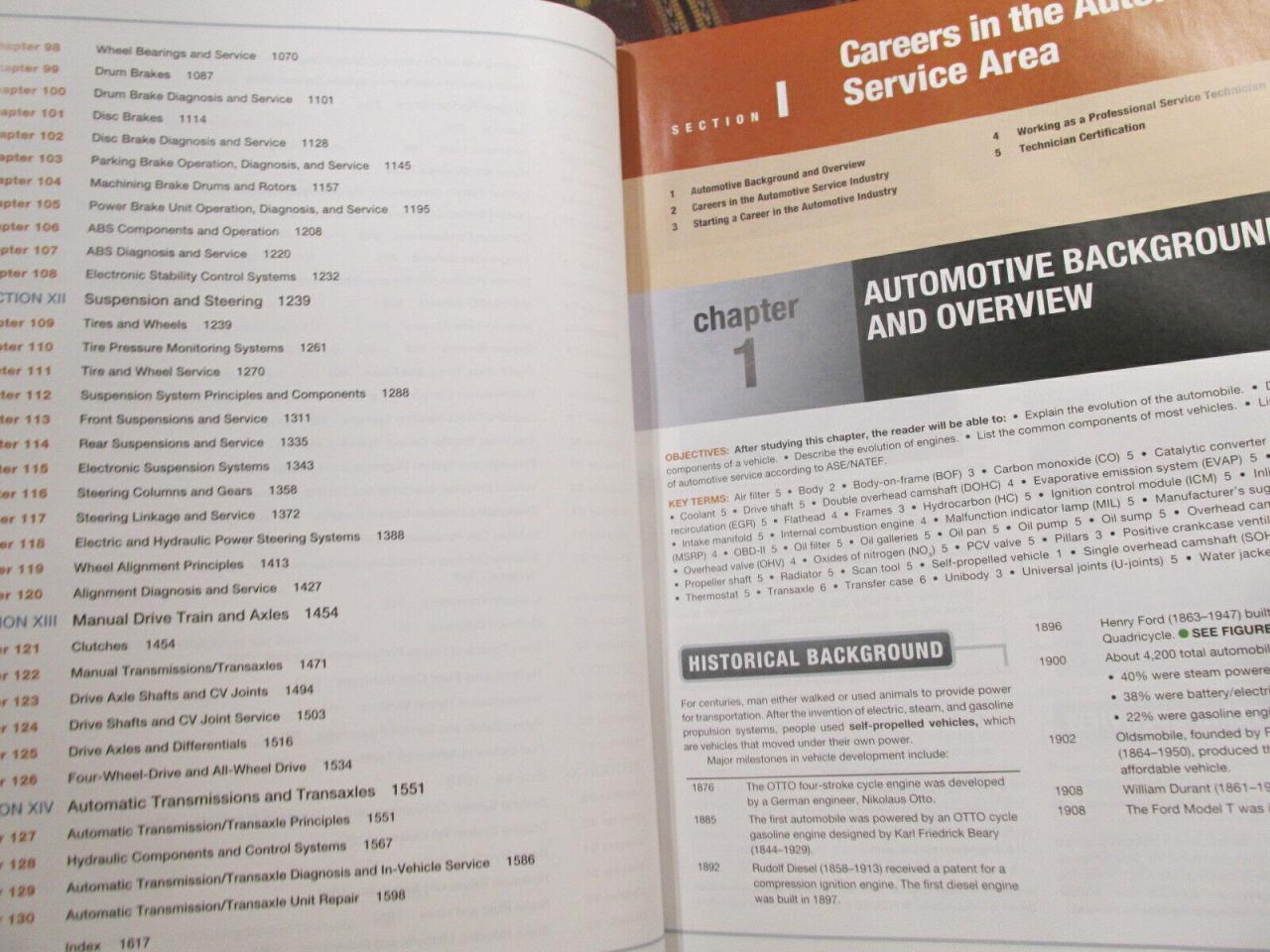

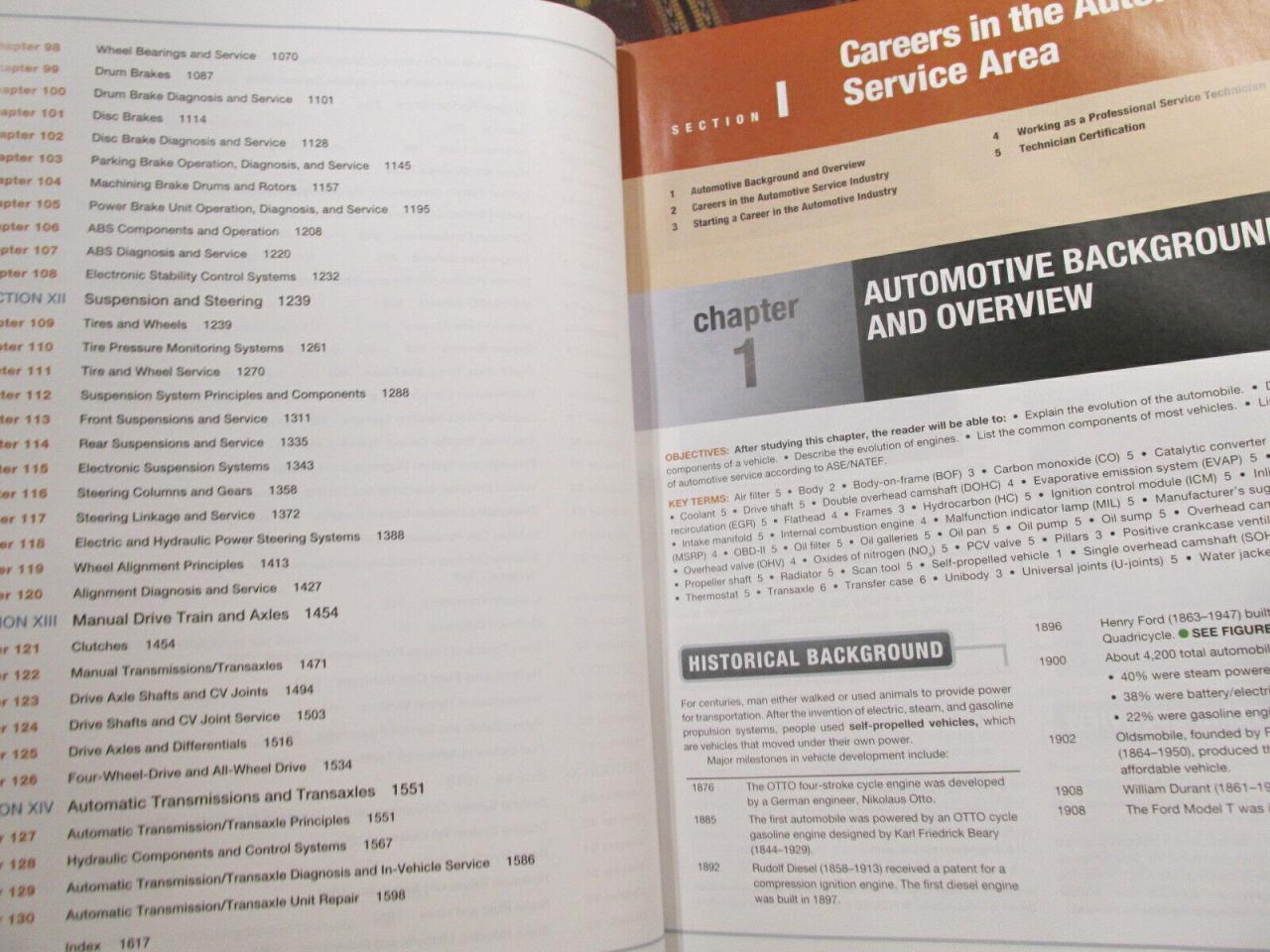

James Halderman Automotive Technology 6th Edition: A Comprehensive Guide

James Halderman Automotive Technology 6th Edition sets the stage for an exploration of the intricate world of modern vehicles, delving into the evolution of automotive technology and providing a detailed […]

James Halderman Automotive Technology 6th Edition sets the stage for an exploration of the intricate world of modern vehicles, delving into the evolution of automotive technology and providing a detailed understanding of the complex systems that power them. This comprehensive guide offers readers a journey through the history of automotive engineering, highlighting key milestones and advancements that have shaped the industry. From the fundamental principles of internal combustion engines to the cutting-edge technologies of electric vehicles and autonomous driving, Halderman’s text provides a thorough and engaging overview of the field.

