Applied Industrial Technologies in Fontana: A Technological Landscape

Applied industrial technologies fontana – Applied industrial technologies in Fontana set the stage for a compelling narrative, exploring the intersection of innovation and industry in this vibrant Californian city. This […]

Applied industrial technologies fontana – Applied industrial technologies in Fontana set the stage for a compelling narrative, exploring the intersection of innovation and industry in this vibrant Californian city. This exploration delves into the heart of Fontana’s industrial landscape, examining the major industries, their technological adoption, and the challenges and opportunities they face. From manufacturing and logistics to energy and beyond, we uncover the diverse applications of industrial technologies and their impact on the region’s economic growth and sustainability.

This analysis delves into the most commonly used technologies, showcasing specific examples of their implementation in different sectors. We also explore the potential impact of emerging technologies like artificial intelligence (AI), robotics, and automation, and their influence on the future of Fontana’s industrial landscape. The discussion further examines the impact of technology on the workforce, the need for workforce development, and the potential for job creation and economic growth driven by technological advancements.

Impact of Applied Technologies on the Workforce

The rapid adoption of advanced technologies in Fontana’s industrial sector is transforming the local workforce, creating new opportunities while also demanding a shift in skills and knowledge. This section will explore the impact of technology adoption on employment and skills requirements, highlighting initiatives and programs for workforce development, and analyzing the potential for job creation and economic growth driven by technological advancements.

