James E. Duffy Auto Body Repair Technology: Innovations in Automotive Repair

James e duffy auto body repair technology – James E. Duffy Auto Body Repair Technology stands as a testament to the evolution of automotive repair, offering innovative solutions that redefine […]

James e duffy auto body repair technology – James E. Duffy Auto Body Repair Technology stands as a testament to the evolution of automotive repair, offering innovative solutions that redefine the industry. Born from a legacy of expertise, James E. Duffy has consistently pushed the boundaries of repair technology, introducing methods that are both efficient and effective. Their commitment to excellence has driven the development of cutting-edge techniques that enhance repair quality, minimize downtime, and prioritize vehicle safety.

This technology encompasses a range of advanced tools and processes, each designed to address specific challenges encountered in auto body repair. From collision repair to paint technology and structural repair, James E. Duffy’s innovations are tailored to provide comprehensive solutions for a wide range of vehicle damage. The company’s unwavering focus on research and development ensures that their technology remains at the forefront of the industry, continually adapting to meet the demands of the ever-changing automotive landscape.

Core Technologies and Innovations

James E. Duffy Auto Body Repair Technology prioritizes a blend of traditional expertise and cutting-edge advancements to ensure the highest quality repairs. This approach allows them to address the complexities of modern vehicles with precision and efficiency.

Collision Repair

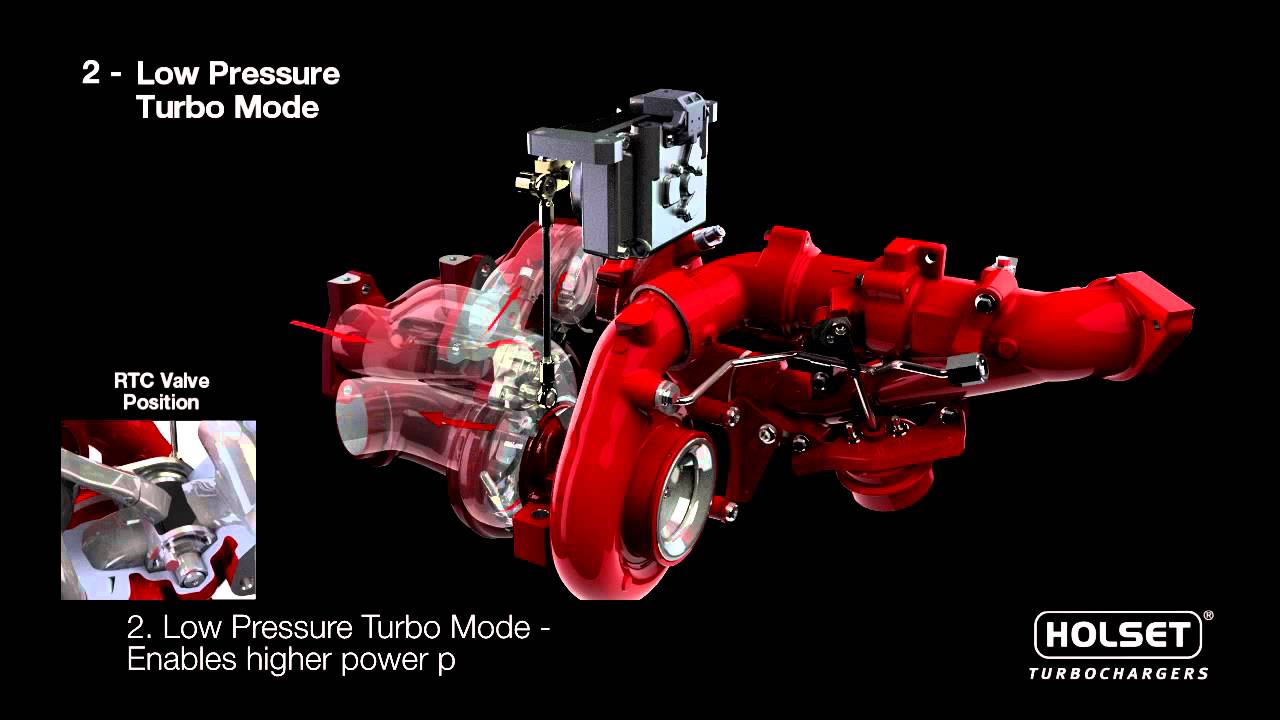

Collision repair at James E. Duffy involves a comprehensive approach that combines traditional techniques with innovative technologies. They utilize advanced measuring systems, such as laser scanners, to create precise digital representations of the vehicle’s damaged areas. This information is then used to guide the repair process, ensuring accuracy and consistency.