The book is divided into eight chapters, each dedicated to a specific area of automotive technology. Readers will explore the intricacies of engine systems, transmission and drivetrain systems, chassis and suspension systems, braking systems, electrical and electronic systems, automotive safety and regulations, and emerging automotive technologies. Each chapter is meticulously crafted to provide a clear and concise explanation of complex concepts, supported by numerous illustrations, diagrams, and real-world examples.

Overview of Automotive Technology

The automotive industry has witnessed a remarkable evolution over the past century, from the early days of the gasoline-powered internal combustion engine to the advent of electric vehicles and autonomous driving systems. This journey has been marked by significant advancements in technology, materials, and manufacturing processes, transforming the way we travel and shaping the landscape of transportation.

History of Automotive Technology

The development of automotive technology has been a gradual process, with key milestones contributing to its progress. The invention of the internal combustion engine in the late 19th century paved the way for the first automobiles. Early vehicles were often unreliable and expensive, but technological advancements, such as the development of the electric starter and the mass production of automobiles, made cars more affordable and accessible to the general public.

- Early Years (1886-1910): Karl Benz’s invention of the first gasoline-powered automobile in 1886 marked the beginning of the automotive era. Early cars were often unreliable and expensive, with limited range and speed. The invention of the electric starter in 1911 significantly improved the convenience and usability of automobiles.

- The Golden Age (1910-1930): This period witnessed the rise of mass production, with companies like Ford Motor Company pioneering assembly line techniques. This led to a significant decrease in the cost of automobiles, making them more accessible to the middle class. The development of the first successful diesel engine in 1924 opened up new possibilities for heavy-duty vehicles.

- Post-World War II (1945-1970): After World War II, the automotive industry experienced a period of rapid growth, fueled by the demand for affordable and reliable transportation. Advancements in engine technology, including the introduction of the V8 engine and the development of automatic transmissions, made cars more powerful and comfortable.

- The Age of Electronics (1970-Present): The introduction of electronic control units (ECUs) in the 1970s revolutionized automotive technology. ECUs allowed for more precise control of engine performance, fuel efficiency, and emissions. This era also saw the development of anti-lock braking systems (ABS), airbags, and other safety features.

Components and Systems of a Modern Vehicle

Modern vehicles are complex machines comprised of numerous interconnected systems working together to provide safe and efficient transportation. These systems can be broadly categorized into:

- Powertrain: This system generates power and transmits it to the wheels. It includes the engine, transmission, drivetrain, and exhaust system.

- Chassis: This system provides structural support for the vehicle and houses the suspension, steering, braking, and wheels.

- Body: This system encompasses the exterior and interior of the vehicle, including the body panels, doors, windows, seats, and dashboard.

- Electrical System: This system powers various components and functions, including the engine, lights, and entertainment systems. It comprises the battery, alternator, wiring, and control modules.

- Safety Systems: These systems are designed to protect occupants in the event of a collision. They include airbags, anti-lock braking systems, electronic stability control, and seatbelts.

- Comfort and Convenience Systems: These systems enhance the driving experience and include features such as air conditioning, heating, entertainment systems, and navigation.

Internal Combustion Engines, James halderman automotive technology 6th edition

Internal combustion engines are the most common type of engine used in automobiles. They convert chemical energy stored in fuel into mechanical energy that drives the vehicle. The basic principle of operation involves the following steps:

- Intake: Air is drawn into the cylinder through the intake valve.

- Compression: The piston compresses the air-fuel mixture.

- Combustion: The compressed air-fuel mixture is ignited by a spark plug, causing rapid expansion and creating pressure.

- Exhaust: The burnt gases are expelled from the cylinder through the exhaust valve.

The efficiency of an internal combustion engine is measured by its thermal efficiency, which is the ratio of the work output to the heat input.

Electric Motors

Electric motors convert electrical energy into mechanical energy, providing power to electric vehicles. Unlike internal combustion engines, electric motors have no emissions and operate silently. The fundamental principle of operation involves the interaction between a magnetic field and an electric current.

- Stator: The stator is the stationary part of the motor and contains electromagnets that create a magnetic field.

- Rotor: The rotor is the rotating part of the motor and contains windings that carry electric current.

- Commutator: The commutator is a device that switches the direction of current flow in the rotor windings, creating a continuous rotation.

Alternative Powertrains

While internal combustion engines and electric motors are the most prevalent powertrains, alternative options are gaining traction. These include:

- Hybrid Electric Vehicles (HEVs): HEVs combine an internal combustion engine with an electric motor, improving fuel efficiency and reducing emissions.