Employment and Skills Requirements

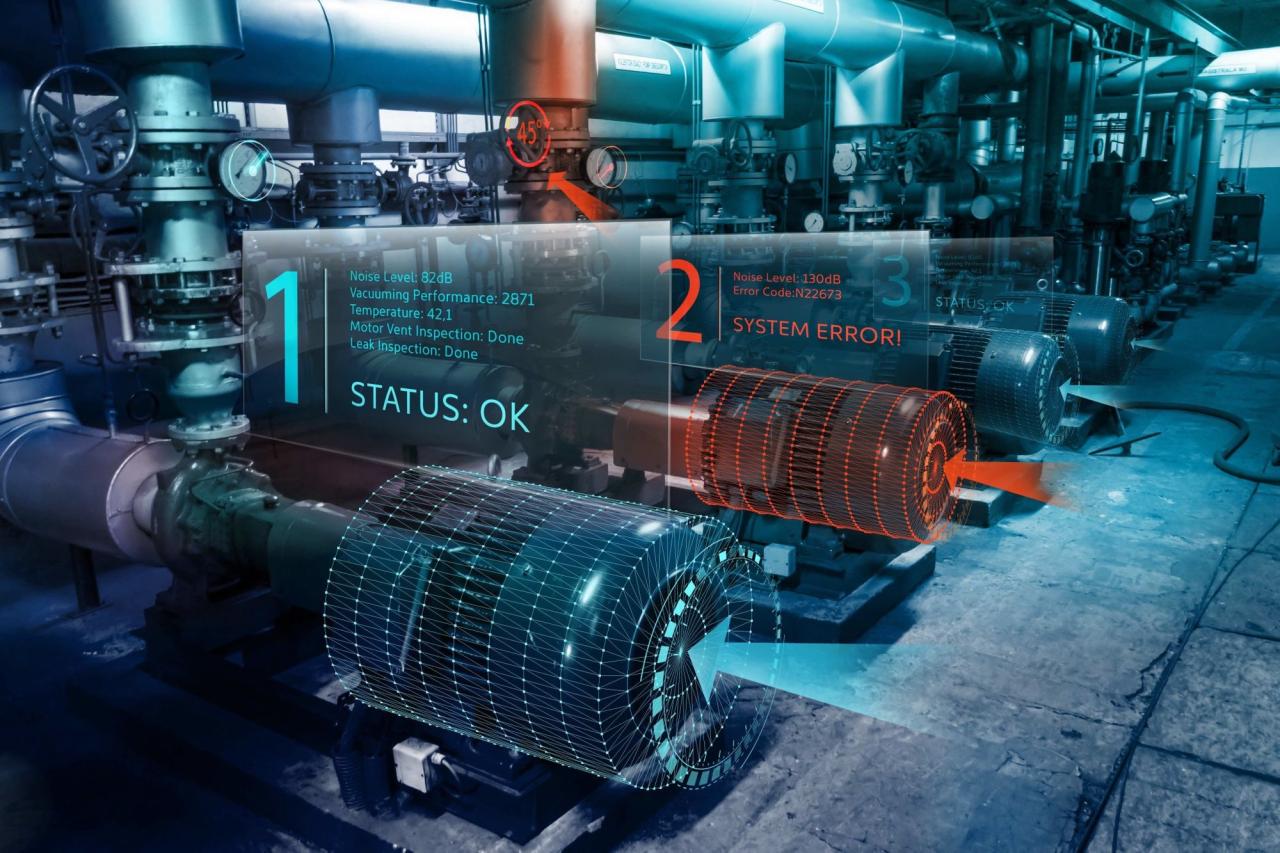

The integration of industrial technologies, such as automation, robotics, artificial intelligence (AI), and advanced manufacturing processes, is influencing the demand for skilled workers in Fontana. While automation and robotics may displace some jobs, they also create new opportunities in areas like technology integration, maintenance, and data analysis. The skills required for these new roles are often more specialized and technical, demanding a workforce adept at operating and maintaining complex equipment, interpreting data, and adapting to rapidly evolving technologies.

Workforce Development Initiatives

Recognizing the evolving needs of the workforce, Fontana has implemented several initiatives and programs to bridge the skills gap and prepare residents for the demands of the modern industrial landscape. These programs provide training and education in areas such as:

- Robotics and Automation: Programs equip individuals with the skills to operate, maintain, and program industrial robots and automated systems.

- Advanced Manufacturing: Courses focus on computer-aided design (CAD), computer-aided manufacturing (CAM), and other advanced manufacturing technologies, providing individuals with the skills needed to work in modern manufacturing environments.

- Data Analytics and Programming: Programs train individuals to analyze data, interpret insights, and use programming languages to develop applications and solutions for industrial processes.

- Cybersecurity: Training in cybersecurity is crucial to protect sensitive data and systems from cyber threats, particularly in industries that rely heavily on interconnected technologies.

These initiatives are often partnerships between local educational institutions, industry leaders, and government agencies, aiming to provide accessible and relevant training opportunities to residents.

Potential for Job Creation and Economic Growth

The adoption of industrial technologies holds significant potential for job creation and economic growth in Fontana. The increasing demand for skilled workers in areas like automation, data analysis, and cybersecurity creates new opportunities for residents, contributing to a more diversified and robust local economy.

“According to a recent study by the National Association of Manufacturers, the adoption of advanced manufacturing technologies is expected to create 2.1 million new jobs in the United States by 2028.”

Moreover, the increased efficiency and productivity enabled by these technologies can boost output, attract new investments, and drive overall economic growth.

Sustainability and Environmental Impact: Applied Industrial Technologies Fontana

Fontana’s industries are increasingly recognizing the critical importance of sustainability and environmental responsibility. Applied technologies play a crucial role in enabling Fontana to minimize its environmental footprint and transition towards a more sustainable future.

Energy Efficiency Technologies

Energy efficiency is a cornerstone of sustainability, and Fontana’s industries are actively adopting technologies to reduce energy consumption. These technologies include:

- Energy Management Systems (EMS): These systems monitor and optimize energy usage across facilities, identifying areas for improvement and implementing strategies to reduce energy waste.

- Variable Speed Drives (VSDs): VSDs adjust the speed of motors based on demand, reducing energy consumption by operating at optimal speeds. This technology is particularly beneficial in applications like pumps and fans.

- High-Efficiency Lighting: Replacing traditional lighting with LED lights significantly reduces energy consumption while improving illumination quality.

- Building Automation Systems (BAS): BAS integrate various building systems, such as HVAC, lighting, and security, to optimize energy use and ensure efficient building operations.

Waste Reduction and Recycling Technologies, Applied industrial technologies fontana

Minimizing waste generation and promoting recycling are essential components of sustainable industrial practices. Fontana industries are implementing technologies to achieve these goals, including:

- Waste Sorting and Recycling Systems: Advanced sorting technologies help separate recyclable materials from waste streams, increasing recycling rates and reducing landfill waste.

