenges.

- Process Simulation and Modeling: This course focuses on the use of simulation software to model and analyze industrial processes. Students will learn how to create process models, conduct simulations, and interpret simulation results to optimize process design and operation.

- Process Optimization: This course covers advanced techniques for optimizing process performance. It includes topics such as statistical process control, design of experiments, and process improvement methodologies. Students will learn how to identify and eliminate process bottlenecks, and implement continuous improvement programs.

- Process Engineering for Specific Industries: This course explores the unique process technologies and challenges faced in specific industries such as pharmaceuticals, chemicals, oil and gas, and food processing. Students will gain insights into industry-specific regulations, best practices, and emerging trends.

- Process Automation and Control Systems: This course provides a comprehensive overview of advanced automation and control systems used in process industries. It covers topics such as industrial communication networks, data historians, and advanced process control systems. Students will learn how to integrate and manage complex automation systems in a process environment.

- Process Safety and Risk Management: This course delves into advanced concepts in process safety and risk management. It covers topics such as process hazard analysis, risk assessment, and safety management systems. Students will learn how to conduct comprehensive risk assessments, develop effective safety procedures, and manage safety risks in complex process environments.

Sample Course Schedule, Online process technology degree

A sample course schedule for an online process technology degree program is presented below. This schedule is a general representation and may vary depending on the specific program and institution.

| Year | Semester | Course |

|---|---|---|

| 1 | Fall | Introduction to Process Technology Process Control Fundamentals Instrumentation and Measurement |

| Spring | Process Automation and Control Systems Process Safety and Risk Management Process Design Principles |

|

| 2 | Fall | Advanced Process Control Process Simulation and Modeling Process Optimization Techniques |

| Spring | Process Engineering for Specific Industries Process Economics and Project Management Capstone Project |

Closing Notes

With an online process technology degree, you’ll be well-positioned to thrive in a rapidly evolving industry. The demand for skilled professionals is high, and your newfound knowledge will open doors to rewarding careers with excellent job prospects. Embrace the flexibility of online learning and embark on a journey that will empower you to shape the future of process technology.

An online process technology degree can equip you with the skills to optimize and automate industrial processes, making them more efficient and cost-effective. This field often intersects with the realm of smart solutions technology , where data analysis and predictive modeling are used to identify and implement improvements.

By understanding the principles of smart solutions, process technology professionals can contribute to the development of intelligent systems that enhance productivity and sustainability within their industries.