- Plug-in Hybrid Electric Vehicles (PHEVs): PHEVs are similar to HEVs but have a larger battery capacity that can be recharged from an external source.

- Fuel Cell Vehicles (FCVs): FCVs use hydrogen fuel cells to generate electricity, emitting only water vapor as a byproduct.

- Biofuel Vehicles: Biofuel vehicles use fuels derived from renewable sources, such as ethanol or biodiesel.

Engine Systems: James Halderman Automotive Technology 6th Edition

The engine is the heart of any vehicle, responsible for converting fuel into mechanical energy that powers the wheels. Understanding how engines work is essential for automotive technicians. This section will explore the operation of different types of internal combustion engines, the functions of key engine components, and the principles behind fuel injection, ignition systems, and emission control systems.

Types of Internal Combustion Engines

Internal combustion engines are classified based on their fuel type, combustion cycle, and number of cylinders. The most common types are gasoline, diesel, and rotary engines.

- Gasoline Engines: Gasoline engines are the most common type of engine found in passenger vehicles. They use a spark plug to ignite a mixture of air and fuel, causing a controlled explosion that drives the pistons. The Otto cycle is the combustion cycle used in gasoline engines.

- Diesel Engines: Diesel engines use a different combustion cycle, the Diesel cycle, where fuel is injected into hot, compressed air, causing it to ignite without a spark plug. Diesel engines are known for their efficiency and high torque output.

- Rotary Engines: Rotary engines, also known as Wankel engines, use a unique design with a triangular rotor that rotates within a housing. They are known for their smooth operation and high power-to-weight ratio.

Engine Components

The following are some of the essential components of an internal combustion engine:

- Cylinder Head: The cylinder head sits on top of the engine block and contains the combustion chamber. It houses the valves, spark plugs, and other components related to the combustion process.

- Crankshaft: The crankshaft is a rotating shaft that converts the linear motion of the pistons into rotational motion. It connects to the pistons through connecting rods.

- Connecting Rods: Connecting rods connect the pistons to the crankshaft, transferring the force of the combustion to the crankshaft.

- Piston: The piston moves up and down inside the cylinder, driven by the force of the combustion. It compresses the air-fuel mixture and transmits power to the crankshaft.

- Valves: Valves control the flow of air and exhaust gases into and out of the combustion chamber. Intake valves allow air to enter the cylinder, while exhaust valves allow exhaust gases to escape.

Fuel Injection Systems

Fuel injection systems deliver fuel to the combustion chamber in a controlled and precise manner. There are two main types of fuel injection systems:

- Port Fuel Injection (PFI): In PFI, fuel is injected into the intake manifold, where it mixes with air before entering the cylinder.

- Direct Injection (DI): In DI, fuel is injected directly into the combustion chamber, allowing for more precise fuel control and improved fuel efficiency.

Ignition Systems

Ignition systems are responsible for igniting the air-fuel mixture in the combustion chamber. The main components of an ignition system are:

- Ignition Coil: The ignition coil transforms low-voltage battery power into high-voltage current to create a spark at the spark plug.

- Distributor: The distributor directs the high-voltage current from the ignition coil to the appropriate spark plug, depending on the firing order of the engine.

- Spark Plug: The spark plug is a small device that creates a spark to ignite the air-fuel mixture in the combustion chamber.

Emission Control Systems

Emission control systems are designed to reduce the amount of harmful pollutants emitted from the engine. They work by capturing and treating exhaust gases before they are released into the atmosphere. Common emission control systems include:

- Catalytic Converter: The catalytic converter uses a chemical reaction to convert harmful pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances.

- Oxygen Sensors: Oxygen sensors monitor the oxygen content in the exhaust gases and send signals to the engine control unit (ECU) to adjust fuel delivery and optimize combustion.

- Exhaust Gas Recirculation (EGR) System: The EGR system recirculates exhaust gases back into the intake manifold, reducing nitrogen oxide emissions.

Transmission and Drivetrain Systems

The transmission and drivetrain systems are crucial components in an automobile, responsible for transferring power from the engine to the wheels. They allow for smooth acceleration, efficient power delivery, and various driving modes. This section explores the different types of transmissions, the role of the drivetrain components, and the advantages and disadvantages of various drivetrain configurations.

Manual Transmissions

Manual transmissions, also known as stick shifts, allow the driver to manually select the gear ratio for optimal power delivery. They consist of a gearbox, a clutch, and a shift lever. The clutch disengages the engine from the transmission, allowing the driver to change gears without stalling the engine.