- Closed-Loop Manufacturing: This approach minimizes waste by reusing and recycling materials within the production process, reducing reliance on virgin materials and promoting circular economy principles.

- Waste-to-Energy Technologies: Technologies like anaerobic digestion and gasification convert organic waste into energy, reducing waste volume and generating renewable energy sources.

Pollution Control Technologies

Reducing air, water, and soil pollution is crucial for environmental protection. Fontana industries are employing various technologies to minimize pollution:

- Air Pollution Control Systems: These systems use technologies like scrubbers, filters, and electrostatic precipitators to remove pollutants from industrial emissions, improving air quality.

- Water Treatment Technologies: Wastewater treatment plants utilize advanced filtration, biological treatment, and disinfection processes to remove contaminants from wastewater before it is discharged.

- Clean Production Technologies: Implementing cleaner production processes, such as using less hazardous materials and reducing waste generation, helps minimize pollution at the source.

Potential for Leadership in Sustainable Industrial Practices

Fontana has the potential to become a leader in sustainable industrial practices. By embracing innovative technologies and collaborating with stakeholders, Fontana can:

- Promote Green Supply Chains: Encourage suppliers to adopt sustainable practices and use environmentally friendly materials, creating a network of sustainable businesses.

- Develop Green Industrial Parks: Create industrial parks with integrated sustainability features, such as renewable energy sources, efficient infrastructure, and waste management systems.

- Invest in Research and Development: Support research and development initiatives focused on developing and deploying new technologies for sustainable industrial practices.

Collaboration and Partnerships

In the realm of technological advancement, Fontana’s progress hinges on collaborative efforts between industry, government, and academia. This tripartite partnership is crucial for fostering innovation, knowledge sharing, and a thriving technological ecosystem.

Key Organizations and Initiatives

These partnerships facilitate the exchange of knowledge, resources, and expertise, accelerating the development and adoption of new technologies.

- Fontana Economic Development Corporation (FEDC): The FEDC plays a vital role in attracting businesses, promoting economic growth, and fostering innovation in Fontana. They offer resources, support, and networking opportunities for businesses, including those in the technology sector.

- San Bernardino County Workforce Development Board: This organization collaborates with local businesses and educational institutions to develop workforce training programs, ensuring a skilled workforce to meet the demands of emerging technologies.

- California State University, San Bernardino (CSUSB): CSUSB serves as a hub for research and development, providing opportunities for collaboration with industry partners and offering specialized programs in areas like engineering, computer science, and technology management.

- Fontana Unified School District: The district plays a crucial role in preparing students for the future workforce by incorporating STEM education into their curriculum and fostering partnerships with local businesses and universities.

Potential for a Technology Hub or Innovation Center

Fontana’s strategic location, coupled with its growing industrial base and proximity to research institutions, makes it an ideal candidate for establishing a technology hub or innovation center. Such a center would serve as a catalyst for:

- Accelerating Technology Transfer: A hub would bridge the gap between research and commercialization, facilitating the adoption of new technologies by local businesses.

- Attracting Investment: A technology hub would attract venture capital and investment, further stimulating innovation and economic growth.

- Developing a Skilled Workforce: The hub could offer training programs and workshops, equipping the local workforce with the skills needed for the technology-driven economy.

“By creating a collaborative environment that fosters innovation and technology transfer, Fontana can become a leading center for technological advancement in Southern California.”

Conclusive Thoughts

As we conclude our journey through the world of applied industrial technologies in Fontana, we recognize the crucial role of collaboration and partnerships between industry, government, and academia in fostering innovation and technological advancement. This collaborative approach holds the key to unlocking Fontana’s potential as a leader in sustainable industrial practices and a hub for technological innovation. By embracing technology and fostering a spirit of innovation, Fontana is poised to shape a brighter future for its industries and its people.

Applied Industrial Technologies Fontana is a leading provider of innovative solutions for various industries. Their expertise spans from automation and robotics to advanced manufacturing processes. One example of a company that embraces cutting-edge technology is bird brain technologies , which focuses on developing intelligent systems for logistics and supply chain management.

This type of forward-thinking approach aligns perfectly with Applied Industrial Technologies Fontana’s commitment to pushing the boundaries of industrial innovation.