- Computerized Frame Straightening: James E. Duffy employs state-of-the-art computerized frame straightening equipment to restore the vehicle’s structural integrity. These machines utilize advanced algorithms to calculate the precise adjustments needed to return the frame to its original specifications. This method is more precise and efficient compared to traditional methods, resulting in a more accurate and durable repair.

- Aluminum Repair: With the increasing use of aluminum in modern vehicles, James E. Duffy has invested in specialized tools and techniques for aluminum repair. These methods involve specialized welding procedures and materials designed to ensure the strength and durability of aluminum components. This expertise allows them to handle the unique challenges posed by aluminum body panels, ensuring a seamless and lasting repair.

Paint Technology

James E. Duffy utilizes advanced paint technology to achieve exceptional color matching and durable finishes. They employ waterborne paint systems that are environmentally friendly and offer superior performance.

- Spectrophotometer Color Matching: James E. Duffy utilizes spectrophotometers to accurately measure and analyze the existing paint on the vehicle. This technology allows them to precisely match the original color, ensuring a seamless blend with the surrounding paint. The spectrophotometer captures the color information from the vehicle’s paint and generates a digital formula that can be used to create a perfect match. This method is far more accurate than traditional methods, resulting in a virtually invisible repair.

- High-Definition Spray Guns: James E. Duffy utilizes high-definition spray guns to apply the paint with precision and consistency. These spray guns create a fine atomized spray, allowing for a smoother and more even application. This technology reduces the risk of paint runs and imperfections, resulting in a high-quality finish. The fine atomization also minimizes the amount of paint wasted, contributing to a more environmentally friendly process.

Structural Repair

James E. Duffy is equipped to handle complex structural repairs, utilizing advanced techniques and materials to ensure the safety and integrity of the vehicle.

- High-Strength Adhesives: James E. Duffy utilizes high-strength adhesives to bond structural components, providing a strong and durable repair. These adhesives offer superior strength and flexibility compared to traditional welding methods, reducing the risk of stress fractures and ensuring a lasting repair. This technology is particularly important in repairing modern vehicles with complex structural designs.

- Advanced Welding Techniques: James E. Duffy utilizes advanced welding techniques, such as laser welding, to repair structural components. These techniques offer greater precision and control, minimizing the risk of distortion and ensuring a strong and durable repair. Laser welding is also less likely to damage surrounding materials, making it ideal for delicate repairs.

Applications and Use Cases: James E Duffy Auto Body Repair Technology

James E. Duffy’s auto body repair technology finds practical applications in various scenarios, ranging from minor dents and scratches to major collision repairs. This technology empowers technicians to efficiently and effectively restore vehicles to their pre-accident condition.

Examples of Applications

The following examples illustrate how James E. Duffy’s technology is used in real-world auto body repair scenarios:

- Dent Removal: Using specialized tools and techniques, technicians can effectively remove dents without the need for traditional body filler. This results in a smoother, more seamless repair that preserves the original factory finish.

- Scratch Repair: Minor scratches can be repaired using advanced paintless dent repair (PDR) techniques, minimizing the need for repainting. This approach saves time and reduces the risk of paint mismatches.

- Collision Repair: In cases of more significant collisions, James E. Duffy’s technology enables precise alignment and repair of damaged body panels. This ensures that the vehicle’s structural integrity is restored, maintaining safety and performance.

Vehicle Damage and Repair Solutions

The following table provides a comprehensive overview of different types of vehicle damage and the corresponding repair solutions offered by James E. Duffy:

| Type of Damage | Repair Solution |

|---|---|

| Minor dents and scratches | Paintless Dent Repair (PDR) |

| Major dents and creases | Traditional bodywork with specialized tools and techniques |

| Collision damage (bumper, doors, fenders) | Structural repair, alignment, and replacement of damaged components |

| Frame damage | Advanced frame straightening and alignment techniques |

Case Study: Complex Repair

A recent case study involved a vehicle that had sustained significant damage to the front end following a collision. The vehicle’s hood, front bumper, and radiator support were heavily damaged.

Using James E. Duffy’s technology, the repair team was able to precisely align the damaged components, restore the vehicle’s structural integrity, and replace the damaged parts. The repair process was completed efficiently and effectively, ensuring the vehicle’s safety and performance were restored to their original condition.