- When the clutch is engaged, the engine’s power is transferred to the transmission through the clutch disc.

- The gearbox contains a set of gears that allow the driver to select different gear ratios, affecting the vehicle’s speed and torque.

- The shift lever allows the driver to change gears by selecting different gear ratios within the gearbox.

Manual transmissions offer better fuel efficiency and a more engaging driving experience, but they require more driver input and skill.

Automatic Transmissions

Automatic transmissions automatically select the appropriate gear ratio based on engine speed, vehicle speed, and load. They use a hydraulic system to shift gears smoothly and efficiently.

- A torque converter, similar to a fluid coupling, connects the engine to the transmission.

- The transmission contains multiple gear sets and clutches that are controlled by a hydraulic system.

- An electronic control unit (ECU) monitors various parameters and adjusts the gear selection for optimal performance.

Automatic transmissions offer convenience and smooth acceleration, but they can be less fuel-efficient than manual transmissions.

Continuously Variable Transmissions (CVTs)

CVTs offer a seamless and smooth acceleration experience by using a belt and pulley system to continuously adjust the gear ratio. This allows the engine to operate at its most efficient RPM for optimal fuel economy.

- CVTs use a belt and pulley system to vary the gear ratio continuously.

- The belt runs between two pulleys that can change their diameter, effectively changing the gear ratio.

- CVTs offer smooth acceleration and excellent fuel economy.

CVTs can sometimes feel less responsive than traditional transmissions, especially during acceleration.

Differentials

Differentials are located within the rear axle or transaxle and allow the wheels to rotate at different speeds during turns. This is essential for vehicles to navigate corners smoothly without wheel slippage.

- The differential contains a set of gears that allow the wheels to rotate at different speeds.

- When a vehicle turns, the outer wheel travels a greater distance than the inner wheel, requiring a different rotational speed.

- The differential ensures that both wheels receive the appropriate amount of power while turning.

Axles and Drive Shafts

Axles connect the differential to the wheels, transmitting power to the wheels. Drive shafts are responsible for transmitting power from the transmission to the differential.

- Axles are typically made of strong steel and are designed to withstand the forces of driving.

- Drive shafts can be either solid or hollow, depending on the application.

- The drive shaft connects the transmission to the differential, transferring power to the wheels.

Drivetrain Configurations

Drivetrain configurations determine the location of the engine and how power is transferred to the wheels.

- Front-wheel drive (FWD): The engine is located at the front of the vehicle, and power is transferred to the front wheels. FWD is common in smaller and more fuel-efficient vehicles, offering good traction in most conditions.

- Rear-wheel drive (RWD): The engine is located at the front of the vehicle, but power is transferred to the rear wheels. RWD is often used in performance vehicles, providing better handling and traction in certain situations.

- All-wheel drive (AWD): Power is distributed to all four wheels, providing excellent traction and stability in various conditions. AWD systems can be either full-time or part-time, depending on the application.

Chassis and Suspension Systems

The chassis and suspension systems are crucial components of any vehicle, responsible for providing a stable platform for the engine, drivetrain, and body while ensuring a comfortable ride and safe handling. These systems work in tandem to absorb road imperfections, maintain control, and provide a balance between ride comfort and handling performance.

Vehicle Frames

The frame serves as the backbone of the vehicle, providing structural support for all other components. It is responsible for distributing weight, absorbing shock and impact, and maintaining the vehicle’s overall rigidity. There are two primary types of frames:

- Body-on-Frame Construction: This traditional design features a separate frame that is bolted to the body. It offers greater strength and durability but adds weight to the vehicle. Examples of vehicles using body-on-frame construction include pickup trucks, SUVs, and some heavy-duty vehicles.

- Unibody Construction: In this design, the body and frame are integrated into a single unit, creating a lighter and more rigid structure. Unibody construction is commonly found in passenger cars, minivans, and some SUVs.

Braking Systems

Braking systems are essential for controlling the speed and stopping a vehicle. They convert kinetic energy into heat, allowing the driver to safely decelerate or bring the vehicle to a complete stop. Modern braking systems are sophisticated, incorporating hydraulic and electronic components to provide efficient and reliable braking performance.