Benefits and Impact

James E. Duffy’s innovative technology for auto body repair offers a wide range of benefits for both repair shops and vehicle owners. This technology streamlines the repair process, reduces costs, and enhances the overall safety of repaired vehicles.

Benefits for Repair Shops

The implementation of James E. Duffy’s technology significantly benefits repair shops by:

- Increased Efficiency: The technology automates several repair processes, such as part identification and ordering, which reduces manual effort and streamlines workflow. This results in faster turnaround times, allowing shops to handle more repairs efficiently.

- Improved Accuracy: The technology utilizes precise measurements and advanced algorithms to ensure accurate part selection and repair procedures. This minimizes the risk of errors and ensures the quality of repairs, leading to greater customer satisfaction.

- Reduced Costs: The technology optimizes resource utilization by minimizing waste and reducing the need for unnecessary repairs. This translates to lower operational costs for repair shops, contributing to improved profitability.

- Enhanced Data Analytics: The technology captures and analyzes data related to repair processes, providing valuable insights into shop performance and customer preferences. This data-driven approach enables shops to make informed decisions regarding inventory management, service offerings, and overall business strategy.

Benefits for Vehicle Owners

Vehicle owners also reap significant benefits from James E. Duffy’s technology:

- Faster Repair Times: The technology’s efficiency translates to faster repair times, allowing vehicle owners to get back on the road quicker. This minimizes inconvenience and downtime, saving valuable time and money.

- Improved Safety: The technology ensures accurate and precise repairs, enhancing the safety of repaired vehicles. This minimizes the risk of future accidents and promotes peace of mind for vehicle owners.

- Reduced Repair Costs: The technology’s cost-effectiveness benefits vehicle owners by reducing repair costs. This can lead to significant savings, particularly for complex repairs.

- Enhanced Transparency: The technology provides vehicle owners with transparent information about the repair process, including part details and estimated repair times. This fosters trust and communication between repair shops and customers.

Impact on Repair Efficiency, James e duffy auto body repair technology

James E. Duffy’s technology revolutionizes the repair process, resulting in significant improvements in efficiency:

- Automated Part Identification and Ordering: The technology utilizes advanced imaging and data analysis to automatically identify damaged parts and order replacements. This eliminates manual searching and reduces errors, streamlining the repair process.

- Optimized Repair Procedures: The technology provides step-by-step instructions for repair procedures, ensuring consistency and accuracy. This reduces the need for extensive training and expertise, enabling technicians to perform repairs efficiently.

- Real-time Progress Tracking: The technology allows repair shops to track the progress of repairs in real-time, providing valuable insights into workflow and potential bottlenecks. This enables efficient resource allocation and minimizes delays.

Impact on Cost-Effectiveness

The technology’s impact on cost-effectiveness is evident in various aspects:

- Reduced Labor Costs: The technology’s automation reduces the need for manual labor, resulting in lower labor costs for repair shops. This translates to lower repair bills for vehicle owners.

- Minimized Waste: The technology’s accurate part identification and ordering minimizes the need for unnecessary parts, reducing waste and associated costs. This contributes to a more sustainable and cost-effective repair process.

- Improved Inventory Management: The technology’s data analytics capabilities enable repair shops to optimize inventory management, reducing the need for excessive stock and minimizing storage costs.

Impact on Vehicle Safety

The technology’s impact on vehicle safety is significant, ensuring repaired vehicles meet safety standards:

- Precise Repair Procedures: The technology ensures that repairs are performed according to manufacturer specifications and industry best practices, minimizing the risk of safety issues.

- Quality Control: The technology’s automated processes and data analysis capabilities enhance quality control, ensuring that repairs are performed correctly and to a high standard.

- Safety Inspections: The technology can be integrated with safety inspection systems, enabling repair shops to conduct comprehensive safety checks on repaired vehicles, ensuring they meet regulatory standards.

Comparison to Traditional Repair Methods

Compared to traditional repair methods, James E. Duffy’s technology offers several advantages:

- Increased Speed and Efficiency: The technology’s automation and data analysis capabilities significantly increase the speed and efficiency of repairs compared to manual processes.

- Improved Accuracy and Precision: The technology’s precise measurements and advanced algorithms ensure greater accuracy and precision in repairs, leading to better outcomes and reduced errors.

- Reduced Costs: The technology’s automation and optimization features reduce labor costs, waste, and inventory expenses, resulting in lower overall repair costs.

- Enhanced Safety: The technology’s adherence to manufacturer specifications and safety standards ensures that repaired vehicles meet safety regulations and minimize the risk of future accidents.