Hydraulic Braking Systems

Hydraulic braking systems use the incompressibility of fluids to transmit force from the brake pedal to the wheels. When the brake pedal is pressed, a master cylinder creates pressure in the brake fluid, which is then transmitted through lines to the wheel cylinders or calipers. These components then actuate the brake pads or shoes, which press against the brake rotors or drums to slow down the vehicle.

- Master Cylinder: The master cylinder is the heart of the hydraulic braking system. It converts the force applied to the brake pedal into hydraulic pressure. When the brake pedal is pressed, a piston inside the master cylinder pushes brake fluid into the brake lines.

- Brake Lines: Brake lines are tubes or hoses that carry brake fluid from the master cylinder to the wheel cylinders or calipers. These lines are typically made of steel or rubber and must be able to withstand high pressure.

- Wheel Cylinders/Calipers: Wheel cylinders or calipers are located at each wheel and contain pistons that push the brake pads or shoes against the brake rotors or drums. When brake fluid pressure is applied to the wheel cylinders or calipers, the pistons move outwards, forcing the brake pads or shoes to engage with the brake rotors or drums.

- Brake Pads/Shoes: Brake pads or shoes are friction materials that create the force needed to slow down the vehicle. They are typically made of a composite material containing metal, ceramic, or organic materials. When the brake pedal is pressed, the pads or shoes are forced against the brake rotors or drums, creating friction that slows the vehicle’s rotation.

- Brake Rotors/Drums: Brake rotors or drums are the rotating components that the brake pads or shoes press against. Rotors are typically made of cast iron or steel, while drums are usually made of cast iron.

Electronic Braking Systems

Electronic braking systems use electronic sensors and actuators to enhance braking performance and safety. These systems can provide features like anti-lock braking (ABS), electronic stability control (ESC), and automatic emergency braking (AEB).

- Anti-Lock Braking System (ABS): ABS prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control. ABS uses wheel speed sensors to detect when a wheel is about to lock up. If a wheel starts to lock, the ABS system rapidly modulates the brake pressure to that wheel, preventing it from locking up. This allows the driver to maintain steering control while braking hard, reducing the risk of skidding.

- Electronic Stability Control (ESC): ESC helps to prevent the vehicle from skidding or losing control during cornering or emergency maneuvers. ESC uses sensors to monitor the vehicle’s speed, steering angle, and yaw rate (the rate at which the vehicle is turning). If the vehicle starts to skid, ESC automatically applies the brakes to individual wheels to help stabilize the vehicle. ESC can significantly reduce the risk of accidents, especially in slippery conditions.

Components of a Braking System

The components of a braking system work together to provide safe and effective braking. These components include:

- Brake Pedal: The brake pedal is the primary control for the braking system. When the brake pedal is pressed, it activates the master cylinder, initiating the braking process.

- Master Cylinder: The master cylinder is the hydraulic heart of the braking system. It converts the force applied to the brake pedal into hydraulic pressure.

- Brake Lines: Brake lines are the tubes or hoses that carry brake fluid from the master cylinder to the wheel cylinders or calipers. They are designed to withstand high pressure.

- Wheel Cylinders/Calipers: Wheel cylinders or calipers are located at each wheel and contain pistons that push the brake pads or shoes against the brake rotors or drums.

- Brake Pads/Shoes: Brake pads or shoes are friction materials that create the force needed to slow down the vehicle.

- Brake Rotors/Drums: Brake rotors or drums are the rotating components that the brake pads or shoes press against.

- Parking Brake: The parking brake, also known as the handbrake or emergency brake, is a separate braking system that is used to hold the vehicle stationary when parked. It typically operates on the rear wheels and is activated by a lever or button.

Anti-Lock Braking Systems (ABS)

ABS is a safety feature that prevents the wheels from locking up during hard braking. When a wheel locks up, the tire loses traction, making it difficult to steer or control the vehicle. ABS uses wheel speed sensors to detect when a wheel is about to lock up. If a wheel starts to lock, the ABS system rapidly modulates the brake pressure to that wheel, preventing it from locking up. This allows the driver to maintain steering control while braking hard, reducing the risk of skidding.

ABS is a safety feature that prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control.

Electronic Stability Control (ESC)

ESC is a safety feature that helps to prevent the vehicle from skidding or losing control during cornering or emergency maneuvers. ESC uses sensors to monitor the vehicle’s speed, steering angle, and yaw rate (the rate at which the vehicle is turning). If the vehicle starts to skid, ESC automatically applies the brakes to individual wheels to help stabilize the vehicle. ESC can significantly reduce the risk of accidents, especially in slippery conditions.