Future Trends and Developments

The auto body repair industry is constantly evolving, driven by technological advancements in vehicle design, materials, and repair processes. James E. Duffy’s technology must adapt to these trends to remain competitive and provide efficient, high-quality repair solutions.

Emerging Trends

Several emerging trends in the auto body repair industry will significantly influence James E. Duffy’s technology. These trends are shaping the future of vehicle design and repair, demanding innovative solutions to address the challenges they pose.

- Advancements in Vehicle Design: Modern vehicles incorporate advanced materials, such as lightweight composites and high-strength steel, which require specialized repair techniques and equipment. The increased use of electronics and complex driver-assistance systems presents unique challenges for repair professionals.

- Electric and Autonomous Vehicles: The growing popularity of electric and autonomous vehicles introduces new repair considerations. Electric vehicles have high-voltage systems that require specialized training and equipment for safe handling. Autonomous vehicles incorporate complex sensor systems and software that require specific repair protocols.

- Sustainability and Environmental Concerns: The auto body repair industry is increasingly focused on sustainability. Repair shops are adopting eco-friendly practices, including using water-based paints, recycling materials, and reducing energy consumption. James E. Duffy’s technology can contribute to sustainability by optimizing repair processes and minimizing waste.

Potential Advancements in Technology

James E. Duffy’s technology can evolve to meet the demands of the future automotive landscape by incorporating several advancements. These advancements can enhance efficiency, accuracy, and sustainability in the repair process.

- Automation and Robotics: The integration of robotics and automation can streamline repetitive tasks, such as sanding and painting, improving efficiency and reducing human error. Robots can also be used for precise welding and other complex repair procedures.

- Artificial Intelligence (AI): AI can analyze vehicle damage, recommend repair procedures, and optimize repair workflows. AI-powered systems can assist technicians in identifying and diagnosing complex problems, improving repair accuracy and reducing downtime.

- Advanced Materials and Repair Techniques: The use of advanced materials, such as carbon fiber and composites, requires specialized repair techniques. James E. Duffy’s technology can incorporate new materials and repair techniques to ensure the longevity and structural integrity of repaired vehicles.

- Virtual and Augmented Reality (VR/AR): VR and AR technologies can be used for training technicians, simulating repair scenarios, and providing real-time guidance during repairs. These technologies can enhance the efficiency and accuracy of the repair process.

Evolution of James E. Duffy’s Technology

To adapt to the changing automotive landscape, James E. Duffy’s technology must evolve to meet the demands of the future. This evolution will involve incorporating emerging trends and advancements in technology.

- Adapting to New Materials and Designs: James E. Duffy’s technology must be able to handle the unique repair challenges posed by advanced materials, such as composites and high-strength steel. The technology should incorporate specialized tools and techniques for working with these materials.

- Integrating AI and Automation: Integrating AI and automation can significantly improve the efficiency and accuracy of the repair process. AI-powered systems can assist technicians in diagnosing problems, recommending repair procedures, and optimizing workflows. Automation can streamline repetitive tasks, reducing human error and improving productivity.

- Adopting Sustainable Practices: James E. Duffy’s technology can contribute to sustainability by optimizing repair processes and minimizing waste. This can involve using eco-friendly materials, reducing energy consumption, and implementing recycling programs.

- Developing Specialized Training Programs: As the automotive industry evolves, technicians require specialized training to handle new technologies and repair procedures. James E. Duffy can develop training programs that equip technicians with the skills and knowledge necessary to work with advanced vehicles and technologies.

Final Summary

In conclusion, James E. Duffy Auto Body Repair Technology represents a paradigm shift in the automotive repair industry. By embracing innovation and prioritizing excellence, James E. Duffy has revolutionized the way vehicles are repaired, delivering a blend of efficiency, quality, and safety. The impact of their technology extends beyond individual repair shops, influencing the entire industry and shaping the future of automotive repair. As the automotive world continues to evolve, James E. Duffy remains committed to pushing the boundaries of repair technology, ensuring that their solutions remain at the forefront of the industry.

James E. Duffy’s auto body repair technology focuses on precision and efficiency, much like the meticulous craftsmanship behind 37 degree technology jewelry. Both fields rely on a deep understanding of materials and their properties to achieve optimal results, whether it’s restoring a damaged vehicle or crafting a stunning piece of jewelry.

Duffy’s commitment to innovation in auto body repair echoes the dedication to detail seen in 37 degree technology jewelry, pushing the boundaries of what’s possible in their respective fields.