ESC is a safety feature that helps to prevent the vehicle from skidding or losing control during cornering or emergency maneuvers.

Automotive Safety and Regulations

Modern vehicles are equipped with a wide array of safety features and are subject to stringent regulations designed to protect occupants and other road users. These advancements have significantly reduced accidents and fatalities, making driving safer than ever before. This section delves into the various safety features, regulations, and their impact on road safety.

Safety Features

Modern vehicles incorporate numerous safety features to mitigate the risk of accidents and protect occupants in the event of a collision. These features can be broadly categorized into passive and active safety systems.

- Passive safety systems are designed to protect occupants in the event of a crash. Examples include:

- Airbags: These inflatable cushions deploy in a collision to cushion the impact and reduce the risk of head and chest injuries.

- Seatbelts: Essential for restraining occupants during a crash, seatbelts prevent them from being ejected from the vehicle and significantly reduce the severity of injuries.

- Collapsible steering columns: These columns are designed to deform during a collision, absorbing impact energy and reducing the risk of injuries to the driver.

- Reinforced passenger compartments: Modern vehicles feature a reinforced passenger compartment designed to withstand high impact forces and protect occupants in a crash.

- Active safety systems are designed to prevent accidents from occurring in the first place. Examples include:

- Anti-lock braking systems (ABS): ABS prevents wheel lock-up during braking, allowing the driver to maintain steering control and avoid skidding.

- Electronic stability control (ESC): ESC detects loss of vehicle control and applies individual brakes to maintain stability, preventing skids and rollovers.

- Adaptive cruise control (ACC): ACC uses sensors to maintain a safe distance from the vehicle ahead, automatically adjusting speed to avoid collisions.

- Lane departure warning (LDW): LDW alerts the driver if the vehicle drifts out of its lane, helping prevent accidents due to inattention.

- Blind spot monitoring (BSM): BSM uses sensors to detect vehicles in the driver’s blind spots, alerting them to potential hazards.

- Automatic emergency braking (AEB): AEB uses sensors to detect potential collisions and automatically applies the brakes to avoid or mitigate the impact.

Impact of Safety Technologies

The widespread adoption of safety features and regulations has significantly improved road safety, resulting in a dramatic reduction in accidents and fatalities.

- Reduced fatalities: According to the National Highway Traffic Safety Administration (NHTSA), the number of traffic fatalities in the United States has been steadily declining since the 1960s, largely due to advancements in vehicle safety technology.

- Reduced severity of injuries: In addition to fewer fatalities, safety features have also reduced the severity of injuries in accidents. Airbags, seatbelts, and other passive safety systems have significantly reduced the risk of serious injuries, even in high-impact collisions.

- Increased awareness and driver behavior: The presence of active safety features, such as lane departure warning and blind spot monitoring, has also contributed to increased driver awareness and safer driving habits.

Government Agencies and Industry Standards

Government agencies and industry standards play a crucial role in setting safety requirements for vehicles. These organizations conduct research, develop regulations, and enforce safety standards to ensure the safety of vehicles on the road.

- National Highway Traffic Safety Administration (NHTSA): The NHTSA is a US government agency responsible for setting safety standards for vehicles, conducting research, and enforcing regulations.

- European New Car Assessment Programme (Euro NCAP): Euro NCAP is an independent organization that tests and rates the safety of new cars sold in Europe.

- Insurance Institute for Highway Safety (IIHS): The IIHS is a non-profit organization that conducts crash tests and rates vehicles based on their safety performance.

Regulations and Standards

Government agencies and industry standards establish various regulations and standards to ensure vehicle safety. These regulations cover a wide range of aspects, including:

- Crashworthiness standards: These standards specify the structural integrity of vehicles and their ability to protect occupants in a crash.

- Safety equipment requirements: Regulations mandate the inclusion of specific safety features, such as airbags, seatbelts, and anti-lock brakes.

- Performance standards: Regulations set performance standards for various vehicle systems, such as braking, steering, and lighting.

- Emission standards: These regulations aim to reduce air pollution and improve fuel efficiency.

Future Trends in Automotive Safety

The automotive industry continues to innovate and develop new safety technologies.

- Advanced driver-assistance systems (ADAS): ADAS technologies, such as adaptive cruise control, lane departure warning, and automatic emergency braking, are becoming increasingly sophisticated and are expected to play a significant role in preventing accidents in the future.

- Autonomous vehicles: Self-driving cars are expected to significantly reduce accidents, as they can react faster and more accurately than humans.

- Connected vehicles: Connected vehicles can communicate with each other and infrastructure, allowing for more efficient traffic flow and improved safety.

Emerging Automotive Technologies

The automotive industry is undergoing a period of rapid transformation, driven by advancements in technology and a growing focus on sustainability. This chapter explores some of the most exciting and impactful developments in automotive technology, including hybrid and electric vehicles, autonomous driving, connected car technology, and alternative fuel sources. We will also examine the environmental impact of these technologies and their role in shaping a more sustainable future.

Hybrid and Electric Vehicles

Hybrid and electric vehicles (HEVs and EVs) are becoming increasingly popular as consumers seek more fuel-efficient and environmentally friendly transportation options. HEVs combine a gasoline engine with an electric motor, while EVs are powered solely by electricity.

HEVs offer improved fuel economy compared to traditional gasoline-powered vehicles, while EVs produce zero tailpipe emissions. Both technologies contribute to reducing greenhouse gas emissions and dependence on fossil fuels.

- Hybrid Electric Vehicles (HEVs): HEVs use a combination of a gasoline engine and an electric motor, allowing for better fuel efficiency than traditional gasoline-powered vehicles. Examples of HEVs include the Toyota Prius and Honda Insight.

- Electric Vehicles (EVs): EVs are powered solely by electricity and produce zero tailpipe emissions. Examples of EVs include the Tesla Model S and Chevrolet Bolt.

Autonomous Driving

Autonomous driving, also known as self-driving technology, is a rapidly developing field that promises to revolutionize the automotive industry. Autonomous vehicles use sensors, cameras, and artificial intelligence (AI) to navigate roads without human intervention.

- Levels of Automation: The Society of Automotive Engineers (SAE) has defined six levels of automation for autonomous vehicles, ranging from Level 0 (no automation) to Level 5 (full automation). Level 3 automation allows for hands-free driving in certain conditions, while Level 5 automation enables fully autonomous driving in all conditions.

- Safety and Benefits: Autonomous vehicles have the potential to significantly improve road safety by reducing human error, which is a major factor in traffic accidents. They can also improve traffic flow, reduce congestion, and provide mobility for people who are unable to drive themselves.

Connected Car Technology

Connected car technology refers to the integration of vehicles with the internet and other devices. This allows for a wide range of features, including:

- Remote Vehicle Access: Drivers can use their smartphones or other devices to lock and unlock doors, start the engine, and monitor vehicle status remotely.

- Navigation and Entertainment: Connected cars can provide real-time traffic information, navigation guidance, and access to music and other entertainment services.

- Safety and Security: Connected cars can provide advanced safety features, such as automatic emergency braking and lane departure warning. They can also be used to track vehicle location and provide roadside assistance.

Alternative Fuel Sources

Alternative fuel sources are being explored as a way to reduce dependence on fossil fuels and mitigate the environmental impact of transportation. Some of the most promising alternative fuel sources include:

- Biofuels: Biofuels are derived from renewable sources, such as plants and algae. They can be blended with gasoline or used as a standalone fuel.

- Hydrogen Fuel Cells: Hydrogen fuel cells convert hydrogen gas into electricity, producing only water as a byproduct. Hydrogen fuel cell vehicles offer long driving ranges and fast refueling times.

- Solar Power: Solar-powered vehicles use photovoltaic cells to convert sunlight into electricity. While solar power is still in its early stages of development for automotive applications, it has the potential to provide a sustainable and emission-free source of energy.

Last Word

James Halderman Automotive Technology 6th Edition serves as an invaluable resource for students, professionals, and enthusiasts alike. Its comprehensive coverage, engaging writing style, and practical applications make it an essential guide for anyone seeking a deeper understanding of the automotive world. Whether you are a novice looking to gain a basic understanding of car mechanics or an experienced technician seeking to expand your knowledge, this book offers a wealth of information and insights that will enhance your appreciation for the complexities and innovations of modern vehicles.

James Halderman’s Automotive Technology 6th Edition provides a comprehensive overview of the automotive industry, delving into the intricacies of various systems. A particularly useful resource within the book is the detailed “technological table” technological table , which outlines key advancements in automotive technology throughout history.

This table serves as a valuable reference point for understanding the evolution of the industry and its impact on modern vehicles.